Method for preparing p-xylene by separating and crystallizing mixed xylenes

A technology of mixing xylene and p-xylene, which is applied in crystallization purification/separation, chemical instruments and methods, purification/separation of hydrocarbons, etc., can solve the problems of high energy consumption, and achieve the reduction of refrigeration energy consumption, energy consumption reduction, The effect of good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The method for separating p-xylene from mixed xylenes described in the present invention.

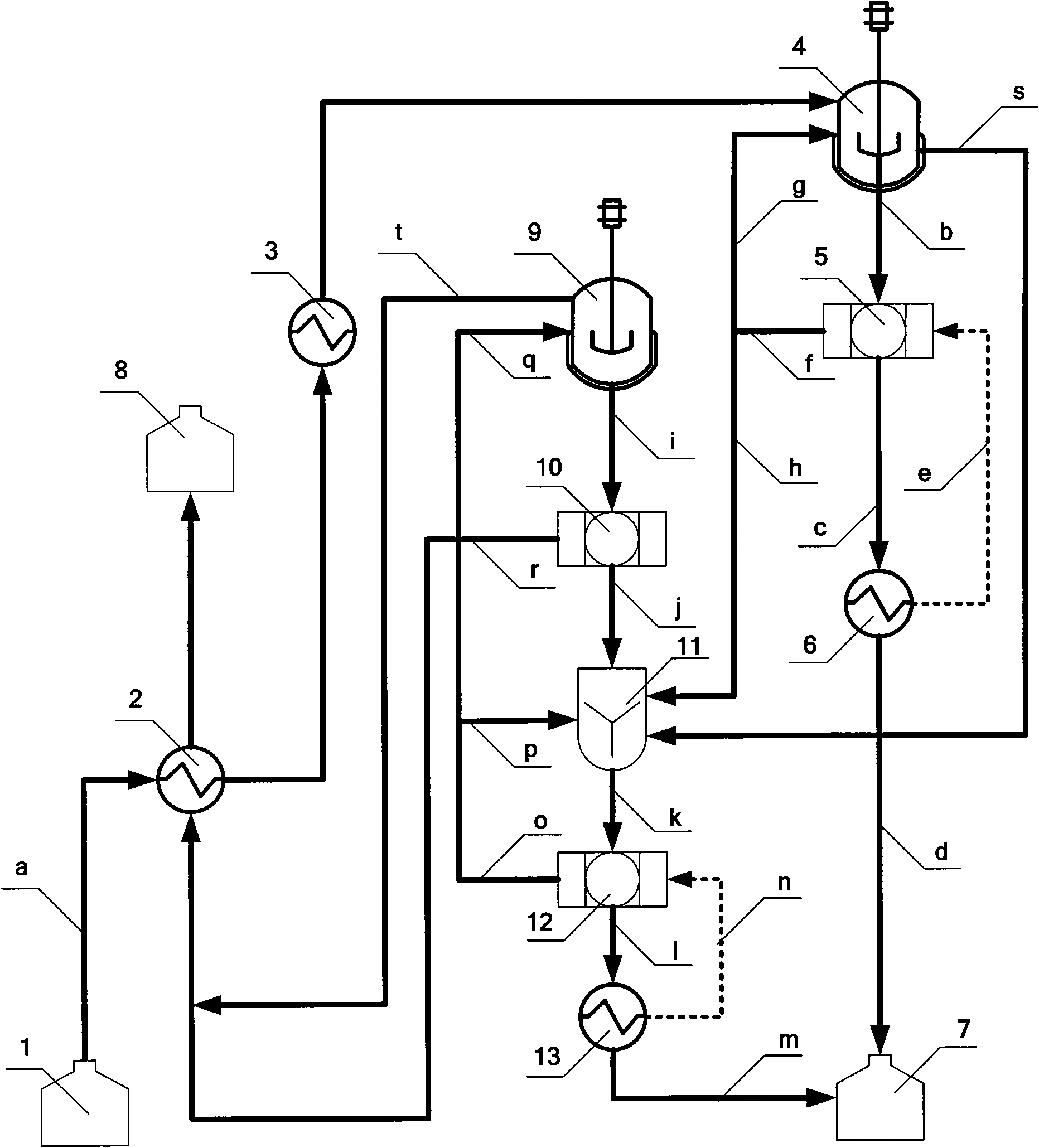

[0016] Such as figure 1 Described, the mixed xylene a from raw material tank 1 contains 90% p-xylene, and temperature is 25 ℃, and flow rate is 1116kg / h, after cooling through heat exchanger 2 and heat exchanger 3, in first stage crystallizer 4 The crystallization is carried out in the crystallizer, and the operating temperature is 4°C. The magma b in the crystallizer 4 is separated from the solid and liquid by the first solid-liquid separator 5 to obtain high-purity p-xylene crystals c and crystallization and filtration mother liquor f. Paraxylene crystal c is melted in heat exchanger 6, and the paraxylene of 20% by weight is washed as washing solution e to the crystal in the first solid-liquid separator 5, and the paraxylene of 80% by weight is used as paraxylene product d enters the product tank 7, and the crystallization and filtration mother liquor f is divided into two str...

Embodiment 2

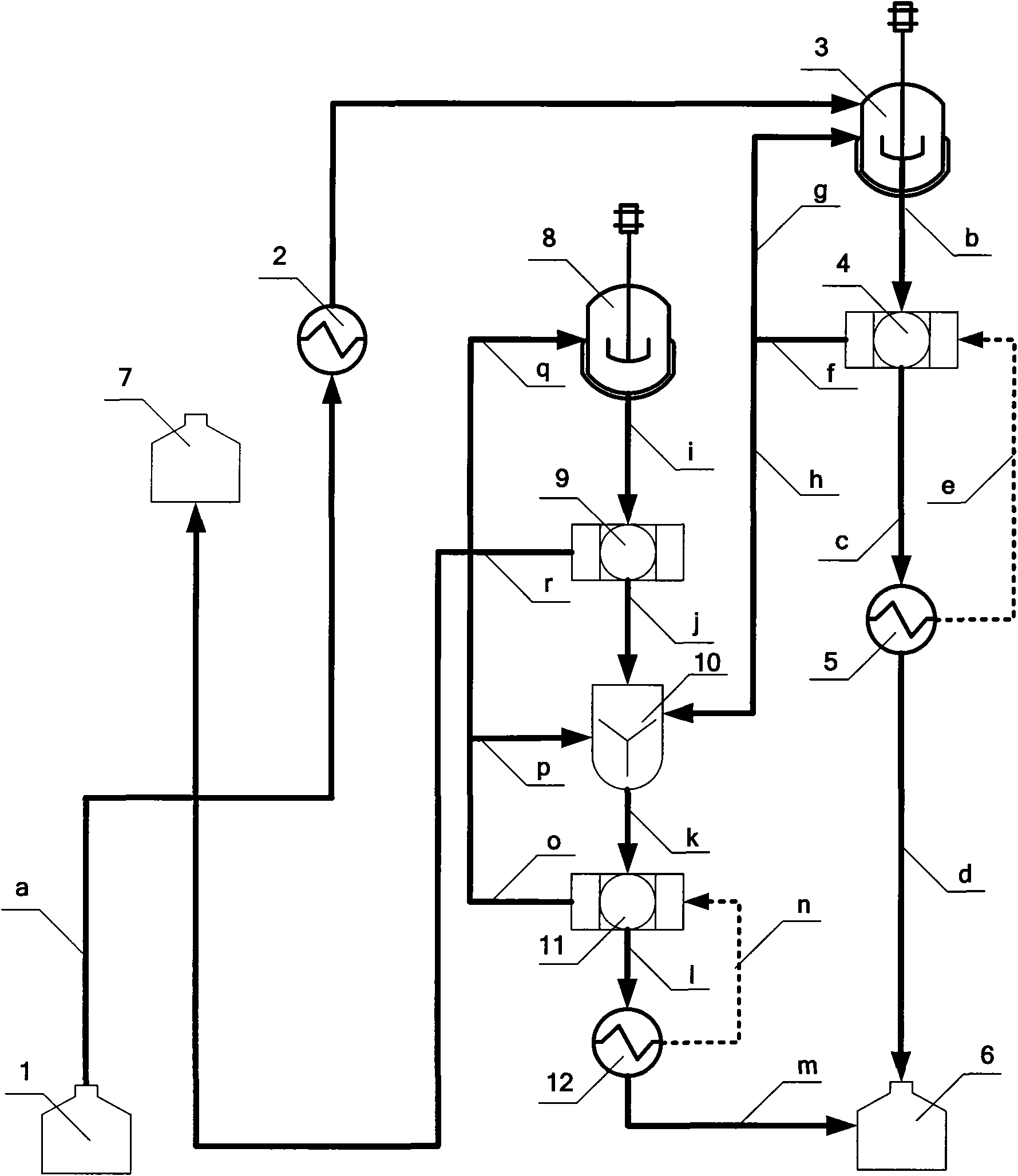

[0018]Existing method for separating p-xylene from mixed xylenes

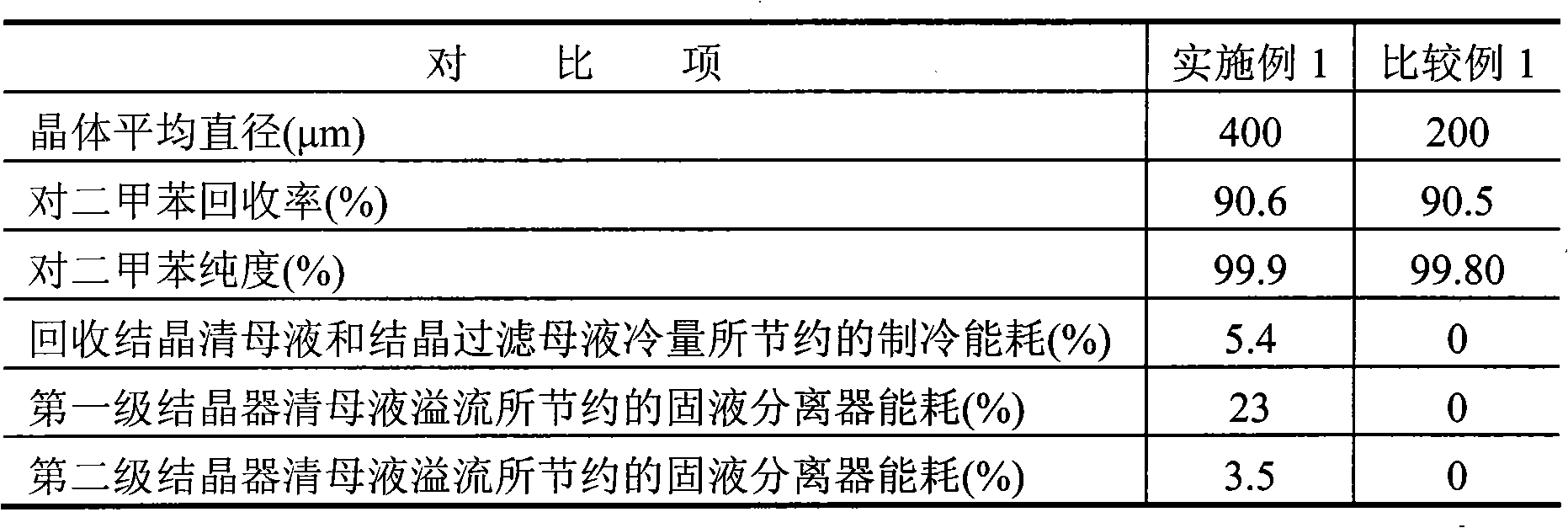

[0019] According to the operating condition of embodiment 1, adopt as figure 2 The result of the method for separating p-xylene by mixed xylene crystallization is listed in Table 1.

[0020] Can find out by comparative example, the method for separating p-xylene by mixed xylene of the present invention has effectively reduced the energy consumption of crystallization separation process, and the cooling capacity of recovery comes from the crystallization clear mother liquor and the crystallization filtration mother liquor of the second stage crystallizer, Among them, the crystal clear mother liquor does not need solid-liquid separation, so the energy consumption of the solid-liquid separator is reduced. The overflow of the crystal clear mother liquor also prolongs the residence time of p-xylene crystals in the crystallizer, and promotes the growth of p-xylene crystals. , which is beneficial to improve the puri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com