Plastic radiating and ventilating water heater and making method thereof

A water heater, plastic technology, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve the problems of complex preparation process, easy leakage, easy to be corroded, etc., and achieve simple structure and preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

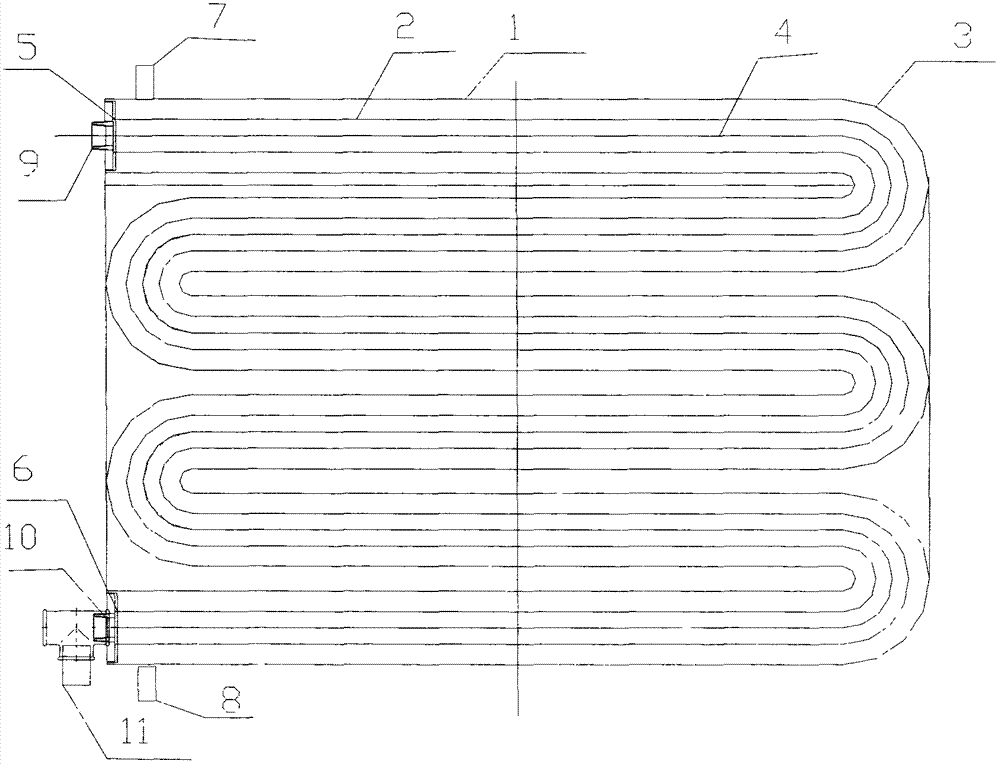

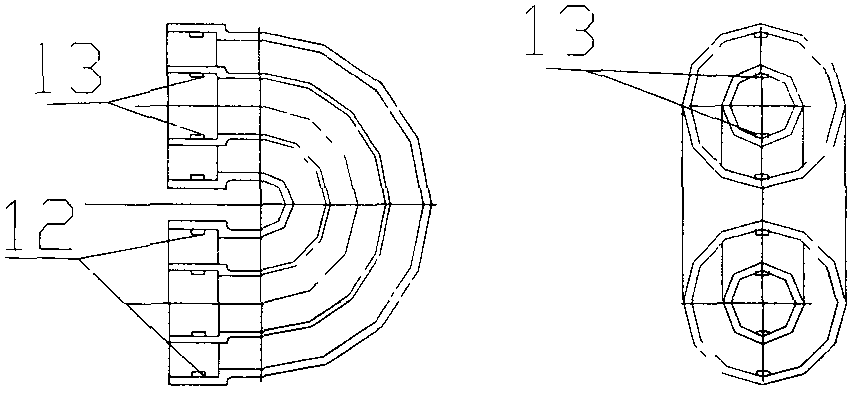

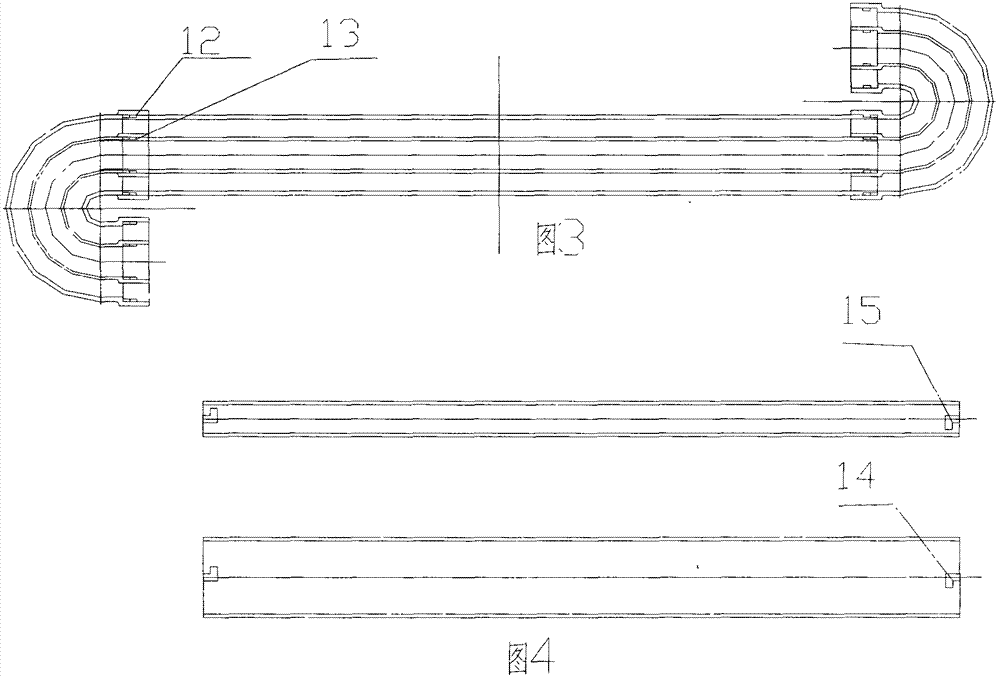

[0071] The present invention as Figure 1 to Figure 4 As shown, the plastic radiator water heater includes an injection molding structure or a molded profile, and is characterized in that:

[0072] The coaxial heat exchanger has a heating medium channel and a heated medium channel;

[0073] The plurality of heat exchange tubes (2) and the plurality of heated medium tubes (1) are coaxially sleeved, and the tubes with larger diameters are sleeved with smaller diameter tubes, and the outermost layer is the heated medium tubes (1);

[0074] The several channels connected in series to the heated medium include the locking groove (14) of the heat exchange tube (1) and the heat exchange special-shaped tube (3) directly inserted into the built-in lock (12) for heating, bonding, fixing or direct insertion Built-in locking glue bonding and fixing, or in-line ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com