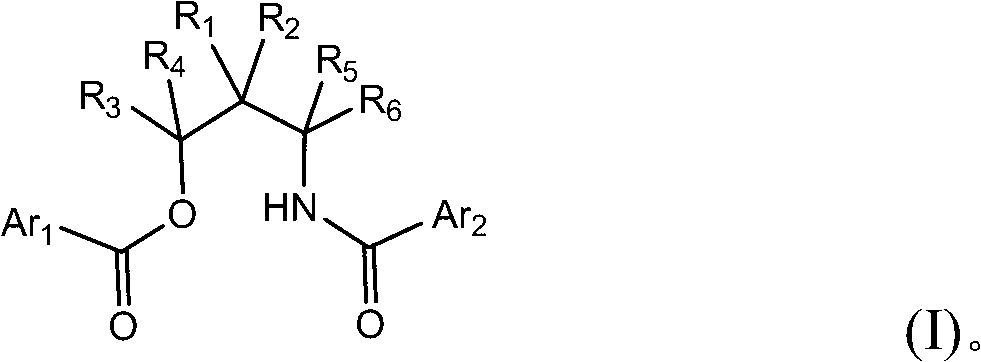

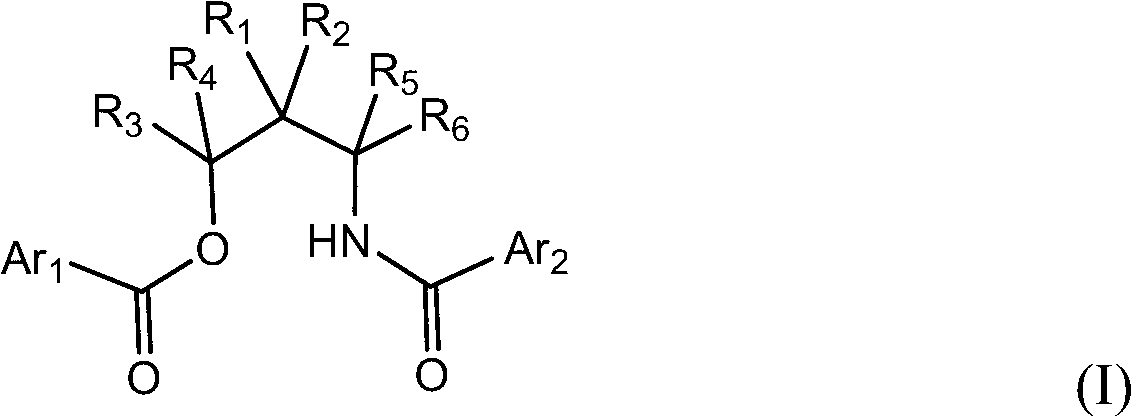

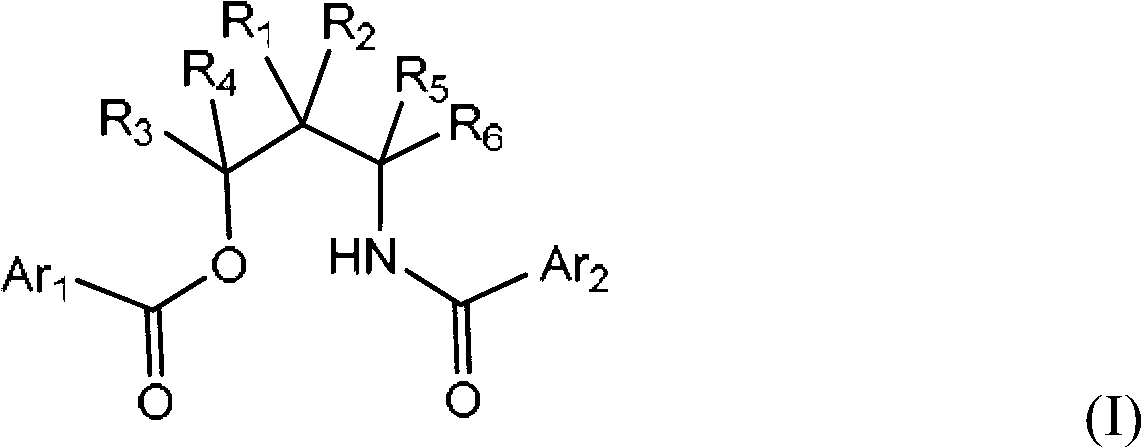

Halogenated amide ester and internal electron donor with same

A technology of halogenated amide ester and halogen, which is applied in the field of halogenated amide ester to achieve the effect of high molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0162] 1. Synthesis of Halogenated Amide Esters

[0163] Ethyl 2-cyano-2-isobutyl-4-methylpentanoate and ethyl 2-cyano-2-isopropyl-3-methylbutanoate:

[0164]

[0165] A 500-ml round bottom flask was equipped with a magnetic stirrer and charged with ethyl 2-cyanoacetate (11.3 g, 0.1 mol) and anhydrous DMF (120 ml). To the stirred solution was added dropwise a solution of 1,8-diazabicyclo[5.4.0]undec-7-ene (DBU) (30.4 g, 0.2 mol, 1.0 equiv) in dry DMF (40 ml). After the addition was complete, the mixture was stirred for another hour. The flask was cooled in an ice-water bath, and a solution of iodide (0.2 mol, 1.0 equiv) in DMF (40 ml) was added dropwise. The mixture was warmed to room temperature and stirred for an additional 14 hours until all starting material was converted to product (monitored by GC). The mixture was poured into ice water, and extracted with diethyl ether. The combined ether extracts were washed with water and brine, dried over magnesium sulfate. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com