Preparing method of polyacrylonitrile (PAN) used for carbon fiber

A polymer, carbon fiber technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the adverse effects of PAN polymer thermal stability spinnable fibers physical properties, affect the spinnability and the improvement of pre-oxidation controllability effect, uneven distribution and other problems, to achieve the effect of shortening the polymerization reaction time, low cost and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

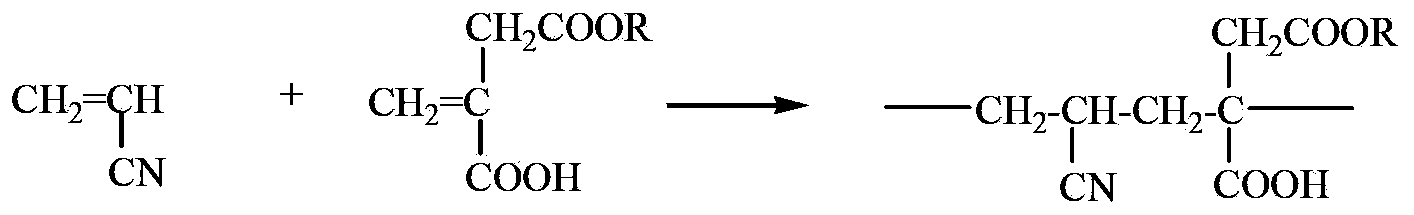

Method used

Image

Examples

Embodiment 1

[0028] Deionized water, acrylonitrile, monomethyl itaconate, ammonium persulfate, sodium bisulfite, and ferrous sulfate were weighed and then added to a polymerization kettle with a stirrer and a jacketed constant temperature water system. Taking the quality of water as a benchmark, the mass percentage of acrylonitrile relative to water is 20%, the relative mass percentage of itaconate monomethyl ester to acrylonitrile is 8%, the relative mass percentage of ammonium persulfate to acrylonitrile is 0.6%, hydrogen sulfite The mass percentage of sodium relative to acrylonitrile is 0.8%, and the mass ratio of ferrous sulfate to acrylonitrile is 1 ppm. Sulfuric acid was used to adjust the pH value to 2.5, and the reaction was carried out for 50 min at a temperature of 58° C. and a stirring speed of 60 rpm. After the reaction, the pH value of the polymerization system was adjusted to 8.5 with ammonia water. Then filter, wash and dry to obtain PAN polymer powder.

[0029] After test...

Embodiment 2

[0032] Deionized water, acrylonitrile, monoethyl itaconate, ammonium persulfate, sodium bisulfite, and ferrous sulfate were weighed and then added to a polymerization kettle with a stirrer and a jacketed constant temperature water system. Taking the quality of water as a benchmark, the relative mass percentage of acrylonitrile to water is 22%, the relative mass percentage of itaconate monoethyl ester to acrylonitrile is 4%, the relative mass percentage of ammonium persulfate to acrylonitrile is 0.7%, hydrogen sulfite The mass percentage of sodium relative to acrylonitrile is 1.2%, and the mass ratio of ferrous sulfate to acrylonitrile is 3ppm. Sulfuric acid was used to adjust the pH value to 3.5, and the reaction was carried out for 70 min at a temperature of 60° C. and a stirring speed of 80 rpm. After the reaction, the pH value of the polymerization system was adjusted to 9 with ammonia water. Then filter, wash and dry to obtain PAN polymer powder.

[0033] After testing, ...

Embodiment 3

[0036] Add deionized water, acrylonitrile, mono-n-propyl itaconate, ammonium persulfate, sodium bisulfite, ferrous sulfate, and weigh them in sequence to a polymerization kettle with a stirrer and a jacketed constant temperature water system. Taking the quality of water as a benchmark, the relative mass percentage of acrylonitrile to water is 24%, the relative mass percentage of itaconate mono-n-propyl ester to acrylonitrile is 2%, the relative mass percentage of ammonium persulfate to acrylonitrile is 1.6%, sulfurous acid The mass percentage of sodium hydrogen relative to acrylonitrile is 1.8%, and the mass ratio of ferrous sulfate to acrylonitrile is 5ppm. Sulfuric acid was used to adjust the pH value to 2.5, and the reaction was carried out for 50 min at a temperature of 62° C. and a stirring speed of 100 rpm. After the reaction, the pH value of the polymerization system was adjusted to 10 with ammonia water. Then filter, wash and dry to obtain PAN polymer powder.

[0037...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com