Preparation method and product of surface modified lithium battery high-nickel positive electrode material

A positive electrode material and surface modification technology, which is applied in battery electrodes, secondary batteries, metal material coating technology, etc., can solve problems such as poor room temperature and storage performance, deterioration of battery performance, and low first-cycle efficiency, so as to achieve easy operation and quality control, simplify the process, and control the effect of simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

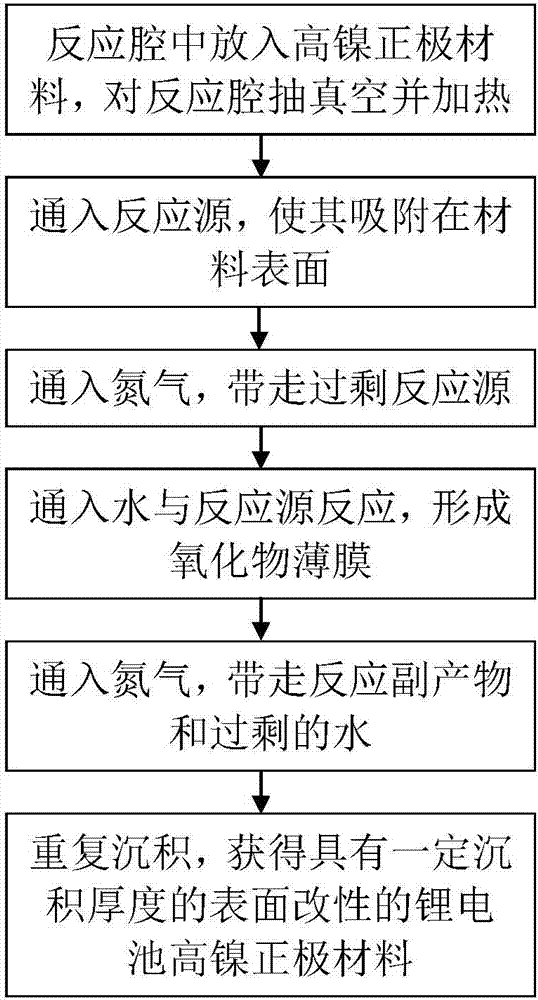

[0037] Such as figure 1 As shown, the invention provides a method for preparing a surface-modified lithium battery high-nickel positive electrode material, comprising the following steps:

[0038] (a) Put the high-nickel cathode material into the reaction chamber of the ALD (Atomic layer deposition, atomic layer deposition) system, and evacuate the reaction chamber for 5s to 10s. The high-nickel cathode material is LiNi x co y m z o 2 , where 0.6≤x≤1, 0≤y≤0.4, 0≤z≤0.4, and x+y+z=1, M is one or more of Mn, Al, Mg, Ti, raise the reaction chamber body temperature, so that the reaction temperature is always maintained at 140 ° C ~ 160 ° C;

[0039] (b) feed a reaction source into the reaction chamber after vacuuming, and make the pressure in the reaction chamber reach 5mbar~8mbar, and the reaction source is adsorbed on the surface of the high-nickel positive electrode material;

[0040] (c) feed N into the reaction chamber 2 , to take away the excess reaction source in the r...

Embodiment 1

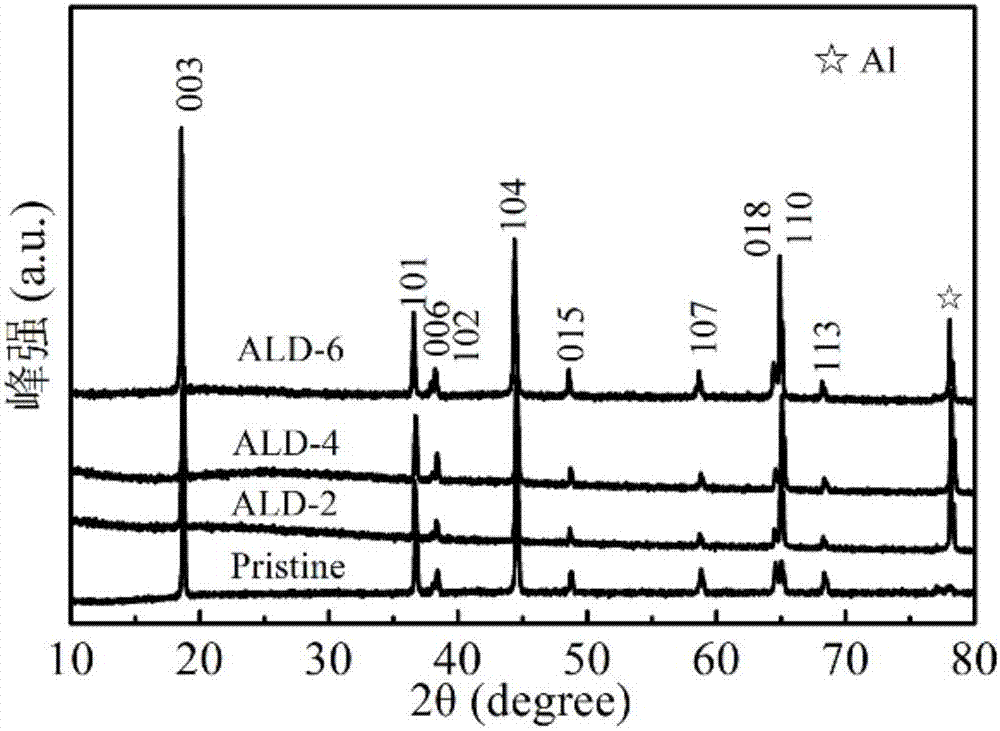

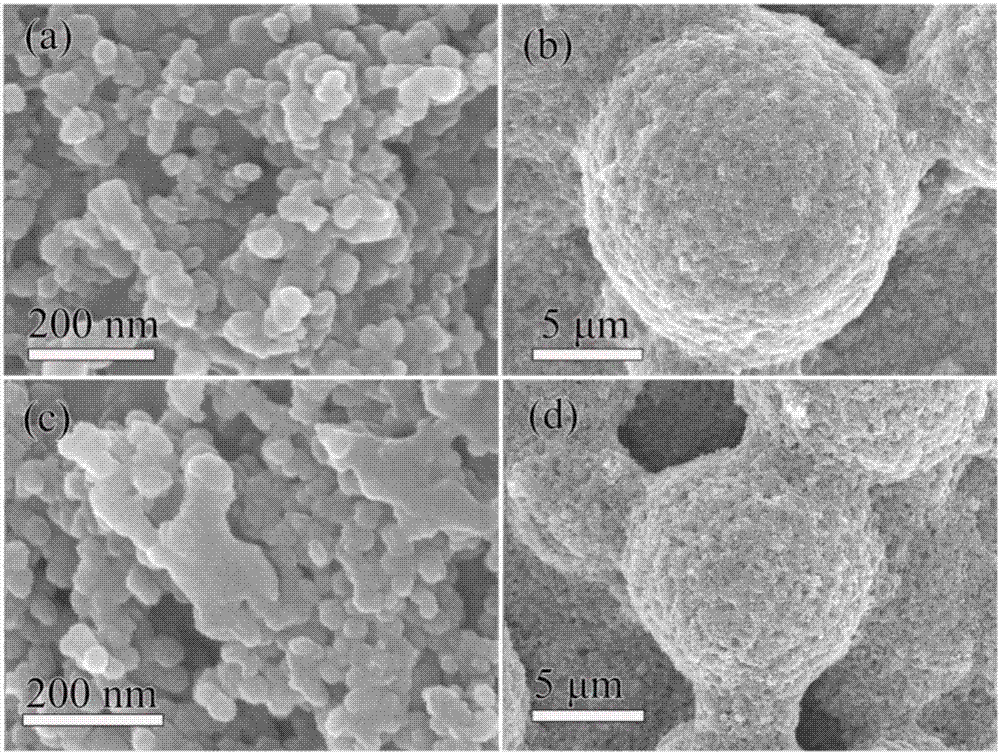

[0055] Using ALD equipment in high nickel cathode material LiNiO 2 Deposited TiO on the surface 2 film, the reaction source is H 2 O and isopropyl titanium, the deposition temperature is 150°C. The high-nickel cathode material LiNiO 2 Put it into the reaction chamber in ALD, and the deposition process is as follows: (1) evacuate the reaction chamber for 5s; (2) feed the reaction titanium source (isopropyl titanium) to make the chamber pressure reach 5mbar; N into the system 2 , the time is 120s, used to take away the by-products of the reaction and excess isopropyl titanium; (4) continue to feed H into the reaction chamber 2 O, end when the chamber pressure reaches 5mbar; (5) feed N into the reaction system 2 , the time is 120s, used to take away the by-products and excess H of the reaction 2 O; Steps (1)-(5) are a complete deposition process, and the number of cycles is 20 times.

Embodiment 2

[0057] Using ALD equipment in high nickel cathode material LiNi 0.6 co 0.4 o 2 Deposit ZnO film on the surface, the reaction source is H 2 O and ZnCl 2 , the deposition temperature was 150 °C. The high nickel cathode material LiNi 0.6 co 0.4 o 2 Put it into the reaction chamber in ALD, and the deposition process is as follows: (1) vacuumize the reaction chamber for 6s; (2) feed the reaction zinc source (ZnCl 2 ) to make the cavity pressure reach 6mbar; (3) feed N into the reaction system 2 , the time is 130s, used to take away the by-products of the reaction and excess zinc chloride; (4) continue to feed H into the reaction chamber 2 O, end when the chamber pressure reaches 6mbar; (5) feed N into the reaction system 2 , the time is 140s, used to take away the by-products and excess H of the reaction 2 O; Steps (1)-(5) are a complete deposition process. , the number of cycles is 25 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com