Preparation method for acrylonitrile/methacrylic acid copolymer foamed plastic

A technology of methacrylic acid and foamed plastics, applied in the field of foamed plastics preparation, can solve the problems of low production efficiency, unstable performance, low product yield and the like, and achieves the effects of improving output, uniform performance and increasing polymerization reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

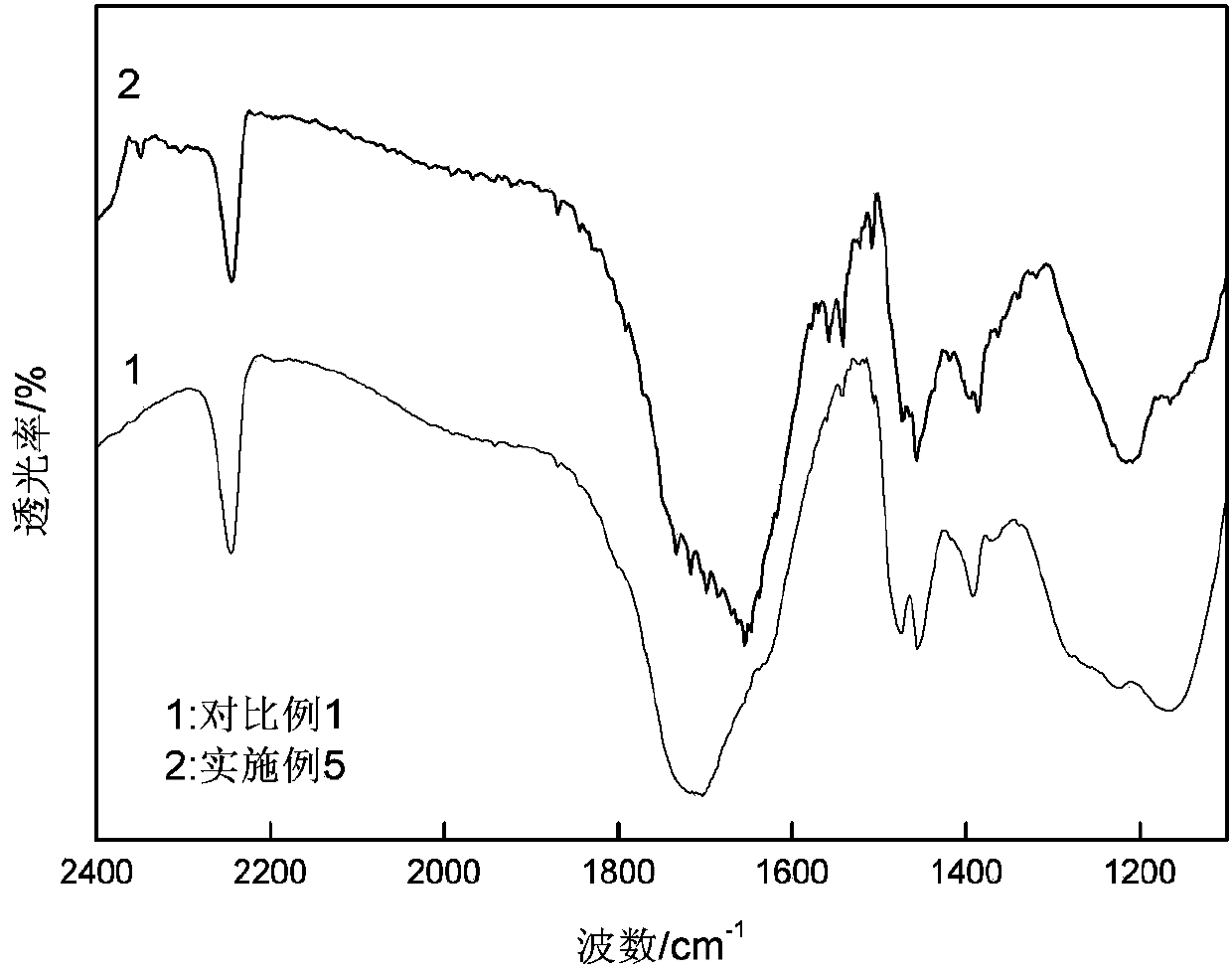

Image

Examples

Embodiment 1

[0039] A kind of acrylonitrile / methacrylic acid copolymer foamed plastics of the present invention, it can be obtained by following component mixing reaction:

[0040] The mass ratio of monomer: acrylonitrile to methacrylic acid is 40:60.

[0041] Dispersion medium: The ratio of the mass of deionized water to the total mass of the monomer is 2:1; the amount of suspending agent PVA1788 is 0.1% of the mass of deionized water.

[0042] Aqueous phase polymerization inhibitor: methylene blue, the dosage is 0.001% of the total mass of monomers.

[0043] Initiator: azobisisobutyronitrile (AIBN), the dosage is 1% of the total mass of monomers.

[0044] Foaming agent: carbonamide, the dosage is 6% of the total mass of monomers.

[0045] Cross-linking agent: BMI, the dosage is 1% of the total mass of monomers.

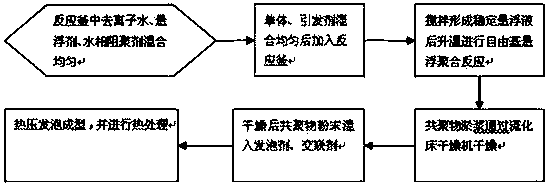

[0046] The preparation method of above-mentioned acrylonitrile / methacrylic acid copolymer foamed plastics, it adopts following steps to carry out successively:

[0047] (1) ...

Embodiment 2

[0053] A kind of acrylonitrile / methacrylic acid copolymer foamed plastics of the present invention, it can be obtained by following component mixing reaction:

[0054] The mass ratio of monomer: acrylonitrile to methacrylic acid is 45:55.

[0055] Dispersion medium: The ratio of the mass of deionized water to the total mass of the monomer is 2.5:1; the amount of suspending agent PVA1788 is 0.3% of the mass of deionized water.

[0056] Aqueous phase polymerization inhibitor: tin chloride, the dosage is 0.003% of the total mass of monomers.

[0057] Initiator: azobisisoheptanonitrile (ADVN), the dosage is 2% of the total mass of monomers.

[0058] Foaming agent: carbonamide, the dosage is 7% of the total mass of monomers.

[0059] Cross-linking agent: BMI, the dosage is 2% of the total mass of monomers.

[0060] The preparation method of above-mentioned acrylonitrile / methacrylic acid copolymer foamed plastics, it adopts following steps to carry out successively:

[0061] (1)...

Embodiment 3

[0067] A kind of acrylonitrile / methacrylic acid copolymer foamed plastics of the present invention, it can be obtained by following component mixing reaction:

[0068] The mass ratio of monomer: acrylonitrile to methacrylic acid is 50:50.

[0069] Dispersion medium: The ratio of the mass of deionized water to the total mass of the monomer is 3:1; the amount of suspending agent PVA1788 is 0.5% of the mass of deionized water.

[0070] Aqueous phase polymerization inhibitor: hydroquinone, the dosage is 0.05% of the total mass of monomers.

[0071] Initiator: benzoyl peroxide (BPO), the dosage is 3% of the total mass of monomers.

[0072] Foaming agent: carbonamide, the dosage is 8% of the total mass of monomers.

[0073] Cross-linking agent: BMI, the dosage is 3% of the total mass of monomers.

[0074] The preparation method of above-mentioned acrylonitrile / methacrylic acid copolymer foamed plastics, it adopts following steps to carry out successively:

[0075] (1) Add deioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com