Prepn. of PVF

A technology of polyvinyl fluoride and vinyl fluoride, which is applied in the field of preparation of polyvinyl fluoride, can solve the problems of difficulty in obtaining polyvinyl fluoride resin and low polymerization activity of vinyl fluoride, and achieve improved catalyst and equipment use efficiency and good film-forming performance , Increase the effect of melting temperature and heat of fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Example 1) Add 6,000 parts of distilled water into a 10-liter polymerization reactor, stir and heat to 30°C, add 1,000 parts of distilled water, 1 part of azobisisobutylamidine hydrochloride and 25 parts of potassium chloride into the batching kettle, and stir After uniformity, add to the polymerization reactor, raise the temperature of the polymerization reactor to 100°C quickly, and use a metering pump to input vinyl fluoride monomer, keep the pressure in the polymerization reactor between 25.0 and 28.0MPa, react for 2.5 hours to cool down, and recover the unreacted monomer body, discharged to obtain white foam powder, filtered, washed and dried to obtain 985 parts of white powder. The product was dissolved in N,N-dimethylformamide at 110°C, and the measured intrinsic viscosity of the polymer was 1.51dL / g.

Embodiment 2

[0014] Example 2) Add 6,000 parts of distilled water to a 10-liter polymerization reactor, stir and heat to 30°C, add 1,000 parts of distilled water, 1 part of azobisisobutylamidine hydrochloride and 25 parts of potassium hydroxide to the batching kettle, and stir After uniformity, add to the polymerization reactor, raise the temperature of the polymerization reactor to 100°C quickly, and use a metering pump to input vinyl fluoride monomer, keep the pressure in the polymerization reactor between 25.0 and 28.0MPa, react for 2.5 hours to cool down, and recover the unreacted monomer body, discharged to obtain white fine spherical particles, filtered, washed and dried to obtain 1320 parts of white powder. The product was dissolved in N,N-dimethylformamide at 110°C, and the measured intrinsic viscosity of the polymer was 1.35 dL / g.

Embodiment 3

[0015] Example 3) Add 6,000 parts of distilled water into a 10-liter polymerization reactor, stir and heat to 30°C, add 1,000 parts of distilled water, 1 part of azobisisobutylamidine hydrochloride and 25 parts of hydrochloric acid into the batching kettle, and stir evenly Add the polymerization reactor, raise the temperature of the polymerization reactor to 100°C quickly, and use a metering pump to input vinyl fluoride monomer, keep the pressure in the polymerization reactor between 25.0 and 28.0MPa, react for 2.5 hours to cool down, and recover the unreacted monomer. Discharge to obtain white foam powder, filter, wash and dry to obtain 311 parts of white powder. The product was dissolved in N,N-dimethylformamide at 110°C, and the measured intrinsic viscosity of the polymer was 1.82dL / g.

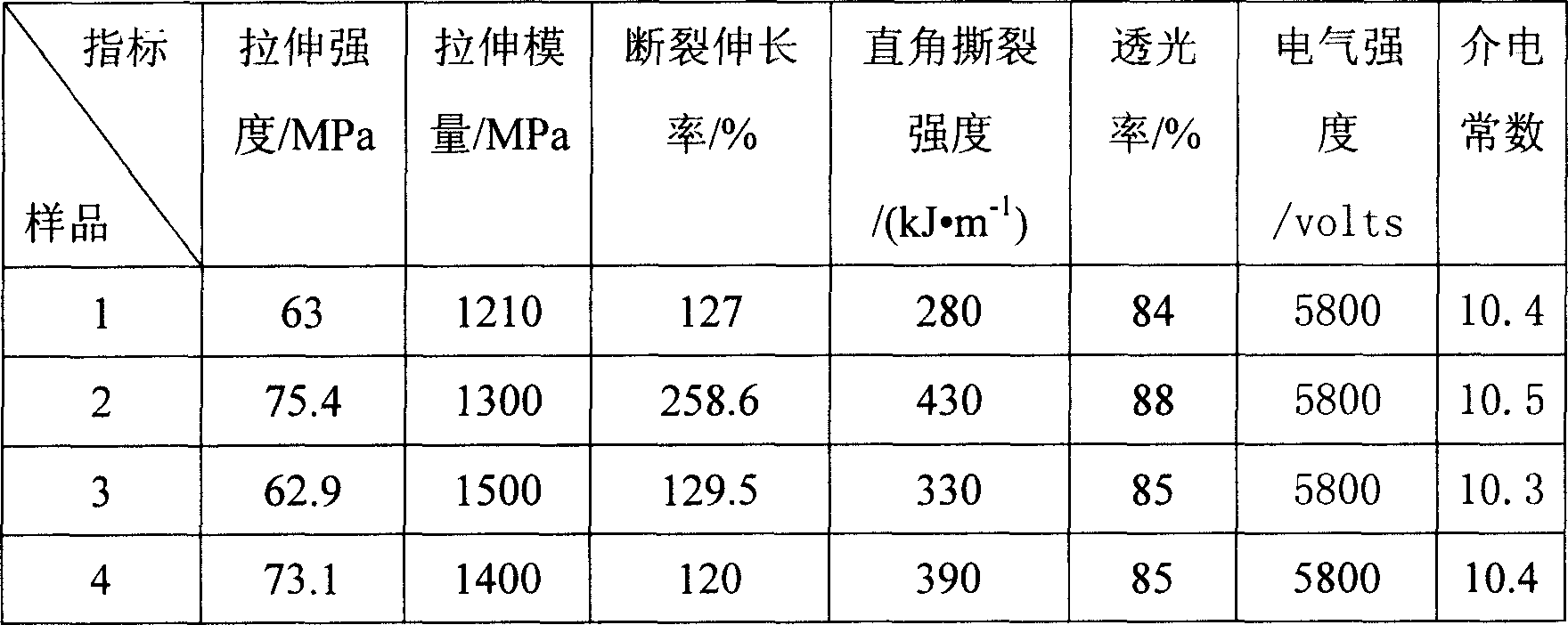

[0016] Polyvinyl fluoride was melted and extruded by latent solvent N,N-dimethylformamide to form a biaxially stretched film and then tested according to GB530-88, GB13022-91, GB / T2410-1980...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com