Preparation method and coating method of biodegradable temperature-responsive slowly-controlled release fertilizer coating material

A temperature-responsive, slow- and controlled-release fertilizer technology, which is applied in fertilizer mixtures, layered/coated fertilizers, applications, etc., can solve the problems of long maintenance time of slow control, high energy consumption and cost, and many chemical additives. Achieve the effects of reducing fertilizer release, improving production efficiency, and overcoming poor degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

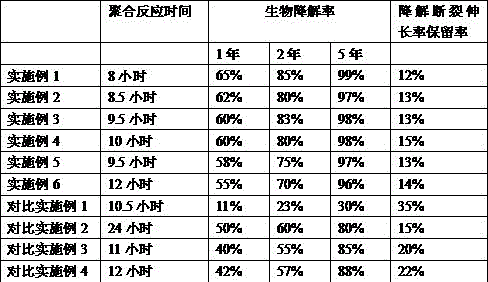

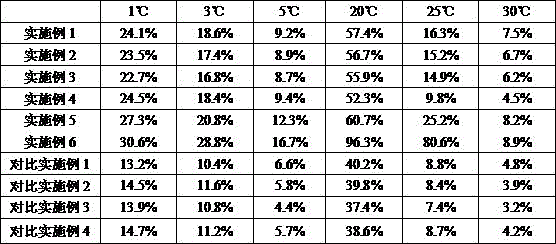

Examples

Embodiment 1

[0027] Example 1: 70 parts of crushed corn stalks, wheat stalks and sawdust (weight ratio 1:1:1) were placed in 165 parts of a buffer solution with a pH value of 8.5 for 10 minutes to disperse fully, and 9 parts of dopamine hydrochloride were added. Activation treatment at 35°C, during the activation process, air was introduced and stirred continuously, the activation time was 3 hours, filtered and washed, and vacuum-dried to obtain 41 parts of dopamine pretreated powder; in acetic acid / sodium acetate buffer solution Prepare 100 parts of enzyme solution with pH 5.5, laccase concentration of 103U / ml and vanillin concentration of 7.5mmol / L; place 41 parts of the obtained dopamine pretreated powder and 100 parts of the obtained enzyme solution in the reaction vessel Mix evenly in 50°C for secondary activation treatment. During the activation process, air is introduced and stirred continuously. The activation time is 1.5 hours, and 32 parts of secondary activated powder are obtaine...

Embodiment 2

[0028] Example 2: Put 75 parts of crushed corn stalks, wheat stalks and sawdust (weight ratio 1:1:1) into 180 parts of a buffer solution with a pH value of 10 for 15 minutes to disperse fully, add 10 parts of dopamine hydrochloride, Activation treatment at 40°C, during the activation process, air was introduced and stirred continuously, the activation time was 4 hours, filtered and washed, and vacuum-dried to obtain 45 parts of dopamine pretreated powder; in acetic acid / sodium acetate buffer solution Prepare 120 parts of enzyme solution with a pH of 6, laccase concentration of 145 U / ml and vanillin concentration of 9 mmol / L; place 45 parts of the obtained dopamine pretreated powder and 120 parts of the obtained enzyme solution in a reaction vessel Mix evenly, and perform secondary activation treatment at 60°C. During the activation process, air is introduced and stirred continuously. The activation time is 3 hours, and 40 parts of the secondary activated powder are obtained; th...

Embodiment 3

[0029]Example 3: Put 65 parts of crushed corn stalks, wheat straws and sawdust (weight ratio 1:1:1) into 150 parts of a buffer solution with a pH value of 8 for 5 minutes to disperse fully, add 8 parts of dopamine hydrochloride, Activation treatment at 30°C, during the activation process, air was introduced and stirred continuously, the activation time was 2 hours, filtered and washed, and vacuum-dried to obtain 35 parts of dopamine pretreated powder; in acetic acid / sodium acetate buffer solution Prepare 80 parts of enzyme solution with pH 4, laccase concentration of 60 U / ml and vanillin concentration of 2.5 mmol / L; place 35 parts of the obtained dopamine pretreated powder and 80 parts of the obtained enzyme solution in the reaction vessel Mix evenly in the medium, and perform secondary activation treatment at 40°C. During the activation process, air is introduced and stirred continuously. The activation time is 0.5 hours, and 25 parts of the secondary activated powder are obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com