Process for producing polyester

A production method and polyester technology, applied in the field of chemical catalysts, can solve the problems of decreased thermal stability, yellow color of polyester, unsatisfactory color of polyester, etc., and achieve the effect of good electrostatic adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

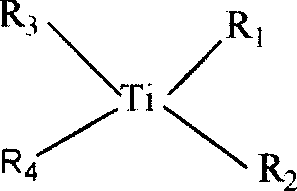

[0029] The invention relates to a method for producing polyester, which is prepared from reactants used to produce polyester in the presence of a catalyst. The catalyst is composed of titanium compound, phosphorus compound and magnesium compound, and the titanium compound is a chelated titanium compound of lactic acid.

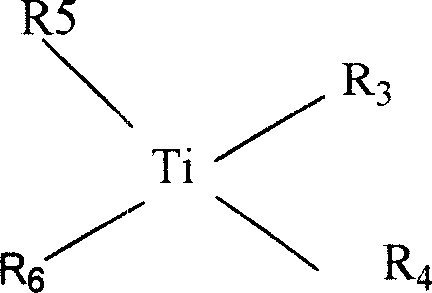

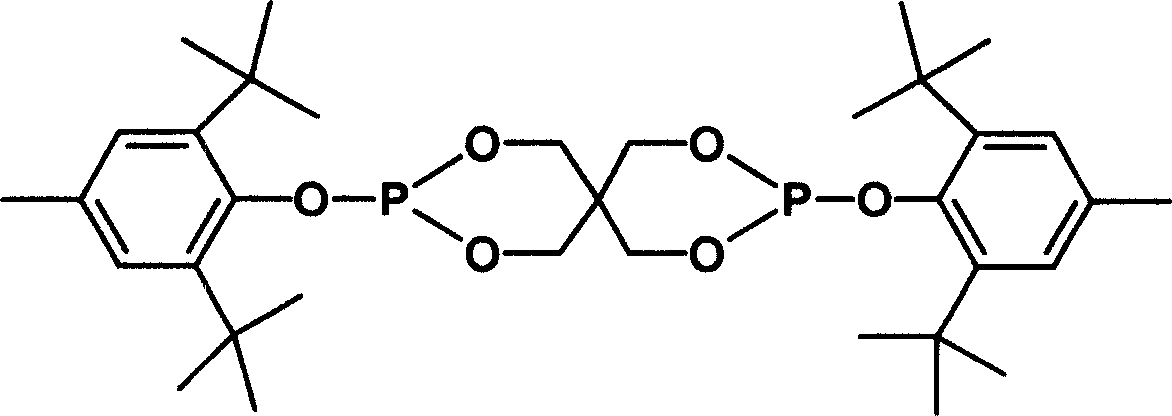

[0030] Phosphorus-containing compounds are compounds of the formula:

[0031]

[0032] The magnesium compound is magnesium oxalate (or magnesium propionate, magnesium malonate, magnesium succinate, magnesium acetate, magnesium stearate, magnesium hydroxide, magnesium sulfate, magnesium chloride).

[0033] The reaction formula for producing polyester is expressed as:

[0034] catalyst

[0035] A+B-------------------Polyester

[0036] Wherein A, B are the reactant of conventional production polyester.

[0037] A is terephthalic acid (also can be isophthalic acid, phthalic acid, methyl terephthalic acid, naphthalene dicarboxylic acid, bipheny...

Embodiment 2

[0053] The consumption of catalyzer is: the addition relative to polyester weight is:

[0054] The addition of titanium element in the titanium compound is 10ppm

[0055] The amount of phosphorus added in the phosphorus compound is 5ppm

[0056] The amount of magnesium added in the magnesium compound is 17ppm

[0057] The amount of dyestuff is: the addition amount of cobalt element in cobalt acetate is 25ppm

[0058] All the other are with embodiment 1.

Embodiment 3

[0060] The consumption of catalyzer is: the addition relative to polyester weight is:

[0061] The addition of titanium element in the titanium compound is 10ppm

[0062] The amount of phosphorus added in the phosphorus compound is 7.5ppm

[0063] The amount of magnesium added in the magnesium compound is 22ppm

[0064] The amount of dyestuff is: the addition amount of cobalt element in cobalt acetate is 25ppm

[0065] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com