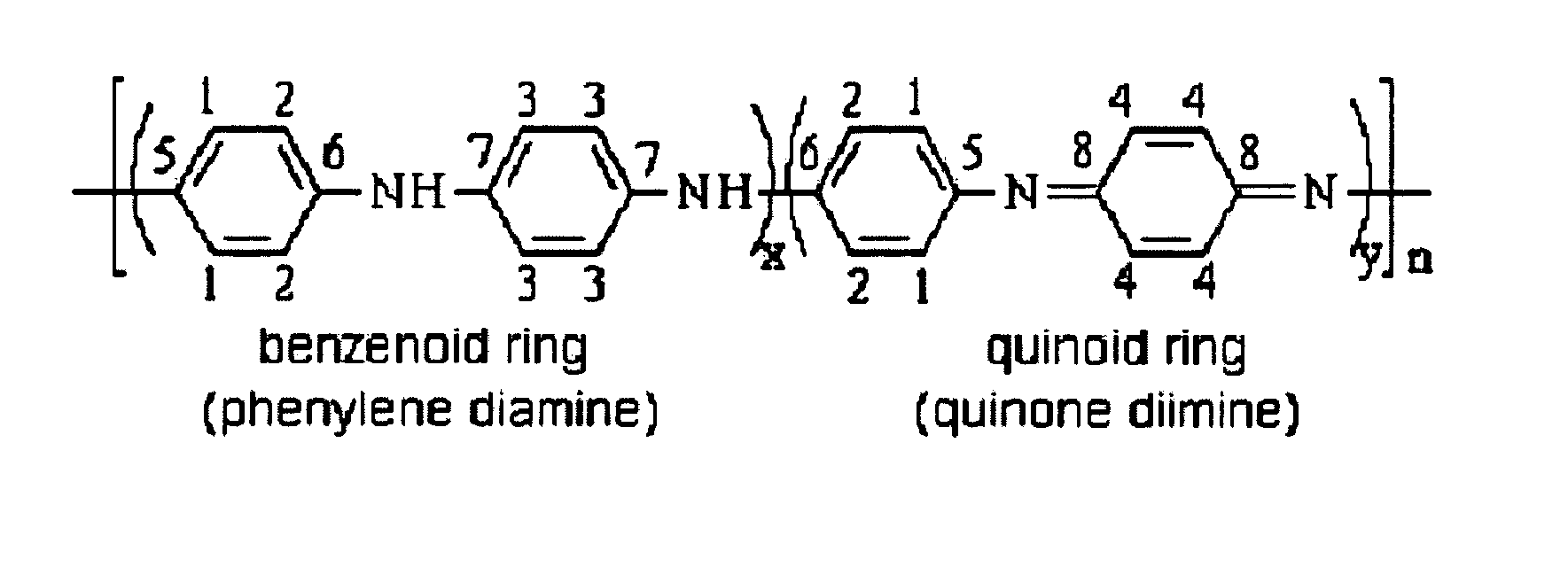

Conductive polymers having highly enhanced solubility in organic solvent and electrical conductivity and synthesizing process thereof

a technology of organic solvents and conductive polymers, which is applied in the direction of conductors, non-metal conductors, organic conductors, etc., can solve the problems of complex processing steps, composites have lower electrical conductivity, and cannot be made from melting, so as to achieve high linear configuration, improve electrical conductivity, and reduce the effect of side chains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

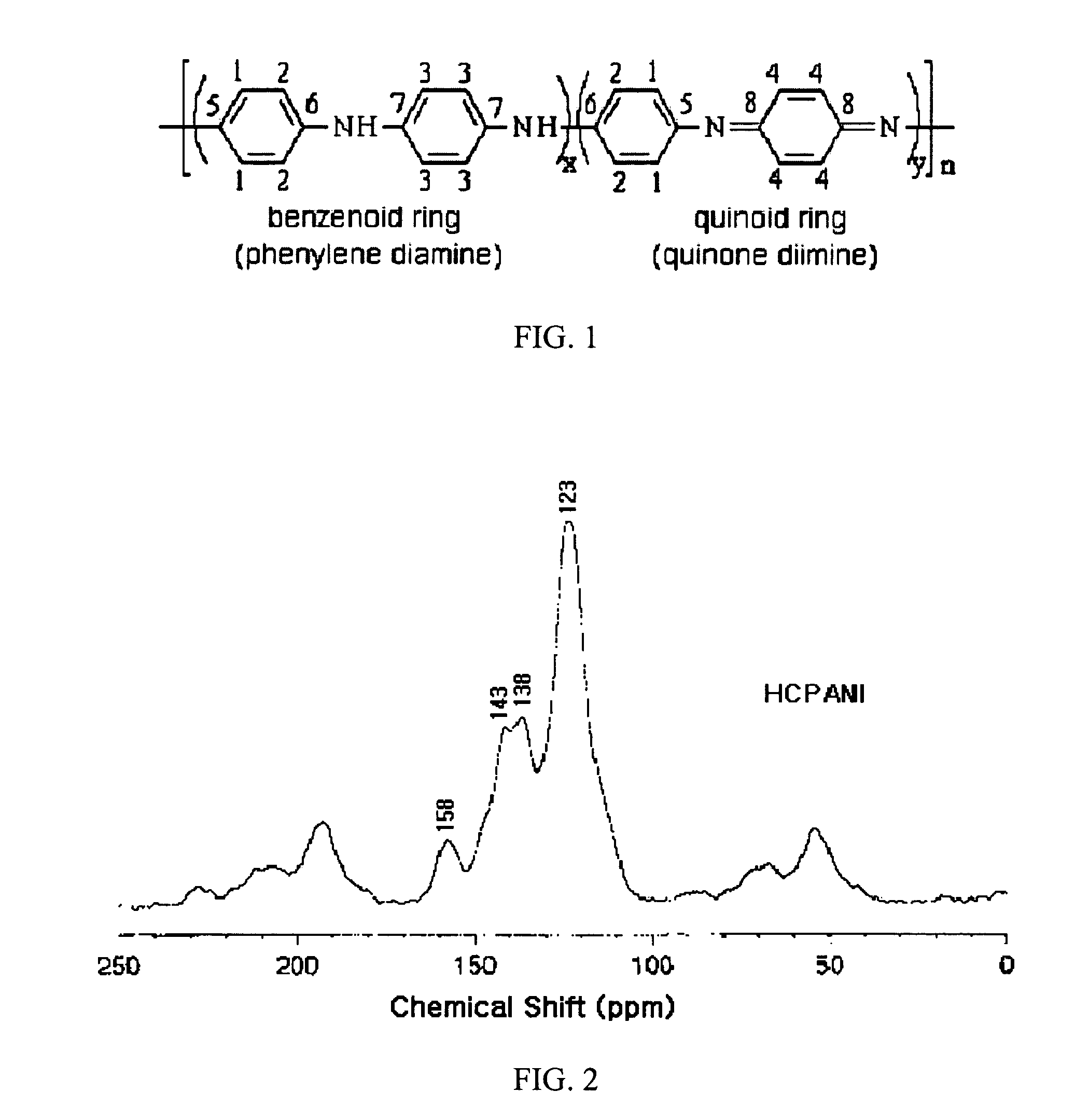

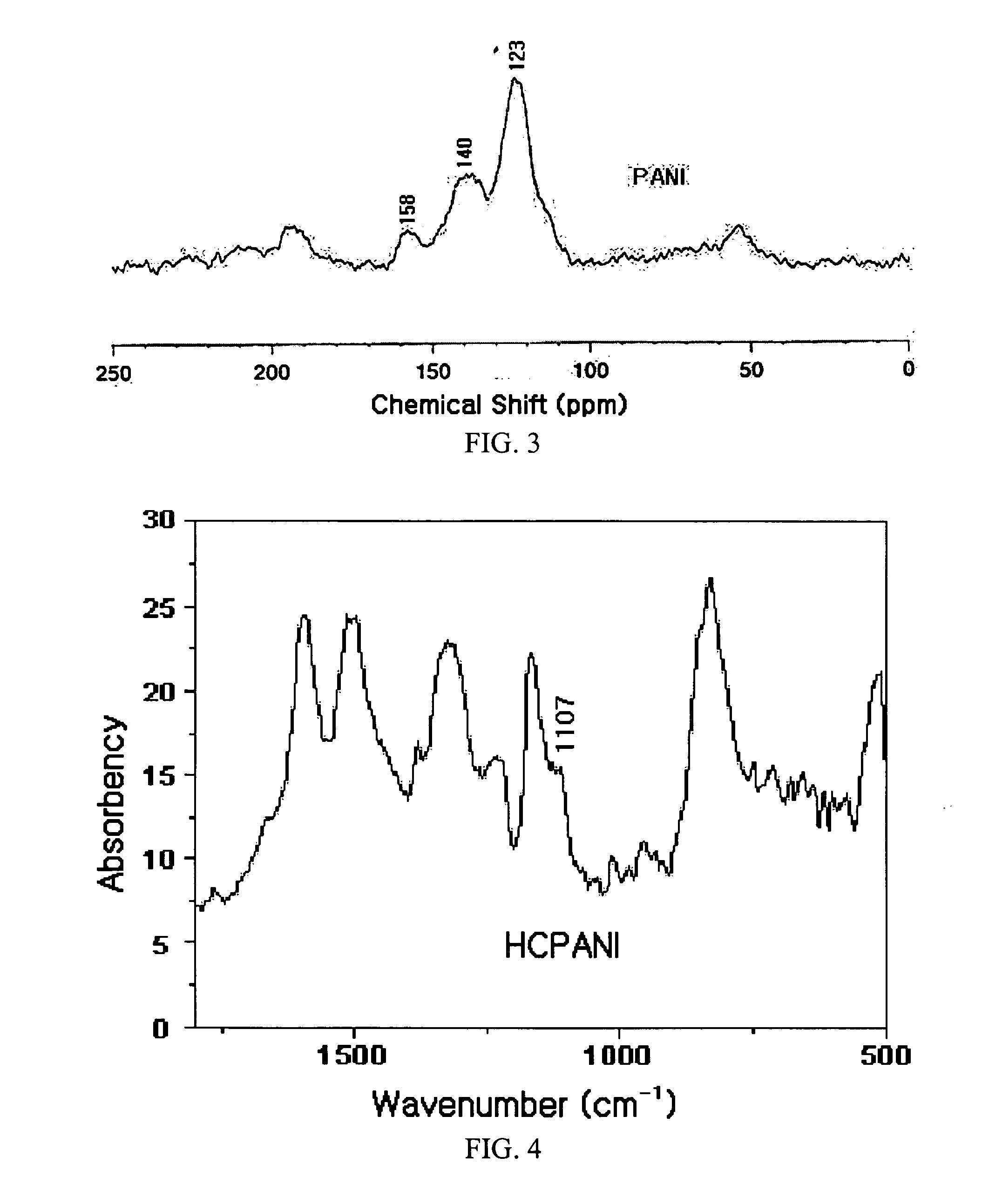

Preparation of Highly Conductive Polyaniline (HCPANI)

[0130] In this example, highly conductive polyaniline (HCPANI) as emeraldine base (EB) form was prepared. 100 mL of distilled and purified aniline was added slowly dropwise into 6 L of 1M HCl and then 4 L of isopropyl alcohol was mixed with the solution. The mixed solution was maintained in the temperature of −15° C. Solution of 56 g of ammonium persulfate ((NH4)2S2O8), as an radical initiator, dissolved in 2 L of 1M HCl was added slowly dropwise into the above mixed solution for 40 minutes with stirring to initiate polymerization reaction. After 3 hours, the polymerization reaction was completed to form precipitate. The obtained precipitate was filtered with filter paper and washed with 1 L of 1M ammonium hydroxide (NH4OH) solution. The precipitate was transferred into 5 L aqueous solution of 0.1M ammonium hydroxide, stirred for 20 hours, washed with water, and then dried with vacuum pump for 48 hours to yield 1.5 g of polyanili...

example 2

[0133] The procedures and conditions were repeated as example 1, except that polymerization reaction was performed at about −25° C. Polymerization reaction were performed for 4˜6 hours. It was certified that obtained material was polyaniline of emeraldine base form through infrared spectroscopy and NMR technology (results are not shown).

examples 3

[0134] The procedures and conditions were repeated as example 1, except that ammonium persulfate as a radical initiator was added drop wise for 3 hours. Polymerization reaction were performed for 3˜8 hours. It was certified that obtained material was polyaniline of emeraldine base form through infrared spectroscopy and NMR technology (results are not shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com