Patents

Literature

202results about How to "High Molecular Weight Distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

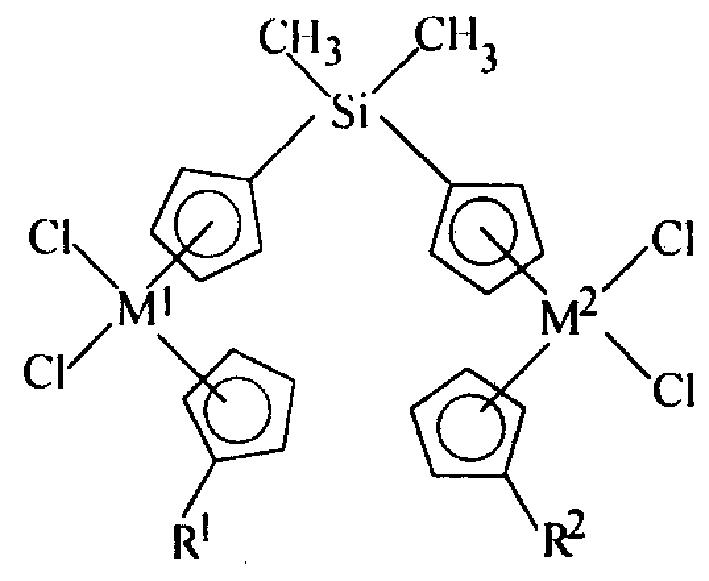

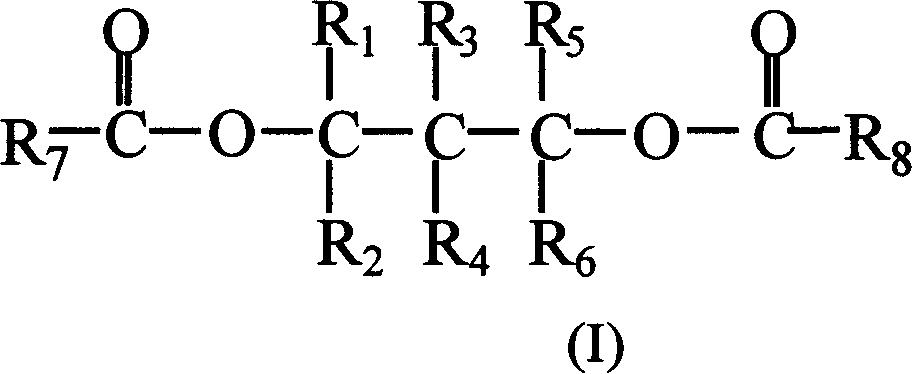

Carbon and/or silicon bridged binuclear metallocene catalyst for styrene polymerization

InactiveUS6010974AHigh catalytic activityHigh Molecular Weight DistributionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationArylSilylene

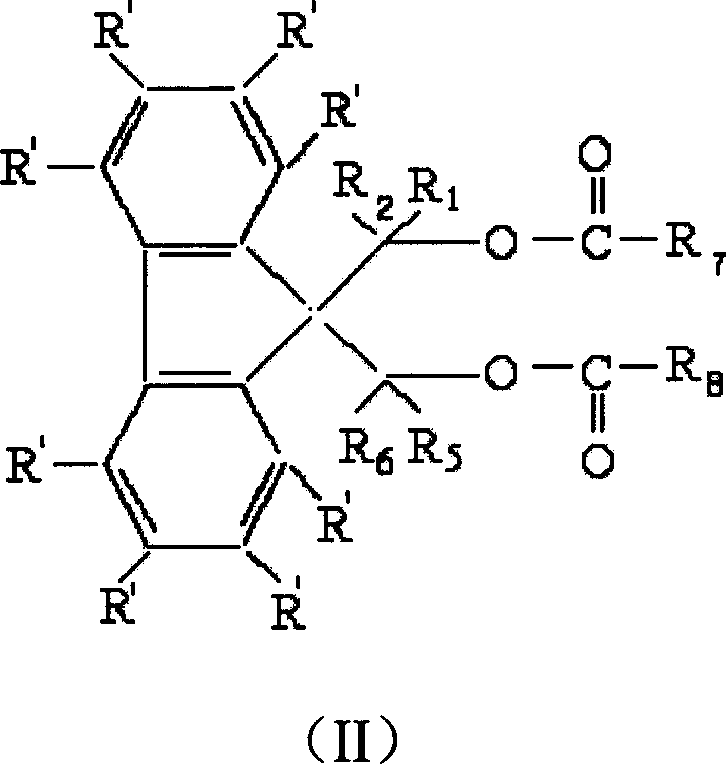

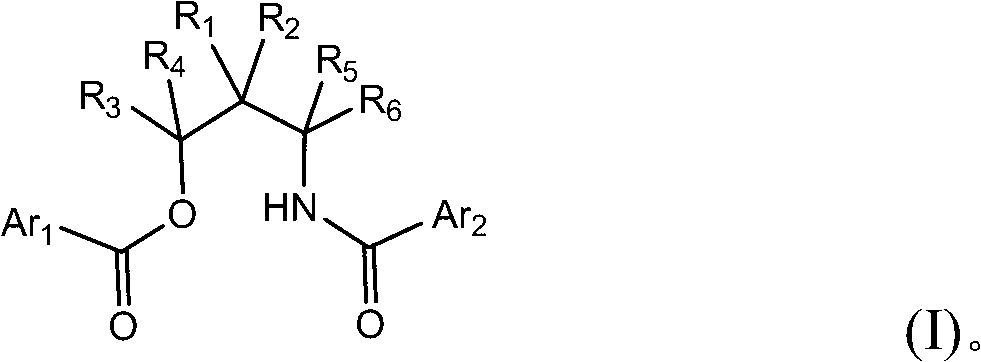

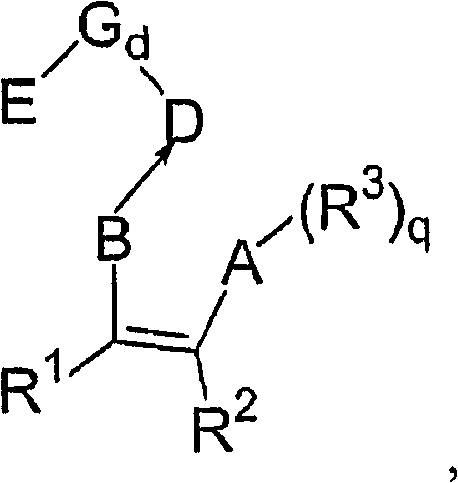

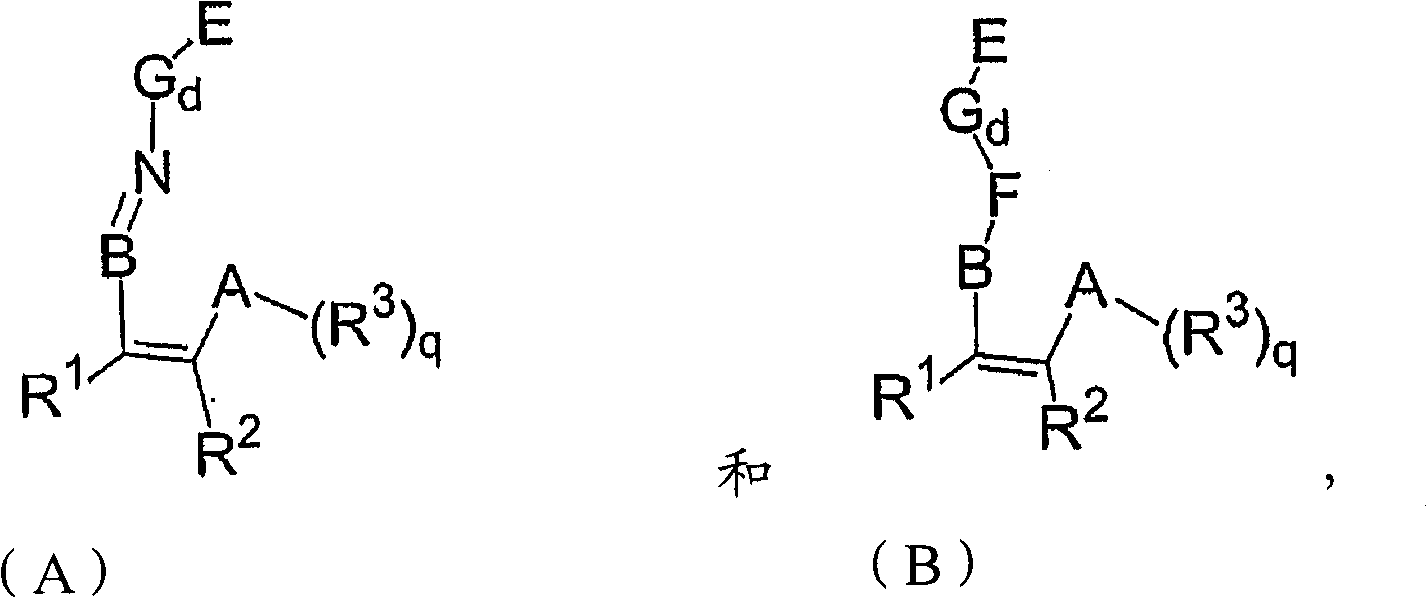

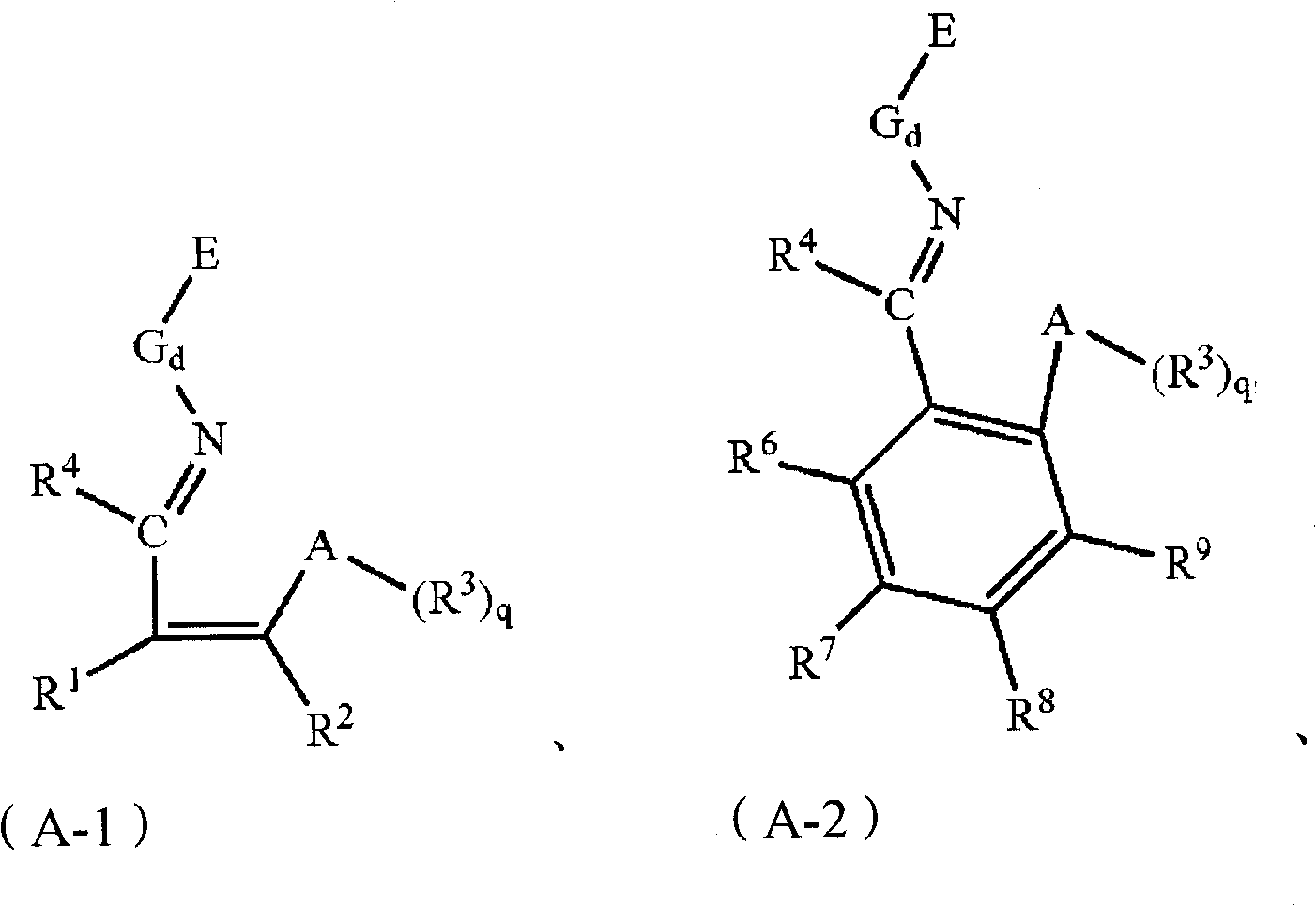

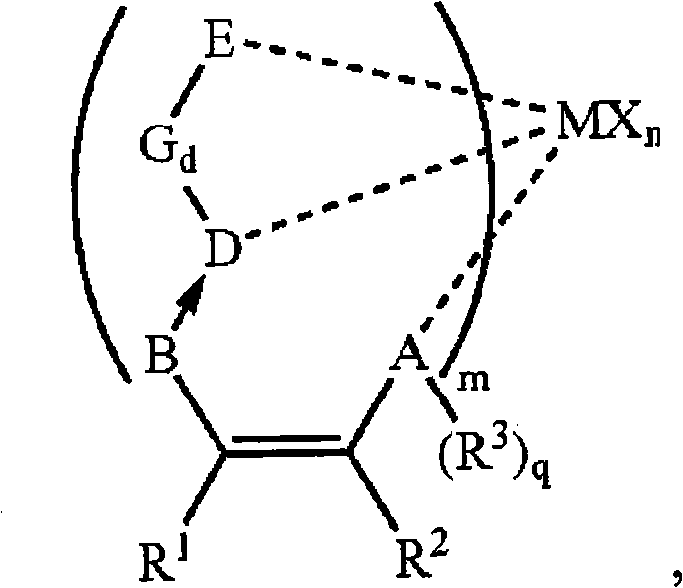

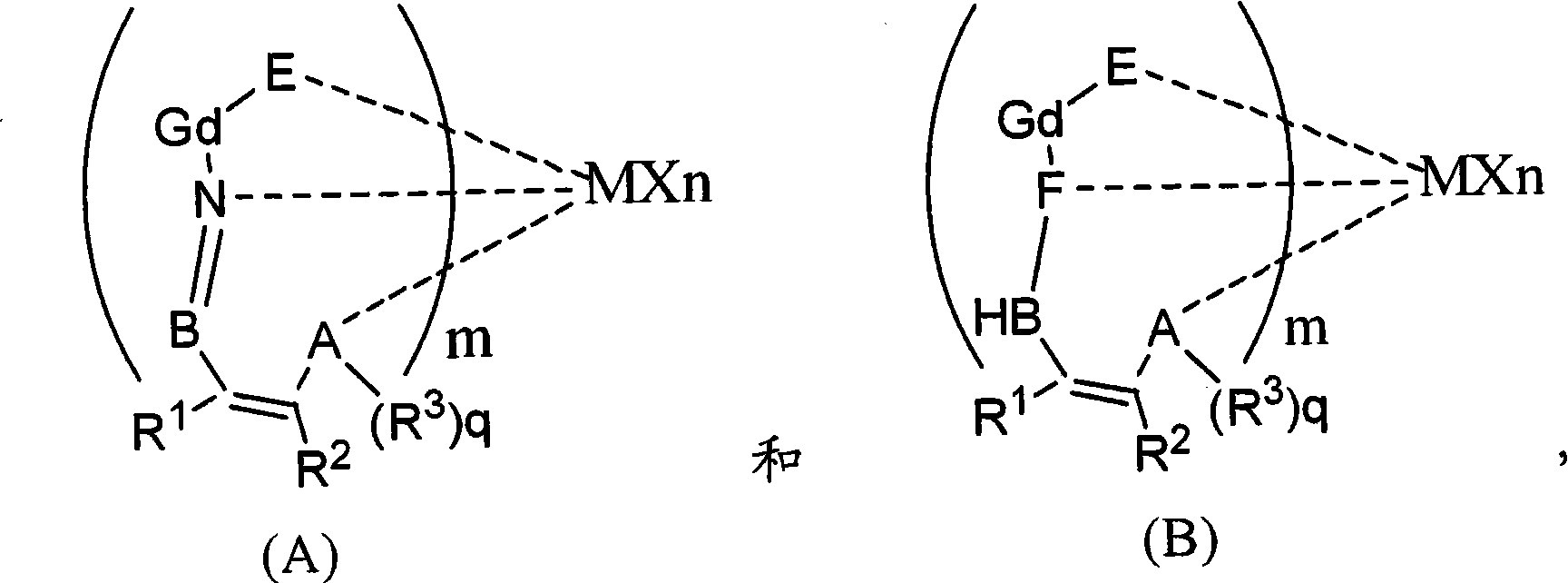

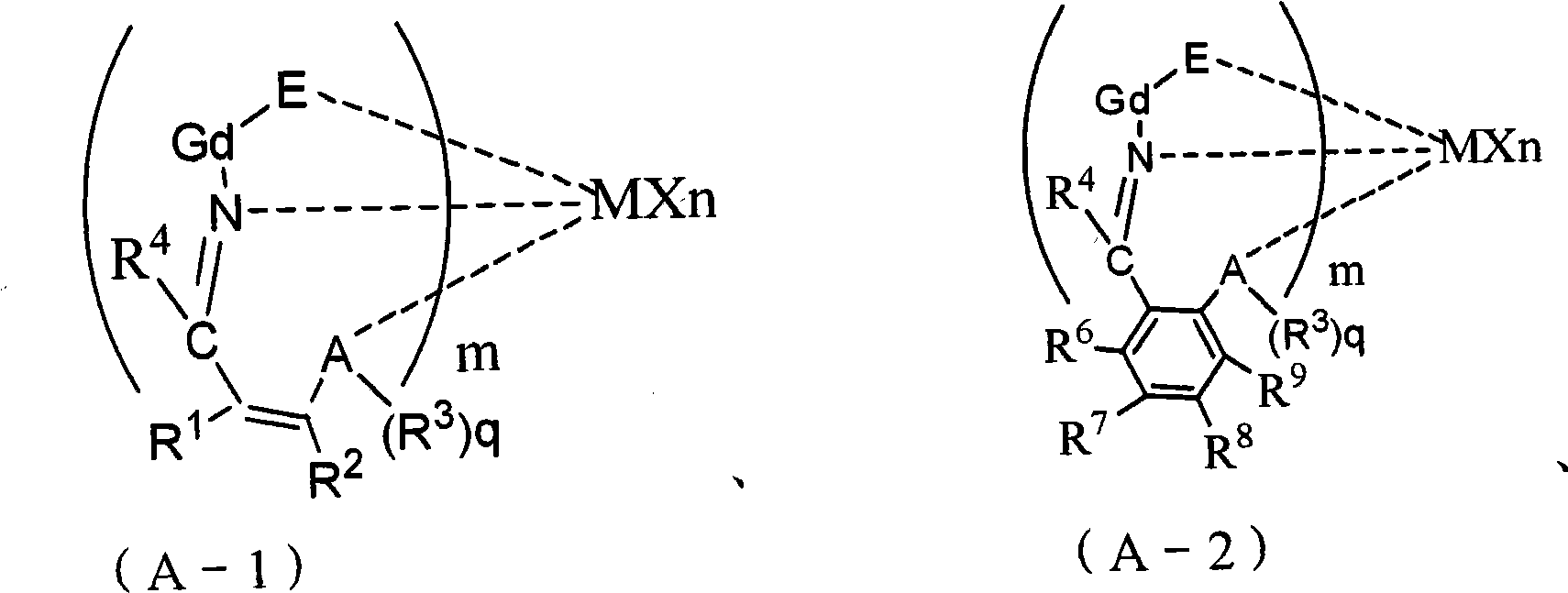

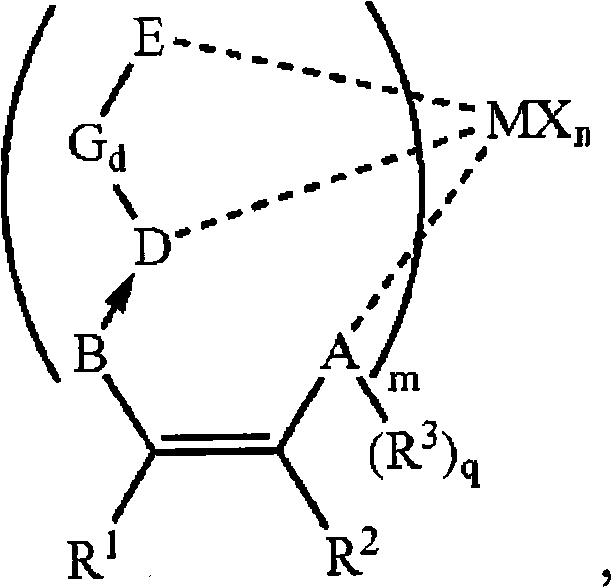

An alkylene and / or silylene bridged binuclear metallocene catalyst for styrene polymerization is represented by the following formula (I): where M1 and M2 are the same or different transition metal of Group IVb of the Periodic Table; Cp1 and Cp2 are the same or different cyclopentadienyl; alkyl, alkoxy, silyl or halogen substituted cyclopentadienyl; indenyl; alkyl, alkoxy, silyl or halogen substituted indenyl; fluorenyl; or alkyl, alkoxy, silyl or halogen substituted fluorenyl, which is capable of pi -electron, eta 5-bonding with M1 or M2; each of E1, E2 and E3, independently of one another, is a carbon atom or a silicon atom; m, p and q are integers of 0 to 15 and m+p+q> / =1; each of R1, R2, R3, R4, R5 and R6, independently of one another, is a hydrogen, an alkyl, an aryl, an alkoxy or a halogen; X is a hydrogen, an alkyl, an alkoxy or a halogen; and n is 3. M1 and M2 may also be in cardin form by mixture of (I) with a compound which abstructs an X gray from each metal atom and substitution then with non-coordinating anions.

Owner:CHEIL IND INC

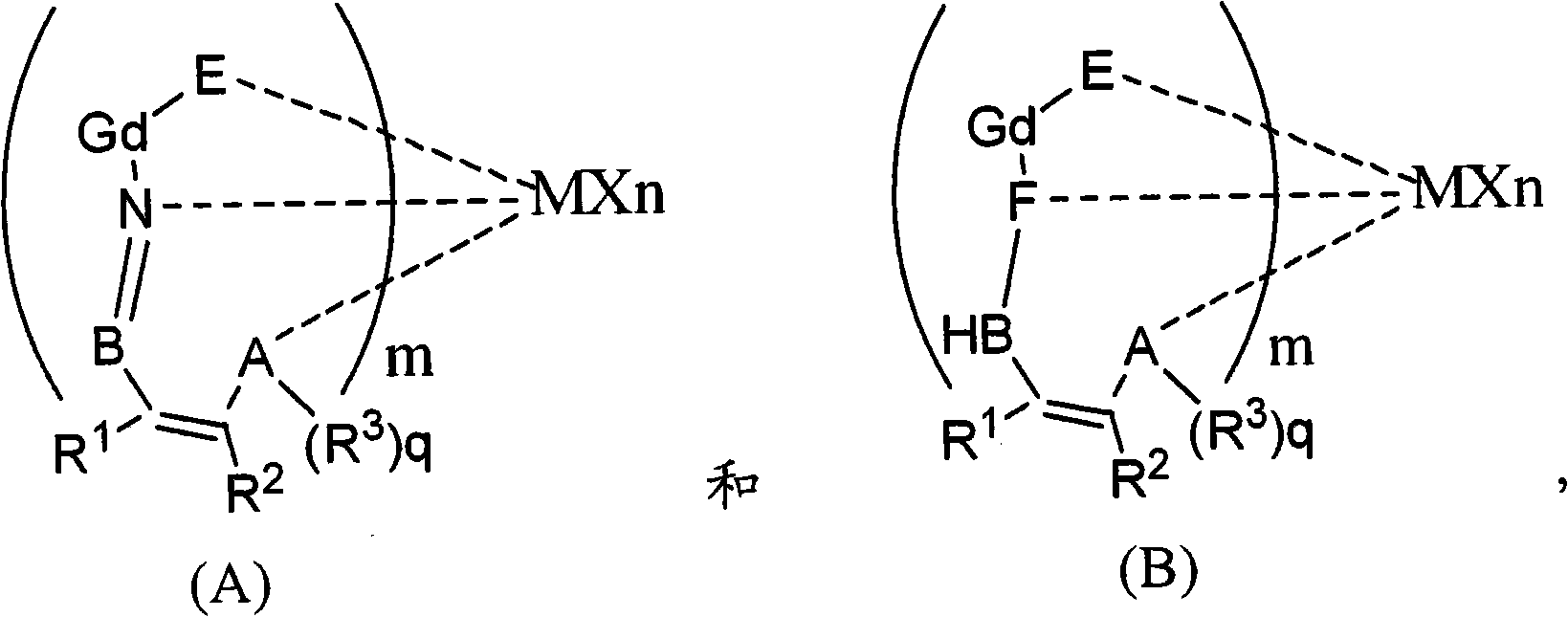

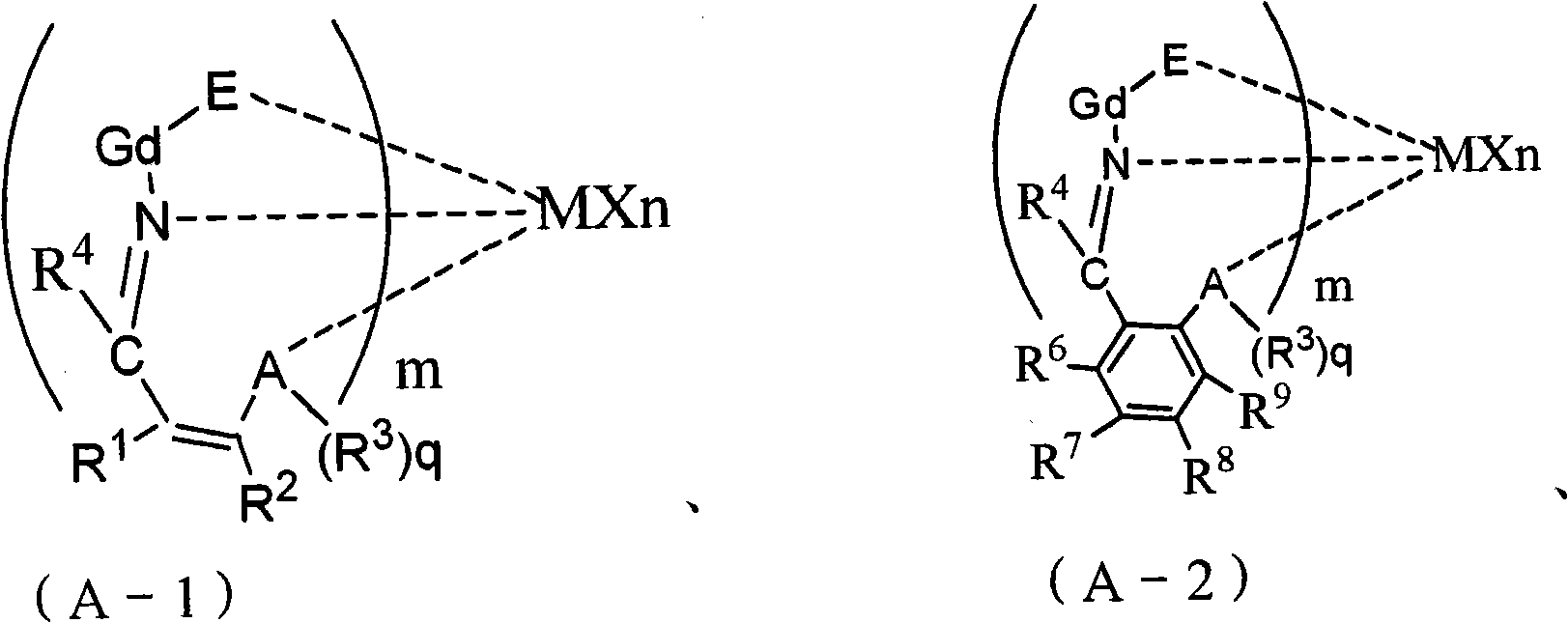

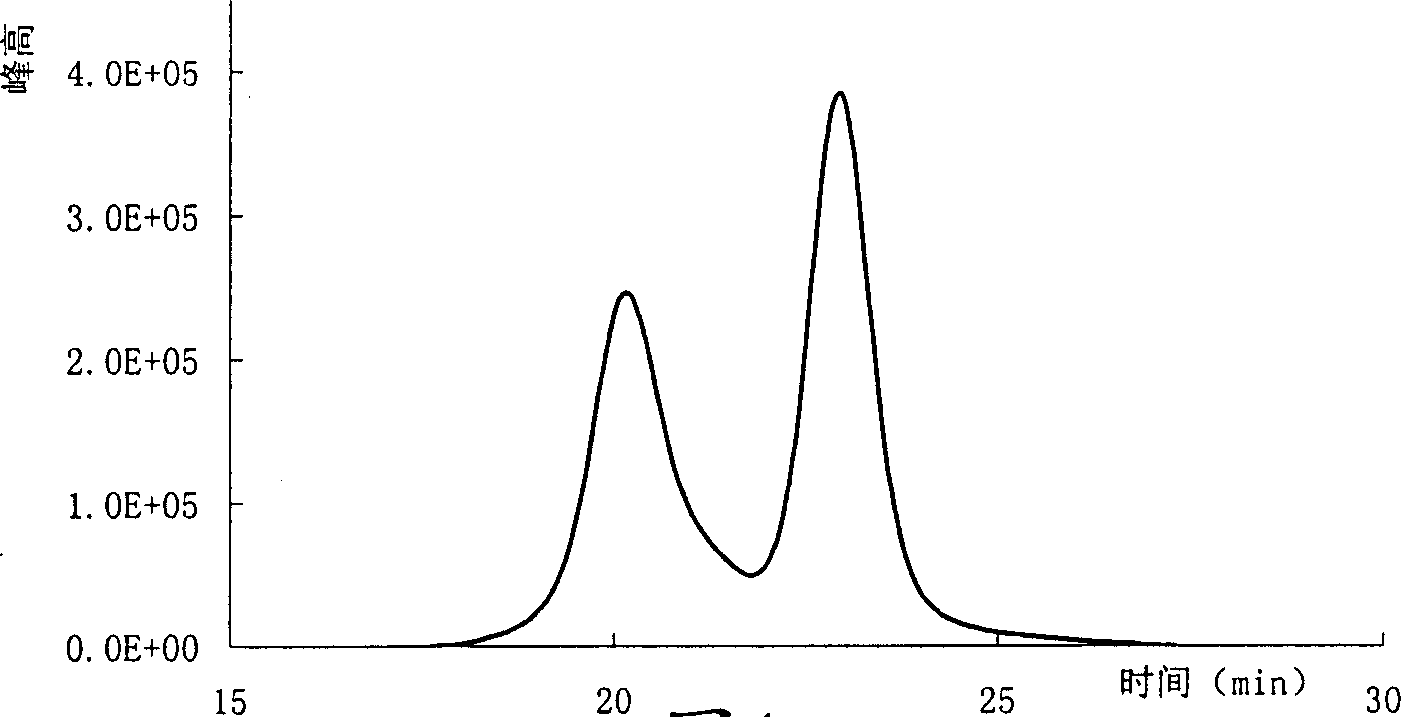

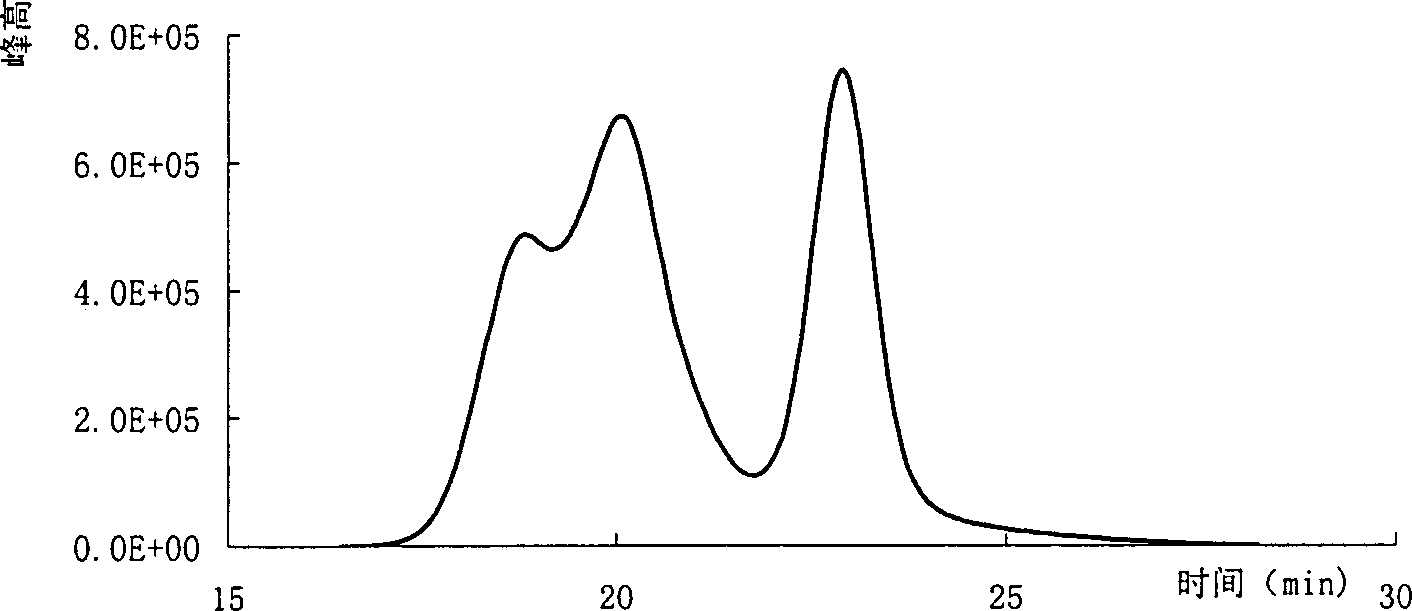

Binuclear metallocene compound and its preparation and application in olefinic polymerization

The present invention relates to a binuclear metallocene compound, its preparation method and its application in olefinic polymerization. Said invention provides its structure expression formula, said compound can be matched with cocatalyst alkyl aluminoxane, and used for olefinic polymerization. It possesses high polymerization reaction activity, and can obtain olefinic polymerization product with high molecular weight and wide molecular weight distribution.

Owner:CHINA PETROLEUM & CHEM CORP +3

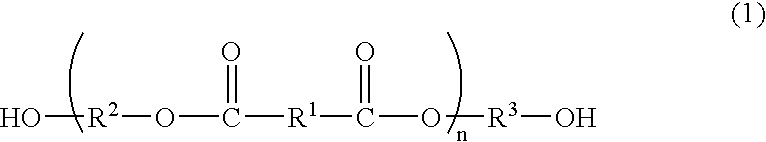

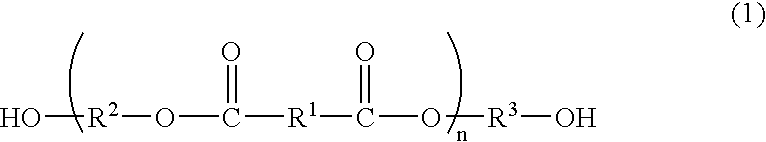

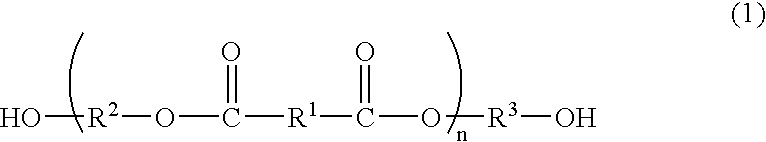

Process for producing polyester resins

In the invention, a polyester resin having dicarboxylic acid constitutional units and diol constitutional units wherein 5 to 60 mol % of the diol constitutional units has a cyclic acetal skeleton is produced by a process including an oligomerization step and a polymerization step. In the oligomerization step, an ester having a limited acid value is transesterified with a diol having a cyclic acetal skeleton in the presence of a titanium compound to obtain an oligomer. The oligomer is then polymerized in the subsequent polymerization step to increase the molecular weight.

Owner:MITSUBISHI GAS CHEM CO INC

Process for producing polyester resins

Owner:MITSUBISHI GAS CHEM CO INC

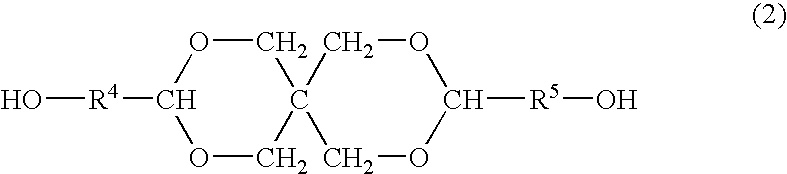

Catalyst compsns. for olefin polymerization and catalyst thereof

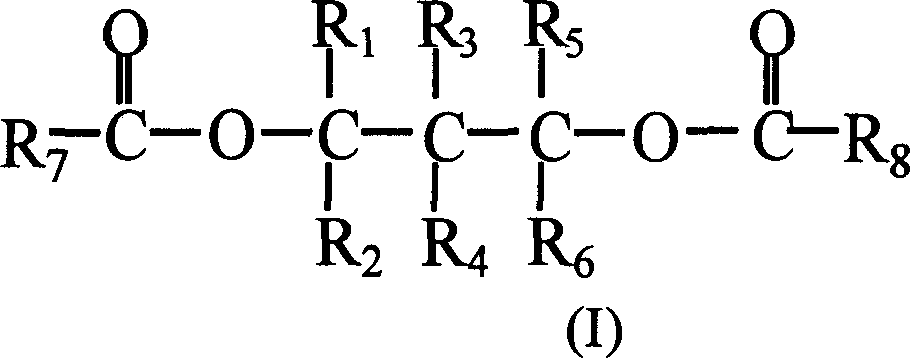

This invention relates to a catalyst component for alkene polymerization and its catalyst, and magnesium chloride-silica gel composite gel is adopted for this component. By introducing diol ester compounds which have a common formula (I) in the preparation of the catalyst component, the catalytic activity can be promoted. When the catalyst component in this invention is used in propylene polymerization, the obtained polymer has higher apparent density, narrower particle size distribution, high isotacticity, wide molecular weight distribution and outstanding comprehensive properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Separating method for isocyanate monomer of urethane curing agent

A method for separating isocyanic ester from polyurethane-curing agent includes; adding acid 0.01 - 0.5% as reaction inhibitor, adding distillation agent 8 -60%, carrying out three-stage separation in an internally or externally cooling membrane distiller, pumping remains separated after second or third stage to pass them into a diluting container with solvent in, heating solvent up to 80 - 140deg.C, and stirring solvent with solid remains 35 - 85% to obtain curing agent with high solid content, low isocyanic ester content, and low viscosity.

Owner:SOUTH CHINA UNIV OF TECH

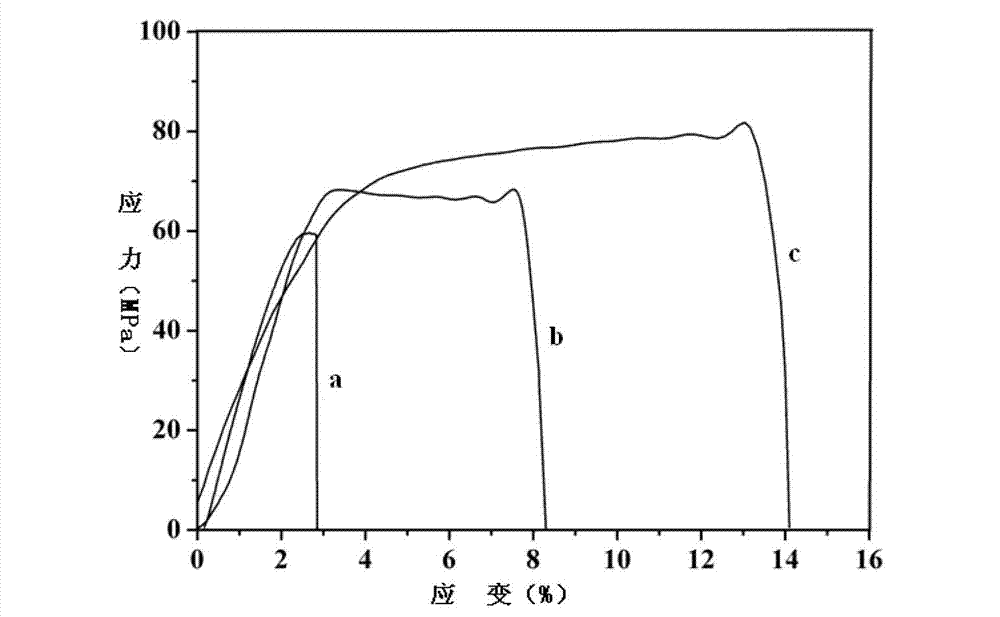

Cycloolefin copolymer and preparation method thereof

The invention discloses a cycloolefin copolymer with a structure shown in the formula (I), wherein m and n are polymerization degrees, m:n>=1.5, and R1 and R2 are independently selected from hydrogen or C1-C10 saturated aliphatic hydrocarbon. According to the invention, a cycloolefin monomer with a structure shown in the formula (II) and alpha-alkene are adopted as polymerization monomers; the copolymerization monomers are subjected to a polymerization reaction under the existence of a catalyst and in an inert solvent, such that the cycloolefin copolymer with the structure shown in the formula (I) is obtained. According to the invention, the cycloolefin monomer with the structure shown in the formula (II) is large-volume cycloolefin. Because of a stereospecific blockade effect, under the condition of a low insertion rate, the cycloolefin copolymer with high glass transition temperature and with the structure of the formula (I) is obtained. The flexible alpha-alkene units in the copolymer are increased, such that the rigidity of the cycloolefin copolymer chains is reduced, the entanglement among the chains is enhanced, such that the anti-tearing performance of the cycloolefin copolymer is improved, and the brittleness of the copolymer is ameliorated.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

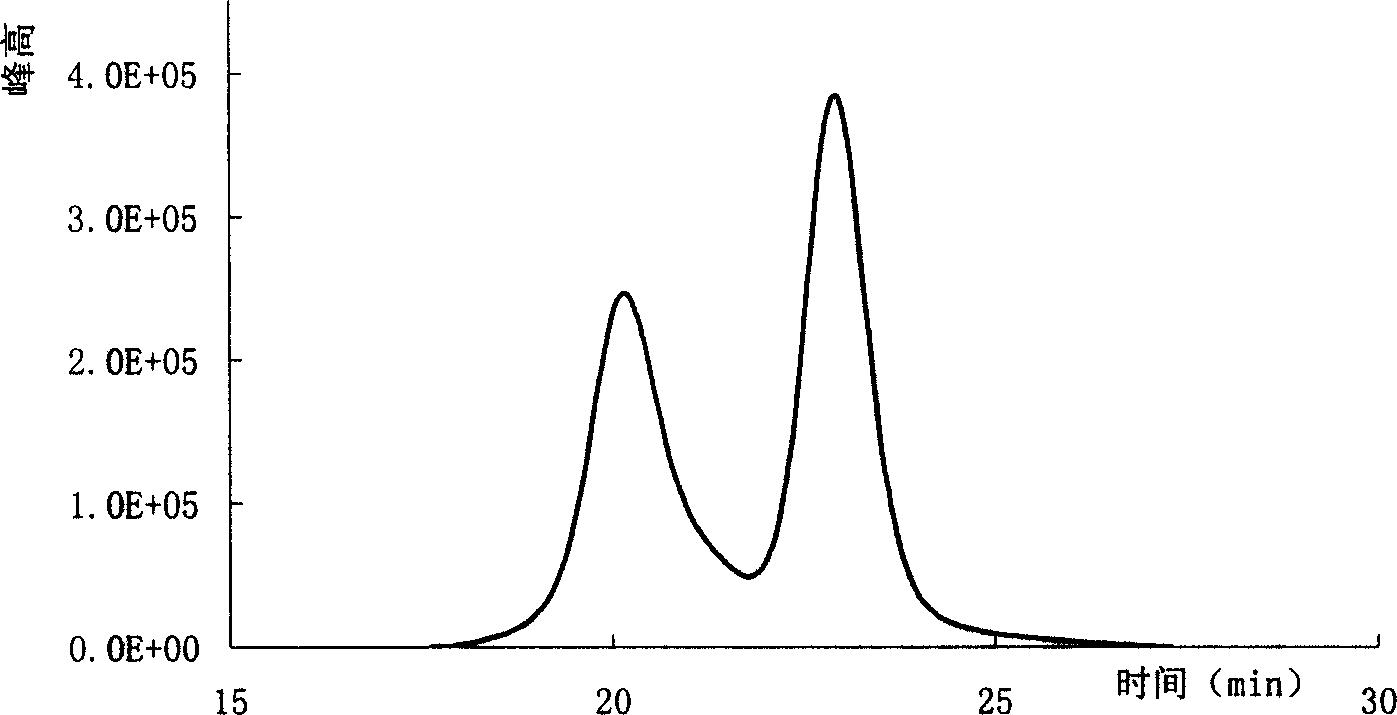

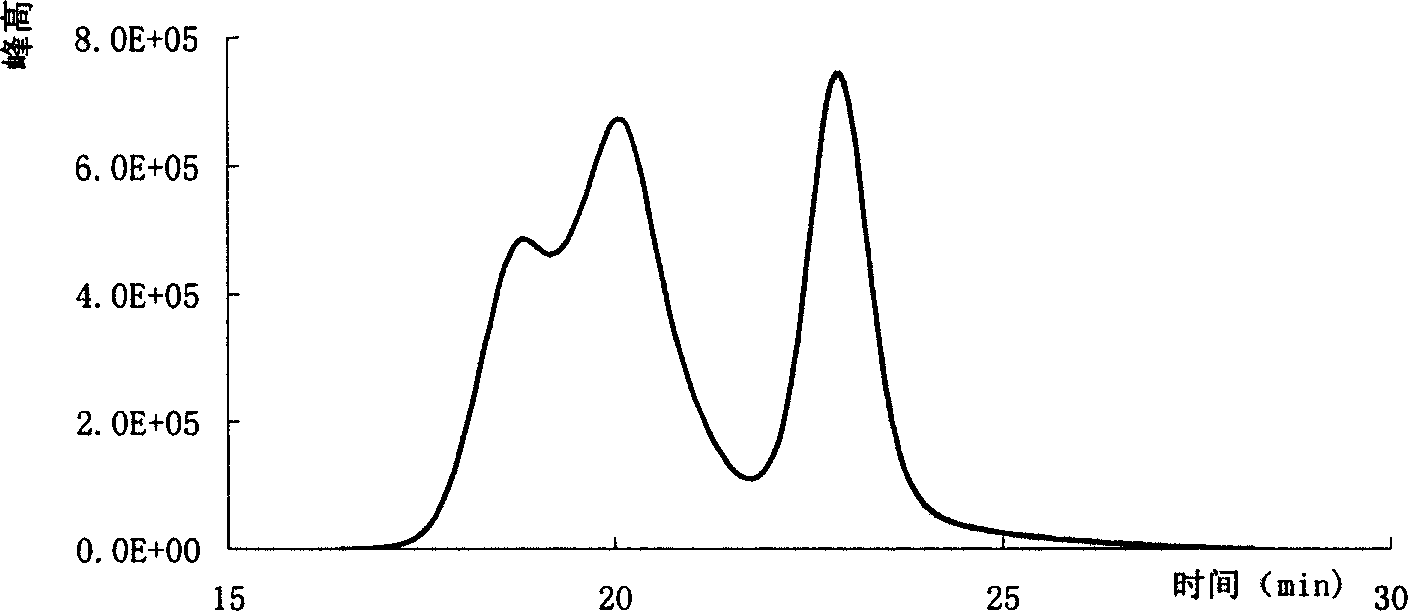

Method for preparing low cis-polybutadiene by stepwise excitation

ActiveCN1640898AReduce the amount of initiator and coupling agentHigh Molecular Weight DistributionHydrocarbon solventsLithium

The 1, 3-butadiene polymerizing process includes two-step initiated polymerization inside intermittent polymerizing system of saturated hydrocarbon solvent containing polar regulator and with alkyl lithium as initiator to produce homopolymer with different molecular weights and certain molecular weight distribution; and subsequent coupling with four functionality degree Lewis acid as coupling agent to prepare low cis-polybutadiene with wide molecular weight distribution. The present invention has the obvious features of widened molecular weight distribution of 1.6-1.8, reduced initiator and coupling agent consumption, improved 5 % styrene liquid chroma of rubber. The present invention is used in modification of polystyrene resin and can improve the degree of luster of anti-shock polystyrene.

Owner:中国石油化工股份有限公司北京燕山分公司研究院

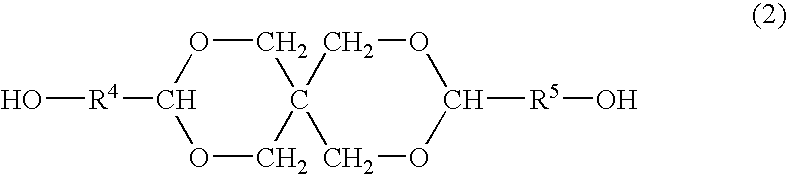

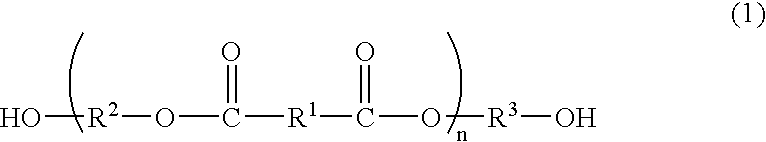

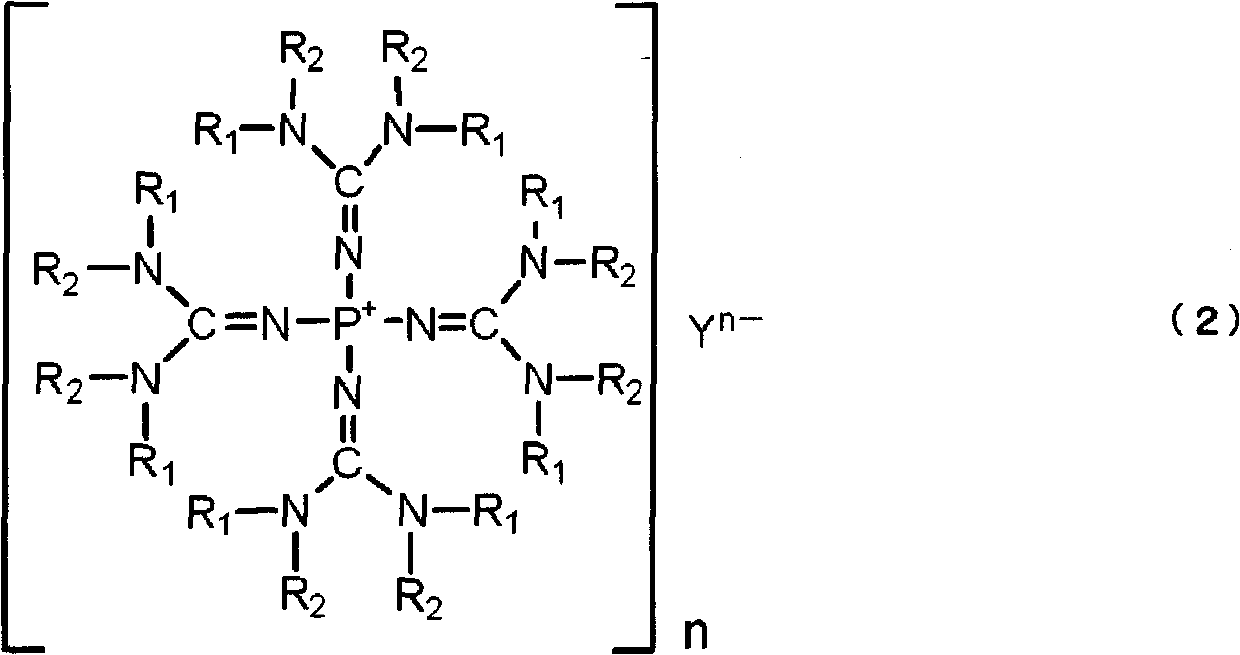

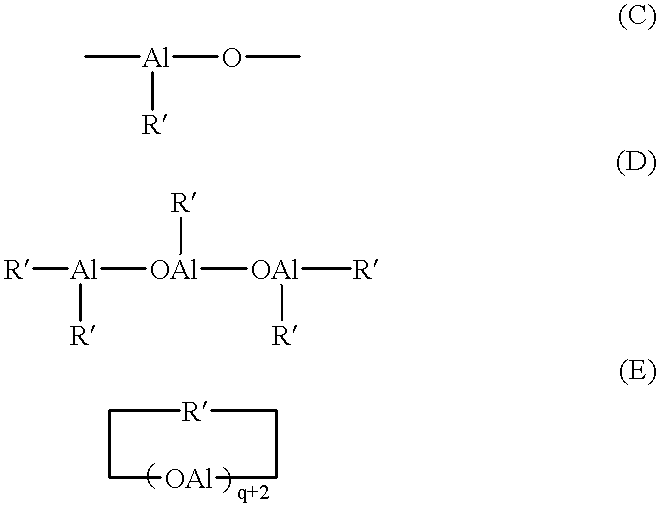

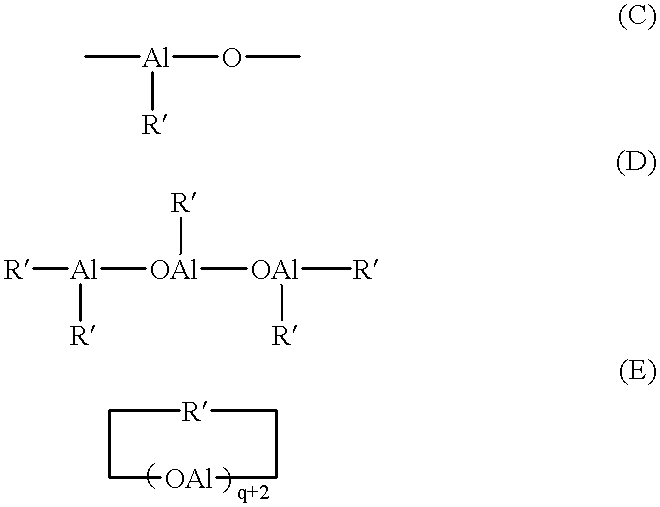

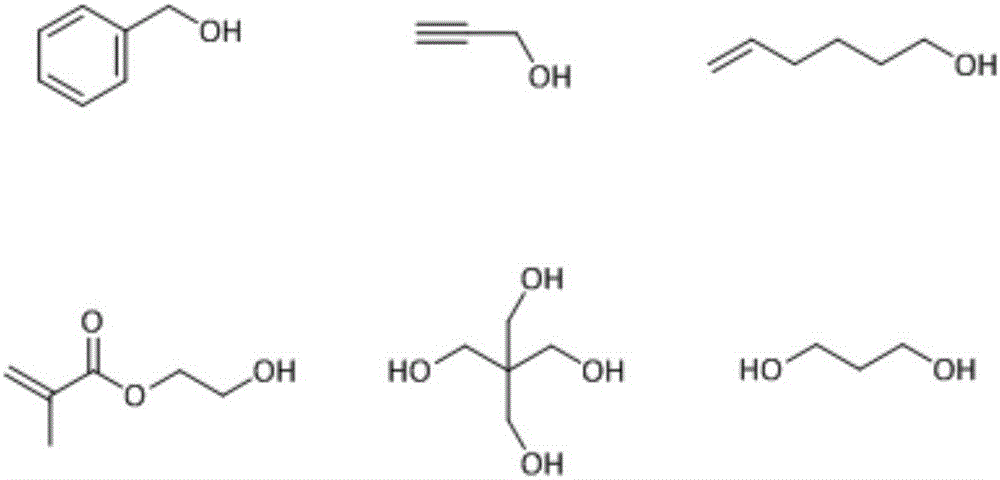

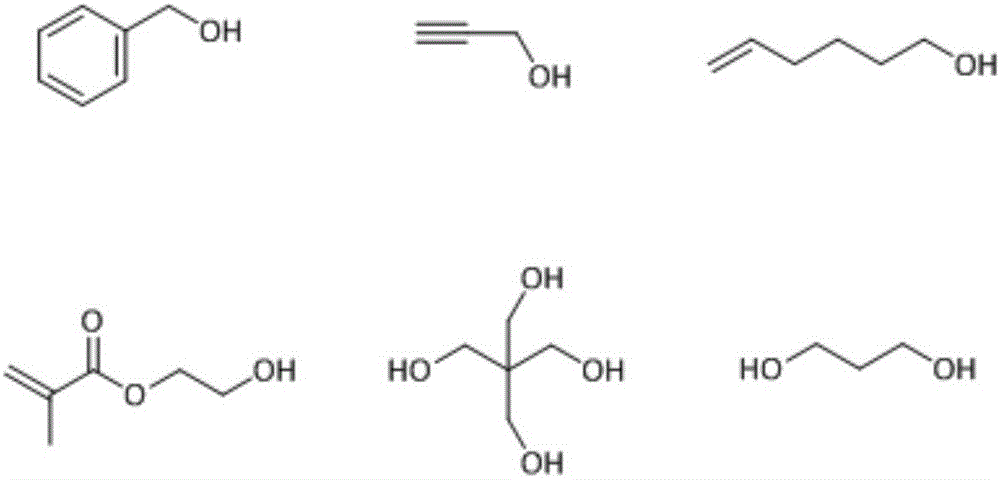

Polyalkylene glycol producing catalyst, and method for producing polyalkylene glycol using same

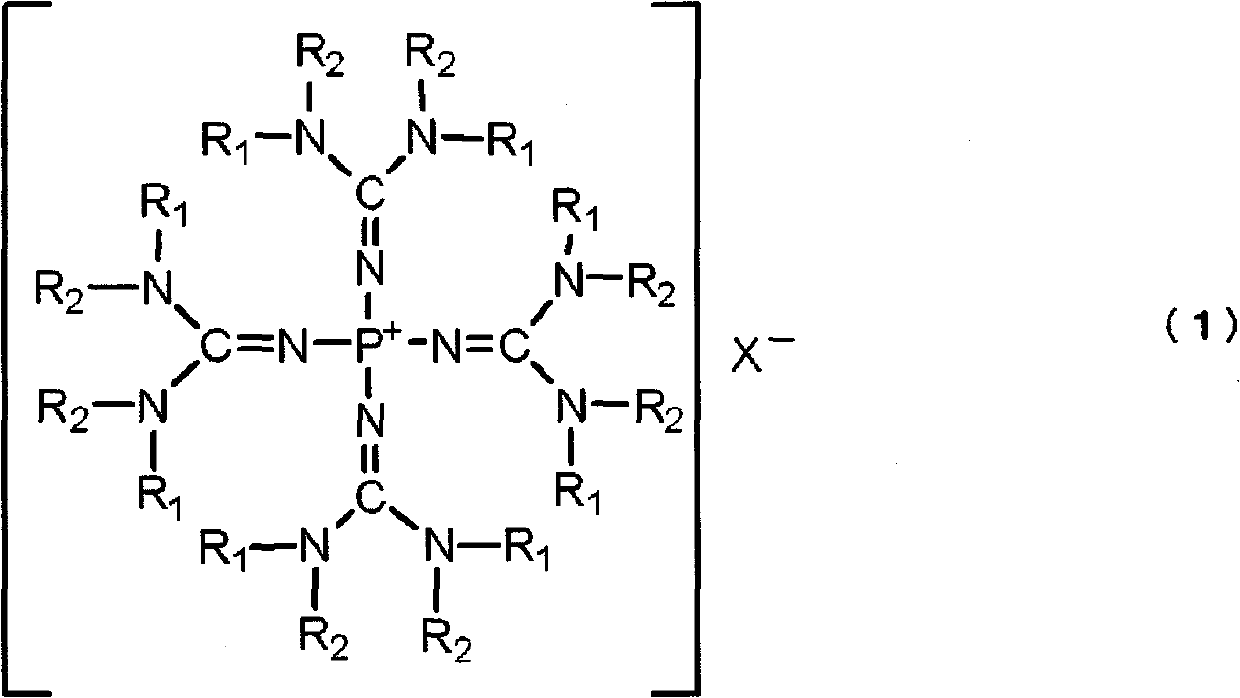

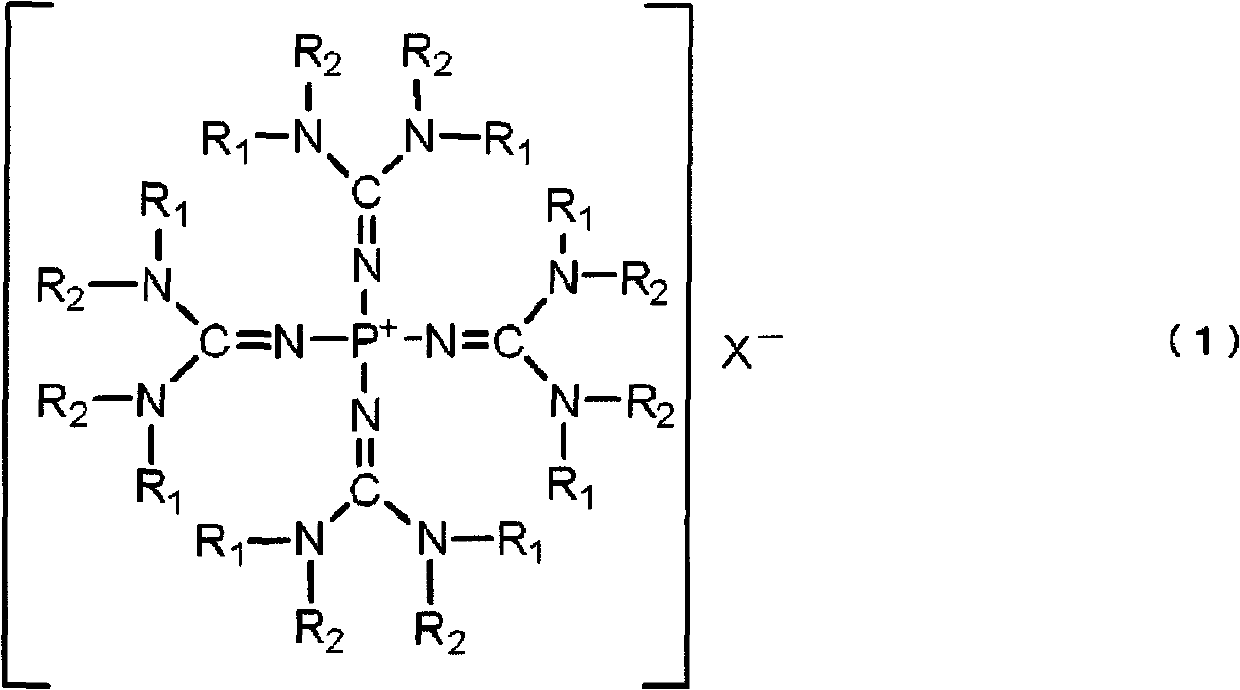

ActiveCN102171272AEasy temperature controlEasy to manufactureGroup 5/15 element organic compoundsProtonPhenyl group

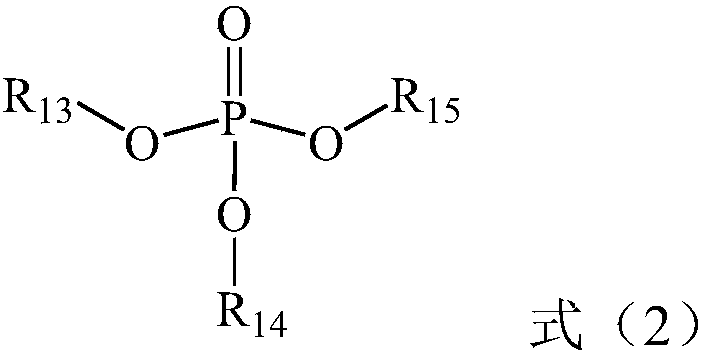

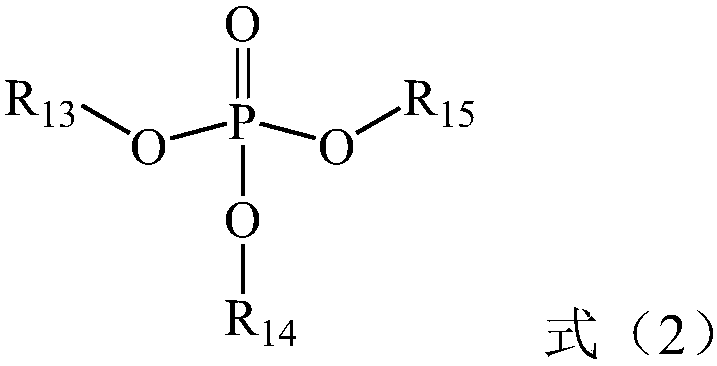

Disclosed is a catalyst composed of a salt of a phosphazenium cation and an active hydrogen compound anion, which can be easily synthesized, does not contain metal components at all, and does not leave any odor on a resulting product. Also disclosed are a method for producing the catalyst and a method for economically and efficiently producing a polyalkylene oxide using the catalyst. Specifically, a salt of a phosphazenium cation and an active hydrogen compound anion, which is represented by general formula (2), is used as a polyalkylene glycol producing catalyst. (In general formula (2), R1 and R2 each independently represents an alkyl group having 1-10 carbon atoms, an unsubstituted or substituted phenyl group having 6-10 carbon atoms, or an unsubstituted or substituted phenylalkyl group having 6-10 carbon atoms, provided that R1 and R2 or R2's may combine together to form a ring structure; n represents a real number of 1-8; and Yn- represents an anion of an active hydrogen compound which is obtained by removing n protons from an active hydrogen compound Y).

Owner:TOSOH CORP

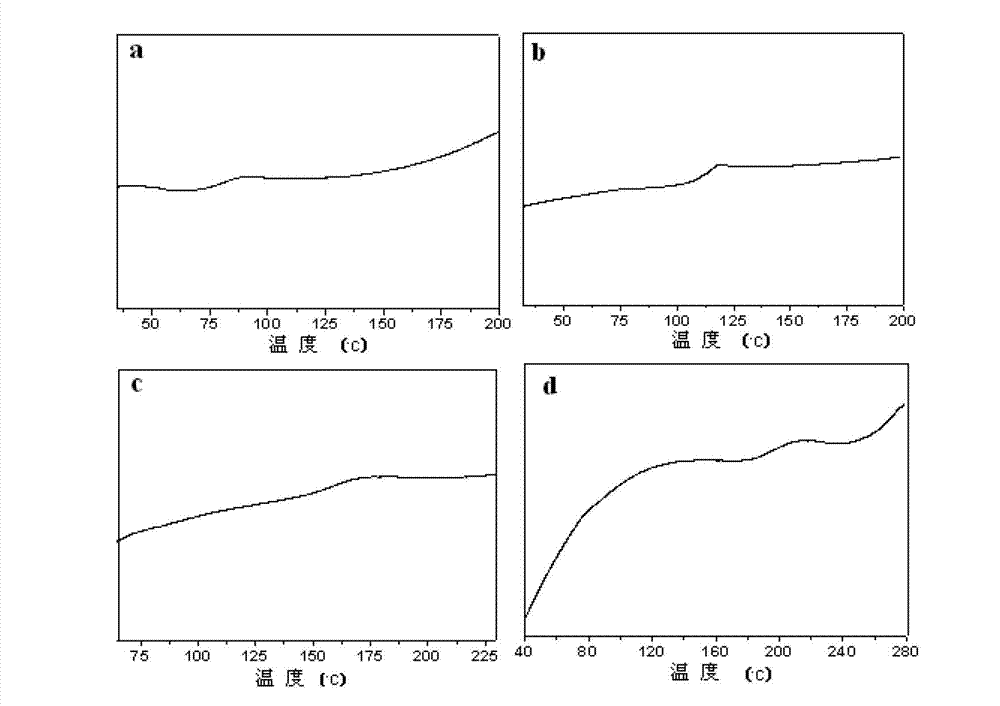

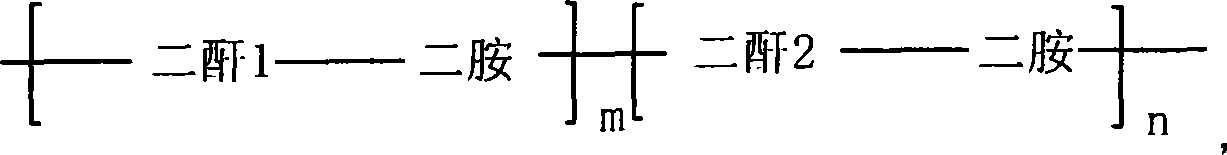

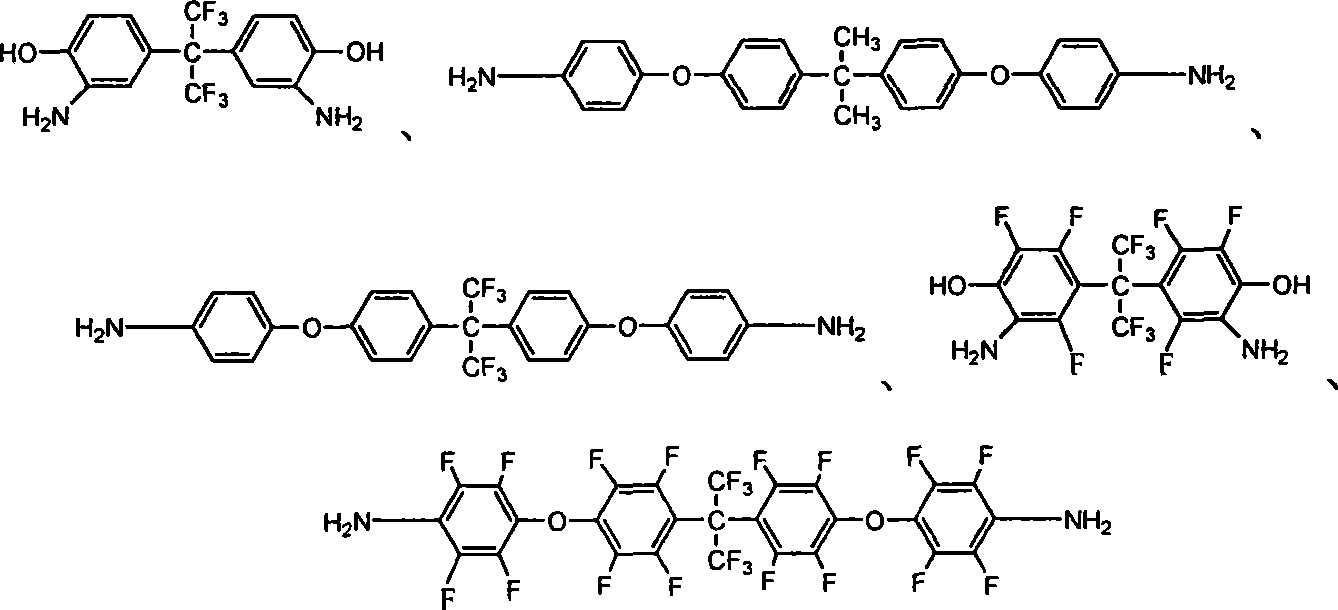

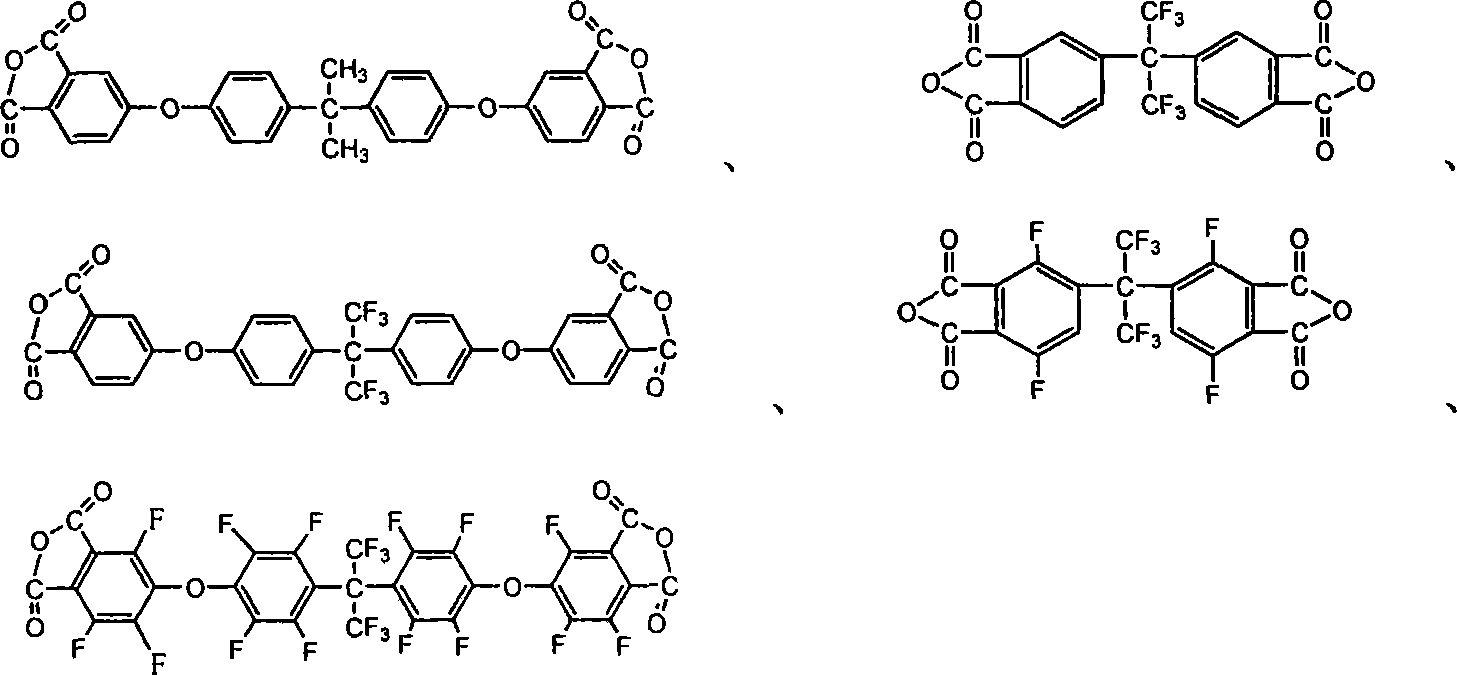

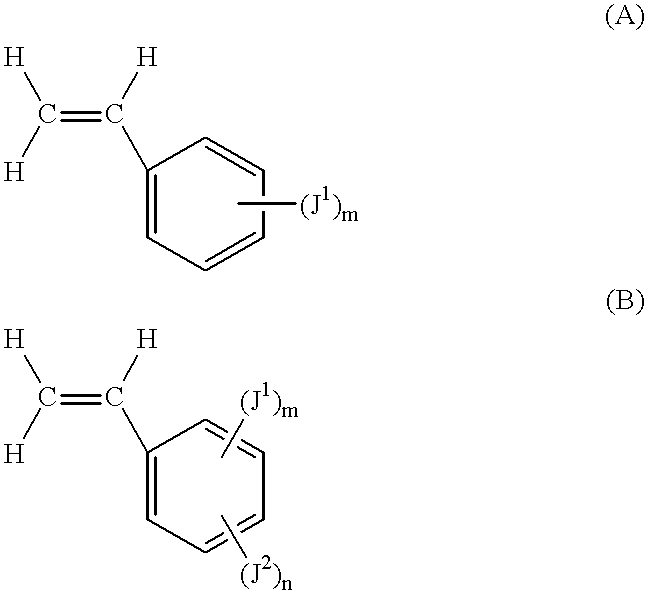

Fluorine-contained polyimide optical waveguide material and method for producing the same

InactiveCN101246222AImprove solubilityEasy to processOptical waveguide light guideRefractive indexOptical communication

The invention provides a fluorine-containing polyimide optical waveguide material and the preparing method thereof relating to the integrating polymer material preparing method in optical device, which can be applied in waveguide optics device, the material is obtained from condensation and copolymerization of three monomers, that is the fluorine-containing polyimide is condensed and copolymerized from two diamine monomers and one dianlydride monomer or from two diamine monomers and one dianlydride monomer, after purification, the fluorine-containing polyimide n-methyl-2-pyrrolidone solution is obtained, and is then dropped on center of clean substrate for spin coating to form film, and desiccation and curing. The glass transition temperature of the material is above 200 DEG C, in the field of optical communication on 1550nm the optical loss is less than 0.6dB / cm, the refractive index on 1550nm is 1.5-1.6.

Owner:SOUTHEAST UNIV

Chemical degradation method of polypropylene

A chemical degradation method of polypropylene comprises the degradation by adding 0.01 weight percent to 0.2 weight percent of organic peroxide and 0.1 weight percent to 1.0 weight percent of nucleating agent into the polypropylene. The method can effectively improve the efficiency of degradation, increase the melt index of degraded polypropylene, improve the molecular weight distribution of polypropylene, and maintain the good mechanical performances at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

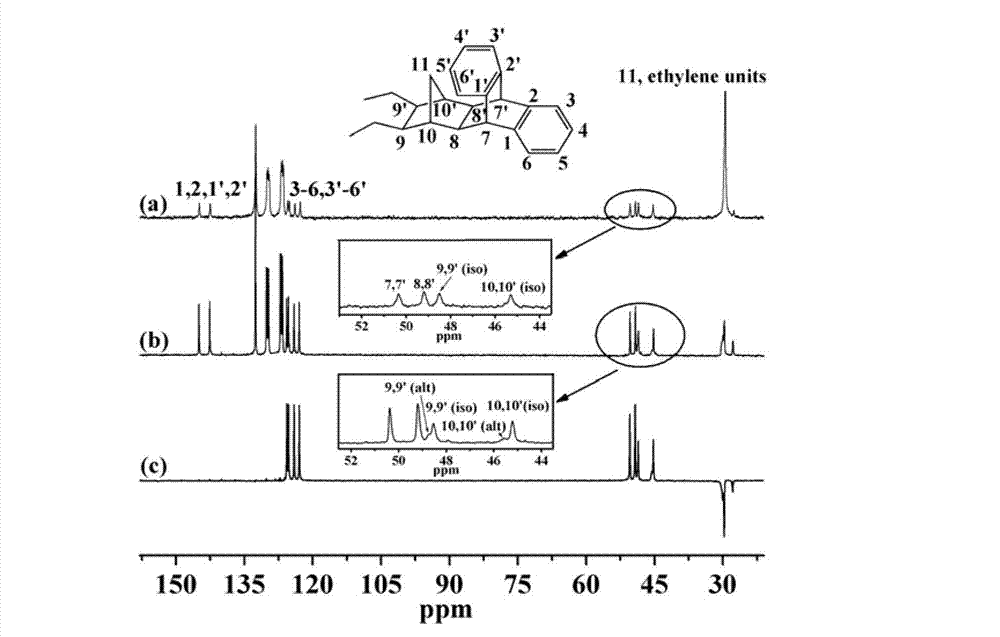

Polymerization process for preparing syndiotactic polystyrenes through microfluidization

InactiveUS6245865B1Accurate particle sizeHigh Molecular Weight DistributionFluidised-bed furnacesChemical/physical processesOrganic solventPolystyrene

The present invention relates to a polymerization process for preparing syndiotactic polystyrenes, which comprises a step of microfluidizing in a microfluidization apparatus both a catalyst mixture consisting of a styrene monomer, a metallocene catalyst and an inert organic solvent and a cocatalyst mixture consisting of a styrene monomer, a cocatalyst and an inert organic solvent, and a step of reacting the microfluidized mixture with a catalyst and a cocatalyst in a reactor. The metallocene catalyst has a bridged structure of a complex of Group IV transition metals such as Ti, Zr, Hf etc. in the Periodic Table and a ligand having one or two cycloalkane dienyl groups such as cyclopentadienyl group, indenyl groups, fluorenyl group, and derivatives thereof. The reactor is a well stirred reactor equipped with agitating blades therein to mix the reactants well. In this invention, the plural number of reactors can be employed in series for more effective polymerization, and the plural number of microfluidization apparatuses can be employed in parallel.

Owner:SAMSUNG ATOFINA CO LTD

Preparation method of cellulose acetate propionate

ActiveCN102127169AThe broken crystal zone works wellHigh Molecular Weight DistributionCellulosePropanoic acid

The invention relates to a preparation method of cellulose acetate propionate, belonging to technical field of cellulose modification. The preparation method of cellulose acetate propionate comprises the following steps of: taking cellulose as a raw material, activating by a mixed solution of acetic anhydride and propionic anhydride, adding acetic acid and propionic acid solvents and a solid super acidic catalyst for esterification, after esterification, filtering to remove the catalyst, adding waste acid water for hydrolyzing, settling out by waste acid water, and finally obtaining the cellulose acetate propionate by steps of filtering, washing, drying and the like. The production process is simple to operate, the solid super acidic catalyst substitutes the concentrated sulfuric acid catalyst and can be cyclically used for many times, thus alleviating the problem of serious corrosion of the original process equipment. The waste acid water generated in the reaction process only contains acetic acid and propionic acid without sulfuric acid and can be fully recovered and cyclically used, thus decreasing the tension in environmental protection, realizing zero discharge and greatly reducing the production cost. The cellulose acetate propionate prepared by the method has fine toughness, heat stability and compatibility, thus being extensively used.

Owner:CHANGMAO BIOCHEMICAL ENG CO LTD +1

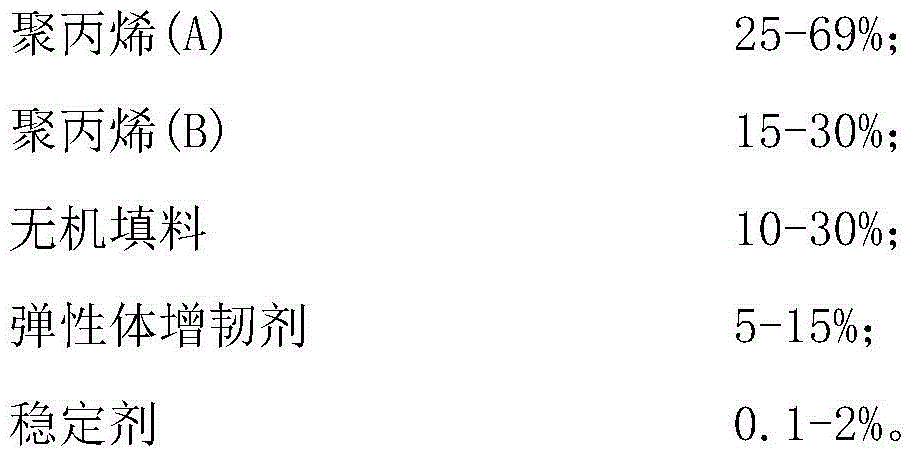

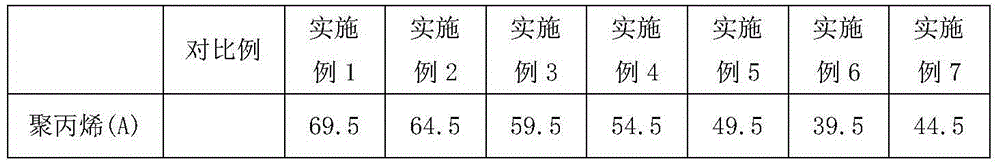

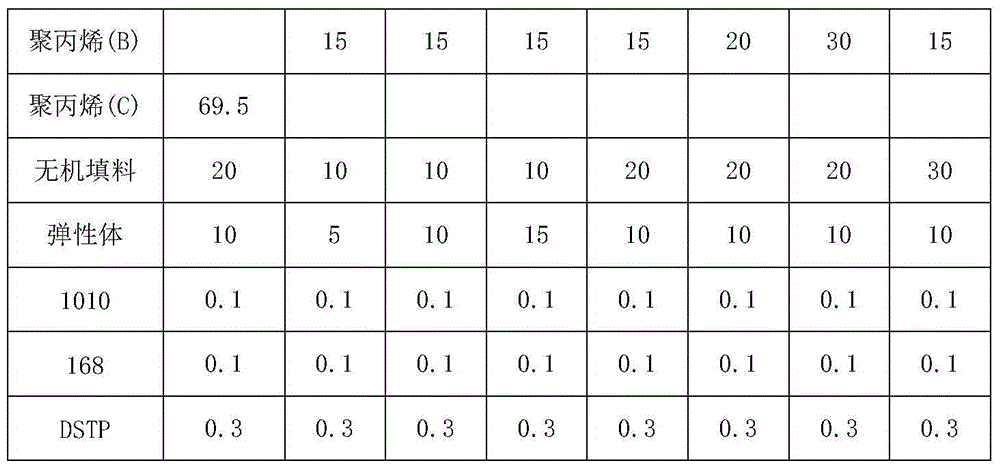

Injection molding-grade high-performance polypropylene composite material with good appearance and preparation method of injection molding-grade high-performance polypropylene composite material

InactiveCN104558834AHigh Molecular Weight DistributionImprove the appearance of injection moldingElastomerPolypropylene composites

The invention discloses an injection molding-grade high-performance polypropylene composite material with a good appearance and a preparation method of the injection molding-grade high-performance polypropylene composite material. The polypropylene composite material comprises the following raw materials in percent by weight: 25-69 percent of polypropylene (A), 15-30 percent of polypropylene (B), 10-30 percent of an inorganic filler, 5-15 percent of an elastomer flexibilizer, 0.1-2 percent of a stabilizer, and 0-5 percent of other additives. The polypropylene composite material and the preparation method have the advantages that 1, the molecular weight distribution of a PP matrix is improved to achieve the effect of improving the appearance of the injection molded polypropylene composite material through synergistic effect of polypropylene resin with high molecular weight and polypropylene resin with low molecular weight; 2, the original optimum proportion of the inorganic filler to the elastomer flexibilizer is not changed, and an excellent mechanical property is still kept while the injection molded polypropylene composite material has a good appearance; 3, the component kinds of an original modified material are not changed, the material performance is not influenced, and at the same time, the cost is not remarkably increased.

Owner:SHANGHAI PRET COMPOSITES +2

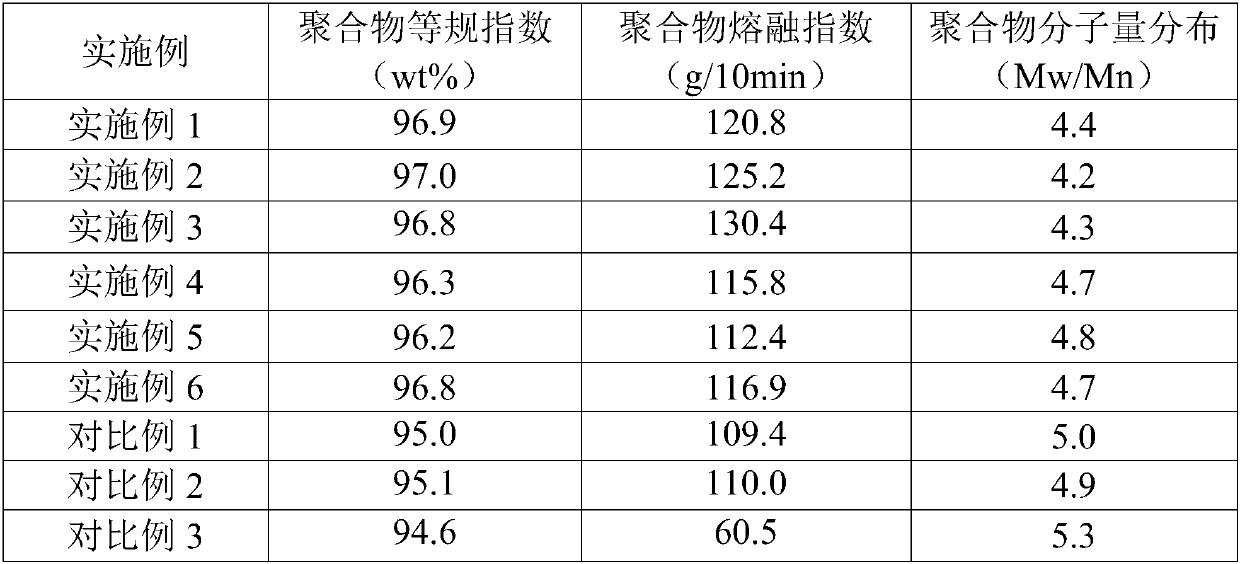

Catalyst for olefin polymerization, preparation method and applications thereof

ActiveCN107629154AHigh stereospecificityNarrow molecular weight distributionResponse sensitivityHydrogen

The present invention relates to the field of olefin polymerization, particularly provides a catalyst for olefin polymerization, a preparation method and applications thereof. The catalyst for olefinpolymerization contains (i) a catalyst component, (ii) at least an alkyl aluminum compound and (iii) an external electron donor, wherein the catalyst component contains the product obtained by carrying out a reaction on a magnesium source, a titanium source and an internal electron donor, the internal electron donor contains a phosphate compound and a diether compound, the phosphorus content (calculated as the phosphorus element) in the catalyst component is not more than 0.06 wt% by using the total weight of the catalyst component as the reference, and the external electron donor has a structure represented by a formula (1). According to the present invention, the catalyst does not contain phthalate compounds (plasticizers), has high hydrogen response sensitivity and high stereospecificity, and can be used in olefin polymerization so as to obtain the polymer having narrow molecular weight distribution. The formulas (1) is (R17)x(R18)ySi(OR19)z.

Owner:CHINA PETROLEUM & CHEM CORP +1

Chemic grouting polyurethane material, prepolymer thereof and preparation method

The invention discloses a preparation method of a prepolymer of a chemic grouting polyurethane material. The method comprises the following steps of: mixing polyether, retarder and an isocyanate compound under anaerobic and anhydrous conditions, reacting at 50-60 DEG C for 2-3 h and reacting at 80-90 DEG C for 2-3 h to obtain the prepolymer, wherein the polyether comprises polyether 480 and polyether DL1000D, and the isocyanate compound is one or more of polymer MDI, liquid MDI and MDI-50. The invention also provides the prepolymer prepared by using the preparation method as well as a chemic grouting polyurethane material and a preparation method thereof. The chemic grouting polyurethane material is synthesized by adopting cheaper raw materials and a chemic grouting polyurethane material with better molecular weight distribution is prepared by phased full reaction of the product. Compared with a traditional chemic grouting polyurethane material, the chemic grouting polyurethane material provided by invention has higher compression strength, adhesion strength, tensile strength, anti-osmotic performance and consumed water.

Owner:SHANGHAI DONGDA CHEM

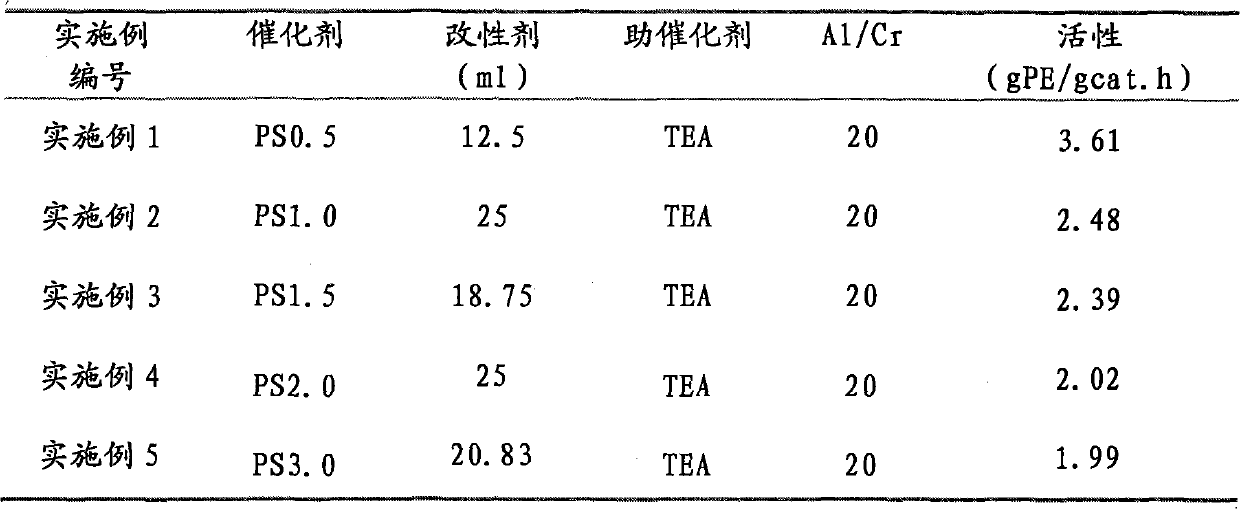

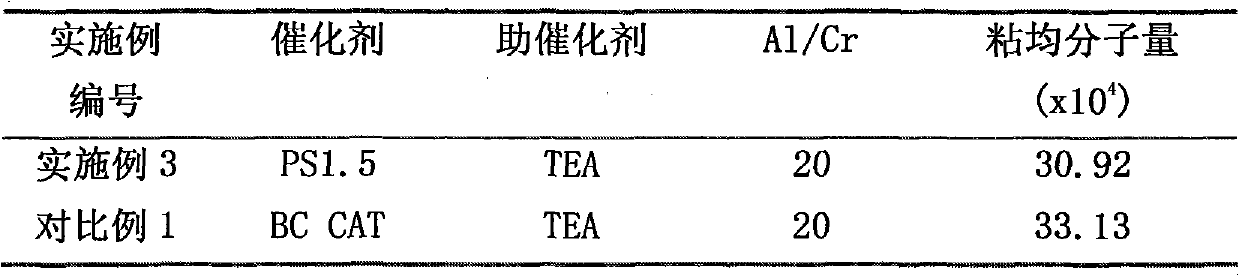

Organic chromium catalyst for ethylene polymerization and preparation method thereof

ActiveCN102453154AHigh activityInduction time is suitableChemical recyclingBulk chemical productionHigh activityInorganic oxide

The invention provides an organic chromium catalyst for ethylene polymerization and a preparation method thereof. The catalyst comprises a main active catalyst, an inorganic oxide carrier, a modifier and a cocatalyst, wherein the main active catalyst is a chromium salt, and the content of the main active catalyst in the catalyst is 0.01-5% by mass; technical requirements of the carrier inorganic oxide comprise that the surface area is about 200-700m<2> / g, the pore volume is about 1-4cc / g, the aperture is about 60-700 and the particle dimension is about 10-200mum; the modifier is a recovery liquid for the preparation of an alkylsilane chromate catalyst; and the cocatalyst is an alkyl compound of Al, Li, B and Zn. The organic chromium catalyst for the ethylene polymerization provided in theinvention has the advantages of high activity, proper induction time, and suitableness of the production of wide molecular weight distribution range polyethylene products; and the preparation method provided in the invention has the advantages of simple synthetic technology and low preparation cost.

Owner:CHINA PETROLEUM & CHEM CORP

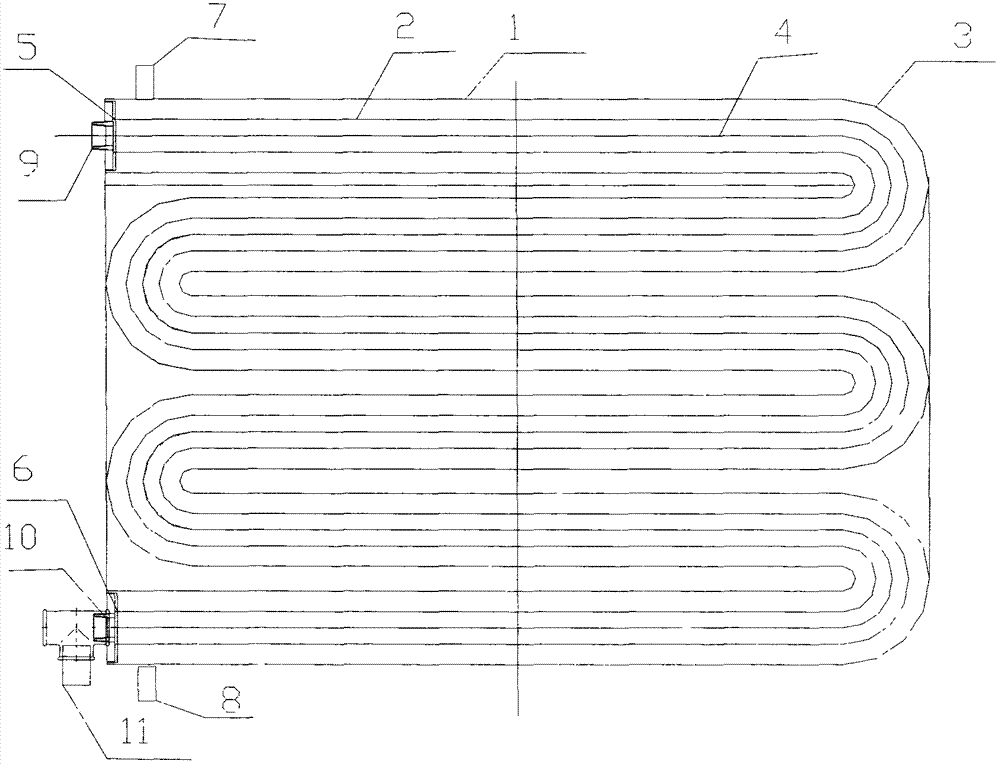

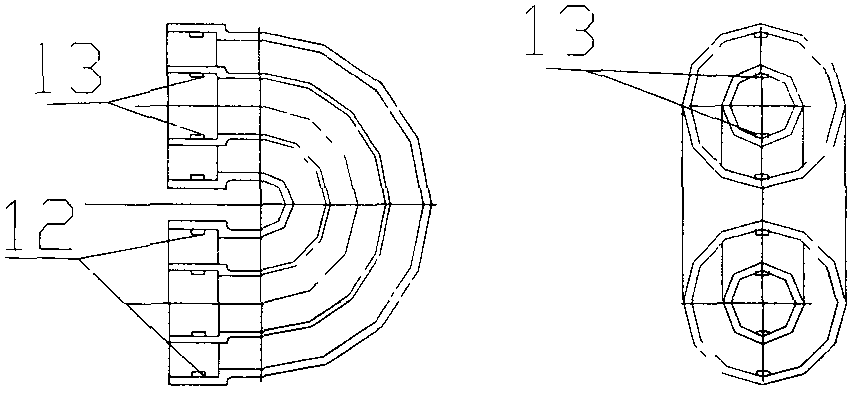

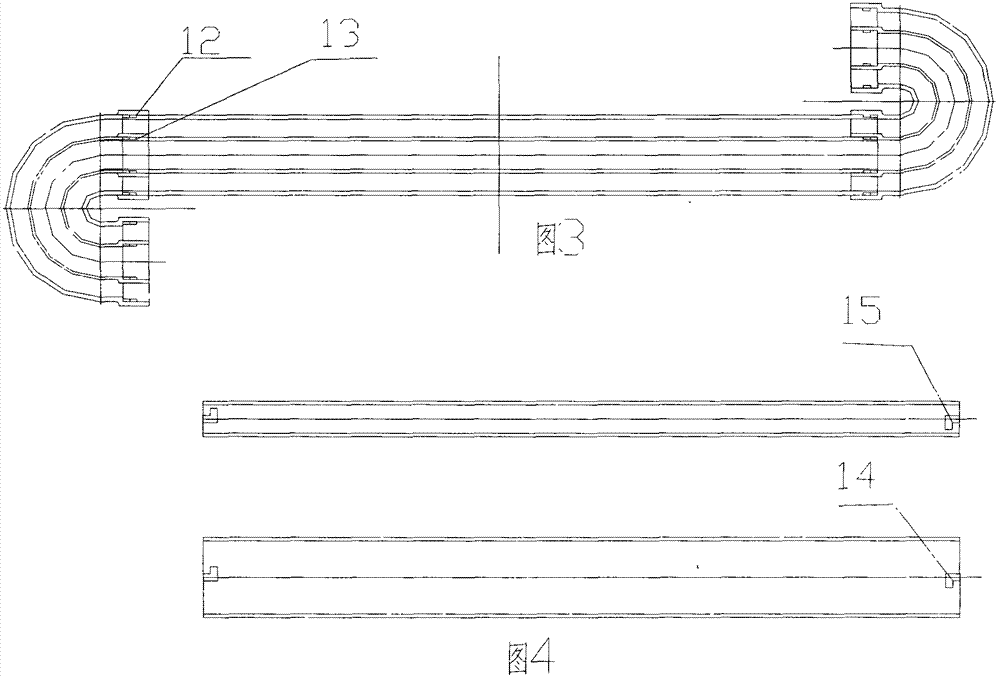

Plastic radiating and ventilating water heater and making method thereof

ActiveCN103033075AGreenSimple structure and processHeat exchanger casingsStationary tubular conduit assembliesEngineeringThermal water

The invention relates to a plastic radiating and ventilating water heater used in the field of heating and bath radiating and ventilating water heaters adopting hot water as a heat medium and relates to a method for making the radiating and ventilating water heater and a material thereof. The plastic radiating and ventilating water heater comprises an injection-molded structure or a molded sectional material and is characterized in that a coaxial heat exchanger is provided with heating medium channels and heated medium channels; a plurality of heat exchange pipes and a plurality of heated medium pipes are axially arranged in a sleeving way, the pipes with a bigger diameter are arranged outside the pipes with a smaller diameter in a sleeving way, and the heated medium pipes are arranged on the outermost layer; lock catch grooves of the heated medium channels and the heat exchange pipes, which are connected in series and communicated are fixedly connected with heat exchange abnormal pipes in a way of directly plugging in built-in lock catches and bonding under a heated condition, or in a way of directly plugging in the built-in lock catches and bonding with a glue solution, or in a way of direct-plug-in heated bonding and glue solution bonding; or the lock catch grooves and the abnormal heat exchange pipes are injection-molded into a whole by a die. The plastic radiating and ventilating water heater belongs to a novel radiating and ventilating water heater which can avoid oxidation or alkali corrosion problems, has excellent heat radiation and conduction properties and long service life, and can overcome the defect that the environment is worsened by the water quality of the heat medium.

Owner:ZAOZHUANG FUYUAN ENVIRONMENTAL PROTECTION & ENERGY SAVING MACHINERY MFG CO LTD

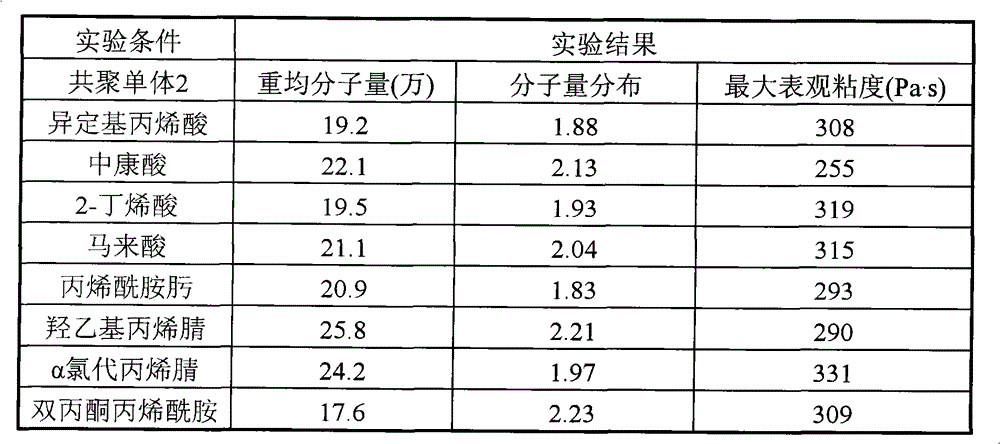

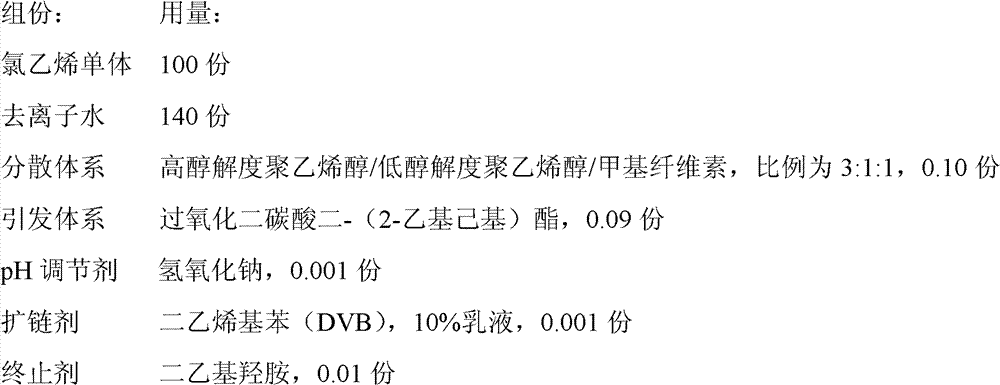

Method for preparing high-performance polyacrylonitrile solution for carbon fibers

ActiveCN102746453AImprove technical effectHigh molecular weightMonocomponent synthetic polymer artificial filamentSpinning solutions preparationCarbon fibersAcrylonitrile

The invention relates to a method for preparing a high-performance polyacrylonitrile solution for carbon fibers, and especially relates to a method for preparing the polyacrylonitrile solution through adopting a new initiator to mainly solve a problem of difficult process control caused by wide molecular weight distribution or abundant gel generation of solutions prepared through a single initiator used for preparing an acrylonitrile solution in the prior art. According to the invention, the initiator comprises 70-100 parts by weight of azodiisobutyronitrile and 1-30 parts by weight of azobisisoheptonitrile. The method well solves the problem through above technical scheme, and can be used for the industrial production of the acrylonitrile solution polymerization

Owner:CHINA PETROLEUM & CHEM CORP +1

Halogenated amide ester and internal electron donor with same

ActiveCN103140510AHigh Molecular Weight DistributionWide molecular weight distributionOrganic chemistryZiegler–Natta catalystElectron donor

Disclosed are halogenated amide esters that are suitable as internal electron donors in procatalyst compositions. Ziegler-Natta catalyst compositions containing the present procatalyst compositions exhibit improved catalyst activity and / or improved catalyst selectivity and produce propylene-based olefins with broad molecular weight distribution.

Owner:WR GRACE & CO CONN

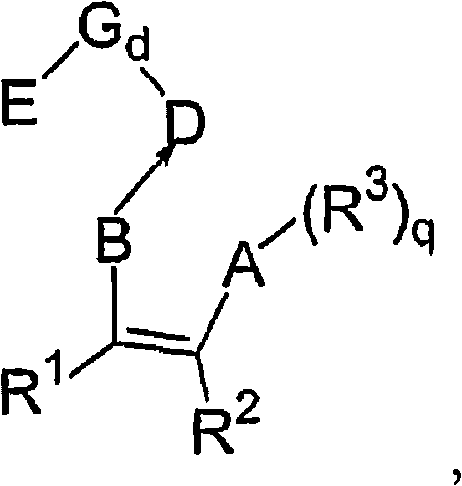

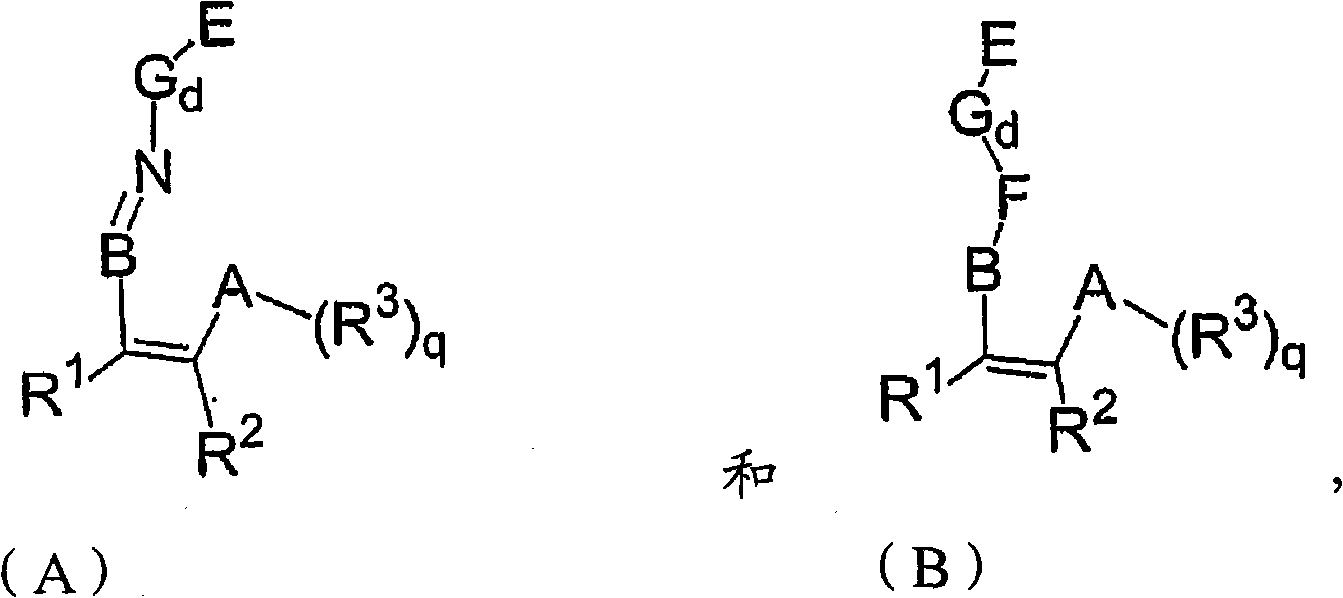

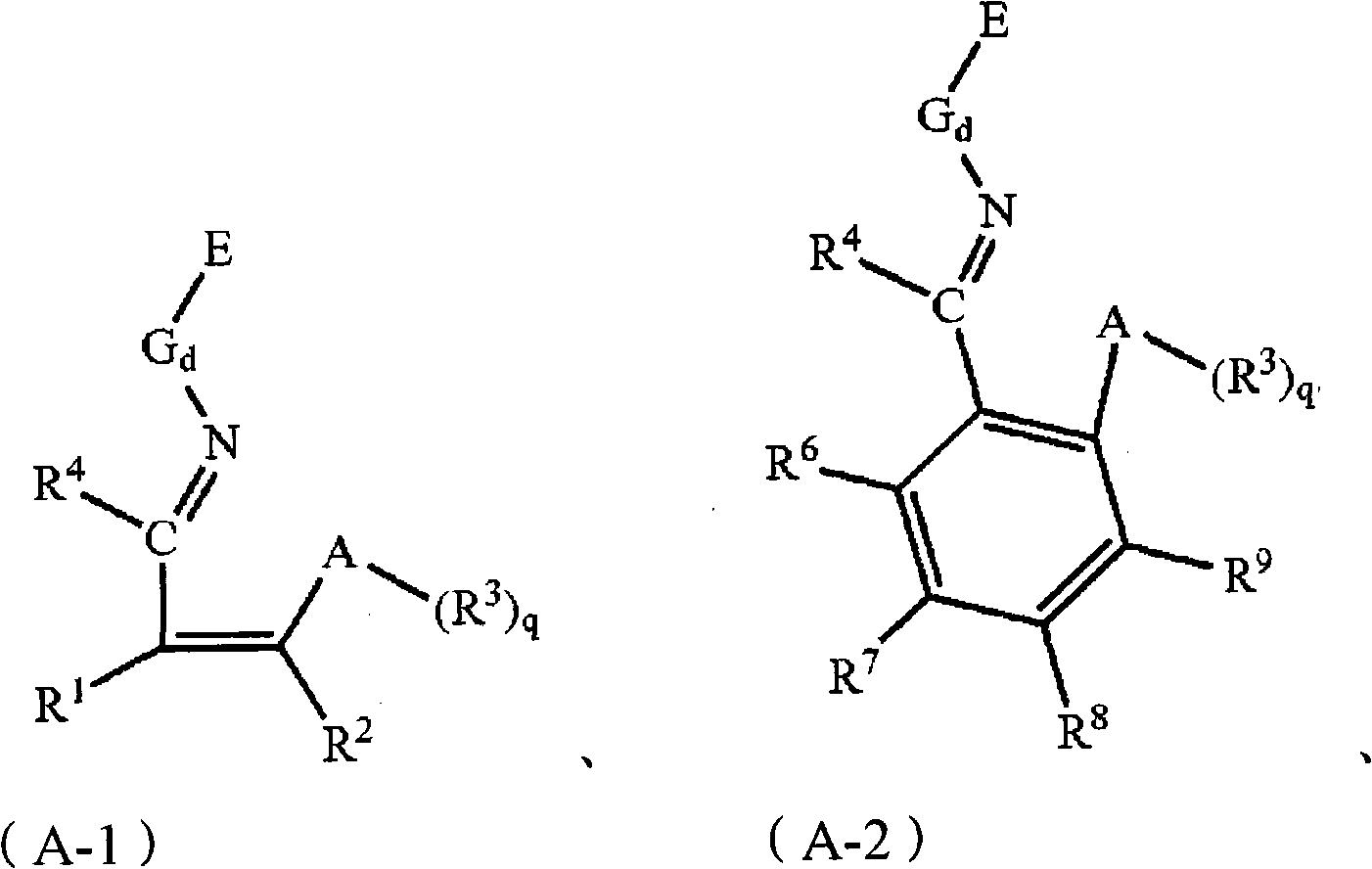

Supported non-metallocene catalyst, preparation method and application

The invention relates to a supported non-metallocene catalyst and a preparation method. The supported non-metallocene catalyst is prepared by the steps of dissolving a non-metallocene ligand in a magnesium compound solution, performing an in-situ reaction with a chemical treatment agent, and dipping a solution of a non-metallocene complex. The preparation method is simple and feasible, the ingredients content of the non-metallocene is adjustable, and the copolymerization effect is substantial. The invention also relates to the application of the supported non-metallocene catalyst in olefin homopolymerisation / copolymerization. Compared with the prior art, the polymerization activity by catalysis of alkene is high, the bulk density of the polymer is high, and the molecular weight distribution is narrow and controllable.

Owner:CHINA PETROLEUM & CHEM CORP +1

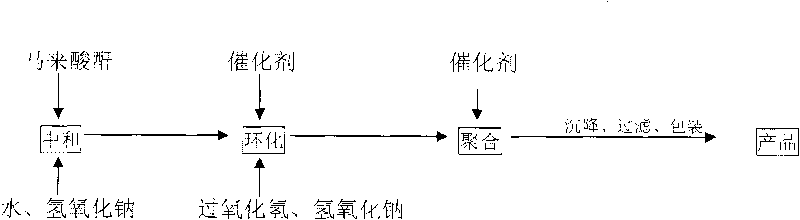

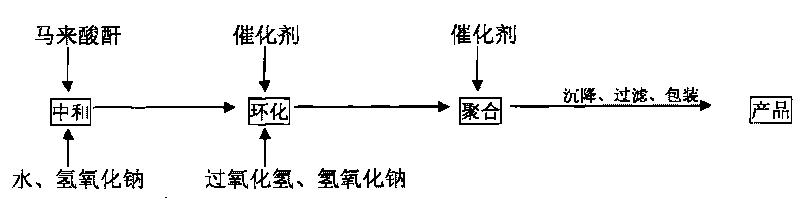

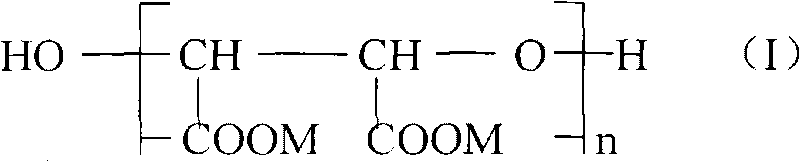

Synthesis method of high-concentration polyepoxysuccinic acid and salt thereof

InactiveCN101717498AIncrease concentrationImprove conversion rateHigh concentrationSynthesis methods

The invention discloses a synthesis method of high-concentration polyepoxysuccinic acid and salt thereof. The method comprises the following main processes: simultaneously adding maleic anhydride and sodium hydrate into water in a mode of feeding in batches; controlling the pH value of solution at 5-7 and the reaction temperature at 40-60 DEG C; adding sodium tngstate into a hydrolysis product as expoxidation catalyst at 50-60 DEG C; carrying out expoxidation reaction by adding hydrogen peroxide; adding sodium hydrate solution at the same time; controlling the pH value at 4-7; finishing the expoxidation reaction; stirring; raising the temperature to above 80 DEG C; adding initiator calcium oxide; and after polymerization, lowering the temperature and filtering to obtain the polyepoxysuccinic acid and salt solution thereof. In the preparation method, a one-pot synthesis is adopted, and therefore, the preparation method has the advantages of simple and unique technology, high product concentration, high raw material conversion rate, ideal molecular weight distribution and favorable industrial operability.

Owner:INNER MONGOLIA TIANCHEN SCI & TECH

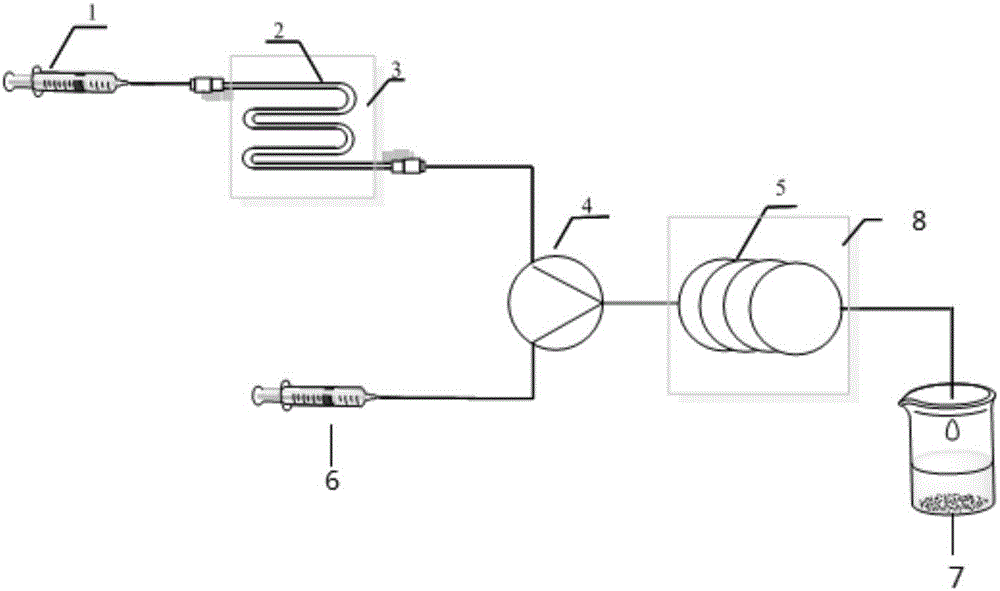

Method for synthesizing segmented copolymer by coupling enzymatic catalysis and organic catalysis by virtue of micro reactor

ActiveCN106520851ATo achieve high-efficiency copolymerizationIncrease the rate of polymerizationBioreactor/fermenter combinationsBiological substance pretreatmentsReaction rateOrganocatalysis

The invention discloses a method for synthesizing a segmented copolymer by coupling enzymatic catalysis and organic catalysis by virtue of a micro reactor, and relates to the field of the synthesis of polymers. The method comprises the following steps: (a) dissolving a monomer 1 and an initiating agent in an organic solvent, pumping an obtained solution into an immobilized enzyme micro reactor, and conducting a full reaction; (b) dissolving a monomer 2 and an organic catalyst in an organic solvent, mixing an obtained solution and reaction liquid outputted from the step (a) in a mixer 4, pumping a mixed solution into a micro-channel reactor 5 and conducting a full reaction; and (c) adding a quenching agent and a third organic solvent to reaction liquid collected from the step (b), and conducting separating and purifying, so as to obtain the pure poly-monomer 1-poly-monomer 2 segmented copolymer. According to the method provided by the invention, the processes of the enzymatic catalysis and the organic catalysis are coupled by virtue of the micro reactor, so that advantages of the enzymatic catalysis and the organic catalysis are integrated, and subsequently reaction efficiency is greatly improved, reaction time is shortened an continuous production is achieved; and the method has the advantages of being safe, efficient, low in energy consumption, high in reaction rate, moderate in reaction conditions and the like.

Owner:NANJING UNIV OF TECH

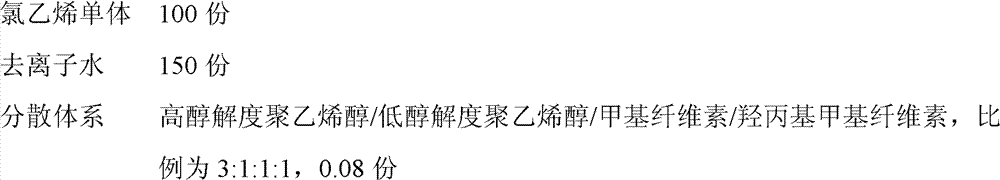

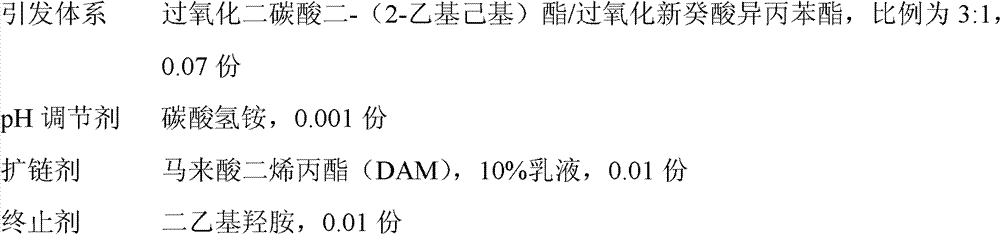

PVC resin with ultra-low degree of polymerization and manufacturing method thereof

ActiveCN101665548AImproved particle morphology and molecular weight distributionImprove processing thermal stabilityChemistryPlasticizer

The invention discloses a PVC resin with ultra-low degree of polymerization and a manufacturing method thereof. In the invention, a polymerization method is adopted to carry out polymerization reaction, the reaction temperature is 60-64 DEG C, and the reaction pressure is less than 1.0 MPa; a first chain transfer agent is added when the polymerization reaction is carried out for 0-30min, and then0.005-0.012% of vinyl chloride monomer (VCM) is added; a second chain transfer agent is added when the polymerization reaction is carried out for 60-90min, and then 0.005-0.02% of monomer is added toobtain the PVC resin with ultra-low degree of polymerization. The PVC resin manufactured by the invention has the advantages of the average degree of polymerization below 500, high apparent density, low melting and gelatinization temperature, low melt viscosity, good transparency, short plasticization time and favorable processability and the like, and the phenomenon of accelerating products agingdue to the transfer of plasticizer does not appear in machining process.

Owner:SICHUAN JINLU GRP

Supported non-metallocene catalyst, preparation method and application

The invention relates to a supported non-metallocene catalyst and a preparation method. The supported non-metallocene catalyst is prepared by the steps of performing in-situ loading on a non-metallocene complex and dipping a solution. The preparation method is simple and feasible, the ingredients capacity of the non-metallocene is adjustable, and the copolymerization effect is substantial. The invention also relates to the application of the supported non-metallocene catalyst in olefin homopolymerisation / copolymerization. Compared with the prior art, the polymerization activity by catalysis of alkene is high, the bulk density of the polymer is high, and the molecular weight distribution is controllable.

Owner:CHINA PETROLEUM & CHEM CORP +1

Supported non-metallocene catalyst, preparation method and application

ActiveCN102964482AEasy to prepareSuitable for industrial productionBulk chemical productionChemical treatmentAlkene

The invention relates to a supported non-metallocene catalyst, a preparation method and an application. The supported non-metallocene catalyst is prepared by the steps of introducing a first non-metallocene complex in a magnesium compound solution, processing by a chemical treatment agent and then reacting with a second non-metallocene complex. The method of the invention has the characteristics of simple and feasible process, controllable content of non-metallocene compounds and substantial copolymerization effect and the like. The invention also relates to the application of the supported non-metallocene catalyst in olefin homopolymerisation / copolymerization. Compared with the prior art, the polymerization activity by catalysis of alkene is high, the bulk density of the polymer is high, and the molecular weight distribution is controllable.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of fluorine-containing high-molecular surfactant

InactiveCN103483513AHigh molecular weight distributionNarrow molecular weight distributionCritical micelle concentrationEmulsion polymerization

The invention discloses a preparation method of a fluorine-containing high-molecular surfactant, and the preparation method comprises the following steps: enabling an initiator, methacrylic acid-N,N-ethyl dimethylamide, a chain transfer agent and 1,4-dioxane to react at 60-90 DEG C in the presence of the argon to obtain polymethylacrylic acid-N,N-ethyl dimethylamide; adding the initiator, hexafluorobutyl acrylate and 1,4-dioxane, and reacting for 2-8 hours at 65-95 DEG C in the presence of argon; precipitating in n-hexane; drying to obtain the fluorine-containing high-molecular surfactant. By adopting an RAFT polymerization technology, the prepared fluorine-containing high-molecular surfactant contains a fluorine-containing unit similar to the structure of a fluorine-containing monomer, has the characteristics of narrow molecular weight distribution, adjustable structure, low critical micelle concentration, good emulsibility, low foamability and the like, and has broad application prospect in emulsion polymerization.

Owner:广州市科灵精细化工有限公司

Supported non-metallocene catalyst, preparation method and application

The invention relates to a supported non-metallocene catalyst and a preparation method. The supported non-metallocene catalyst is prepared by the steps of introducing a non-metallocene complex in a magnesium compound solution, treating by a chemical treatment agent and performing an in-situ reaction with a non-metallocene ligand. The preparation method is simple and feasible, the ingredients content of the non-metallocene is adjustable, and the copolymerization effect is substantial. The invention also relates to the application of the supported non-metallocene catalyst in olefin homopolymerisation / copolymerization. Compared with the prior art, the polymerization activity by catalysis of alkene is high, the bulk density of the polymer is high, and the molecular weight distribution is narrow and controllable.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing low cis-polybutadiene by stepwise excitation

The 1, 3-butadiene polymerizing process includes two-step initiated polymerization inside intermittent polymerizing system of saturated hydrocarbon solvent containing polar regulator and with alkyl lithium as initiator to produce homopolymer with different molecular weights and certain molecular weight distribution; and subsequent coupling with four functionality degree Lewis acid as coupling agent to prepare low cis-polybutadiene with wide molecular weight distribution. The present invention has the obvious features of widened molecular weight distribution of 1.6-1.8, reduced initiator and coupling agent consumption, improved 5 % styrene liquid chroma of rubber. The present invention is used in modification of polystyrene resin and can improve the degree of luster of anti-shock polystyrene.

Owner:中国石油化工股份有限公司北京燕山分公司研究院

Polyvinyl chloride production method adding chain extender to match with later-stage heating process

The invention relates to a polyvinyl chloride production method adding a chain extender to match with a later-stage heating process. The production method is characterized in that during the polymerization reaction process, when the polymerization conversion rate achieves 50%-75%, the chain extender is added into a polymerization kettle by a high-pressure pump, the using quantity of the chain extender is 10-10000ppm of the total quantity of polyvinyl chloride, the material temperature in the polymerization kettle is simultaneously increased by 1-25 DEG C, and the temperature increasing speed is 0.2-3 DEG C / min. Polyvinyl chloride resin produced by adopting the production method disclosed by the invention has a larger molecular weight distribution width index than that of the resin with the same number-average molecular weight and further keeps the excellent processing performance of the resin produced by a pure polymerization later-stage heating process; and simultaneously, the impact strength and tensile strength of a simply supported girder gap of a product are higher than those of the resin produced by adopting the pure polymerization later-stage heating process and equivalent to those of the resin produced by a constant-temperature polymerization process, and good resin processing performance and great product mechanical performance are further realized.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com