Preparation method of porous-super-absorbent resin

A superabsorbent resin and porous technology, applied in the field of superabsorbent resin, can solve the problems of complex synthesis process, unfavorable industrial production, and increased production cost, and achieve the effects of simple process, shortened polymerization reaction time, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) 100g of acrylic acid was added to 100g of deionized water, neutralized with 30wt% sodium hydroxide aqueous solution, and the neutralization temperature was controlled to be 80°C to obtain a mixed solution with a monomer concentration of 40% and a neutralization degree of 80%.

[0028] (2) Add 0.03g crosslinking agent N, N'-methylenebisacrylamide and stir until completely dissolved, then add 1g oxidant ammonium persulfate and 10g foaming agent sodium bicarbonate, and pour the mixture into the reactor , Then add 0.1g reducing agent sodium bisulfite to carry out polymerization reaction.

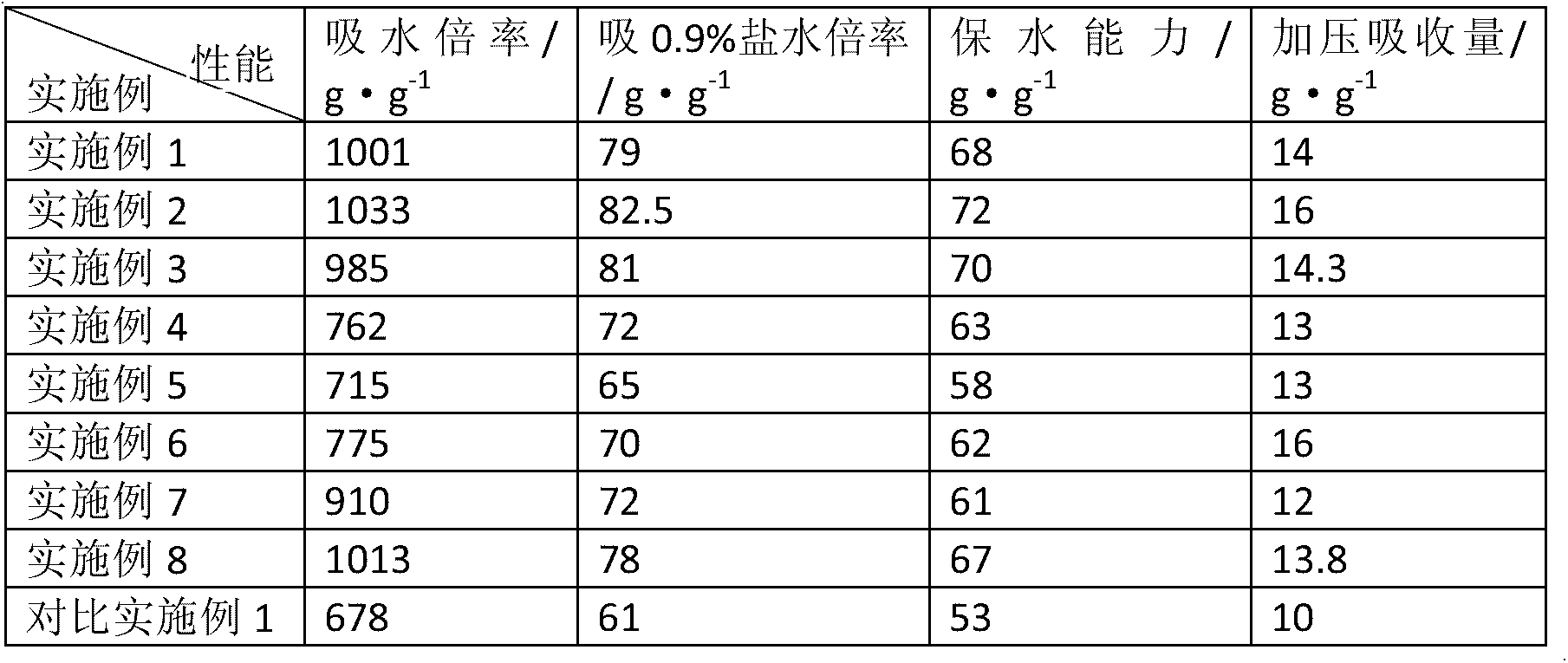

[0029] (3) The obtained porous gel is granulated by a meat grinder, then put into an oven, and dried for 18 hours at a temperature of 80°C to obtain gel particles, which are pulverized and sieved to obtain 60 ~100 mesh white powdery solid granular superabsorbent resin products. After testing, its performance test results are shown in Table 1.

Embodiment 2

[0031] (1) 100g of acrylic acid was added to 100g of deionized water, neutralized with 20wt% sodium hydroxide aqueous solution, and the neutralization temperature was controlled to be 80°C to obtain a mixed solution with a monomer concentration of 40% and a neutralization degree of 80%.

[0032] (2) Add 0.03g crosslinking agent N, N'-methylenebisacrylamide and stir until completely dissolved, then add 1g oxidant ammonium persulfate and 15g foaming agent potassium bicarbonate, and pour the mixture into the reactor , Then add 0.1g reducing agent sodium bisulfite to carry out polymerization reaction.

[0033] (3) The obtained porous gel is granulated by a meat grinder, then put into an oven, and dried for 18 hours at a temperature of 80°C to obtain gel particles, which are pulverized and sieved to obtain 60 ~100 mesh super absorbent resin products. The performance test results are shown in Table 1.

Embodiment 3

[0035] (1) 100g of acrylic acid was added to 100g of deionized water, neutralized with 40wt% sodium hydroxide aqueous solution, and the neutralization temperature was controlled to be 80°C to obtain a mixed solution with a monomer concentration of 40% and a neutralization degree of 80%.

[0036] (2) Add 0.5g of cross-linking agent polyvinyl alcohol and stir until completely dissolved, then add 0.5g of oxidant sodium persulfate and 20g of foaming agent sodium bicarbonate, pour the mixture into the reactor, and then add 0.1g of reducing agent Sodium bisulfite for polymerization.

[0037] (3) The obtained porous gel is granulated by a meat grinder, then put into an oven, and dried for 18 hours at a temperature of 80°C to obtain gel particles, which are pulverized and sieved to obtain 60 ~100 mesh super absorbent resin products. The performance test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com