Preparation method of poly(carbonic ester-ether)polyol

一种多元醇、碳酸酯的技术,应用在聚合物领域,能够解决浪费生产原料、反应时间延长、达不到生产的要求等问题,达到减少时间、诱导期短、反应时间短的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a kind of preparation method of poly(carbonate-ether) polyol, comprising:

[0025] reacting carboxylic acid and epoxide to obtain an intermediate product; the acidity constant of the carboxylic acid is 0.2-4;

[0026] in Zn 3 [Co(CN) 6 ] 2 Under the action of the rare earth doped double metal cyanide, the intermediate product and carbon dioxide are polymerized to obtain poly(carbonate-ether) polyol;

[0027] The Zn 3 [Co(CN) 6 ] 2 The rare earth doped double metal cyanide is composed of rare earth salt compound, zinc salt compound, K 3 [Co(CN) 6 ] and tert-butanol prepared.

[0028] The invention reacts carboxylic acid and epoxide to obtain an intermediate product; the acidity constant of the carboxylic acid is 0.2-4. In an embodiment of the present invention, the reaction temperature of the carboxylic acid and the epoxide is 40°C to 150°C; in other embodiments, the reaction temperature of the carboxylic acid and the epoxide is 60°C to 12...

Embodiment 1

[0039] 0.78g of YCl 3 and 11.42g of ZnCl 2 Dissolve in a mixed solution formed by 60 mL of deionized water and 30 mL of tert-butanol, heat the mixed solution to 50 °C and keep the temperature for 20 min, and add 1.32 g of Analytical grade K 3 [Co(CN) 6 ] and 20mL of deionized water, the reaction time is 45min, and the reaction is carried out at 50°C. After the dropwise addition, continue to stir at 50°C for 1h to obtain a suspension;

[0040] Centrifuge the suspension at a speed of 5000 rpm for 10 min with a centrifuge, pour out the separated clear liquid, and wash the sediment with 60 mL of a mixed solution of tert-butanol and water at 50 ° C for 5 times, and finally Wash once with tert-butanolized pulp, the volume ratios of tert-butanol and water in the mixed solution of tert-butanol and water are 30 / 30, 36 / 24, 42 / 18, 48 / 12, 54 / 6, respectively. The stirring speed is 300rpm, and the washing time of each pulping is 10min. The suspension after each pulping is centrifuged wi...

Embodiment 2

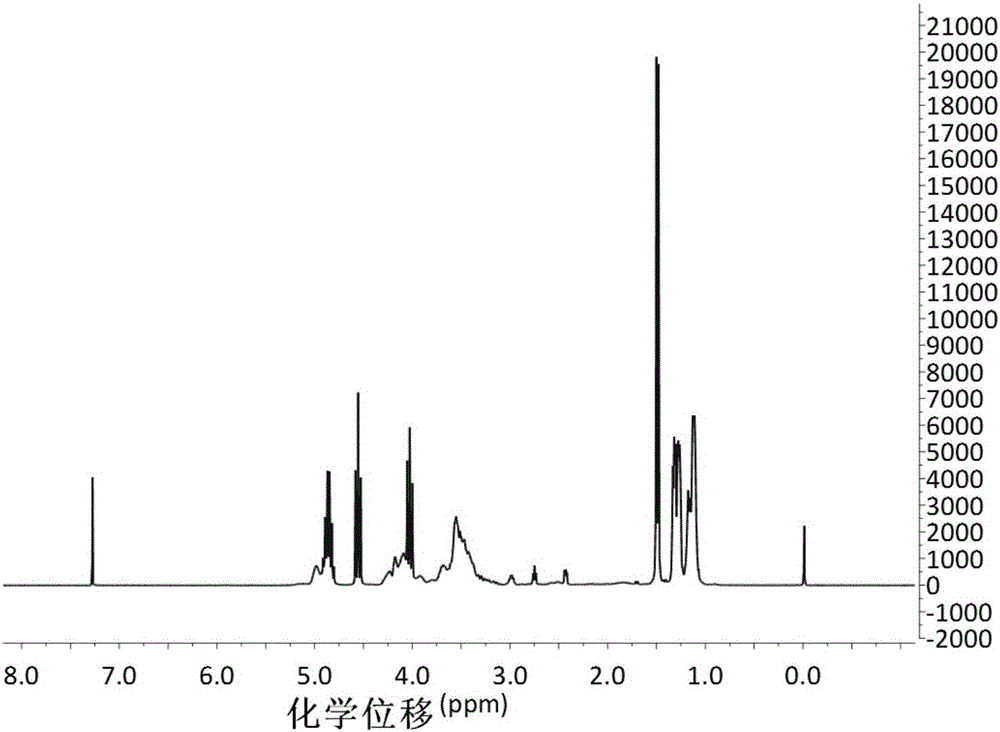

[0042] Place the weighing bottle at 80°C and fill it with CO 2 gas for 6 times, and the weighing bottle was cooled to room temperature, and the above-mentioned weighing bottle was used to weigh trifluoroacetic acid, and the autoclave was evacuated at 80°C to 2 The gas was treated 6 times and then cooled to room temperature, 8g of trifluoroacetic acid was added into the above-mentioned autoclave, 100mL of propylene oxide was added into the autoclave, stirred at a speed of 500rpm, and the autoclave was placed in a constant temperature of 70°C. Carry out reaction in warm bath, the time of reaction is 5min, obtains intermediate product;

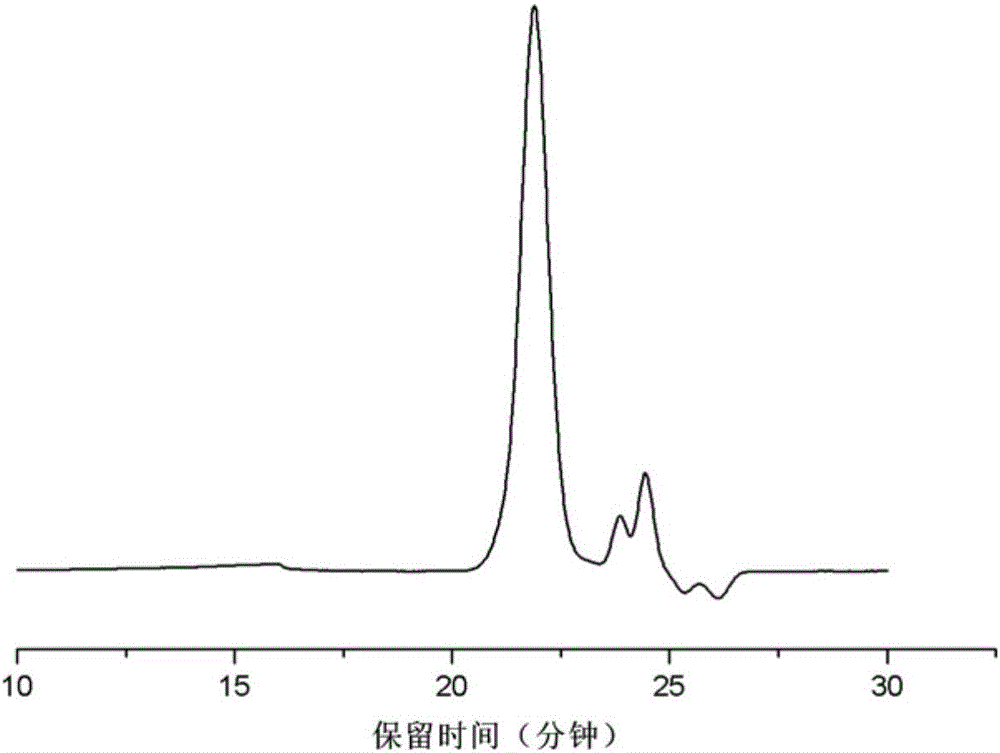

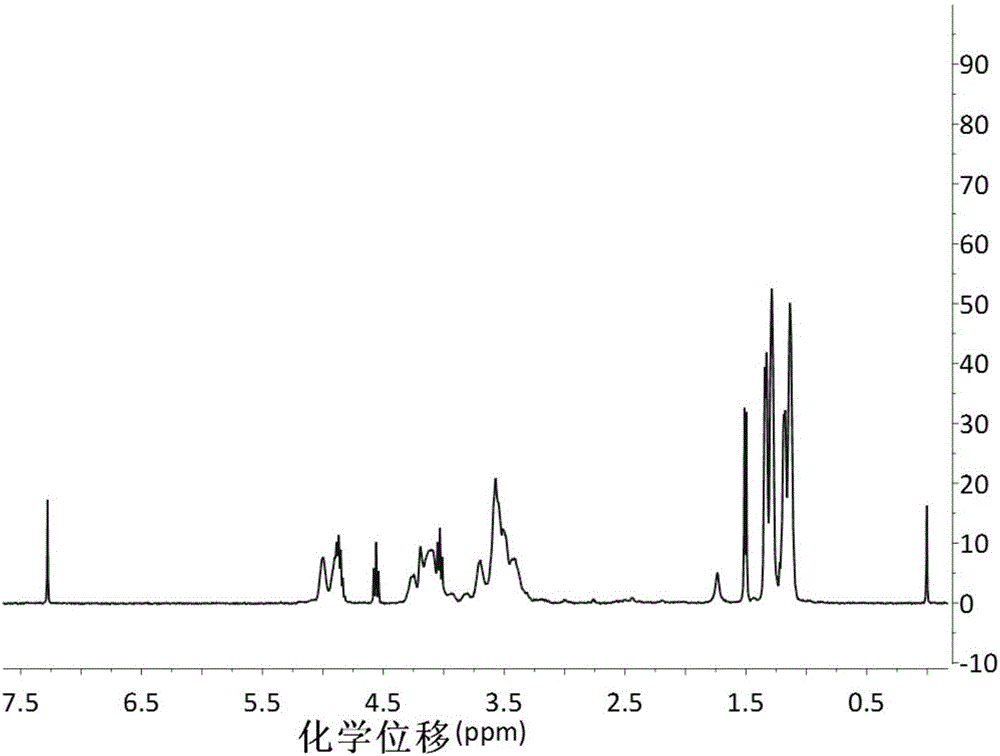

[0043] The Zn that 60mg embodiment 1 prepares 3 [Co(CN) 6 ] 2 The rare earth-doped double metal cyanide compound is added in the above-mentioned autoclave, and carbon dioxide is passed into the above-mentioned autoclave to make the above-mentioned intermediate product and carbon dioxide carry out polymerization reaction, and the reaction press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com