Rapid emulsion polymerization method for vinyl acetate

A vinyl acetate and emulsion polymerization technology, applied in the field of rapid emulsion polymerization of vinyl acetate, can solve problems such as unsatisfactory product quality and performance, and achieve the effects of shortened polymerization reaction time, easy operation, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

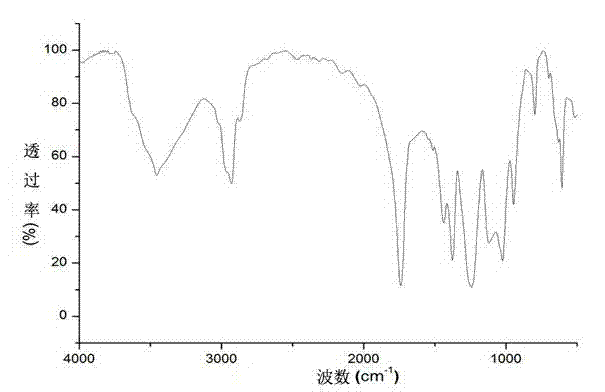

Image

Examples

Embodiment 1

[0012] The method for preparing the polyvinyl acetate emulsion by rapid triggering of the potassium persulfate complex comprises the steps:

[0013] 1) Preparation of potassium persulfate complex solution: add 0.2 parts of potassium persulfate to a 250mL beaker, add 10 parts of deionized water to make a 2% potassium persulfate aqueous solution; add 0.01 part of silver nitrate to a 250mL beaker, add 5 1 part of deionized water, after dissolving, add 0.2 part of ammonia water with a mass percentage concentration of 25-28% and mix evenly to form a silver-ammonia solution;

[0014] 2) Potassium persulfate complex quickly initiates vinyl acetate emulsion polymerization: In a reaction kettle with a thermometer, stirring and reflux device, add 15 parts of 16.7% polyvinyl alcohol 17-88 aqueous solution and 44.5 parts of deionized water respectively, Add 1.5 parts of emulsifier OP-10, add 24 parts of vinyl acetate, start to stir and mix evenly, then gradually raise the temperature to...

Embodiment 2

[0018] Initiate the method for preparing polyvinyl acetate emulsion quickly by ammonium persulfate compound, it comprises the steps:

[0019] 1) Preparation of ammonium persulfate complex solution: Add 0.2 parts of ammonium persulfate to a 250mL beaker, add 10 parts of deionized water to make a 2% ammonium persulfate aqueous solution; add 0.01 part of silver nitrate to a 250mL beaker, add 5 1 part of deionized water, after dissolving, add 0.2 part of ammonia water with a mass percentage concentration of 25-28% and mix evenly to form a silver ammonia solution;

[0020] 2) The ammonium persulfate compound quickly initiates the emulsion polymerization of vinyl acetate: In a reaction kettle with a thermometer, stirring and reflux device, add 12 parts of 16.7% polyvinyl alcohol 17-88 aqueous solution and 52 parts of deionized water, Add 1 part of emulsifier OP-10, add 20 parts of vinyl acetate, start to stir and mix evenly, then gradually raise the temperature to 65°C, add the am...

Embodiment 3

[0023] The method for preparing the polyvinyl acetate emulsion by rapid triggering of the potassium persulfate complex comprises the steps:

[0024] 1) Preparation of potassium persulfate complex solution: add 0.2 parts of potassium persulfate to a 250mL beaker, add 10 parts of deionized water to make a 2% potassium persulfate aqueous solution; add 0.01 part of silver nitrate to a 250mL beaker, add 5 1 part of deionized water, after dissolving, add 0.2 part of ammonia water with a mass percentage concentration of 25-28% and mix evenly to form a silver ammonia solution;

[0025] 2) Potassium persulfate complex quickly initiates vinyl acetate emulsion polymerization: In a reaction kettle with a thermometer, stirring and reflux device, add 12 parts of 16.7% polyvinyl alcohol 17-88 aqueous solution and 52 parts of deionized water, Add 1 part of emulsifier OP-10, add 20 parts of vinyl acetate, start to stir and mix evenly, then gradually raise the temperature to 45°C, add the pot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com