Method for preparing high-performance polyacrylonitrile solution for carbon fibers

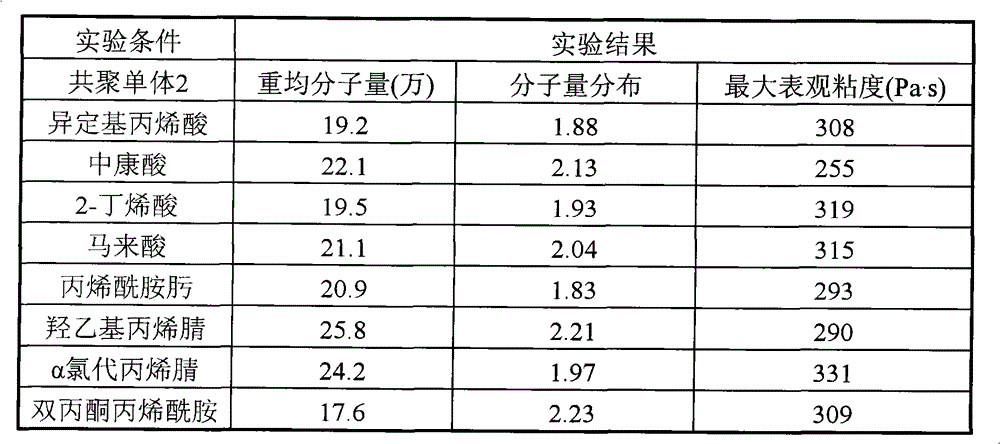

A technology of polyacrylonitrile and acrylonitrile is applied in the field of preparing high-performance polyacrylonitrile stock solution for carbon fiber, which can solve the problems of wide molecular weight distribution and difficult process control, and achieve the effect of good technical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Weigh dimethyl sulfoxide, acrylonitrile, itaconic acid, β-butyl itaconate, and initiator at a weight ratio of 800:196:1.5:2.5:1, wherein azobisisoheptanonitrile accounts for 20 parts of the total weight of the initiator, 80 parts of azobisisobutyronitrile, polymerized at 35°C for 5 hours, raised the temperature to 60°C, and reacted for 19 hours. After the reaction, the residual monomers and bubbles were removed in vacuum to obtain The polyacrylonitrile stock solution obtained by GPC test has a weight-average molecular weight of 208,000, a molecular weight distribution index of 1.72, and a maximum apparent viscosity of 283 Pa·s during the preparation process. The obtained polyacrylonitrile stock solution was transparent and homogeneous, and no gel was produced through the filtration test.

Embodiment 2

[0019] Weigh dimethyl sulfoxide, acrylonitrile, itaconic acid, methyl acrylate, initiator at a weight ratio of 800:180:15:5:1, wherein azobisisoheptanonitrile in the initiator accounts for the total weight of the initiator The number of parts is 30 parts, and azobisisobutyronitrile is 70 parts. Polymerize at 40°C for 4 hours, heat up to 63°C, and react for 28 hours. After the reaction, the residual monomers and bubbles are removed in vacuum to obtain polyacrylonitrile stock solution According to the GPC test, the weight-average molecular weight of the copolymer is 203,000, the molecular weight distribution index is 2.21, and the highest apparent viscosity during the preparation process is 236Pa·s. The obtained polyacrylonitrile stock solution was transparent and homogeneous, and no gel was produced through the filtration test.

Embodiment 3

[0021] Weigh dimethyl sulfoxide, acrylonitrile, itaconic acid, acrylamide, initiator in a weight ratio of 800:190:5:5:0.5, wherein azobisisoheptanonitrile in the initiator accounts for the total weight part of the initiator 10 parts of azobisisobutyronitrile, 90 parts of azobisisobutyronitrile, polymerized at 30°C for 5 hours, raised the temperature to 63°C, and reacted for 30 hours. After the reaction, the residual monomers and bubbles were removed in a vacuum to obtain a polyacrylonitrile stock solution. According to GPC test, the weight average molecular weight of the copolymer is 156,000, the molecular weight distribution index is 1.87, and the highest apparent viscosity during the preparation process is 206Pa·s. The obtained polyacrylonitrile stock solution was transparent and homogeneous, and no gel was produced through the filtration test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com