Polyvinyl chloride production method adding chain extender to match with later-stage heating process

A technology of polyvinyl chloride and production method, which is applied in the field of polyvinyl chloride production in which a chain extender is added and a post-heating process is used, which can solve problems such as long constant temperature polymerization reaction cycle and influence on enterprise output, and achieve Charpy notched impact strength and The effect of high tensile strength, short reaction cycle and wide molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

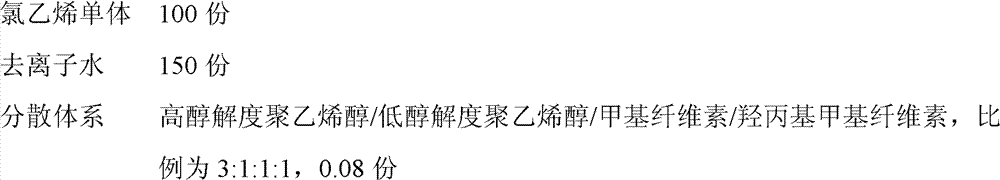

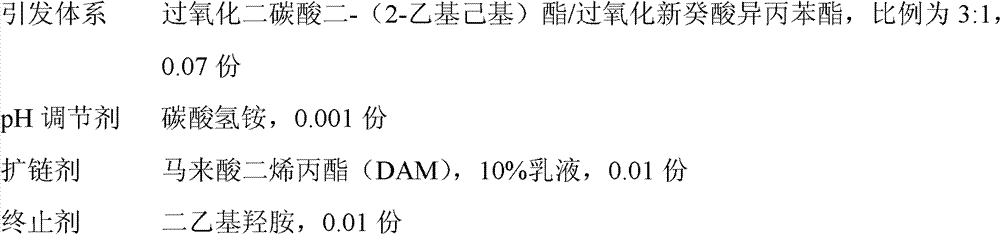

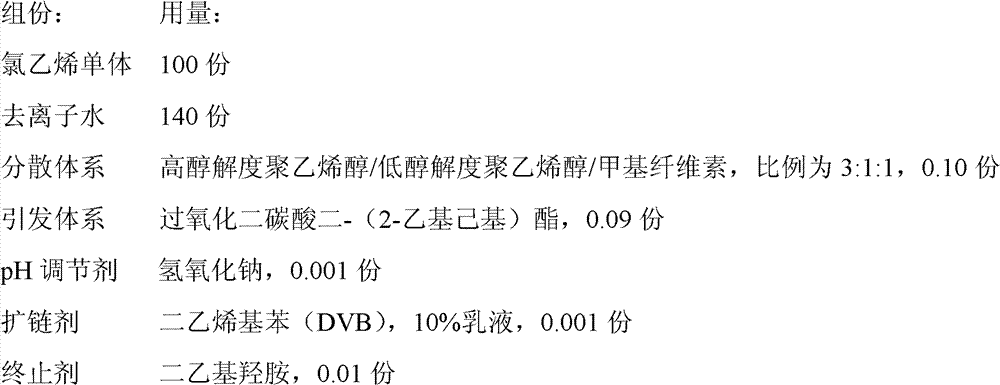

[0031] Components and dosage:

[0032]

[0033]

[0034] The aggregation method is as follows:

[0035] Rinse the polymerization kettle clean, apply anti-sticking agent and rinse, then vacuumize, add deionized water, dispersant, initiator, pH regulator, etc. according to the polymerization formula, and then vacuumize until the vacuum degree is -0.1 Mpa, then add the formula amount of vinyl chloride monomer, stir for 10 minutes, heat up to the first reaction temperature of 55°C and start timing. React for about 2.2 hours, and the polymerization conversion rate reaches about 70%. Use a high-pressure pump to add the chain extender diallyl maleate (DAM) emulsion into the polymerization kettle within 20 minutes, and increase the temperature in the polymerization kettle. The temperature raising speed is 0.8°C / min, reach the second reaction temperature of 65°C, maintain it for a period of time, when the total reaction time reaches 4h and the conversion rate reaches the predete...

Embodiment 2

[0037] After adding the materials, stir coldly for 2 minutes and react for about 2.4 hours. When the polymerization conversion rate reaches about 60%, use a high-pressure pump to add the chain extender diallyl maleate (DAM) emulsion into the polymerization kettle within 20 minutes to extend the chain. The addition amount of diallyl maleate (DAM) emulsion is 1 part. After stirring for 2 minutes, the material was emptied and discharged. All the other components and polymerization method are with embodiment 1.

Embodiment 3

[0039] When the reaction is carried out for about 3.2 hours and the polymerization conversion rate reaches about 50%, the chain extender diallyl maleate (DAM) emulsion is added into the polymerization kettle within 20 minutes with a high-pressure pump, and the chain extender diene maleate The addition amount of propyl ester (DAM) emulsion is 0.7 part. The addition amount of the dispersion system is 0.07 parts, after stirring for 10 minutes, the material is emptied and discharged. All the other components and polymerization method are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com