Easy-to-disperse sericite for cosmetics and preparation method thereof

An easy dispersibility, cosmetic technology, applied in the direction of dyeing organosilicon compound treatment, dyeing low molecular organic compound treatment, fibrous filler, etc., can solve problems such as easy peeling, and achieve reduced aggregation, refreshing skin feel, and excellent gloss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Add 200g of sericite powder for cosmetics (Chuzhou Gerui) into the high-speed mixer, stir and disperse under the rotating speed of 1000rpm, when the temperature reaches 70°C, add the surface treatment agent ( The mass ratio of N-octyltriethoxysilane: polymethylhydrogensiloxane: polydimethylsiloxane: isopropanol = 25:25:50:100), after continuing to stir for 1h, use an electric heating drum Air drying oven aged at 105°C for 1 hour to obtain sericite for cosmetics with easy dispersibility.

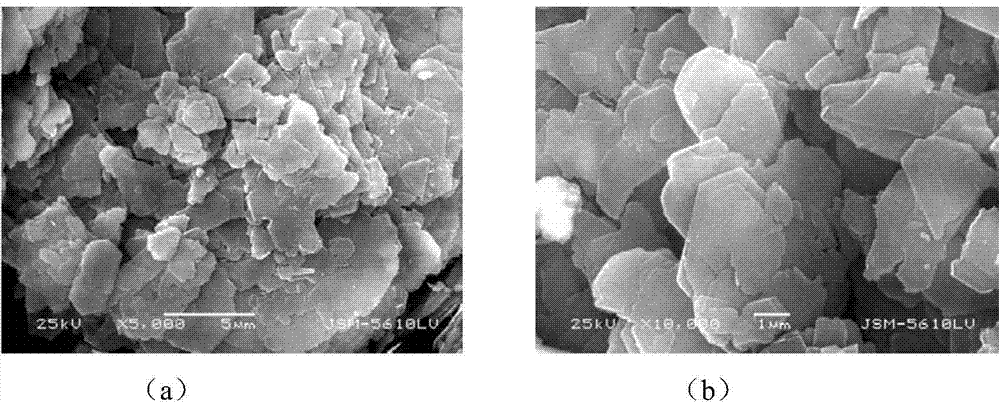

[0046] For the obtained sericite (powder) for cosmetics with easy dispersibility, the particle morphology of the powder and the dispersion of the surface treatment agent are illustrated by SEM photos. figure 1 . Depend on figure 1 It is known that the surface modifier is densely distributed on the surface of sericite crystals in a star-like manner. By infrared spectrum (IR) figure (KBr tablet method)【 Figure 5 In (a)], activation index and contact angle (Table 1) were measured to ...

Embodiment 2

[0048] Add 200g of sericite powder for cosmetics (Chuzhou Gerui) into the high-speed mixer, stir and disperse under the rotating speed of 1000rpm, when the temperature reaches 70°C, add the surface treatment agent ( The mass ratio of N-octyltriethoxysilane: polymethylhydrogensiloxane: polydimethylsiloxane: isopropanol = 25:25:50:100), after continuing to stir for 1h, use an electric heating drum Air drying oven aged at 105°C for 1 hour to obtain sericite powder for cosmetics with easy dispersibility.

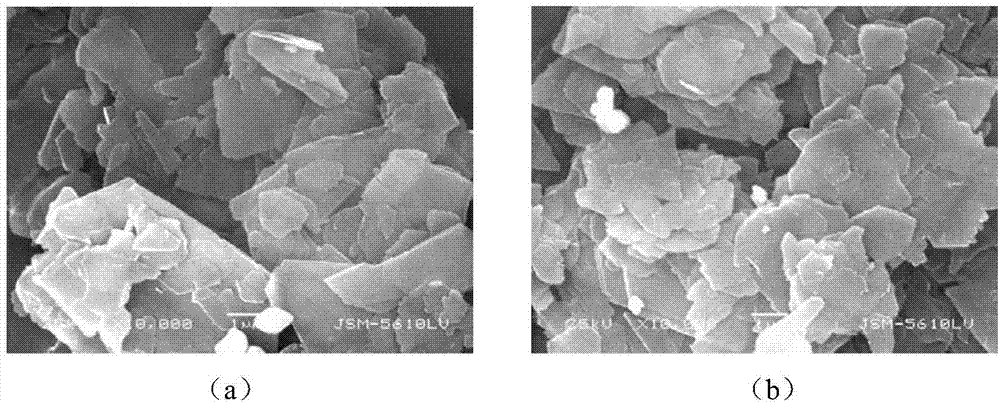

[0049] For the obtained sericite (powder) for cosmetics with easy dispersibility, the particle morphology of the powder and the dispersion of the surface treatment agent are illustrated by SEM photos. figure 2 . figure 2 It is known that the surface modifier is densely distributed on the surface of sericite crystals in a star-like manner. By infrared spectrum (IR) figure (KBr tablet method) [ Figure 5 In (b)], activation index and contact angle (Table 1) were measured to i...

Embodiment 3

[0051] Add 200g of sericite powder for cosmetics (Chuzhou Gerui) into the high-speed mixer, stir and disperse under the rotating speed of 1000rpm, when the temperature reaches 70°C, add the surface treatment agent ( Polymethylhydrogensiloxane: polydimethylsiloxane: isopropanol (mass ratio = 50:50:100), after continuing to stir for 1 hour, use an electric blast drying oven at 105°C for 1 hour to obtain Dispersive sericite powder for cosmetics.

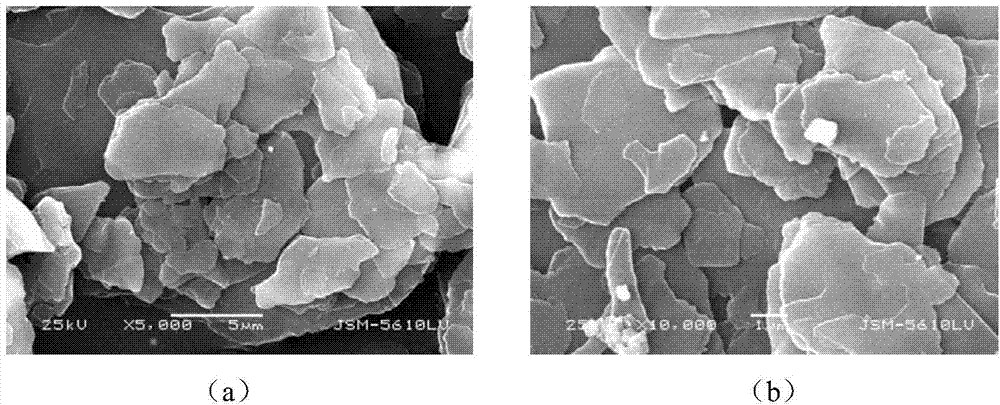

[0052] For the obtained sericite (powder) for cosmetics with easy dispersibility, the particle morphology of the powder and the dispersion of the surface treatment agent are illustrated by SEM photos. image 3 . image 3 It is known that the surface modifier is densely distributed on the surface of sericite crystals in a star-like manner. By infrared spectrum (IR) figure (KBr tablet method) [ Figure 5 In (c)], activation index and contact angle (Table 1) were measured to illustrate the surface treatment effect. Figure 5 Medium (c)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com