Method for modifying polyvinylidene fluoride microporous film to be protein contamination resistant

A polyvinylidene fluoride, microporous membrane technology, applied in the direction of fiber type, textile and paper making, fiber processing, etc. Fluorinated vinyl microporous membrane and other problems, to achieve the effect of good surface modification, strong anti-protein pollution, high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

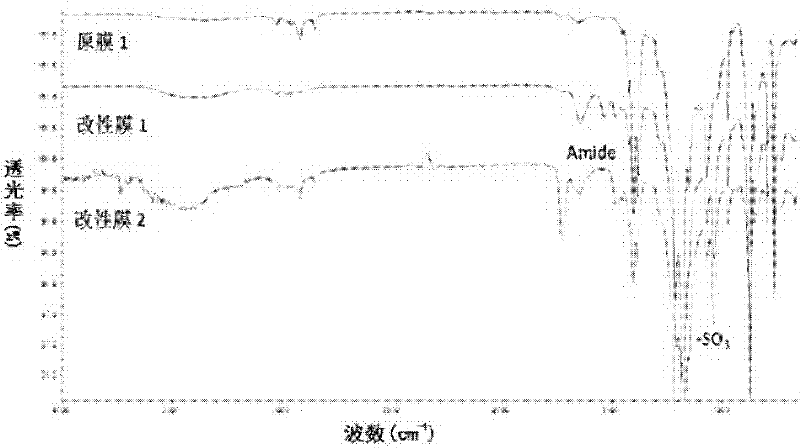

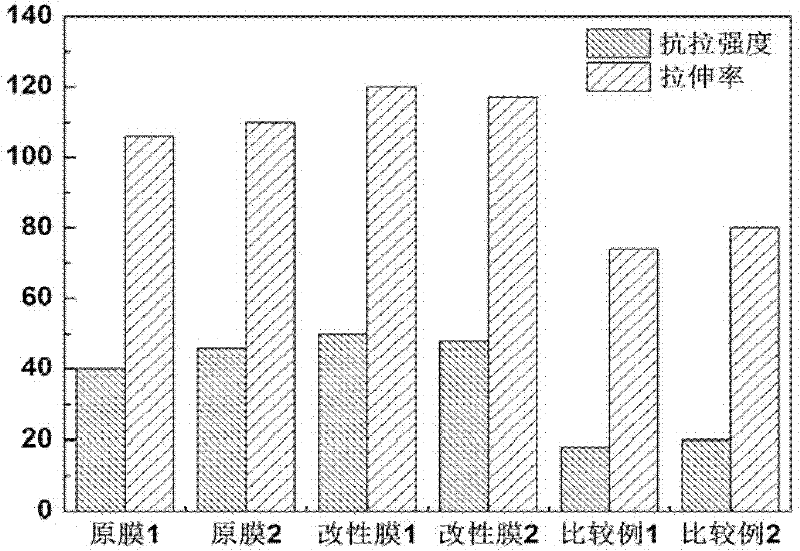

Image

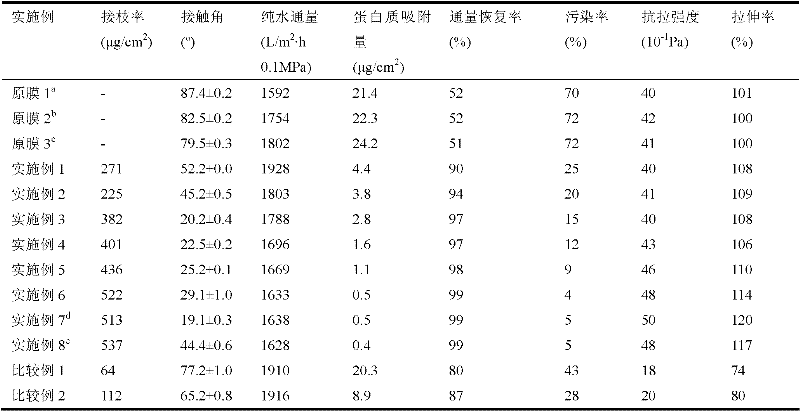

Examples

Embodiment 1

[0021] Put the polyvinylidene fluoride flat microporous membrane into the reaction kettle after methanol pretreatment, and under the protection of nitrogen, mix hydroxyethyl methacrylate: copper fluoride / cuprous fluoride: pentamethyldialkylenetriamine : Distilled water with a weight ratio of 600: 1.5 / 1.5: 2: 1000 was added to the reaction kettle, reacted at 40° C. for 1 hour at a constant temperature, and the film was taken out, washed successively with distilled water, and vacuum-dried. These membranes are then placed in a sodium ion mixture containing sodium ammonium nitrate, nitric acid, methylenebisacrylamide, 3-(methacrylamide)propyl-dimethyl(3-sulfopropyl)amine and distilled water, wherein the mass percentages of sodium ammonium nitrate and nitric acid are 0.1% and 4% respectively, the mass percentage of methylenebisacrylamide is 0.1%, 3-(methacrylamide) propyl-dimethyl (3- The mass percent of sulfopropyl) amine is 1%. React at 40° C. for 1 hour under the protection of ...

Embodiment 2

[0023]Put the polyvinylidene fluoride roll-type microporous membrane into the reactor after methanol pretreatment, under the protection of nitrogen, mix hydroxypropyl methacrylate: cupric chloride / cuprous chloride: bipyridine: distilled water according to the weight ratio of The solution of 700:1 / 1:1.5:1000 was added into the reaction kettle, and the reaction was carried out at a constant temperature of 50°C for 10 hours. The membrane was taken out, washed successively with distilled water, and dried in vacuum. These membranes are then placed in a mixed solution of cerium ions, which contains ammonium cerium nitrate, nitric acid, vinylbisacrylamide, 3-[N,N-dimethyl-[2-(2-methylpropane-2 -alkenoyloxy)ethyl]ammonium]propane-1-sulfonic acid inner salt and distilled water, wherein the mass percentages of ceric ammonium nitrate and nitric acid are 5% and 2% respectively, and the mass percentage of vinylbisacrylamide is 2% , The mass percent of 3-[N,N-dimethyl-[2-(2-methylprop-2-eno...

Embodiment 3

[0025] Put the polyvinylidene fluoride hollow fiber microporous membrane into the reactor after pretreatment with methanol, under the protection of nitrogen, adjust the weight ratio of hydroxybutyl methacrylate: copper bromide / cuprous bromide: ethylenediamine: distilled water The ratio of 800:0.5 / 0.5:1:1000 was added to the reaction kettle, and the temperature was kept at 60°C for 6 hours. The membrane was taken out, washed with distilled water in sequence, and dried in vacuum. These films are put into sodium ion mixed solution again, there are sodium ammonium phosphate, phosphoric acid, carbodiimide, dodecyl ethoxy betaine and distilled water in this solution, wherein the mass percent of sodium ammonium phosphate and phosphoric acid are respectively 3% and 0.1%, the mass percentage of carbodiimide is 1%, and the mass percentage of dodecyl ethoxy betaine is 8%. React at 60° C. for 3 hours under the protection of nitrogen, take out the membrane, wash it with phosphate buffer so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com