Synthesis method of high-concentration polyepoxysuccinic acid and salt thereof

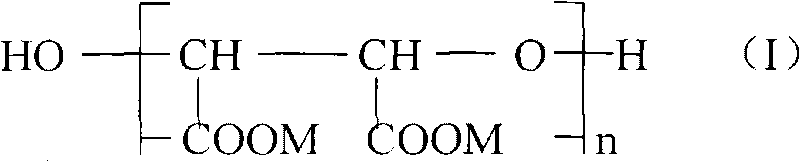

A technology of polyepoxysuccinic acid and synthesis method, applied in the field of synthesis of high-concentration polyepoxysuccinic acid and its salts, can solve the problems of unsatisfactory polymerization molecular weight distribution, poor scale inhibition effect, low polymer concentration and the like , to achieve good industrial operability, ideal molecular weight distribution, simple and unique process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

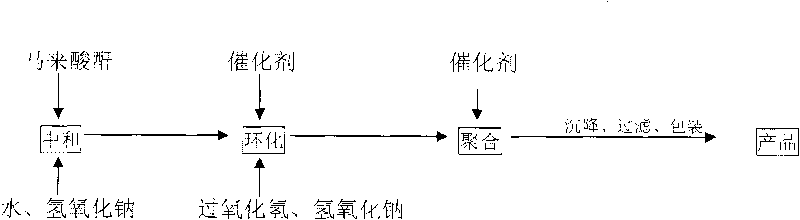

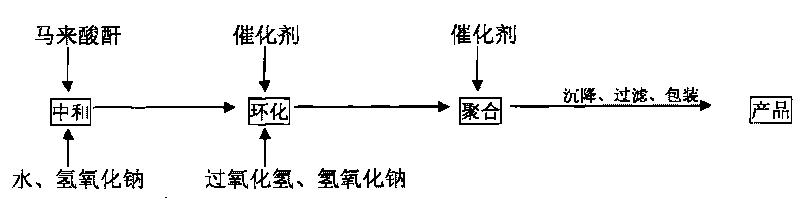

Method used

Image

Examples

Embodiment

[0012] 5000 liter reactor with mechanical agitation, pH meter, heating jacket and cooling brine coil, equipped with two header tanks. Pour 1200 liters of deionized water into the reactor, add 1000 kg of maleic anhydride and 600 kg of sodium hydroxide uniformly within two hours at the same time, and control the reaction temperature to 45 °C by cooling the brine. After adding the material, keep stirring for 1 hour. When the reaction solution is between 56°C, add 60kg of sodium tungstate, heat up to 68°C, start adding 1400kg of hydrogen peroxide (concentration 27.5%), and add 40% sodium hydroxide solution at the same time to control the pH value of the reaction solution at 6 . Stirring was maintained at this temperature for 2 hours after the addition was complete. Raise the temperature to 86°C, add 60kg of calcium oxide, and keep at 90°C for 3 hours. After cooling down and filtering, 4400 kg of polyepoxysuccinic acid and its salt solution products with a nearly colorless appea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com