Method for Improving the Electrochemical Performance of Hydrogen Storage Alloy Powder Using Electropolymerized Polyaniline

A hydrogen storage alloy and polyaniline technology, applied in battery electrodes, circuits, electrolytic coatings, etc., can solve problems such as uneven mixing, difficult alloys to combine, affecting alloy structure and electrochemical performance, and achieve obvious improvement effects and production The effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Prepare 100ml of aniline containing 0.3mol / L, 3×10 -3 The mixed solution of the sulfuric acid of mol / L;

[0020] 2) Add 20g AB to the aforementioned mixed solution 5 Type (La 0.60 Ce 0.28 PR 0.03 Nd 0.09 Ni 3.94 mn 0.31 co 0.45 al 0.26 ) The hydrogen storage alloy powder is then placed in the electroplating device;

[0021] 3) Graphite is inserted into a mixed solution containing hydrogen storage alloy powder, the hydrogen storage alloy powder is used as an anode, graphite is used as a cathode, a DC voltage of 1.7V is applied, and the electrification time is 1 min. Stir at a rotating speed of 50 rpm, wash the processed alloy powder twice with water, filter with suction, and place it in a vacuum drying oven for vacuum drying before use;

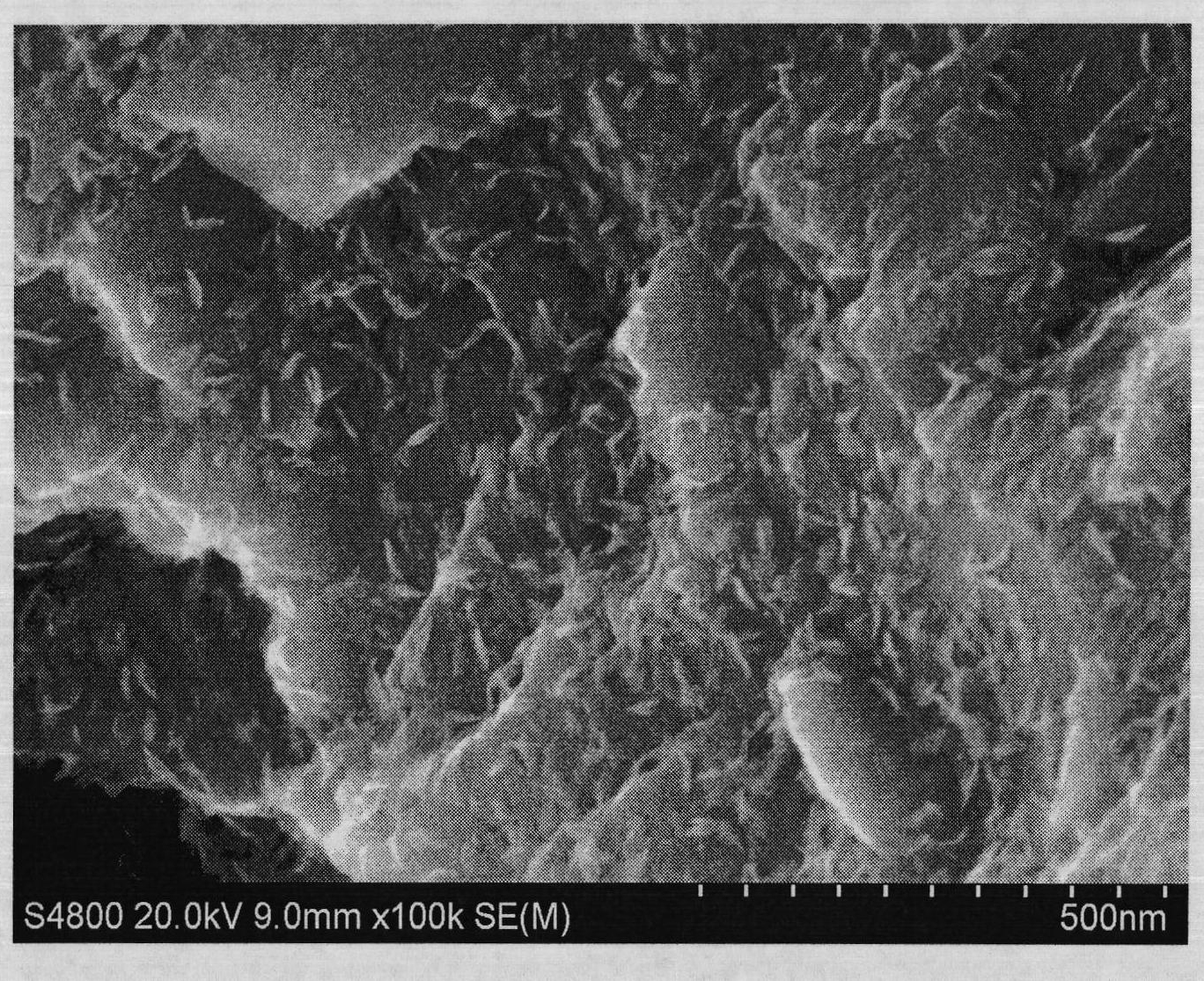

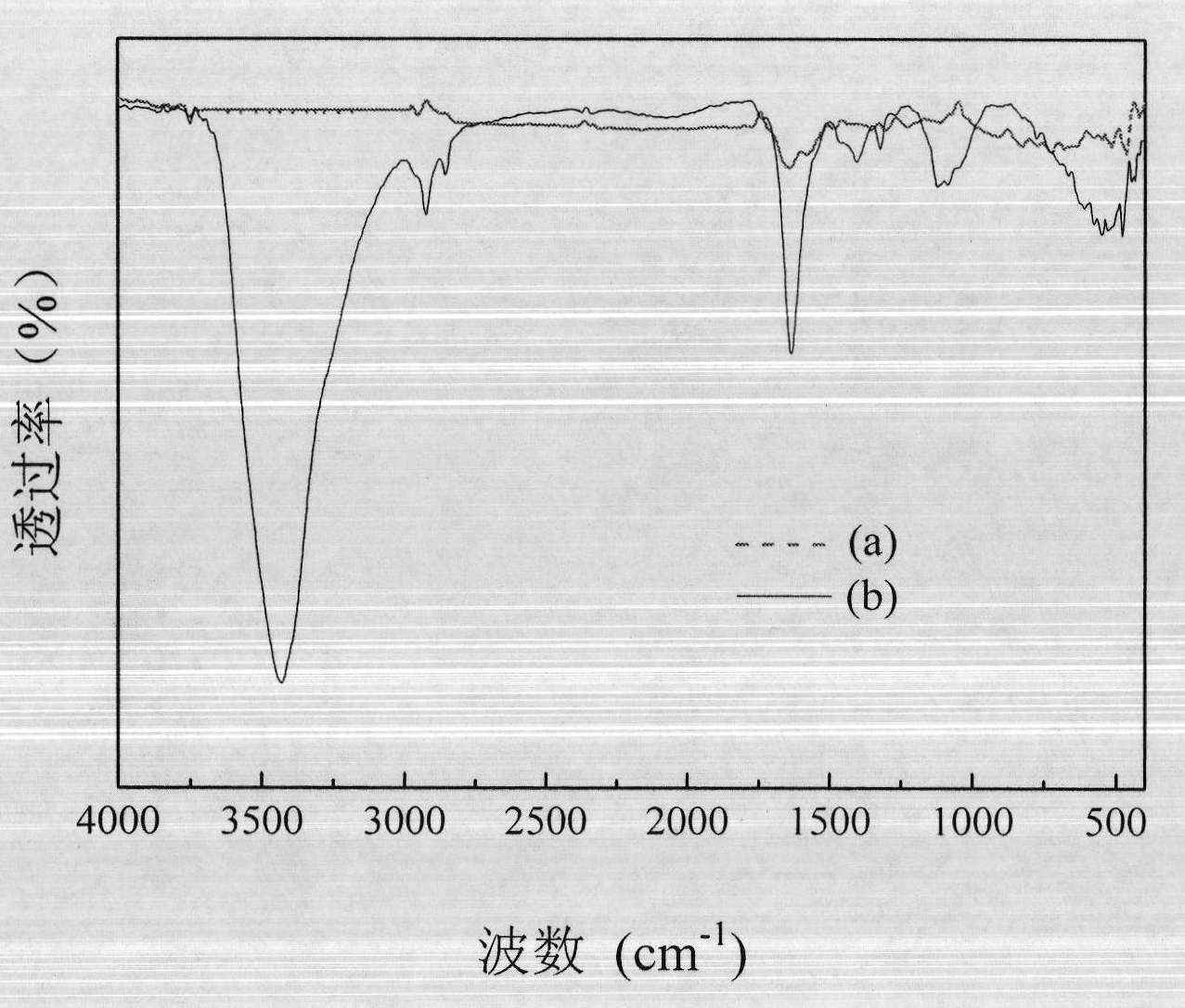

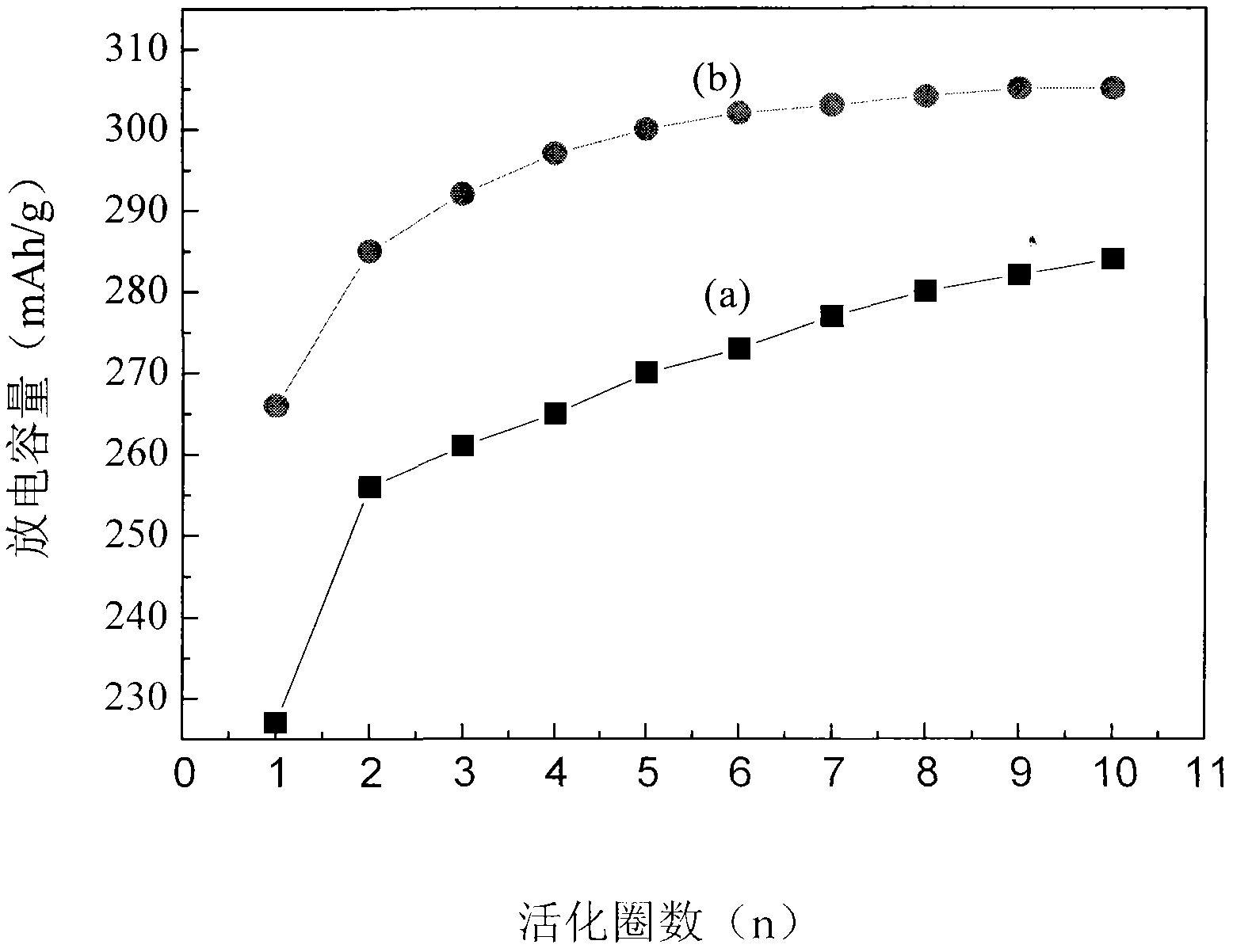

[0022] 4) The treated alloy powder was characterized by field emission scanning electron microscopy and Fourier transform infrared spectroscopy, the results are shown in the attached figure 1 and figure 2 , it can be see...

Embodiment 2

[0024] 1) Prepare 100ml of aniline containing 0.25mol / L, 2×10 -3 The mixed aqueous solution of the dodecylbenzenesulfonic acid of mol / L;

[0025] 2) Add 10g AB to the aforementioned mixed solution 3 Type (La 0.85 Mg 0.15 Ni 2.95 mn 0.15 co 0.50 Al 0.10 ) hydrogen storage alloy powder;

[0026] 3) Using hydrogen storage alloy powder as the anode and graphite as the cathode, apply a DC voltage of 1V for 2 minutes. Stir at a rotating speed of 65 rpm, wash the treated alloy powder with water three times, filter it with suction, and place it in a vacuum drying oven for vacuum drying before use;

[0027] 4) The treated alloy powder was characterized by field emission scanning electron microscopy and Fourier transform infrared spectroscopy, the results are shown in the attached figure 1 and figure 2 , it can be seen from the figure that coral-like polyaniline can be found on the surface of the alloy in the field emission scanning electron microscope, and benzoquinone (N=Q=...

Embodiment 3

[0029] 1) Prepare 100ml of aniline containing 0.4mol / L, 3×10 -3 mol / L mixed aqueous solution of hydrofluoric acid;

[0030] 2) Add 50g AB to the aforementioned mixed solution 5 type (MlNi 4.19 mn 0.31 co 0.42 Al 0.23 ) hydrogen storage alloy powder;

[0031] 3) Using hydrogen storage alloy powder as the anode and graphite as the cathode, apply a DC voltage of 1.7V for 3 minutes. Stir under the condition that the rotating speed is 70 rpm, wash the processed alloy powder with water, filter it with suction, and place it in a vacuum drying oven for vacuum drying before use;

[0032] 4) The treated alloy powder was characterized by field emission scanning electron microscopy and Fourier transform infrared spectroscopy, the results are shown in the attached figure 1 and figure 2 , it can be seen from the figure that coral-like polyaniline can be found on the surface of the alloy in the field emission scanning electron microscope, and benzoquinone (N=Q=N), carbon-carbon doub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com