Nano-sheet lithium-rich cathode material and preparation method and application thereof

A lithium-rich cathode material and nanosheet technology, applied in the field of materials, can solve the problems of low coulombic efficiency, low first-cycle charge and discharge capacity, poor cycle performance, etc., and achieve shortened lithium ion transmission channels and novel morphology and structure. , good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

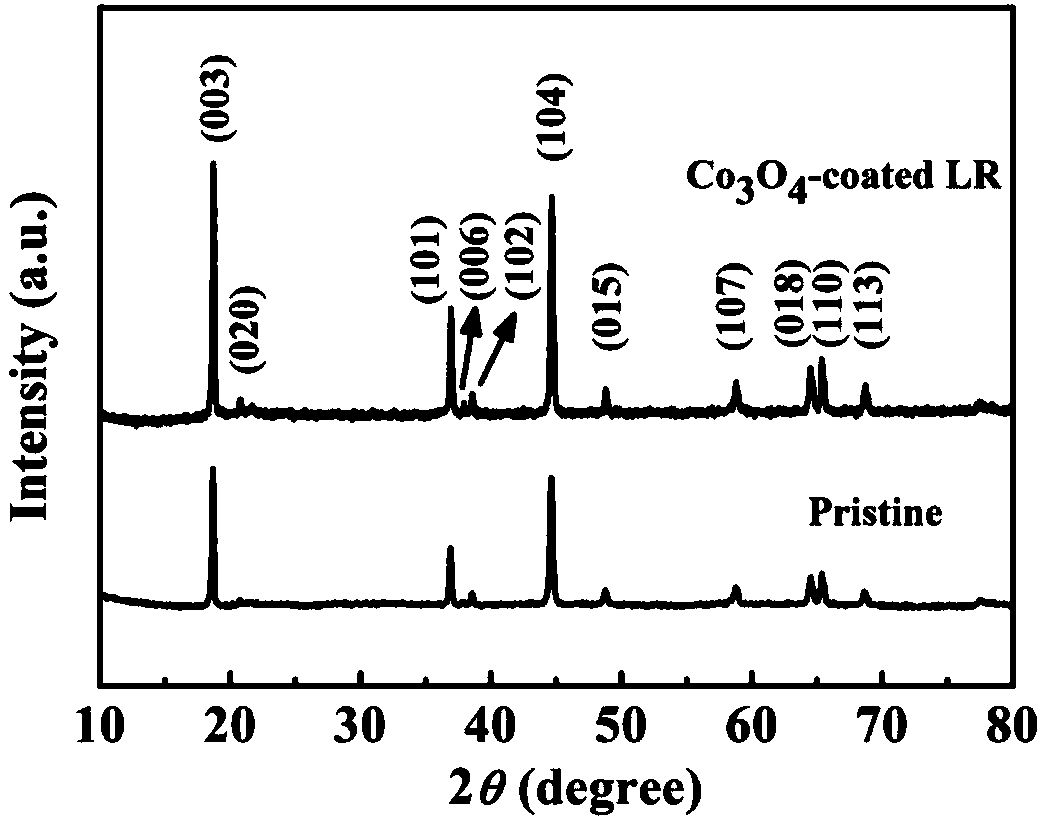

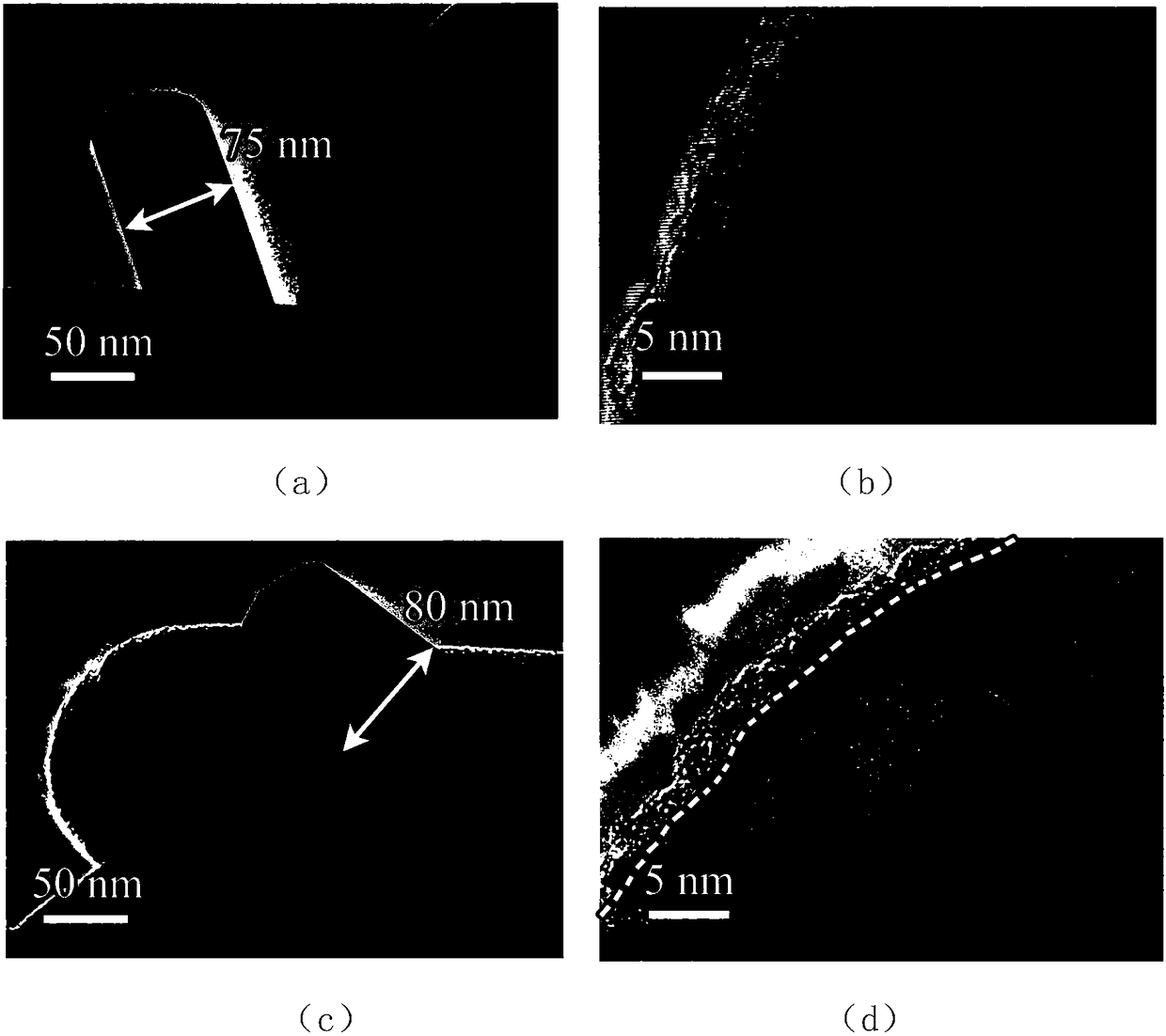

[0043] Example 1: Preparation of Nanosheet Lithium-rich Cathode Material

[0044] NiSO 4 ·6H 2 O. CoSO 4 ·7H 2 O and MnSO 4 ·H 2 O was dissolved in deionized water at a stoichiometric ratio of 1:1:4 to prepare a 2mol / L mixed metal ion sulfate solution A; NaOH was dissolved in deionized water to prepare a 4mol / L solution B; Dissolve in deionized water and prepare 0.5mol / L solution C; add solutions A, B and C to the co-precipitation reactor at the same time with a peristaltic pump under an inert gas environment, at a pH of 10.8 and a temperature of 60°C , stirred at 500rpm for 10 hours; the solid product obtained after stirring was centrifugally cleaned 5 times with deionized water, and then vacuum-dried to obtain the hydroxide precursor D; the precursor D was mixed with Li 2 CO 3 Mix evenly and place in a corundum boat for calcination. First, pre-calcine at 500°C for 5h, then calcinate at 850°C for 15h. The heating rate is 2°C / min, thereby preparing a lithium-rich cathode ...

Embodiment 2

[0045] Example 2: Preparation of Nanosheet Lithium-rich Cathode Material

[0046] NiSO 4 ·6H 2 O. CoSO 4 ·7H 2 O and MnSO 4 ·H 2 O was dissolved in deionized water at a stoichiometric ratio of 1:1:4 to prepare a 2mol / L mixed metal ion sulfate solution A; NaOH was dissolved in deionized water to prepare a 4mol / L solution B; Dissolve in deionized water and prepare 0.5mol / L solution C; add solutions A, B and C to the co-precipitation reactor at the same time with a peristaltic pump under an inert gas environment, at a pH of 11 and a temperature of 50°C , and stirred at 400rpm for 8 hours; the solid product obtained after stirring was centrifugally cleaned 5 times with deionized water, and then vacuum-dried to obtain the hydroxide precursor D; the precursor D was mixed with Li 2 CO 3 Mix evenly, and place in a corundum boat for calcination treatment. First, pre-calcine at 400°C for 6h, and then calcinate at 900°C for 12h. The heating rate is 2°C / min, thereby preparing the n...

Embodiment 3

[0047] Example 3: Preparation of Nanosheet Lithium-rich Cathode Material

[0048] NiSO 4 ·6H 2 O. CoSO 4 ·7H 2 O and MnSO 4 ·H 2 O was dissolved in deionized water at a stoichiometric ratio of 1:1:4 to prepare a 2mol / L mixed metal ion sulfate solution A; NaOH was dissolved in deionized water to prepare a 4mol / L solution B; Dissolve in deionized water and prepare 0.5mol / L solution C; Add solutions A, B and C to the co-precipitation reactor at the same time with a peristaltic pump under an inert gas environment, at a pH of 10.5 and a temperature of 70°C , and stirred at 1000rpm for 12 hours; the solid product obtained after stirring was centrifugally cleaned 5 times with deionized water, and then vacuum-dried to obtain the hydroxide precursor D; the precursor D was mixed with Li 2 CO 3 Mixed evenly, and placed in a corundum boat for calcination treatment, first pre-calcined at 600°C for 4h, then calcined at 800°C for 18h, with a heating rate of 2°C / min, thereby preparing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com