High-strength heat-conducting silica gel gasket and preparation method thereof

A thermally conductive silica gel, high-strength technology, used in chemical instruments and methods, heat exchange materials, dyed organosilicon compound treatment, etc. Insufficient and other problems, to achieve the effect of being suitable for large-scale industrial production, good heat soaking function, and improving stretching and tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

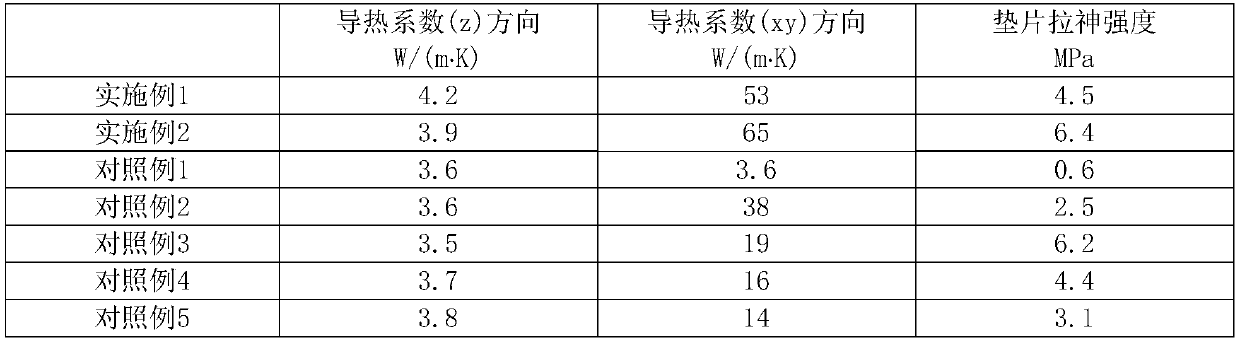

Examples

Embodiment 1

[0042] The components used in the preparation process of the high-strength thermally conductive silicone gasket product of the present invention are as follows: (A) 20 parts by weight of methyl vinyl silicone oil, with a viscosity of 400mPa·s; (B) 6 parts by weight of hydrogen-containing silicone oil, containing hydrogen 0.1%; (C) 4 parts by weight of γ-(2,3-glycidyloxy) propyltrimethoxysilane coupling agent; (D) 1.5 parts by weight of platinum catalyst; (E) spherical thermally conductive alumina powder 300 parts by weight of filler, particle size 50 μm, 200 parts by weight of irregular zinc oxide powder, particle size 4 μm; (F) 200 parts by weight of n-hexane; (G) 80 parts by weight of carbon fiber material, monofilament diameter 6 μm, length 70 μm; (H) 3 parts by weight of ethynylcyclohexanol. The preparation process includes the following steps: (1) heating and drying the (E) at 120 degrees under a vacuum environment for 1 to 2 hours, and removing excess moisture by heating...

Embodiment 2

[0044] The components used in the preparation process of the high-strength thermally conductive silicone gasket product of the present invention are as follows: (A) 25 parts by weight of methyl vinyl silicone oil, with a viscosity of 1000mPa·s; (B) 4 parts by weight of hydrogen-containing silicone oil, containing hydrogen 0.15%; (C) 4 parts by weight of vinyltrimethoxysilane coupling agent; (D) 1.5 parts by weight of catalyst; (E) 350 parts by weight of spherical heat-conducting alumina powder filler, particle size 70 μm, irregular zinc oxide 150 parts of powder with a particle size of 5 μm; (F) 230 parts by weight of n-hexane; (G) 80 parts by weight of carbon fiber material with a diameter of 15 μm and a length of 500 μm; (H) 3 parts by weight of ethynyl cyclohexanol. The preparation process includes the following steps: (1) heating and drying the (E) at 120 degrees under a vacuum environment for 1 to 2 hours, and removing excess moisture by heating; (2) drying the (A) to (E),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com