Patents

Literature

79results about How to "Shorten the polymerization reaction time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

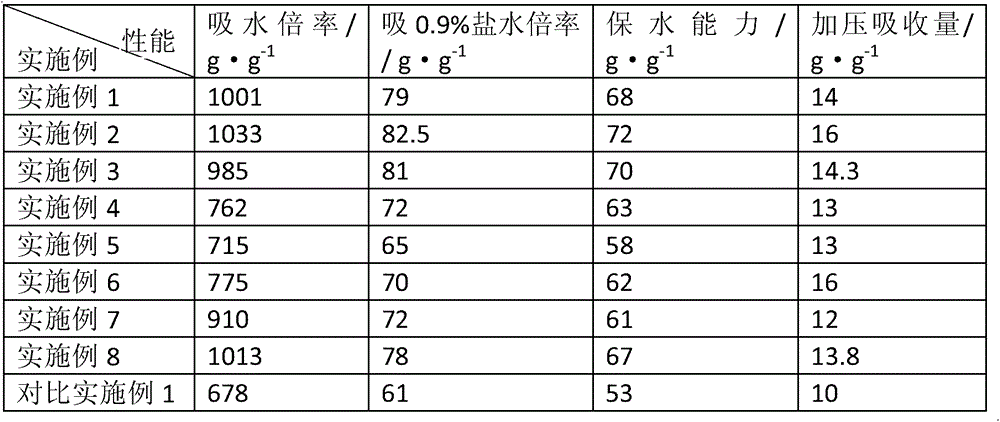

Preparation method of porous-super-absorbent resin

InactiveCN103214616AShorten the polymerization reaction timeIncrease productivityCross-linkSodium hydroxide

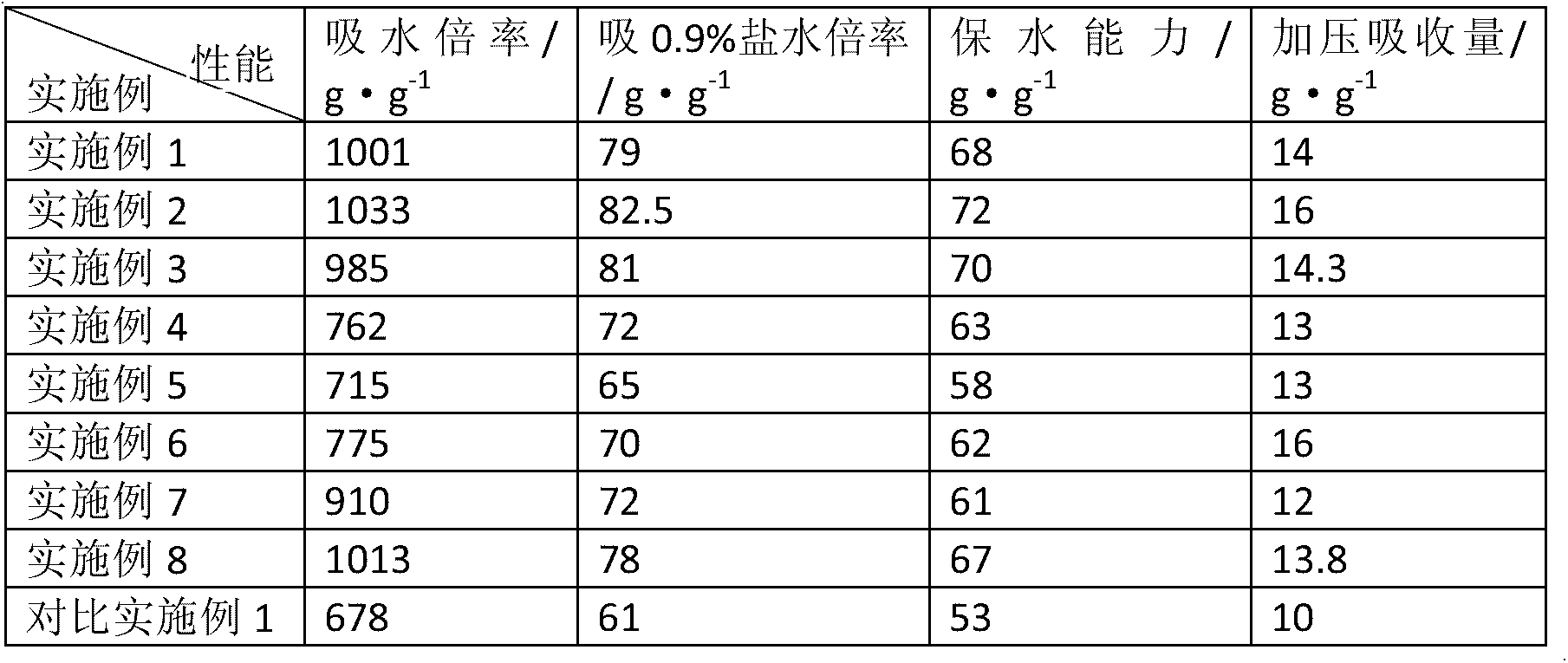

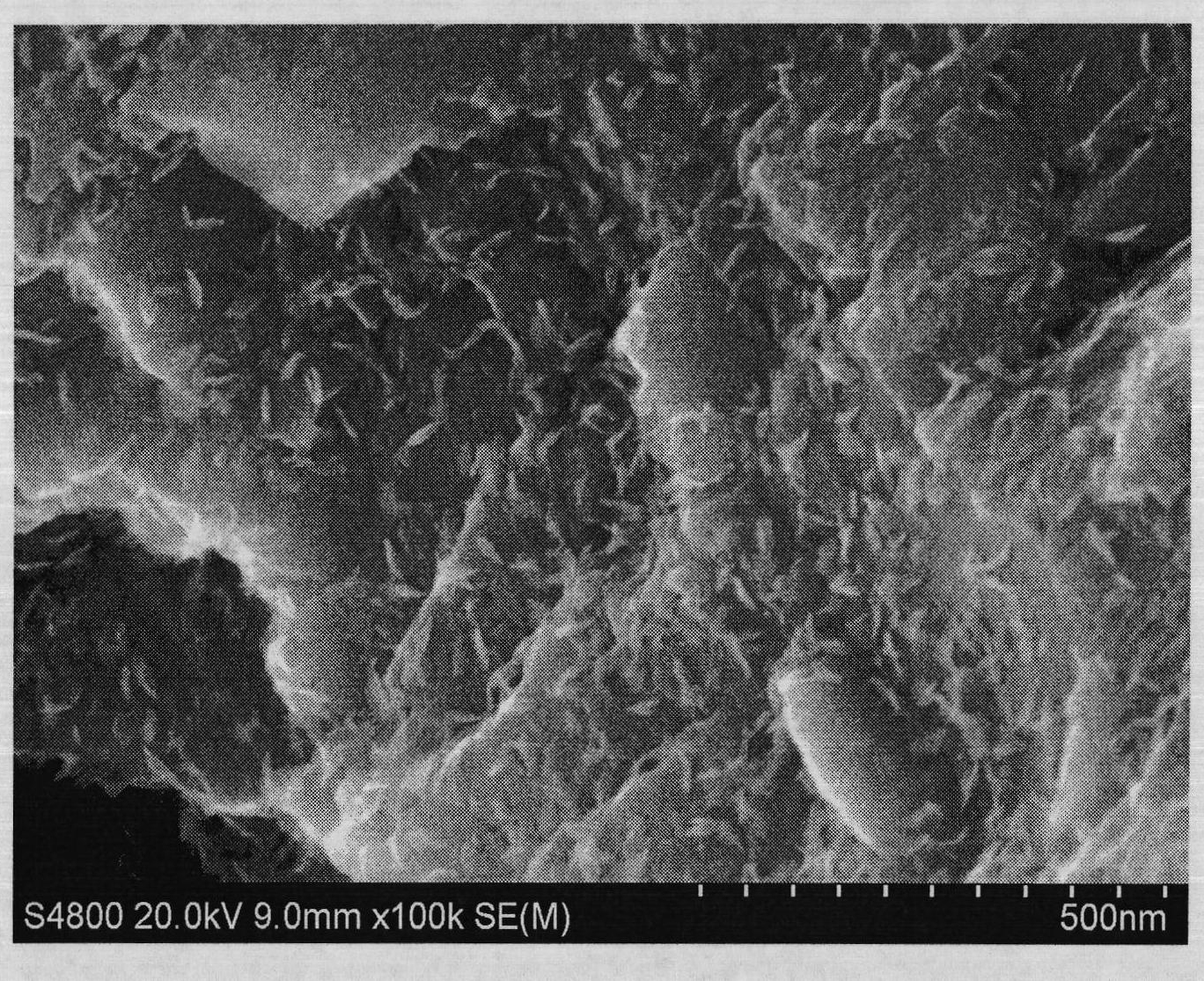

The invention discloses a preparation method of porous-super-absorbent resin. The preparation method comprises the following steps of: adding acyclic acid to deionized water, neutralizing with a sodium hydroxide aqueous solution, and controlling neutralization temperature at 50 DEG C to 80 DEG C and neutralization degree at 60-80%; mixing the solution; adding a cross-linking agent and stirring till completely dissolving, then adding an oxidant and a foaming agent, afterwards, adding a reducing agent, carrying out polymerization reaction by heat of neutralization, and generating porous-super-absorbent resin gel; and pelleting, drying, crushing and screening to obtain the porous-super-absorbent resin. Additional heating equipment is not needed in the porous-super-absorbent resin preparation method; heat released in neutralization process is directly used for enabling a polymerization reaction system to reach the temperature needed by the reaction; and an oxidation reduction initiating agent is added at high temperature, so that the whole polymerization reaction time is shortened, and the production efficiency is improved; and the added foaming agent can be used for preparing porous gel, so that the water retaining capacity and the water-absorption capability of the water-absorbent resin are improved.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of super absorbent resin with high return permeability resistance

ActiveCN106750475AImprove uniformityIncrease surface areaAbsorbent padsLight irradiationFoaming agent

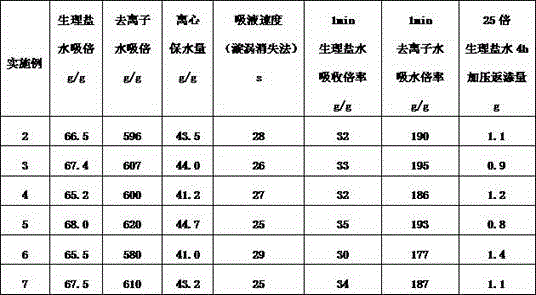

The invention relates to a preparation method of super absorbent resin with high return permeability resistance. The method comprises the following steps: neutralizing an acrylic acid aqueous solution by using alkali, adding a composite initiator, a crosslinking agent and a foaming agent, and performing polymerization reaction under UV light irradiation; cutting up and pelleting hydrogel after polymerization, adding a gel cutting aid in the cut-up process, drying and pulverizing to obtain primary granules of super absorbent resin; and spray-coating the surfaces of the primary granules with surface crosslinking liquid, and performing reaction at high temperature to obtain a final product of the super absorbent resin. The super absorbent resin prepared by the method has the characteristics of high absorbing rate, high absorbing speed, high water-retaining property, excellent return permeability resistance and the like.

Owner:JIANGSU SAILBOAT PETROCHEMICAL CO LTD

Polyesterimide enamelled wire paint capable of straightly soldering and method for preparing same

InactiveCN101338157AShort synthesis timeReduce energy consumptionPlastic/resin/waxes insulatorsCoatingsPolyesterLacquer

The invention discloses direct welding polyester imine enamel wire paint and a preparation method thereof. Firstly, polyester imine resin generates from monacid, aromatic dicarboxylic acid, 4-methacryoxypropyl, 4, 4'-diaminodiphenyl-methane, trihydric alcohol, triethanolamine, dihydric alcohol and monoethanolamine through the melt copolycondensation under the function of catalyst; secondly, modified etherifying amino resin is prepared from melamine, urea, benzoguanamine, 37 percent of formaldehyde, methanol, isopropanol and normal butyl alcohol through the hydroxymethylation and etherification; thirdly, modified etherified phenolic resin is prepared from technical xylenol, isopropylidene diphenol, boric acid, 37 percent of formaldehyde, methanol, isopropanol and normal butyl alcohol through the hydroxymethylation and etherification; finally, three products obtained through the three steps are mixed with mixed environmental solvent according to the quality ratio of 1-1.9 to 0.2-0.9 to 0.2-0.9 to 8 to obtain the direct welding polyester imine enamel wire paint. The enamel wire painted through the enamel wire paint of the invention can be welded directly under the condition of not higher than 400 DEG C and the stretch of the enamel wire paint or the fluting of zero pinhole can be realized.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Synthesis method and application of water soluble chitosan-based flocculant

ActiveCN105622847ASpeed up homolysisThe polymerization reaction is fastWater/sewage treatment by flocculation/precipitationFunctional monomerAlcohol ethyl

The invention provides a synthesis method and application of a water soluble chitosan-based flocculant. The method comprises the steps of adding chitosan into acid solution, adding acylated monomer aqueous solution into the acid solution, uniformly stirring and mixing, performing vibration reaction for 1 to 10 h at 5 to 60 DEG C, performing precipitation and purification through ethyl alcohol and acetone, drying, and obtaining N-acylated chitosan; sequentially adding the N-acylated chitosan, deionized water, acrylamide and strong cation functional monomer into a reactor, uniformly stirring, leading nitrogen into homogenous solution to remove oxygen, adding a photoinitiator and a cosolvent, uniformly stirring and mixing, putting the raw materials into an ultraviolet light reaction device to perform polymerization reaction, drying, performing granulation and powder process, and obtaining the water soluble chitosan-based flocculant; the flocculant can be used for the removal treatment of alga in source water. The flocculant is good in solubility property, high in viscosity coefficient and short in synthesis time, does not need temperature reduction control, simplifies the production technology, reduces energy consumption, and reduces the production cost.

Owner:NANJING UNIV OF TECH

Preparation method of poly(carbonic ester-ether)polyol

ActiveCN105061746AReduce generationReduce contentMetal/metal-oxides/metal-hydroxide catalystsRare earthCarboxylic acid

The present invention provides a preparation method of poly(carbonic ester-ether)polyol. The method comprises the steps of: reacting carboxylic acid with acidity constant of 0.2-4with epoxide to obtain an intermediate product; reacting the intermediate product with carbon dioxide for a polymerization reaction under the effect of Zn3[Co(CN)6]2 rare earth-doped double metal cyanide to obtain poly(carbonic ester-ether)polyol. The preparation method of poly(carbonic ester-ether)polyol provided by the present invention employs carboxylic acid with appropriate acidity constant as an initiator; carboxylic acid is used to activate the epoxide; and the activated in-situ generated polyethers with different molecular weight are used as a chain transfer agent for participating polymerization reaction of carbon dioxide and an epoxide under the effect of Zn3[Co(CN)6]2 rare earth-doped double metal cyanide. The preparation method of the poly(carbonic ester-ether)polyol the has short reaction time, and content of a byproduct propylene carbonate is low.

Owner:HUAFON GROUP +1

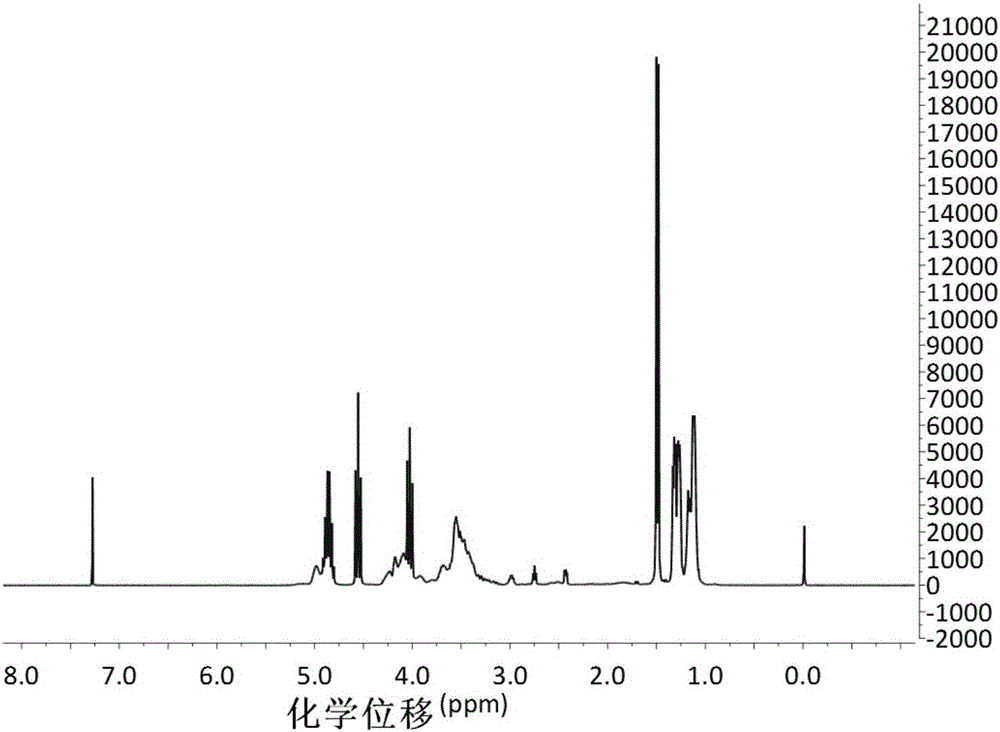

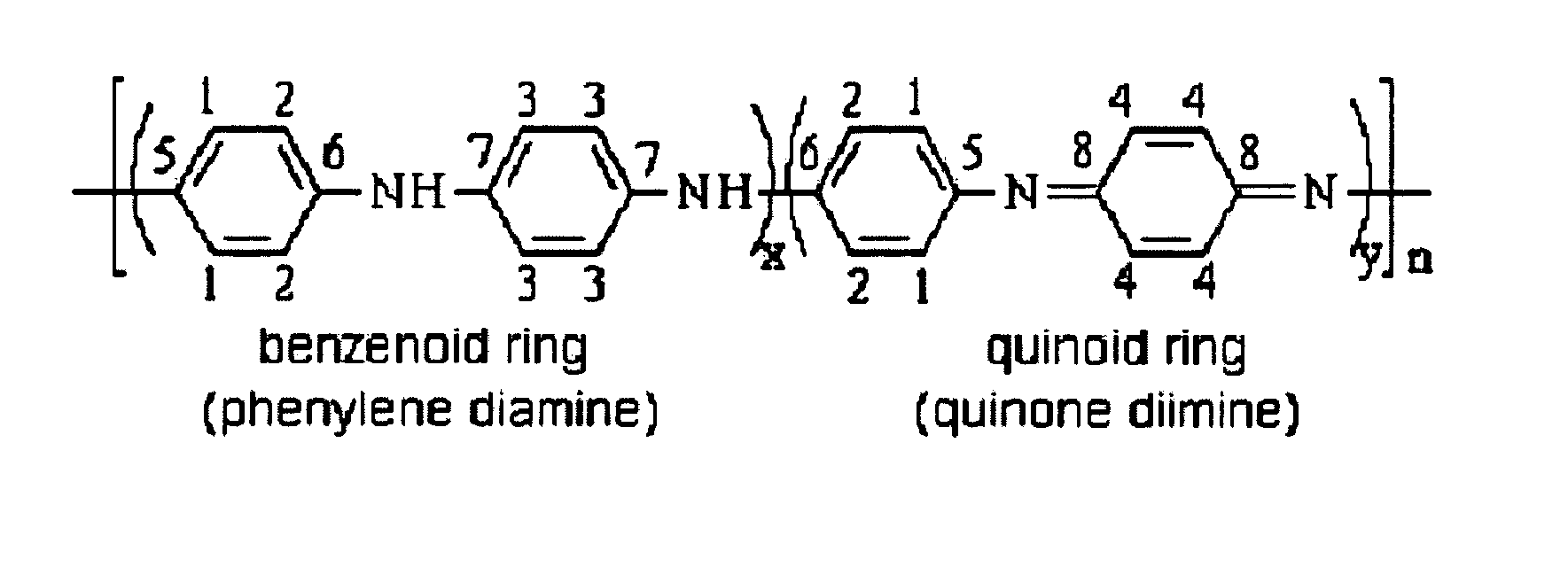

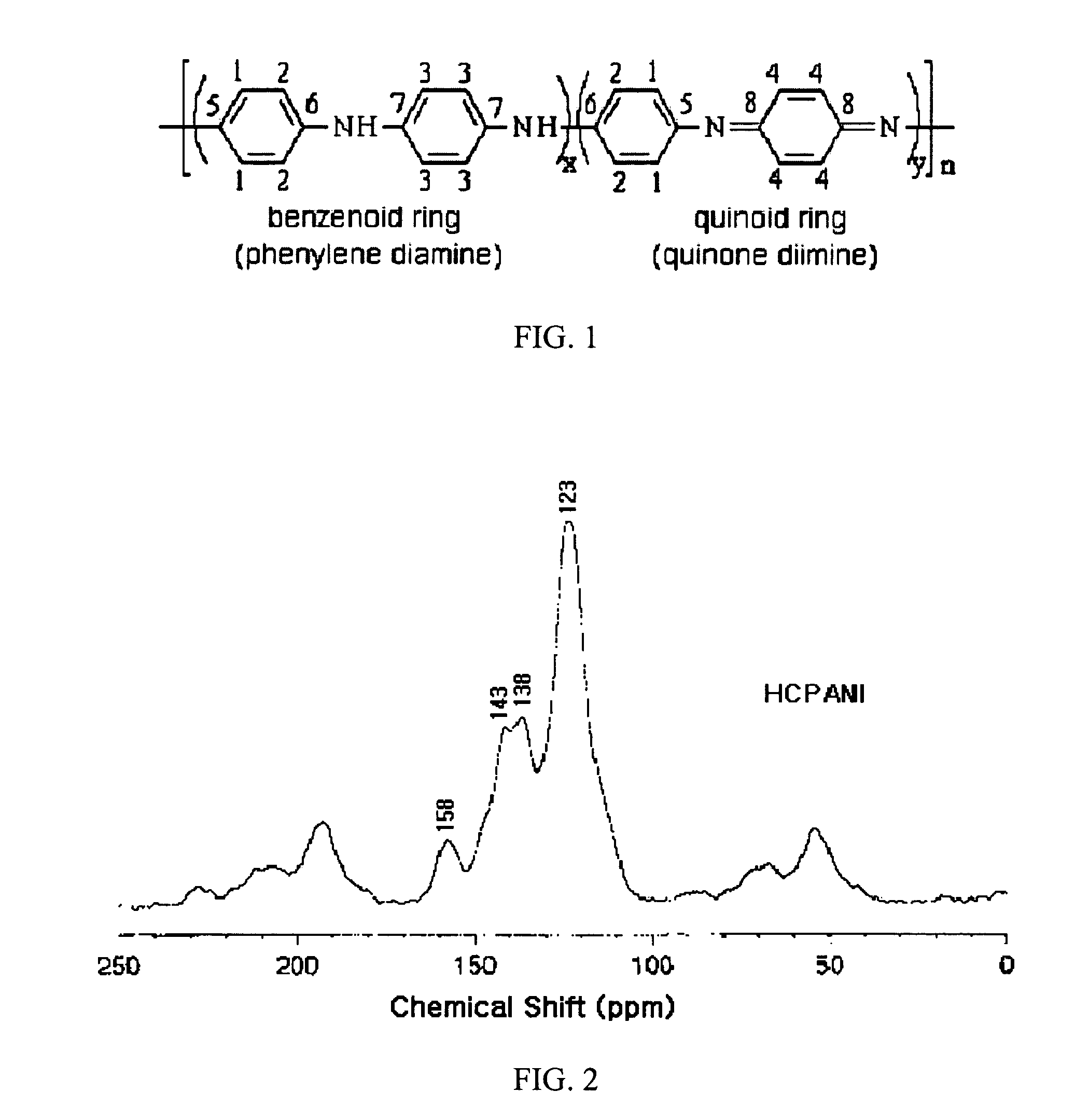

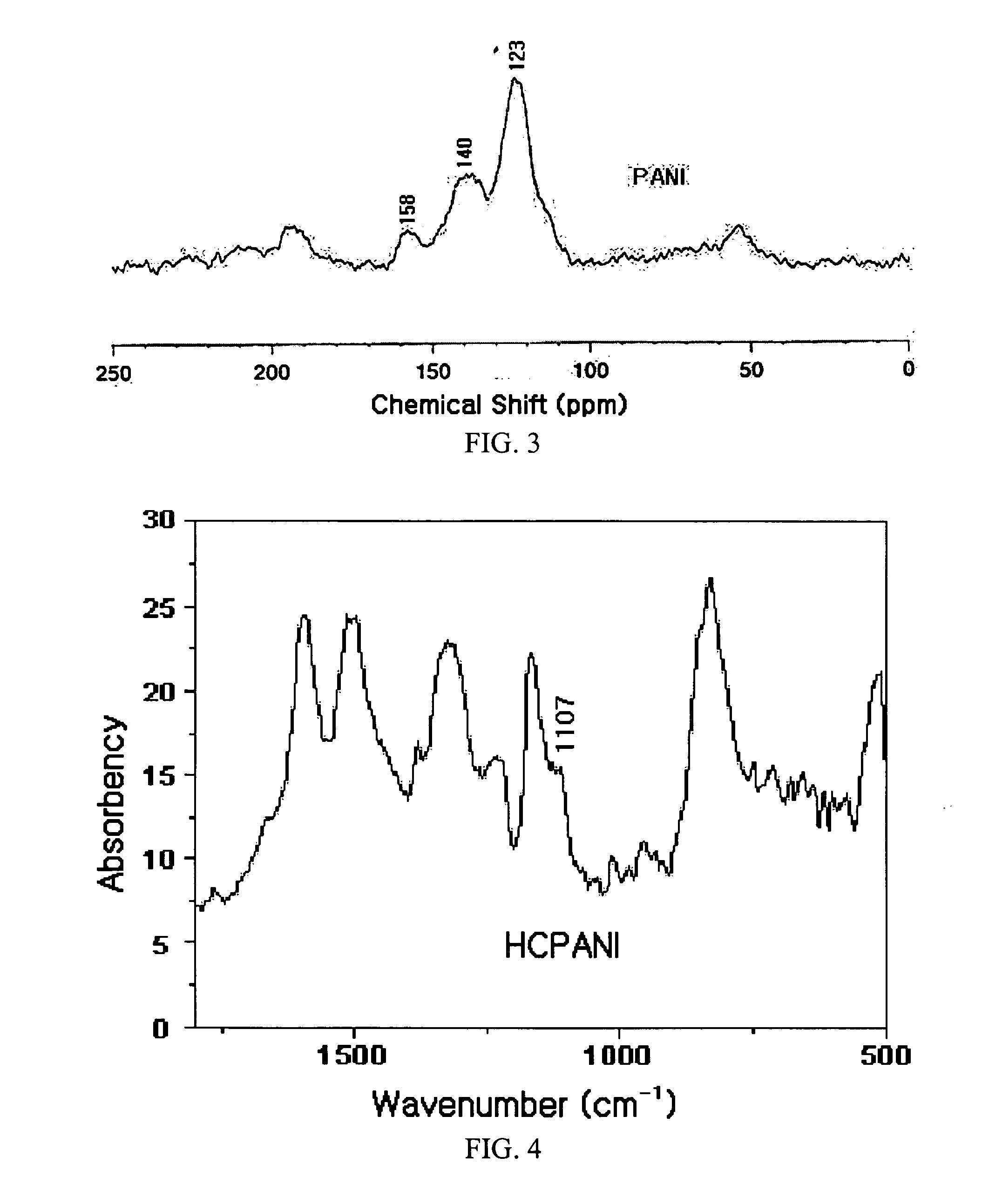

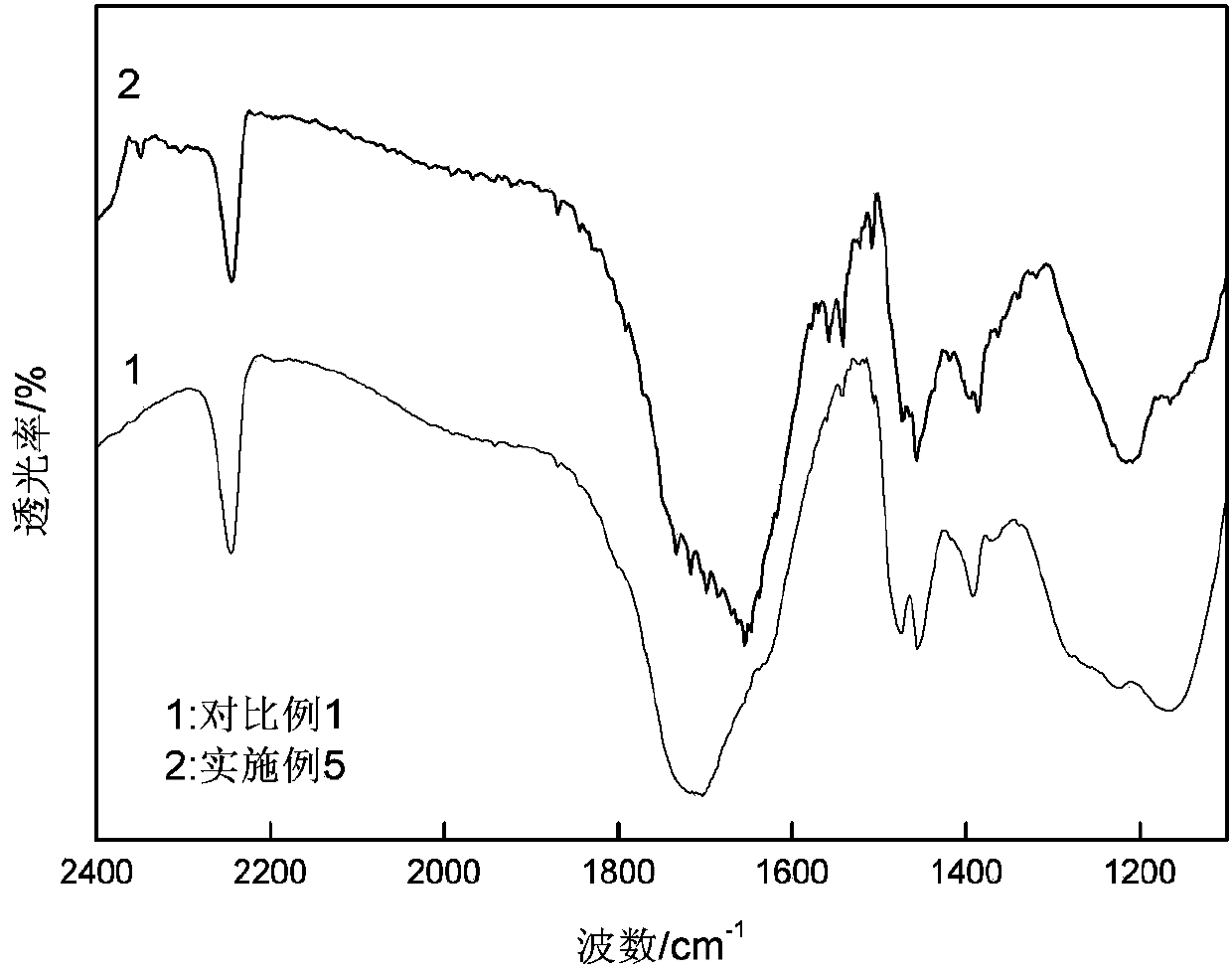

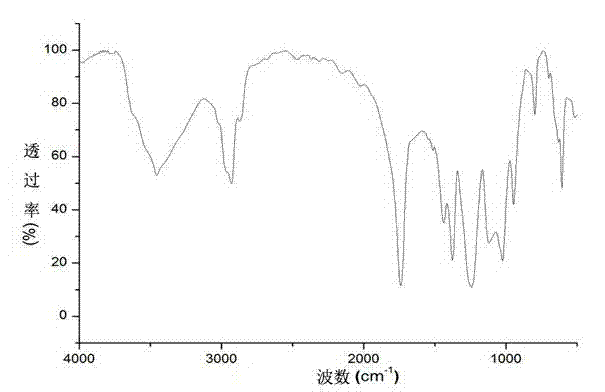

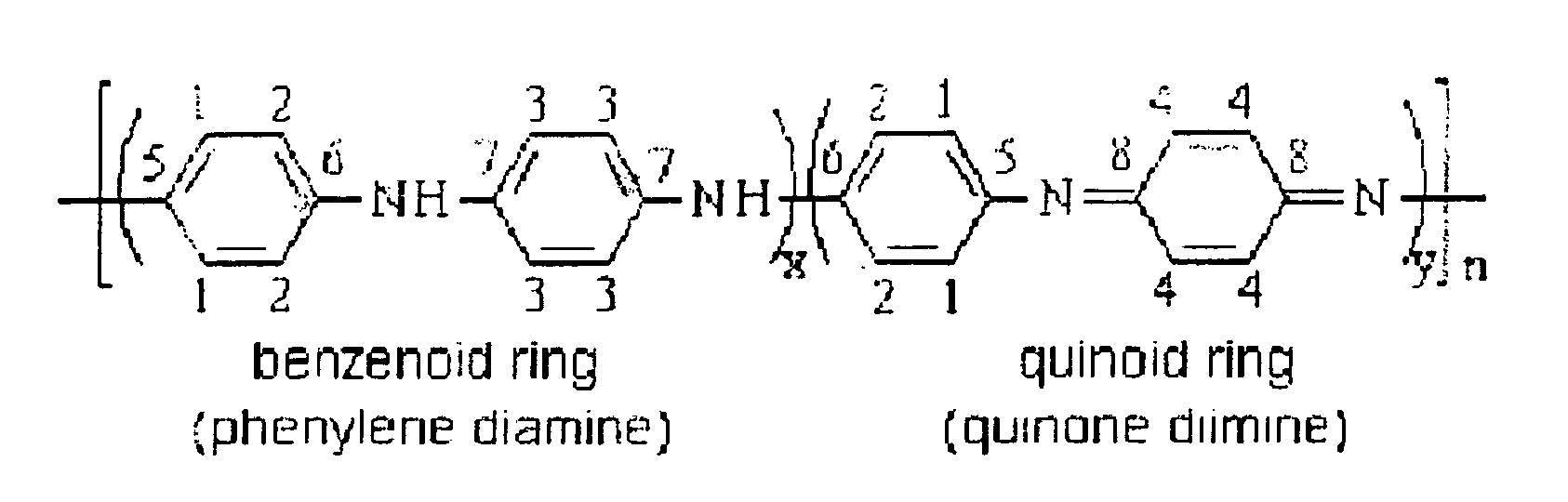

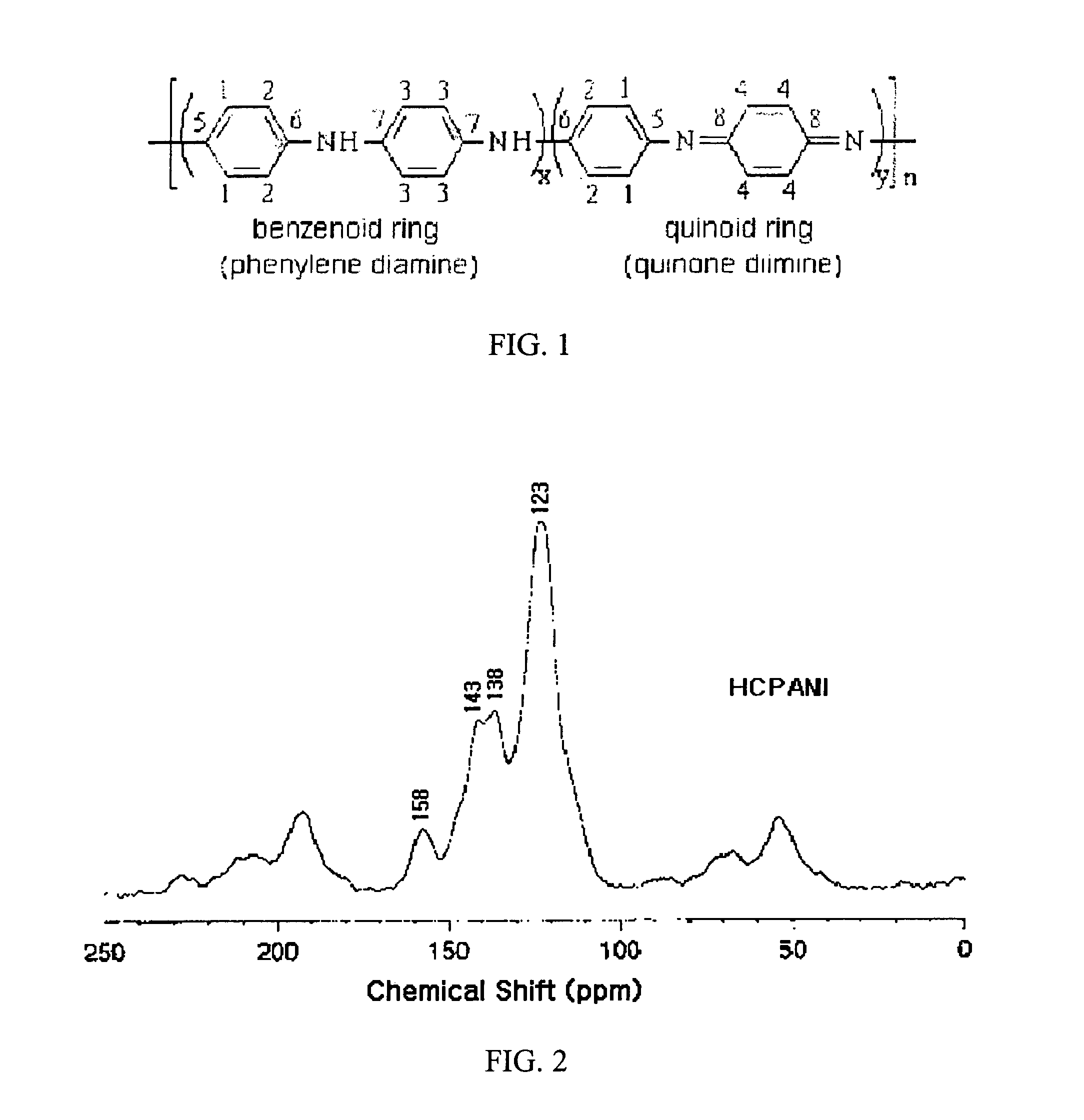

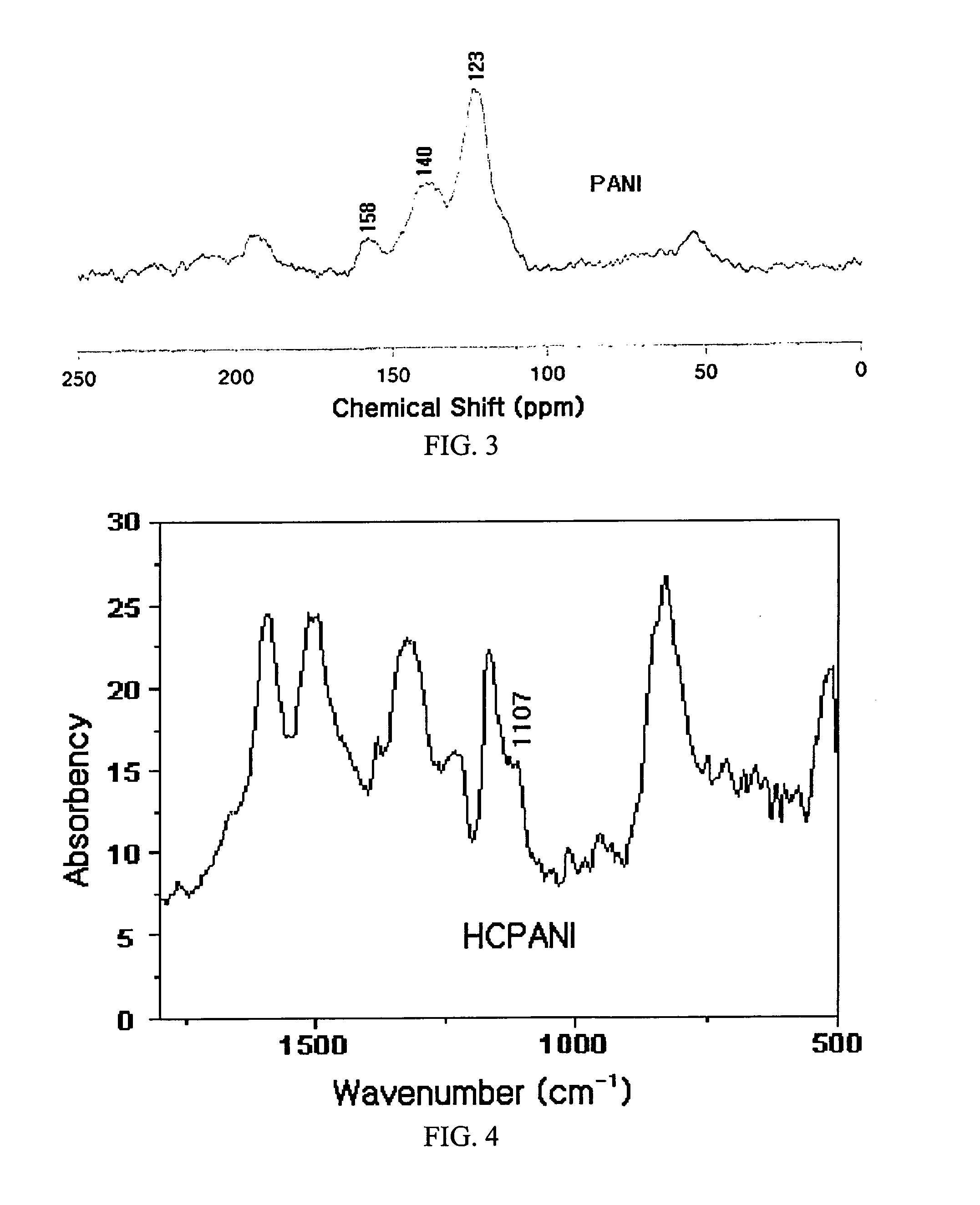

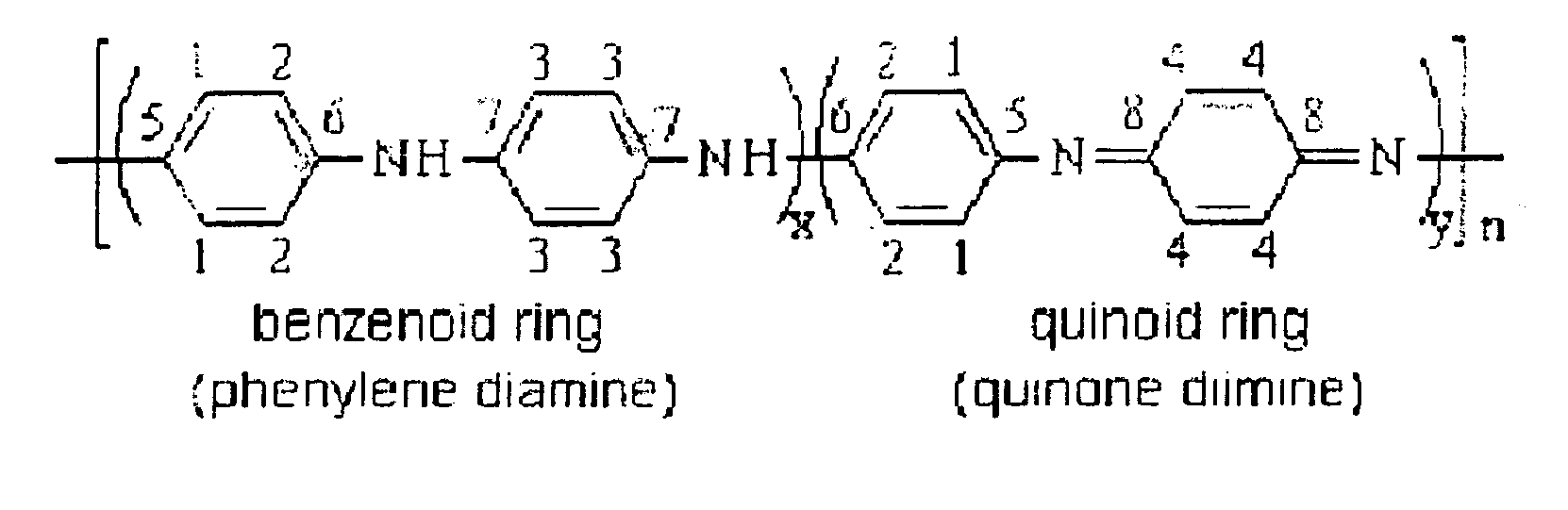

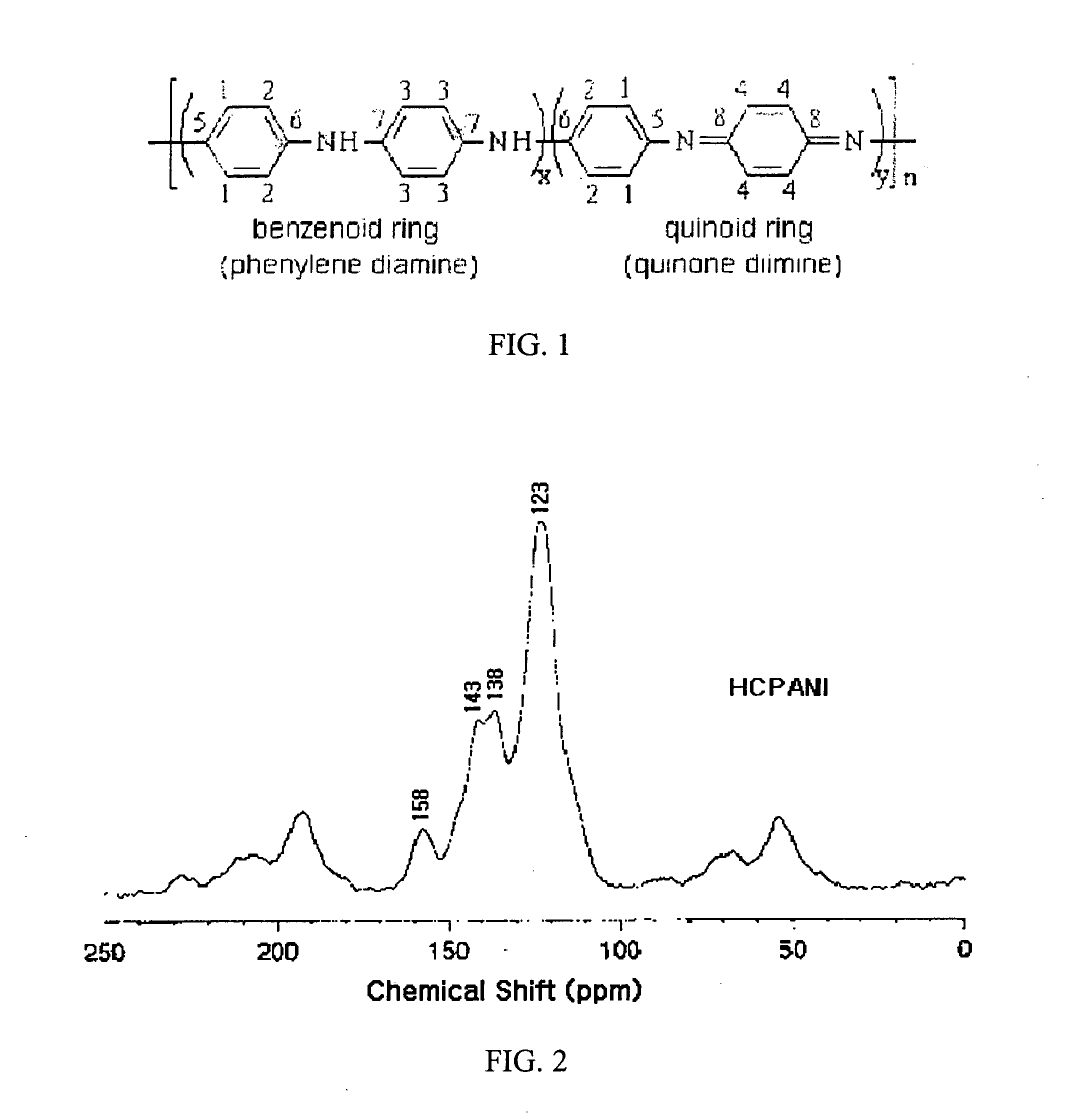

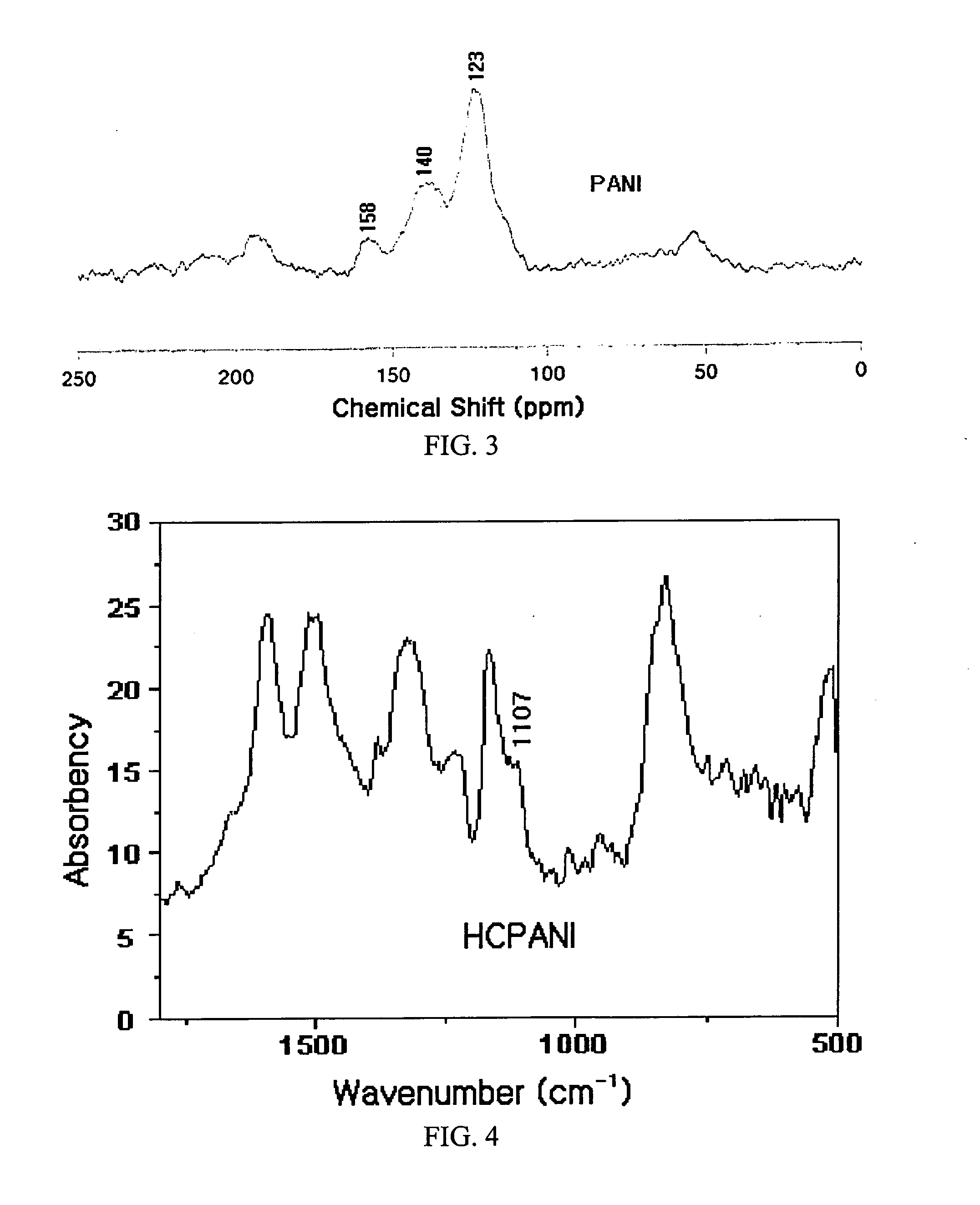

Conductive polymers having highly enhanced solubility in organic solvent and electrical conductivity and synthesizing process thereof

InactiveUS20050269555A1Highly linear configurationFew side chainConductive materialOrganic conductorsSolubilityFiber

The present invention relates to a new process of synthesizing conductive polymers from monomers substituted with amine group. The process provides simple synthesizing steps for the conductive polymers without using other additives such as stabilizers or emulsifiers. The conductive polymers synthesized according to the present invention have highly enhanced solubility in common organic solvents and electrical conductivity compared to conventional conductive polymers. Therefore, the conductive polymers synthesized according to the present process can be utilized in applications that require high electrical conductivity, for example an electromagnetic interference shield or a transparent electrode of thin film, as well as in specific applications such as various conductive films, fibers, polymer blends, battery electrodes or conductive etch mask layers.

Owner:YOON HO SUNG +1

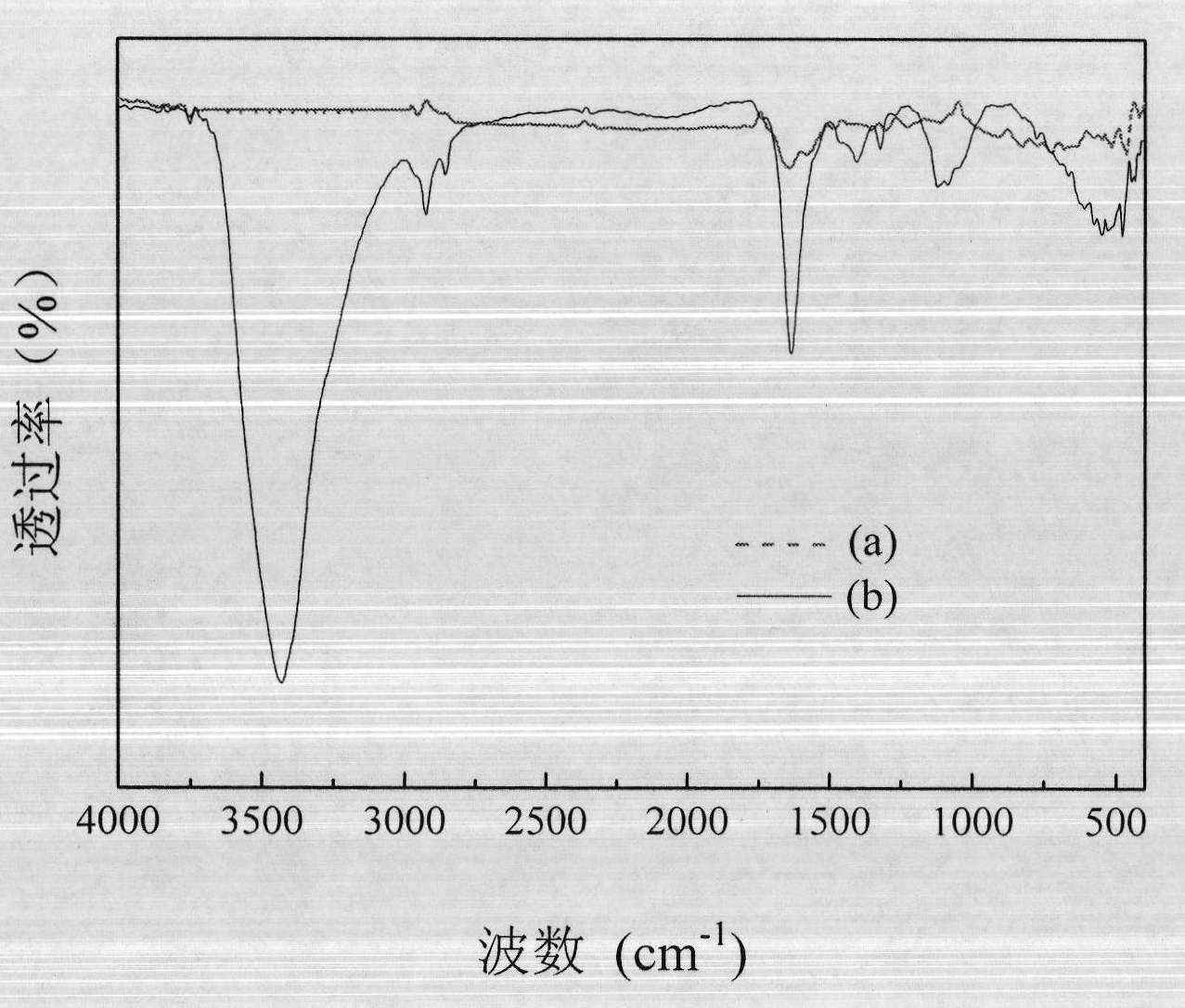

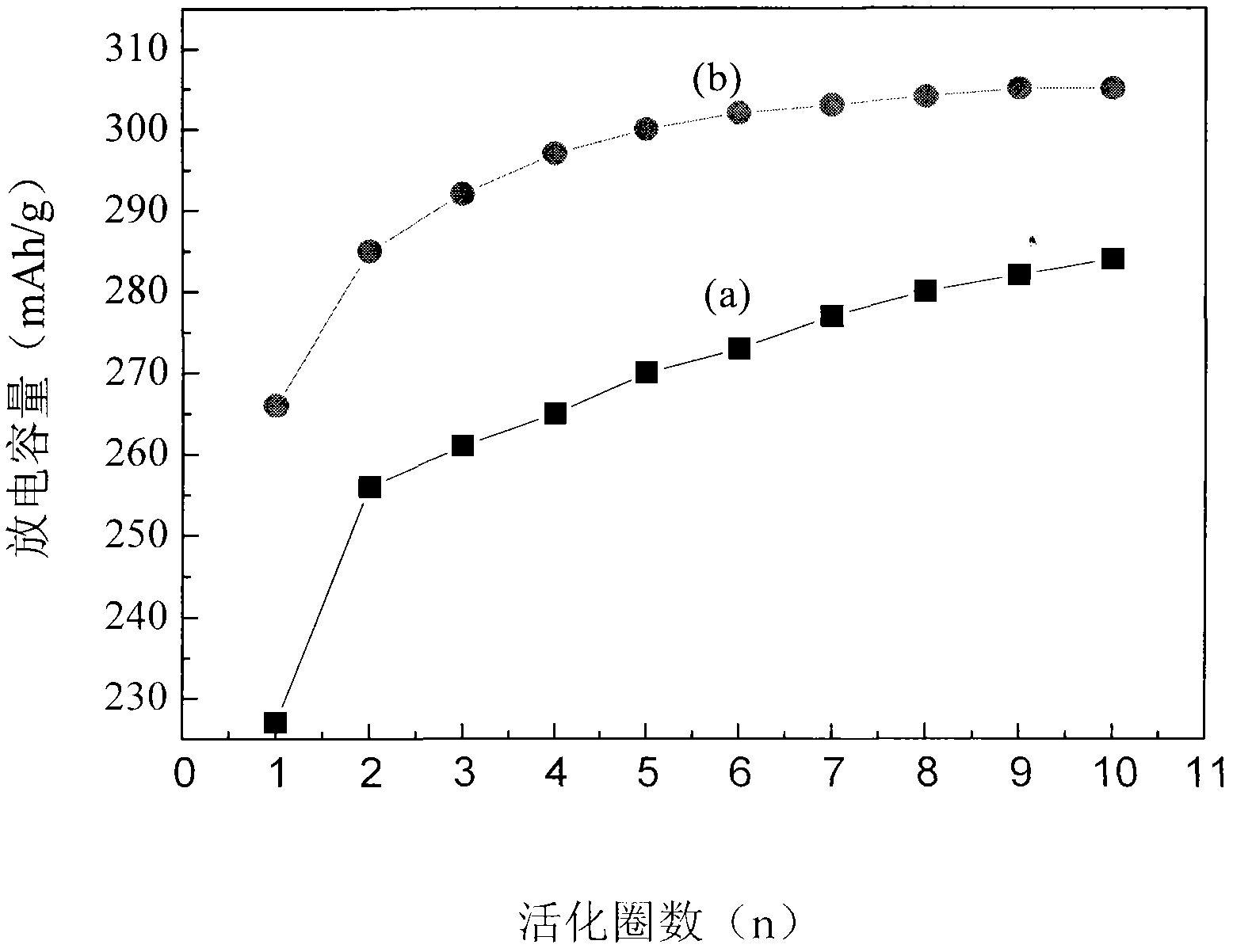

Method for Improving the Electrochemical Performance of Hydrogen Storage Alloy Powder Using Electropolymerized Polyaniline

ActiveCN102274965AEasy to operateReduce manufacturing costCell electrodesElectrophoretic coatingsElectrochemistryCorrosion

The invention relates to a method for improving the electrochemical performance of hydrogen storage alloy powder by utilizing electropolymerization polyaniline, and belongs to the technical field of the surface treatment of hydrogen storage alloy. The method comprises the following steps of: putting hydrogen storage alloy powder of which the granularity is between 100 and 400 meshes into mixed solution containing phenylamine and protonic acid in a certain ratio, and stirring uniformly at a speed of between 50 and 100 revolutions / minute, wherein the mass ratio of the hydrogen storage alloy powder to the mixed solution is 10 / 100-100 / 100; and applying direct-current voltage of between 1 and 2 V for 0.5 to 5 minutes by taking the hydrogen storage alloy powder as an anode and graphite as a cathode, so that the phenylamine performs electro-deposition polymerization reaction on the surface of the hydrogen storage alloy powder to form a polyaniline membrane layer. In the method, a polyanilinewrapped membrane with electrical conductivity and corrosion resistance is formed on surfaces of hydrogen storage alloy powder particles to improve the hydrogen storage capacity, high-multiplying power discharging performance and cyclic stability of the hydrogen storage alloy. The method has the characteristics of simplicity of operation, low production cost, obvious improvement effect and the like.

Owner:INNER MONGOLIA XIAOKE HYDROGEN STORAGE ALLOY CO LTD +1

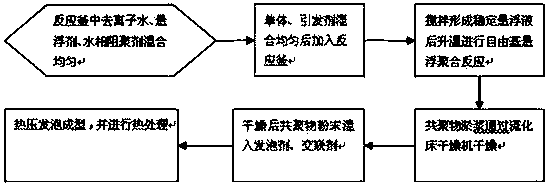

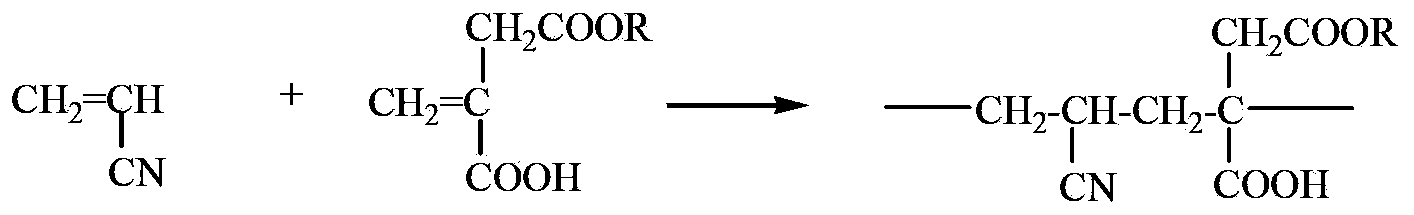

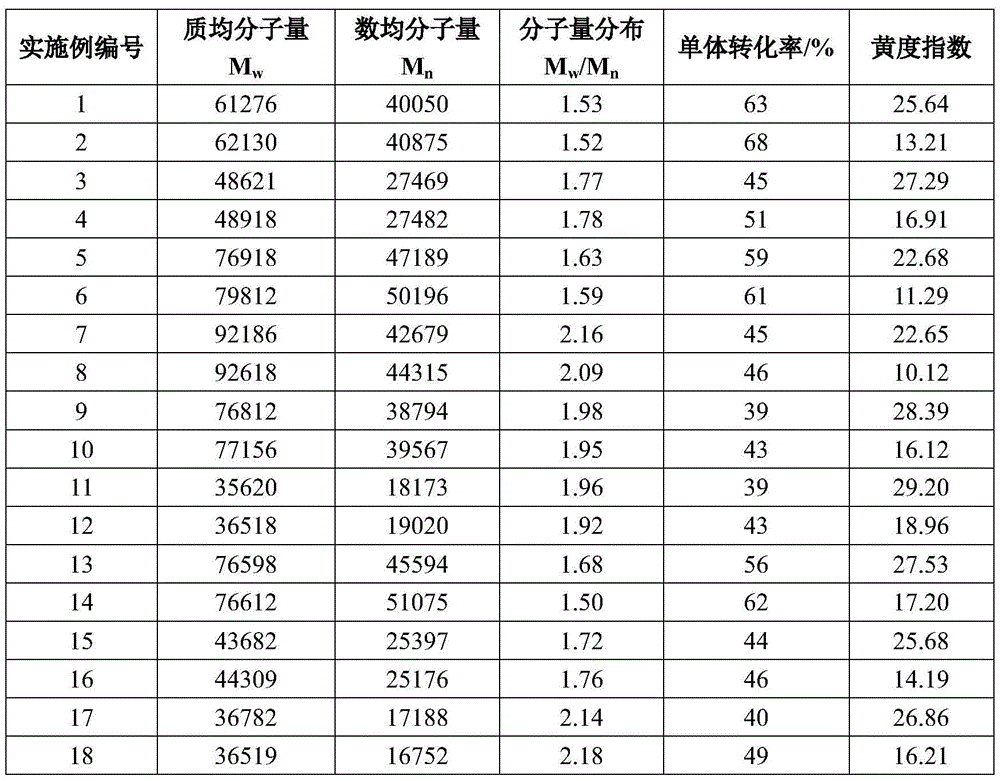

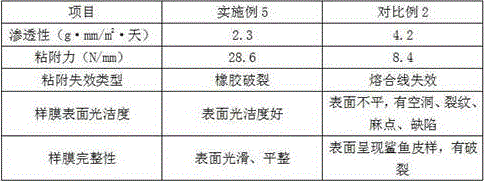

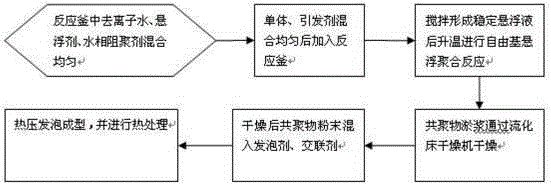

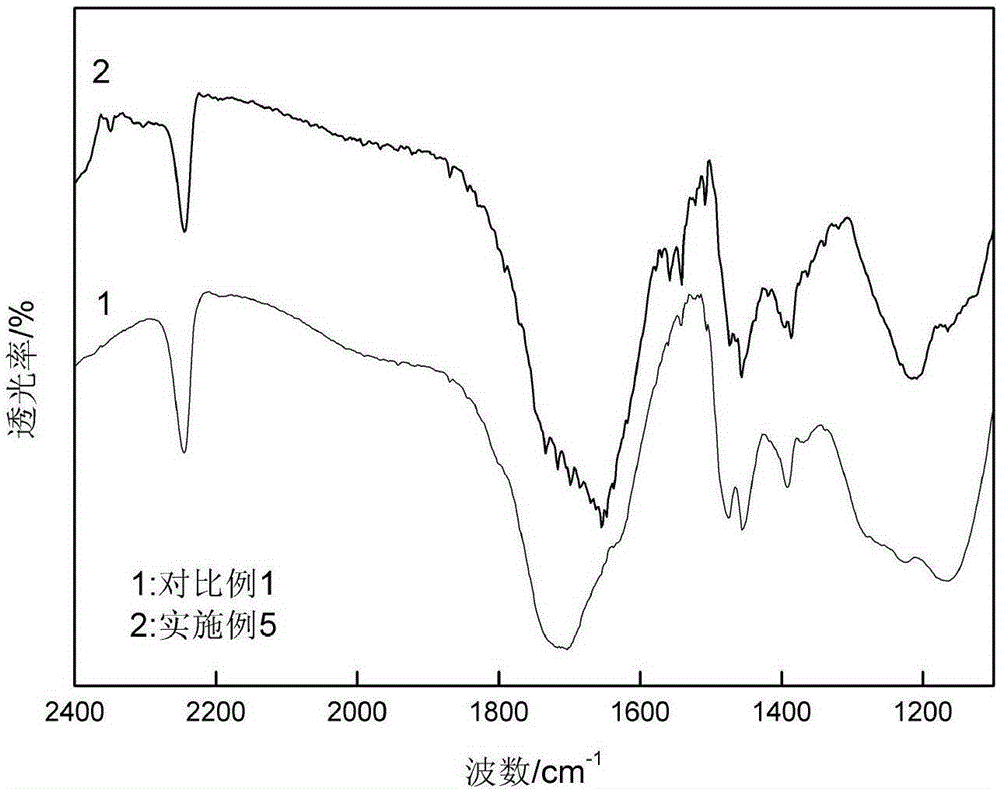

Preparation method for acrylonitrile/methacrylic acid copolymer foamed plastic

The invention discloses a preparation method for acrylonitrile / methacrylic acid copolymer foamed plastic. The preparation method comprises the following steps: adding deionized water, a suspending agent and an aqueous phase inhibitor into a reactor, and uniformly agitating; uniformly mixing monosomic acrylonitrile, methacrylic acid and an initiator, adding the mixture into the reactor, agitating the mixture at the room temperature so as to obtain a stable suspension, rising the temperature to a reaction temperature, and performing free radical suspension polymerization under the condition of agitation; drying a slurry-shaped mixture obtained after the reaction; uniformly mixing copolymer powder, a carbamide foaming agent and a bismaleimide (BMI) crosslinking agent which are obtained after drying; performing hot-pressing foaming formation of the mixture, and otaining polymethacrylimide foamed plastic via heat treatment. The technical scheme provided by the invention is high in production efficiency and yield, can obtain a product with stable performance, is simple and convenient to operate and environmental-friendly, and realizes a beneficial implement effect.

Owner:HAOBO FUJIAN NEW MATERIAL TECH

Preparation method and coating method of biodegradable temperature-responsive slowly-controlled release fertilizer coating material

ActiveCN106589258AIncrease profitImprove practicalityLayered/coated fertilisersFertilizer mixturesCelluloseCross-link

The invention relates to a preparation method and coating method of a biodegradable temperature-responsive slowly-controlled release fertilizer coating material. Agricultural organic waste containing cellulose serves as the raw material and is crushed, sieved, modified with dopamine and subjected to enzyme activation secondary treatment, and activated powder is obtained; the activated powder is mixed with a thermo-sensitive poly phosphate ester monomer, an initiator and a beta-cyclodextrin accelerant, the mixture is heated and stirred, a free radical polymerization reaction is conducted under protection of the inert gas, and the biodegradable temperature-responsive slowly-controlled release fertilizer coating material is obtained after vacuum drying is conducted; and the biodegradable temperature-responsive slowly-controlled release fertilizer coating material is heated to be a molten state and smeared on surfaces of fertilizer particles in a coating machine, and coated slowly-controlled release fertilizer can be obtained. Dopamine-activated agricultural organic waste is adopted from the angle of bionics, a polymerization reaction is effectively promoted in combination with enzyme activation secondary treatment, and production efficiency is improved; and meanwhile, the thermo-sensitive poly phosphate ester monomer serves as a cross-linking agent, the beta-cyclodextrin serves as the accelerant, and polymerization reaction time is shortened, so that the fertilizer intelligently regulates and controls nutrients along with soil temperature change.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

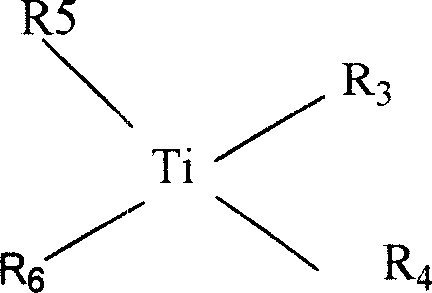

Titanium-silicon catalyst, preparation method and uses thereof

The invention discloses a titanium-silicon catalyst and a preparation method as well as an application thereof. The preparation method includes the following steps: (1) organic titanic acid ester and 2 / 3 cubic content of anhydrous alcohol are mixed evenly, and stirred sufficiently to achieve A solution; deionized water is mixed with the remained 1 / 3 cubic content of anhydrous alcohol sufficiently, acid or alkali is added, the acid or alkali concentration is controlled within 0.01-1mol / L, B solution is prepared, and B solution is dripped into A solution by a burette; (2) the mixture is stirred for 3-5 hours after dripping, the precipitate achieved after centrifugal separation is grinded and calcined to achieve titanium-silicon catalyst. The titanium-silicon catalyst achieved by the method is stable during the process of polymerization without hydrolysis reaction; the method can be used to catalytic synthesis of aliphatic and aromatic co-polyester, the titanium-silicon catalyst can reduce the dosage of catalyst, shorten the duration of polymerization, improve the quality of biodegradation co-polyester product, and the terminal carboxyl group content in the product as well as the b value are reduced.

Owner:KINGFA SCI & TECH CO LTD +1

Method for synthesizing polybutylene terephthalate

ActiveCN103665349AHigh catalytic activityShorten the polymerization reaction timePolytetramethylene terephthalatePolyethylene terephthalate

The invention discloses a method for synthesizing polybutylene terephthalate. The method comprises steps of firstly carrying out esterification between diacid and dihydric alcohol in presence of a chelate titanium catalyst at 150-230 DEG C under normal pressure, when the reaction liquid is totally transparent, gradually raising temperature of a reaction system to be 240-265 DEG C and reducing pressure to be absolute pressure of 30-300Pa, and then carrying out polycondensation so as to prepare PBT (polybutylene terephthalate) with intrinsic viscosity of 0.75-1.1, wherein the chelate titanium catalyst is prepared from organic titanate and fatty dihydric alcohol through decompression reaction at 50-90 DEG C. According to PBT prepared by the method, on the basis of not lowering general performances, the chelate titanium catalyst has stronger catalytic activity compared with traditional a titanate catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

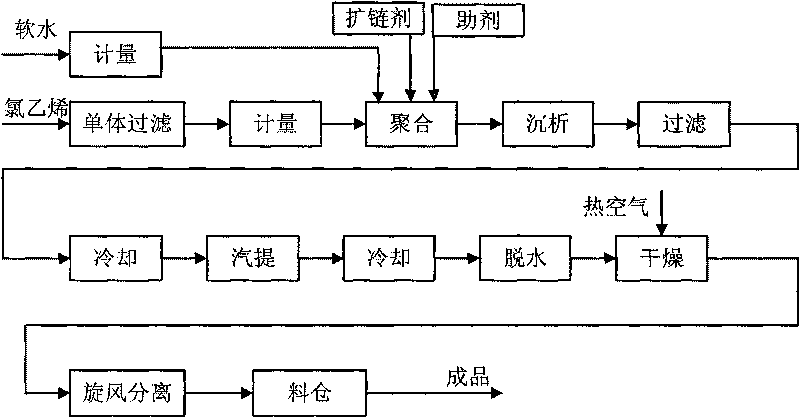

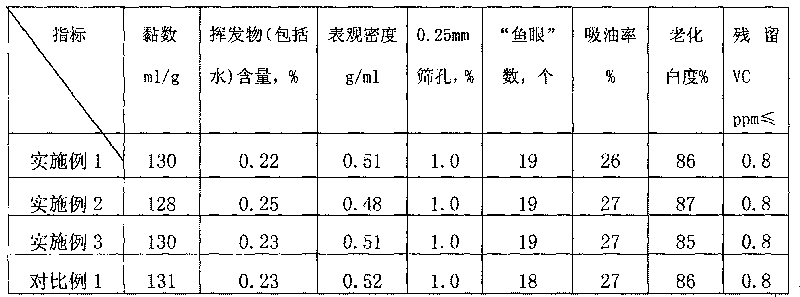

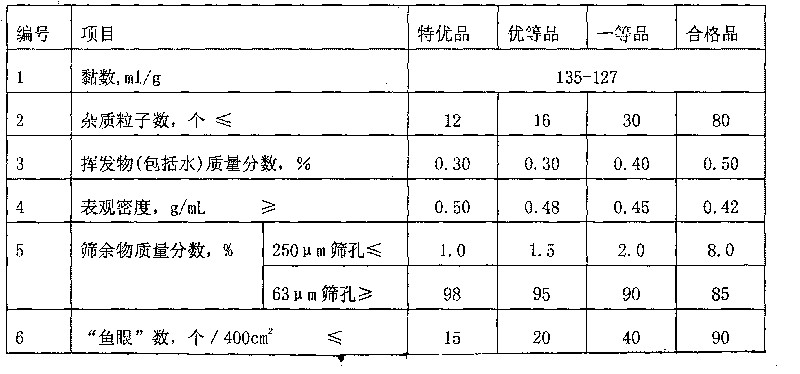

New process for SG3 type PVC (polyvinyl chloride) resin production

ActiveCN101735373ARaise the polymerization temperatureShorten the polymerization reaction timePolymer sciencePolyvinyl chloride

The invention relates to a new process for SG3 type PVC (polyvinyl chloride) resin production, which comprises the following steps of: adding a vinyl chloride monomer, pure water, a dispersant, an initiator and a conventional amount of thermal stabilizer and terminator into a reaction kettle, and meanwhile adding a chain extender of maleic acid di-allyl ester into the reaction kettle; wherein the reaction kettle is in a middle size, the mass proportion of the monomer, the pure water, the dispersant, the initiator and the chain extender is 20,000-25,000:30,000-33,000:490-530:120-140:4.5-5.5, and the temperature of polymerization reaction is 54-58 DEG C. Under the condition of no changing of traditional main production equipment, the invention adjusts the proportioning of relevant auxiliary agents, improves the temperature of the polymerization reaction, optimizes the control conditions of the production, and shortens the time of the polymerization reaction for about 60 minutes while adding a proper amount of the chain extender in a production formula, thereby saving power and energy consumption, improving production capacity of the equipment, and having safe and stable production system operation and better economic benefit.

Owner:昊华宇航化工有限责任公司

Preparation method for polycarboxylate high-performance water reducer

Provided is a preparation method for a polycarboxylate high-performance water reducer. The water reducer is prepared by copolymerization reaction of macromolecule monomer methoxy polyethylene glycol mono(meth) acrylate ester, small molecule monomer (meth)acrylic acid and sodium styrene sulfonate in an aqueous solution under the protection of inert gas and the action of a redox initiation system and a chain transferring agent. According to the invention, a high-activity redox initiation system is employed, which enhances the polymerization rate, reduces polymerization temperature, shortens reaction time, ensures non-hydrolysis of macro-molecular polyester monomers in the process of polymerization and a high conversion rate of raw materials, and guarantees that polymers have long side chains arraying at uniform intervals and an ideal comb shaped molecular structure. The water reducer prepared in the invention has the characteristics of a high water-reducing rate, a small slump loss and the like, and enables concrete with the water reducer to have high strength; simultaneously, the copolymerization reaction is carried out in water in the method, and therefore the method has the characteristics of simple preparation technology, environmental protection, low cost, etc.

Owner:江苏天音化工有限公司 +1

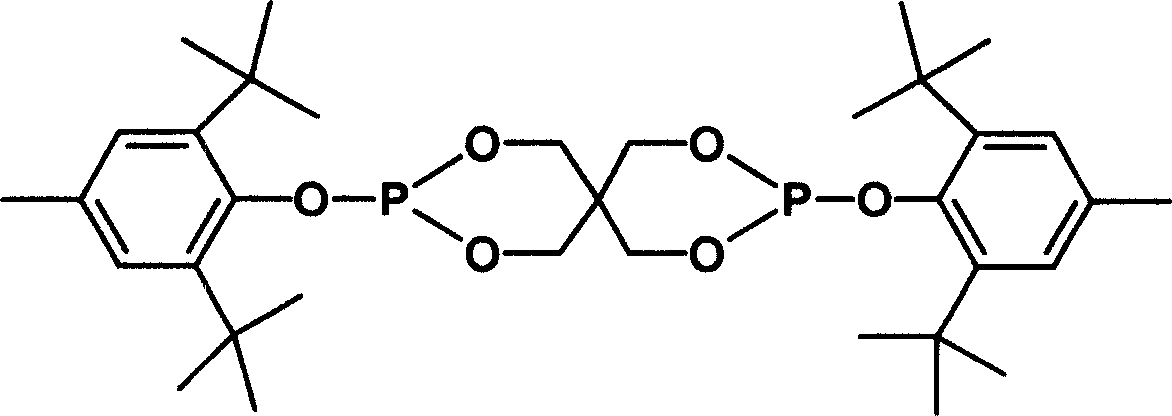

Process for producing polyester

The invention discloses a manufacturing method of polyester, wherein the catalyst is composed of titanium compound, phosphor compound and magnesium compound. The time of polymerization reaction is short with little side-reaction, which possesses excellent color, heat-proof, paintability and electrostatic adsorbing ability.

Owner:TORAY IND INC

Prepn. of PVF

This invention discloses a method to prepare polyvinyl fluoride in which vinyl fluoride is adopted as monomers for polymerization. It has the characteristics that polymerization takes place with the existence of soluble radical initiators and auxiliary reagents. The auxiliary reagents in this invention can be: A) neutral inorganic salts; B) alkali or alkali compounds; C) acid or acidic compounds. This invention has the advantages that compared to previous literature, a) polymerization time can be reduced and efficiency of catalyst and facility can be promoted without obvious change in product properties such as intrinsic viscosity, melting point and melting heat by addition of auxiliary reagent A); b) melting point and melting heat of the product can be raised by addition of auxiliary reagent B); c) melting point and melting heat of the product can be lowered by addition of auxiliary reagent C). The polyvinyl fluoride membrane by melting tape-casting extrusion with potential solvent such as N, N-dimethylformamide and biaxial orientation of vinyl fluoride has wonderful comprehensive properties.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH

Solution polymerization method

ActiveCN102887970AOmit nitrogen filling and deoxygenation operationHigh molecular weightDrilling compositionPolymer sciencePersulfate

The invention provides a solution polymerization method. The solution polymerization method comprises the following steps that an aqueous solution containing monomers and sodium hydrosulfite contact under oxidation reaction conditions; and after contact, the mixture is mixed with a persulfate under the conditions of acrylamide low-temperature polymerization, wherein the monomers comprise 75 to 100 mol% of acrylamide and a mole ratio of oxygen dissolved in the aqueous solution to sodium hydrosulfite is 1: (0.4 to 2). The solution polymerization method can avoid a process of nitrogen-filling oxygen-removal of an aqueous solution containing monomers, eliminate an inhibition effect produced by oxygen dissolved in the aqueous solution on monomer polymerization, realize preparation of an acrylamide polymer having ultra-high molecular weight, and greatly reduce polymerization time of acrylamide polymer preparation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparing method of polyacrylonitrile (PAN) used for carbon fiber

A preparing method of polyacrylonitrile (PAN) used for carbon fiber is provided. The preparing method adopts a water-phase precipitation polymerization reaction, adopts water-soluble ammonium sulfate-sodium bisulfite-ferrous sulfate as an oxidation-reduction initiation system, adopts a monoester of itaconic acid as a bifunctional copolymerization monomer, and adopts sulfuric acid as a pH conditioner. The bifunctional copolymerization monomer and acrylonitrile are subjected to a precipitation polymerization reaction in a water phase, then the reaction system is alkalified by aqueous ammonia, and after separation, washing and drying, PAN powder is obtained. The preparing method is low in cost, short in polymerization time, and high in production efficiency, and the prepared polyacrylonitrile is high in purity and good in spinnability and preoxidation controllability, so that the preparing method is suitable for large-scale production of carbon fiber precursor and facilitates reduction of the production cost of carbon fiber.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method of narrow-distribution polyacrylonitrile-based carbon fiber spinning solution

ActiveCN110684149AImprove mass transfer efficiencyImprove heat transfer efficiencyFibre chemical featuresPolymer scienceCarbon fibers

The invention relates to a preparation method of a narrow-distribution polyacrylonitrile-based carbon fiber spinning solution. The preparation method of the narrow-distribution polyacrylonitrile-basedcarbon fiber spinning solution mainly solves the problems of wide molecular weight distribution of polyacrylonitrile, high residual monomer content and long polymerization reaction time in the priorart. The preparation method of the narrow-distribution polyacrylonitrile-based carbon fiber spinning solution includes the following steps that (1) polymerization raw material acrylonitrile, a comonomer 1 and / or a comonomer 2, a solvent and an initiator are added into a reactor, a thermostatic reaction is started under the protection of inert gas to the reaction materials, and a reaction temperature is controlled to 60-65 DEG C; (2) when the conversion rate exceeds T1, the temperature is increased by 5-10 DEG C; (3) when the conversion rate exceeds T2, the temperature is increased by 5-10 DEGC; and (4) when the conversion rate reaches T3, the reaction is finished, and preparation of the spinning solution is completed. According to the technical scheme, the problems of wide molecular weight distribution of polyacrylonitrile, high residual monomer content and long polymerization reaction time are well solved, and the preparation method can be used in the industrial production of the polyacrylonitrile-based carbon fiber spinning solution.

Owner:CHINA PETROLEUM & CHEM CORP +1

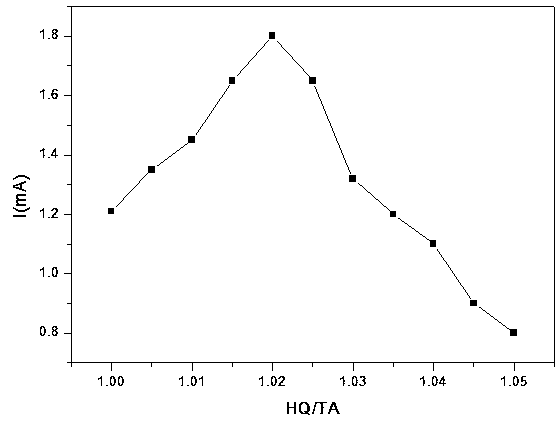

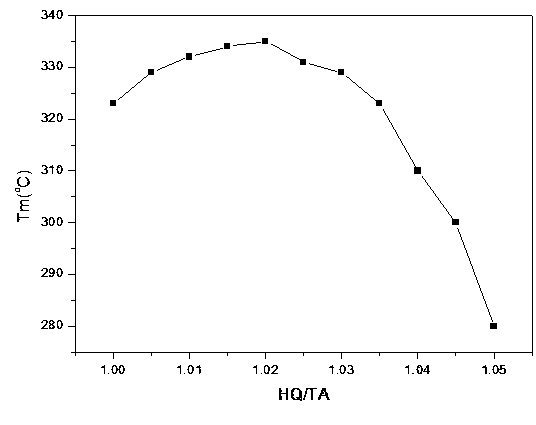

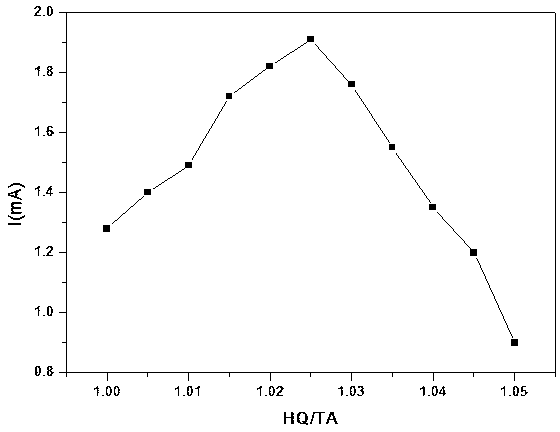

Method for improving molecular weight of thermotropic liquid crystal polymer

InactiveCN103804667AShorten the polymerization reaction timeIncrease productivityLiquid crystal compositionsBenzoic acidPolymer science

The invention provides a method for improving the molecular weight of a thermotropic liquid crystal polymer. According to the method, in the process of preparing the thermotropic liquid crystal polymer by using p-hydroxybenzoic acid / p-acetoxybenzoic acid, 6-hydroxy-2-naphthoic acid / 6-acetoxy-2-naphthoic acid, hydroquinone / hydroquinone diacetate and terephthalic acid, the molar ratio of the hydroquinone / hydroquinone diacetate to the terephthalic acid is controlled to be (1.005-1.025): 1. The molecular weight of the polymer product is controlled by controlling the addition amount of certain monomers, so that the polymerization time can be greatly shortened and the production efficiency is improved.

Owner:NANTONG HAIDI CHEM +2

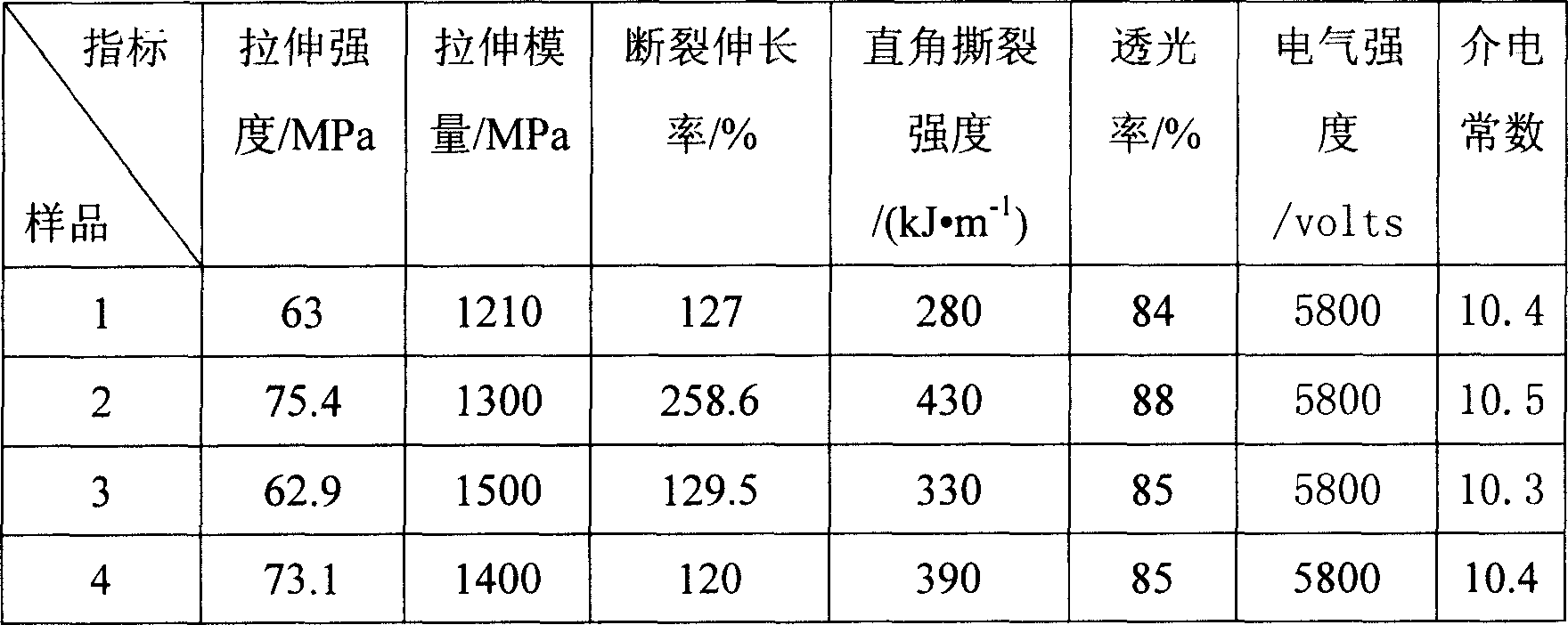

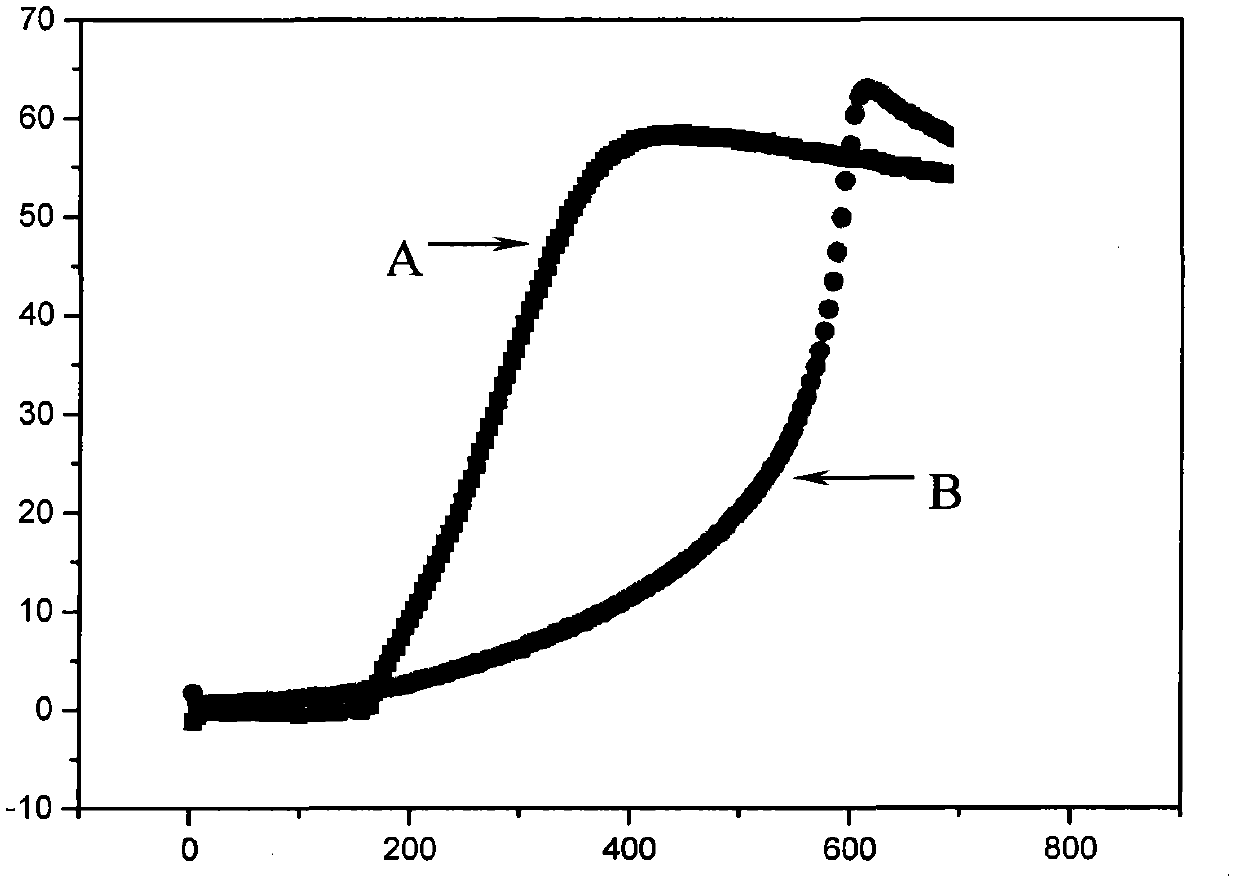

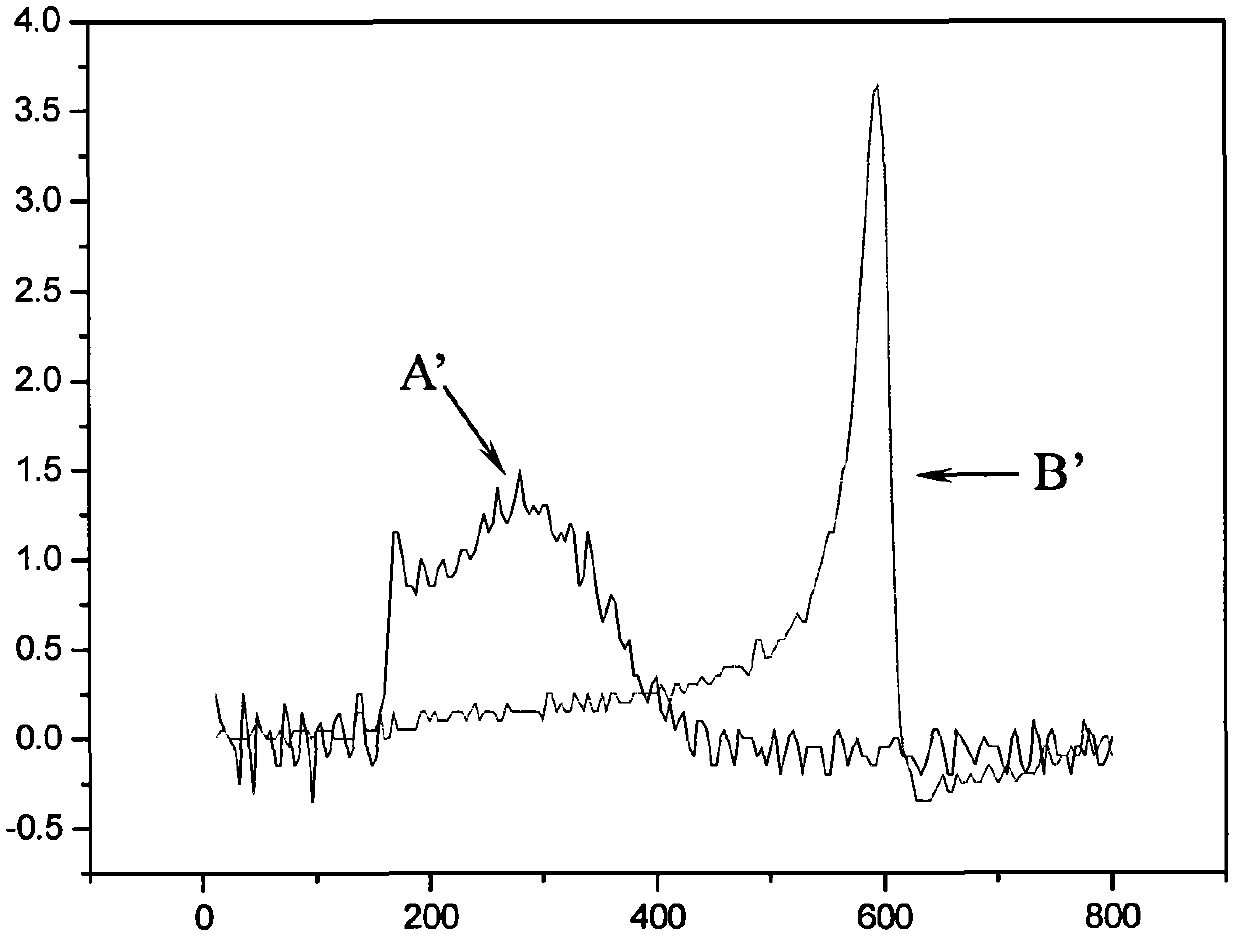

Preparation method of dielectric material for high energy storage capacitor

The invention discloses a preparation method of a dielectric material for a high energy storage capacitor, the invention relates to the technical field of dielectric materials, the preparation methoduses polyaniline coated with inorganic nanoparticles as a filler, polyvinylidene fluoride as polymer matrix, metal Ni as the load. Firstly, the surface of inorganic nanoparticles is modified by physical ball milling and chemical surfactant, a supercritical fluid reaction is adopted to coat polyaniline on the surface of the inorganic nanoparticles, so that a composite fill is prepared, the composite fill and the polyvinylidene fluoride are spun into a fibrous membrane by melt electrospinning, at last, the metal Ni load and the polyvinylidene fluoride are composited on the fiber membrane by magnetron sputter, the load of the metal Ni not only helps to fill the high porosity of the electrospun fiber film, but also helps to maintain high breakdown field strength, high energy storage density, high dielectric constant and low dielectric loss of the dielectric material, and the composite dielectric material has high energy storage performance.

Owner:滨州高新高端装备制造产业园有限公司

Rapid emulsion polymerization method for vinyl acetate

InactiveCN102757518AEasy to operateReduce polymerization temperature control conditionsPolyvinyl alcoholReaction temperature

The invention relates to a rapid emulsion polymerization method for vinyl acetate. The method comprises the followings steps of: adding 10-15 parts by mass of 16.7 percent polyvinyl alcohol, 17-88 parts by mass of an aqueous solution, 37-52 parts by mass of deionized water, 0.5-2 parts by mass of octyl phenol polyoxyethylene ether and 15-40 parts by mass of vinyl acetate into a reaction kettle with a thermometer and a stirring and reflowing device; stirring and mixing uniformly, and gradually heating to 45-70 DEG C; adding a persulfate aqueous solution and a silver ammonia solution respectively; reacting at the temperature of 45-70 DEG C for 20-45 minutes; and naturally cooling to the room temperature after finishing the reaction to obtain a milky white blueing light-stable vinyl acetate emulsion. The method has the beneficial effects: operation is easy, equipment is simple, polymerization temperature control conditions are reduced, the lowest reaction temperature can be lowered to 45 DEG C, and the polymerization reaction time can be shortened to 20-45 minutes.

Owner:WUHAN UNIV OF TECH

Conductive polymers having highly enhanced solubility in organic solvent and electrical conductivity and synthesizing process thereof

InactiveUS7695645B2Good dispersionGood physical propertiesSynthetic resin layered productsConductive materialFiberSolubility

Owner:LEE SUCK HYUN +1

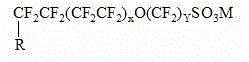

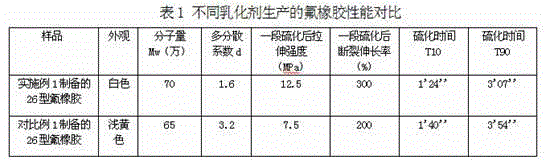

Preparation method for preparing type 26 fluororubber from fluoroether sulfonate

The invention provides a preparation method for preparing type 26 fluororubber from a fluoroether sulfonate and belongs to the technical field of synthesis of the high polymer material fluoroelastomers. The preparation method comprises the following steps: 1) blowing nitrogen into an airtight polymerization reaction kettle to remove oxygen, and adding deionized water, an emulsifier, disodium hydrogen phosphate, potassium persulfate, diethyl malonate, vinylidene fluoride and hexafluoropropylene, wherein the emulsifier is the fluoroether sulfonate; 2) reacting under the pressure of 3.0-7.0Mpa and at a temperature ranging from 50 to 120 DEG C, starting a mixing propeller at a rotating speed of 300-700r / min, and ending the reaction after 0.5-2.5 hours, thereby obtaining fluororubber latex; 3) coagulating by use of calcium chloride, washing the coagulated solid particles by use of deionized water until the bubble disappears, and drying in vacuum to obtain the finished product. The preparation method for preparing the type 26 fluororubber from the fluoroether sulfonate has the advantages of increasing the molecular weight of the fluororubber, improving the molecular weight distribution and the mechanical properties of the fluororubber, and protecting the environment.

Owner:ZHEJIANG FLUORINE CHEM NEW MATERIAL

A kind of preparation method of porous superabsorbent resin

InactiveCN103214616BShorten the polymerization reaction timeIncrease productivityCross-linkSodium hydroxide

The invention discloses a preparation method of porous-super-absorbent resin. The preparation method comprises the following steps of: adding acyclic acid to deionized water, neutralizing with a sodium hydroxide aqueous solution, and controlling neutralization temperature at 50 DEG C to 80 DEG C and neutralization degree at 60-80%; mixing the solution; adding a cross-linking agent and stirring till completely dissolving, then adding an oxidant and a foaming agent, afterwards, adding a reducing agent, carrying out polymerization reaction by heat of neutralization, and generating porous-super-absorbent resin gel; and pelleting, drying, crushing and screening to obtain the porous-super-absorbent resin. Additional heating equipment is not needed in the porous-super-absorbent resin preparation method; heat released in neutralization process is directly used for enabling a polymerization reaction system to reach the temperature needed by the reaction; and an oxidation reduction initiating agent is added at high temperature, so that the whole polymerization reaction time is shortened, and the production efficiency is improved; and the added foaming agent can be used for preparing porous gel, so that the water retaining capacity and the water-absorption capability of the water-absorbent resin are improved.

Owner:SOUTH CHINA UNIV OF TECH

Method for reducing yellowness index of polyglycolic acid

The invention provides a method for preparing polyglycolic acid. The yellowness index of polyglycolic acid is very low, and even when the polymerization temperature is high, the yellowness index of the product is also low. A catalyst is a composite catalyst, and the main component of the composite catalyst is a mixture of a traditional metal catalyst and an additive of an equal amount of substance. Compared with a single metal catalyst system, the catalytic activity of the composite catalyst is greatly improved. The polymerization reaction time is shortened to be within 20 min, and thus the polyglycolic acid production efficiency is greatly improved. The yellowness index of polyglycolic acid prepared through the method is low.

Owner:CHANGZHOU UNIV

Ethylene-tetrafluoroethylene copolymer and preparation method and application thereof

ActiveCN106084113AEnsure uniformity and thoroughnessShorten the polymerization reaction timeFlexible pipesHigh pressureMonomer

The invention relates to the field of fluorine-containing high molecular materials, in particular to an ethylene-tetrafluoroethylene copolymer and a preparation method thereof. The preparation method includes: (1), vacuumizing a high-pressure kettle, and adding a polymerization medium; (2), adding an initial monomer into the polymerization medium until pressure is 0.9-1.2 Mpa, heating to 58-62 DEG C, adding an initiator; (3), after reaction is started, continuously adding a replenishing monomer for equal-temperature equal-pressure polymerization, and stopping adding the replenishing monomer when adding amount of the replenishing monomer accounts for 10-14% of total mass of the polymerization medium and the replenishing monomer; (4), lowering temperature and pressure, discharging, washing materials, and drying to obtain the copolymer. The preparation method is short in polymerization time, simple to operate and easy for industrial production. The invention further provides application of the ethylene-tetrafluoroethylene copolymer in fuel hose inner layers.

Owner:SHANDONG HUAFU FLUORO CHEM

A kind of preparation method of acrylonitrile/methacrylic acid copolymer foamed plastics

ActiveCN103421206BRaise the polymerization temperatureShorten the polymerization reaction timeImidePolymer science

The invention discloses a method for preparing an acrylonitrile / methacrylic acid copolymer foam plastic, which comprises the following steps: adding deionized water, a suspending agent and a water-phase polymerization inhibitor into a reaction vessel, and stirring evenly; After the nitrile, methacrylic acid and initiator are mixed evenly, add to the reaction vessel, and stir at room temperature to obtain a stable suspension, heat up to the reaction temperature, and carry out free radical suspension polymerization reaction under the condition of stirring again; the slurry obtained after the reaction The mixture is dried; after drying, the obtained copolymer powder, carbonamide foaming agent, and bismaleimide (BMI) crosslinking agent are mixed evenly; the obtained mixture is hot-pressed and foamed, and heat-treated to obtain polymethacrylic Amine foam. The technical scheme of the invention has high production efficiency, high yield, stable product performance, simple and convenient operation, and environmental friendliness, thereby obtaining beneficial implementation effects.

Owner:HAOBO FUJIAN NEW MATERIAL TECH

A kind of synthetic method and application of water-soluble chitosan-based flocculant

ActiveCN105622847BSpeed up homolysisThe polymerization reaction is fastWater/sewage treatment by flocculation/precipitationFunctional monomerAlcohol ethyl

The invention provides a synthesis method and application of a water soluble chitosan-based flocculant. The method comprises the steps of adding chitosan into acid solution, adding acylated monomer aqueous solution into the acid solution, uniformly stirring and mixing, performing vibration reaction for 1 to 10 h at 5 to 60 DEG C, performing precipitation and purification through ethyl alcohol and acetone, drying, and obtaining N-acylated chitosan; sequentially adding the N-acylated chitosan, deionized water, acrylamide and strong cation functional monomer into a reactor, uniformly stirring, leading nitrogen into homogenous solution to remove oxygen, adding a photoinitiator and a cosolvent, uniformly stirring and mixing, putting the raw materials into an ultraviolet light reaction device to perform polymerization reaction, drying, performing granulation and powder process, and obtaining the water soluble chitosan-based flocculant; the flocculant can be used for the removal treatment of alga in source water. The flocculant is good in solubility property, high in viscosity coefficient and short in synthesis time, does not need temperature reduction control, simplifies the production technology, reduces energy consumption, and reduces the production cost.

Owner:NANJING TECH UNIV

Titanium-silicon catalyst, preparation method and uses thereof

The invention discloses a titanium-silicon catalyst and a preparation method as well as an application thereof. The preparation method includes the following steps: (1) organic titanic acid ester and 2 / 3 cubic content of anhydrous alcohol are mixed evenly, and stirred sufficiently to achieve A solution; deionized water is mixed with the remained 1 / 3 cubic content of anhydrous alcohol sufficiently, acid or alkali is added, the acid or alkali concentration is controlled within 0.01-1mol / L, B solution is prepared, and B solution is dripped into A solution by a burette; (2) the mixture is stirredfor 3-5 hours after dripping, the precipitate achieved after centrifugal separation is grinded and calcined to achieve titanium-silicon catalyst. The titanium-silicon catalyst achieved by the method is stable during the process of polymerization without hydrolysis reaction; the method can be used to catalytic synthesis of aliphatic and aromatic co-polyester, the titanium-silicon catalyst can reduce the dosage of catalyst, shorten the duration of polymerization, improve the quality of biodegradation co-polyester product, and the terminal carboxyl group content in the product as well as the b value are reduced.

Owner:KINGFA SCI & TECH CO LTD +1

Area liconductive polymers having highly enhanced solubility in organic solvent and electrical conductivity and synthesizing process thereofght

InactiveUS20080308771A1Good dispersionGood physical propertiesConductive materialOrganic conductorsSolubilityFiber

The present invention relates to a new process of synthesizing conductive polymers from monomers substituted with amine group. The process provides simple synthesizing steps for the conductive polymers without using other additives such as stabilizers or emulsifiers. The conductive polymers synthesized according to the present invention have highly enhanced solubility in common organic solvents and electrical conductivity compared to conventional conductive polymers. Therefore, the conductive polymers synthesized according to the present process can be utilized in applications that require high electrical conductivity, for example an electro-magnetic interference shield or a transparent electrode of thin film, as well as in specific applications such as various conductive films, fibers, polymer blends, battery electrodes or conductive etch mask layers.

Owner:LEE SUCK HYUN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com