Graphene material directional arrangement and silica gel pad composite molding method and product

A technology of directional arrangement and composite molding, applied in the field of thermal interface materials, can solve the problems of easy falling off and insufficient strength, and achieve the effect of good heat dissipation function, firm connection, and easy large-scale industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

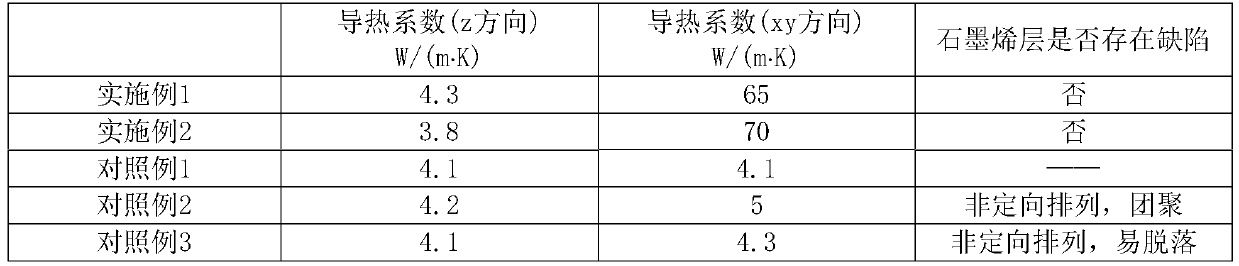

Examples

Embodiment 1

[0042] Graphene material directional arrangement of the present invention and the heat-conducting silica gel gasket product that is compositely formed with silica gel pad utilize the following components in the preparation process: (A) 15 parts by weight of methyl vinyl silicone oil, and the viscosity is 400mPa·s; ( B) 3 parts by weight of hydrogen-containing silicone oil, 0.1% of hydrogen content; (C) 4 parts by weight of γ-methacryloxypropyl trimethoxysilane coupling agent; (D) concentration is 1.5 parts by weight of platinum catalyst of 2000ppm Parts; (E) 500 parts by weight of spherical heat-conducting alumina powder fillers, including alumina powders of large and small particle sizes, the particle size of the large particle size alumina powder is 90 μm, and the particle size of the small particle size alumina powder is 5 μm , wherein the ratio of large and small particle size alumina powder is 300 parts by weight: 200 parts by weight; (F) 150 parts by weight of organic dil...

Embodiment 2

[0044] Graphene material directional arrangement of the present invention and the heat-conducting silica gel gasket product that is compounded with silica gel mat molding utilize in the preparation process the following components: (A) 20 parts by weight of methyl vinyl silicone oil, viscosity is 1000mPa·s; ( B) 3 parts by weight of hydrogen-containing silicone oil, 0.15% hydrogen content; (C) 4 parts by weight of vinyltrimethoxysilane coupling agent; (D) 1.5 parts by weight of platinum catalyst with a concentration of 2000ppm; (E) spherical thermal oxidation 500 parts by weight of aluminum powder filler, including alumina powders with large and small particle sizes, the particle size of the large particle size alumina powder is 95 μm, and the particle size of the small particle size alumina powder is 4 μm. The ratio of powder is 300 parts by weight: 200 parts by weight; (F) 150 parts by weight of organic volatile diluting solvent n-hexane; (G) 30 parts by weight of graphene, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com