Modified aluminum hydroxide and preparation method thereof

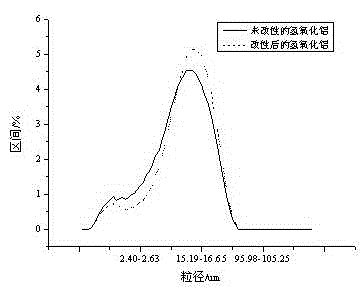

A technology of aluminum hydroxide and modifier, which is applied in the treatment of dyed low-molecular organic compounds, dyed high-molecular organic compounds, and fibrous fillers. Improved compatibility, low cost, and reduced impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

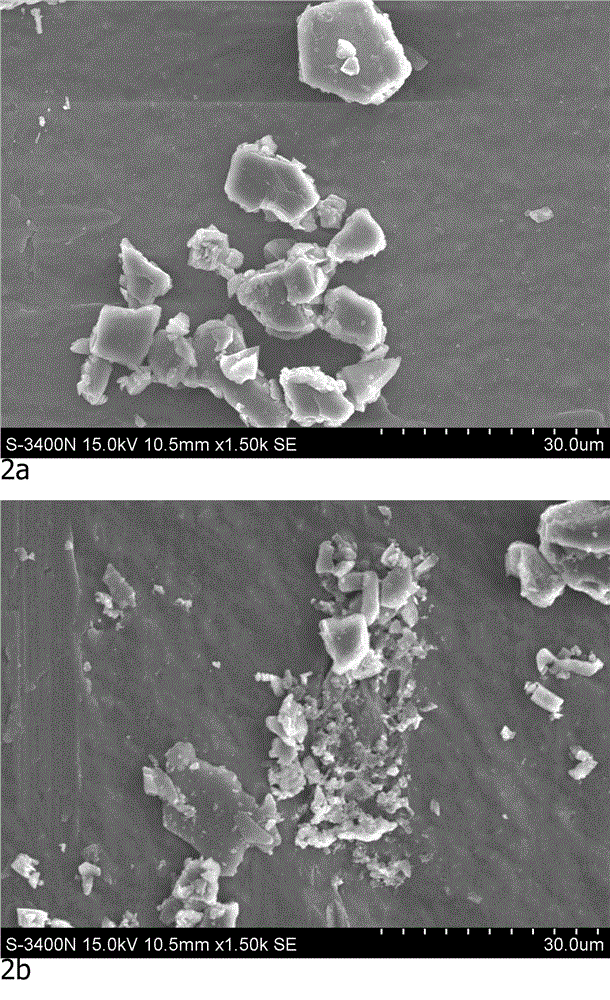

Method used

Image

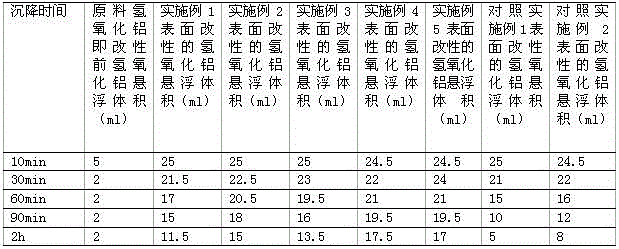

Examples

Embodiment 1

[0034] A surface-modified aluminum hydroxide, calculated in parts by weight, its raw materials and content are as follows:

[0035] Aluminum hydroxide 30 parts

[0036] Modifier 1.2 parts.

[0037] Described modifier is Span;

[0038] The said class is the class 40.

[0039] The preparation method of above-mentioned a kind of surface-modified aluminum hydroxide specifically comprises the following steps:

[0040] (1) Add 30 parts of aluminum hydroxide powder into a certain amount of deionized water to disperse, make an aluminum hydroxide aqueous suspension with a concentration of 10% by mass, and raise the temperature to 80°C;

[0041] (2) Add 1.2 parts of modifier Span to a certain amount of absolute ethanol, and ultrasonically treat it for 10 minutes to obtain an ethanol solution of modifier with a concentration of 1% by mass;

[0042] (3) Control the dropping rate to 10ml / min. Add the ethanol solution of modifier with a mass percentage concentration of 1% to the alumin...

Embodiment 2

[0047] A surface-modified aluminum hydroxide, calculated in parts by weight, its raw material composition and content are as follows:

[0048] Aluminum hydroxide 30 parts

[0049] Modifier 0.9 parts.

[0050] The modifier is Span; the Span is Span 60.

[0051] The preparation method of above-mentioned a kind of surface-modified aluminum hydroxide specifically comprises the following steps:

[0052] (1) Add 30 parts of aluminum hydroxide powder into a certain amount of deionized water for dispersion, and prepare an aluminum hydroxide aqueous suspension with a concentration of 10% by mass, and then heat up to 85°C;

[0053] (2) Add 0.9 parts of Span to a certain amount of absolute ethanol and perform ultrasonic treatment for 10 minutes to obtain an ethanol solution of modifier with a concentration of 1% by mass;

[0054] (3) Control the dropping rate to 10ml / min. Add the ethanol solution of modifier with a mass percentage concentration of 1% to the aluminum hydroxide aqueous ...

Embodiment 3

[0057] A surface-modified aluminum hydroxide, calculated in parts by weight, its raw material composition and content are as follows:

[0058] Aluminum hydroxide 30 parts

[0059] Modifier 0.3 parts.

[0060] The modifier is Span; the Span is Span 85.

[0061] The preparation method of above-mentioned a kind of surface-modified aluminum hydroxide specifically comprises the following steps:

[0062] (1) Add 30 parts of aluminum hydroxide powder into a certain amount of deionized water for dispersion, and prepare an aluminum hydroxide aqueous suspension with a concentration of 10% by mass, and then heat up to 80°C;

[0063] (2) Add 0.3 parts of Span to a certain amount of absolute ethanol and perform ultrasonic treatment for 10 minutes to obtain an ethanol solution of modifier with a concentration of 1% by mass;

[0064] (3) Control the dropping rate to 10ml / min. Add the ethanol solution of modifier with a mass percentage concentration of 1% to the aluminum hydroxide aqueous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com