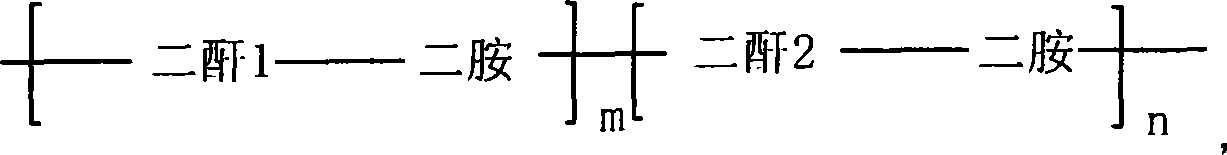

Fluorine-contained polyimide optical waveguide material and method for producing the same

A polyimide light and waveguide technology, which is applied in the directions of optical waveguide, light guide, optics, etc., can solve the problems that do not involve optical loss, refractive index, film forming and mechanical properties, and does not use optical waveguide materials. Good mechanical properties, good solubility and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

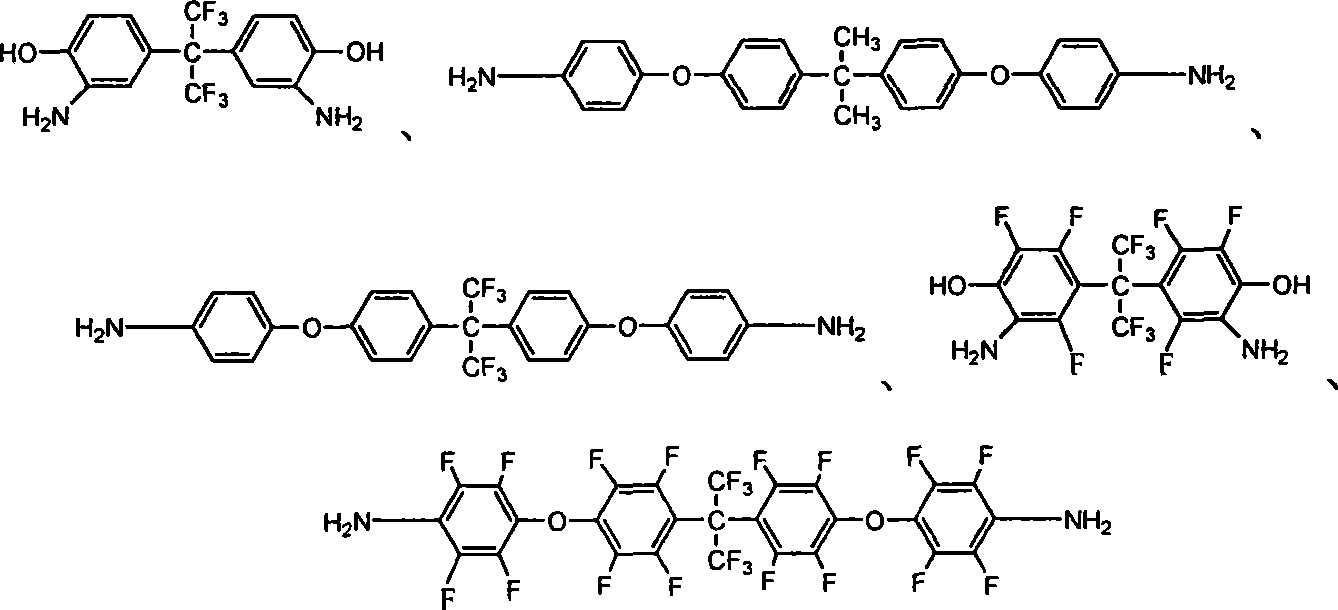

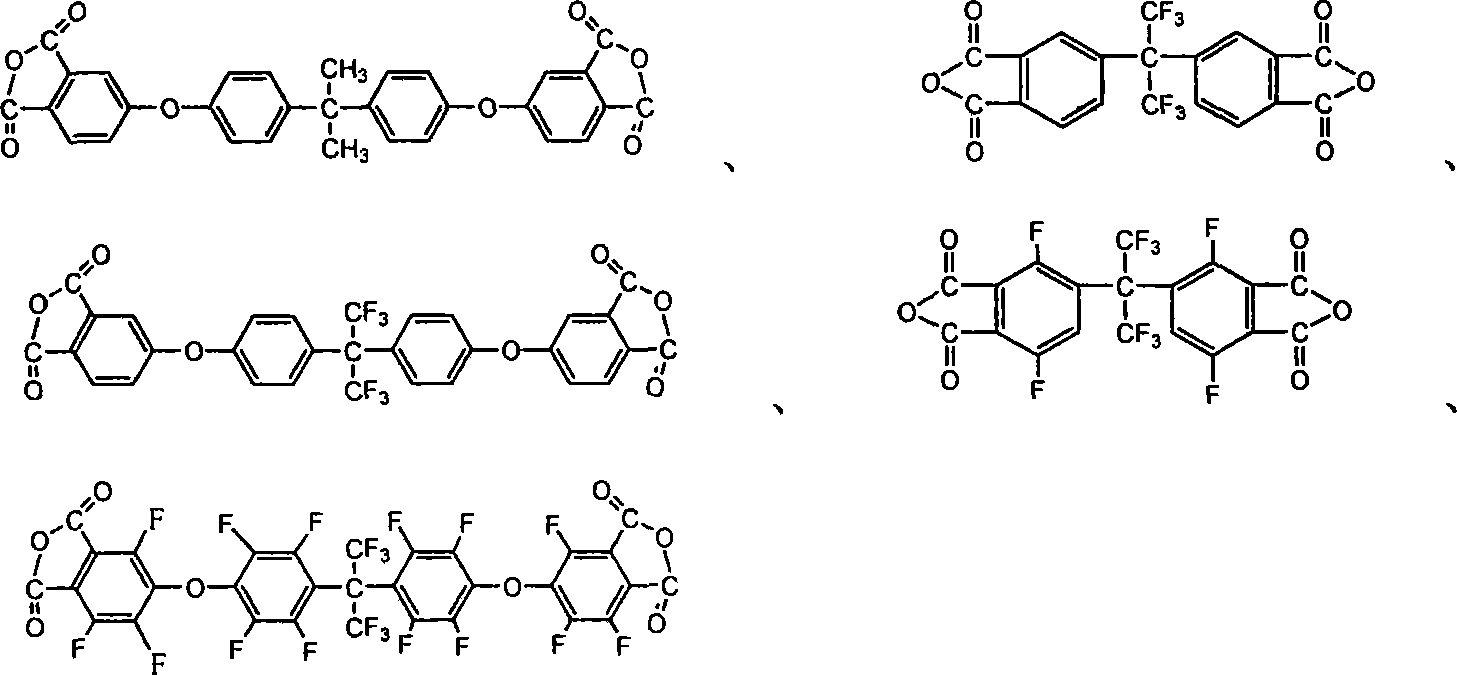

Embodiment 1

[0029] 5,5'-(hexafluoroisopropylidene)-bis-(2-aminophenol) (6FHP) (3mmol), 4,4'-hexafluoroisopropylidene-phthalic anhydride (6FDA) (1.5mmol) and bisphenol A dianhydride (1.5mmol) were dissolved in 5mL DMF, then under nitrogen atmosphere, the 6FHP solution was mixed with the solution of 6FDA and bisphenol A dianhydride, reacted at room temperature for 24h, added 8mL magnesium sulfate and dried xylene, heated up to 160°C, and continued to react for 3-10 hours, and the reaction water and xylene were distilled out azeotropically. After cooling to room temperature, the reacted solution was added dropwise to 200 mL of a mixed solution of methanol / water (1:1) and 2N HCl (2 mL) to precipitate a precipitate, which was filtered to obtain a crude fluorine-containing polyimide. Dissolve the crude fluorine-containing polyimide in 10 mL of tetrahydrofuran, and then add the THF solution dropwise to 200 mL of a mixed solution of methanol / water (1:1) and 2N HCl (2 mL) to precipitate a precipit...

Embodiment 2

[0032] Dissolve 6FDA (3mmol), 6FHP (1.5mmol) and bisphenol A diamine (1.5mmol) in 5mL DMF respectively, then mix 6FDA solution with 6FHP and bisphenol A diamine solution under nitrogen atmosphere, and react at room temperature for 24h , add 8 mL of magnesium sulfate dried xylene, raise the temperature to 160°C, continue the reaction for 3-10 hours, and distill off the reaction water and xylene azeotropically. After cooling to room temperature, the reacted solution was added dropwise to 200 mL of a mixed solution of methanol / water (1:1) and 2N HCl (2 mL) to precipitate a precipitate and filter to obtain a crude fluorine-containing polyimide. Dissolve the crude product of fluorine-containing polyimide in 10 mL of tetrahydrofuran, and then add this tetrahydrofuran solution dropwise to 200 mL of a mixed solution of methanol / water (1:1) and 2N HCl (2 mL) to precipitate precipitates. Reflux the precipitate with methanol in the extractor to purify the precipitate, evaporate the extra...

Embodiment 3

[0035] 6FHP (3 mmol), 6FDA (1.5 mmol) and fluorine-containing bisphenol A dianhydride (1.5 mmol) were dissolved in 5 mL of DMF, respectively. Then, under a nitrogen atmosphere, mix the 6FHP solution with the solution of 6FDA and fluorine-containing bisphenol A dianhydride, react at room temperature for 24 hours, add 8 mL of magnesium sulfate dried xylene, raise the temperature to 160°C, and continue the reaction for 3 to 10 hours. Water and xylene were distilled off azeotropically. After cooling to room temperature, the reacted solution was added dropwise to 200 mL of a mixed solution of methanol / water (1:1) and 2N HCl (2 mL) to precipitate a precipitate and filter to obtain a crude fluorine-containing polyimide. Dissolve the crude product of fluorine-containing polyimide in 10 mL of tetrahydrofuran, and then add this tetrahydrofuran solution dropwise to 200 mL of a mixed solution of methanol / water (1:1) and 2N HCl (2 mL) to precipitate precipitates. Reflux the precipitate wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com