Preparation method for preparing type 26 fluororubber from fluoroether sulfonate

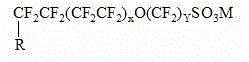

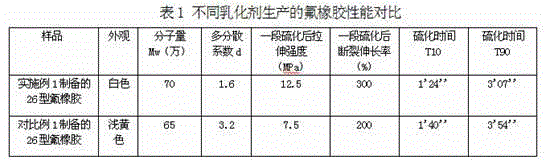

A technology of fluoroethersulfonate and fluororubber, which is applied in the field of preparation of 26-type fluororubber by using fluoroethersulfonate, which can solve the problems of poor strength of fluororubber, difficult degradation of perfluorooctanoic acid, uneven vulcanization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 6kg of deionized water into the 10L polymerization reactor, and then replace the oxygen in the reactor with nitrogen to make the oxygen content in the reactor lower than 10ppm, then add 20g of fluoroether sulfonate, 10g of disodium hydrogen phosphate, and 0.5kg of six Fluoropropene, 2kg vinylidene fluoride, turn on the stirring paddle at a speed of 250r / min, heat up to 90°C, pour 10g of potassium persulfate into the reaction kettle with a metering pump to initiate the polymerization reaction, and continuously add mass to the reaction kettle through the middle tank Hexafluoropropylene / vinylidene fluoride mixed gas with a ratio of 5 / 12, maintain the reaction pressure at 4MPa, add 10g of diethyl malonate to the reaction kettle after 30 minutes, complete the polymerization reaction after 2.5 hours, and recover unreacted mixed monomers , the emulsion in the reactor is transported to the emulsion tank through the pressure control valve, 6g of calcium chloride powder is add...

Embodiment 2

[0029] Add 5.5kg of deionized water to a 10L polymerization reactor, then add 3.5g of fluoroether sulfonate, 3.5g of disodium hydrogen phosphate, 0.7kg of hexafluoropropylene, 2.5kg of vinylidene fluoride, and turn on the stirring paddle at a speed of 350r / min, heat up to 50°C, pour 3.2g of potassium persulfate into the reaction kettle with a metering pump to initiate the polymerization reaction, and continuously add hexafluoropropylene / vinylidene fluoride mixture with a mass ratio of 7 / 25 to the reaction kettle through the middle tank gas, maintain the reaction pressure to be 3MPa, add diethyl malonate 5g in the reactor after 10min, finish the polymerization reaction after 1 hour, reclaim a small amount of unreacted mixed monomer, and the emulsion in the reactor is delivered to In the emulsion tank, add 10g of calcium chloride powder for coagulation, and then the solid matter enters the washing tank for washing. After washing, the block-shaped finished product is placed in a ...

Embodiment 3

[0031]Add 6kg of deionized water to a 10L polymerization reactor, add 42.5g of fluoroether sulfonate, 8.5g of disodium hydrogen phosphate, 0.7kg of hexafluoropropylene, and 1kg of vinylidene fluoride to ensure that the oxygen content in the kettle is lower than 10ppm, and then open Stirring paddle, the rotating speed is 700r / min, the temperature is raised to 120°C, inject 34g of potassium persulfate into the reaction kettle with a metering pump to initiate the polymerization reaction, and continuously add hexafluoropropylene with a mass ratio of 7 / 10 to the reaction kettle through the middle tank / vinylidene fluoride mixed gas, maintain the reaction pressure at 7MPa, add 39g of diethyl malonate to the reactor after 20min, end the polymerization reaction after 2.5 hours, recover a small amount of unreacted mixed monomer, and turn the reactor to The emulsion in the emulsion is transported to the emulsion tank, and 9.4g of calcium chloride powder is added for coagulation, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com