Polymer-based high energy storage density material and preparing method thereof

A high energy storage density, polymer technology, applied in the direction of fixed capacitor dielectric, fixed capacitor parts, etc., can solve the problems of composite material loss, leakage conduction increase, breakdown field strength decrease, etc., to achieve good surface modification, Low density, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention relates to a polymer base high energy storage density material and a preparation method thereof. The preparation steps are as follows:

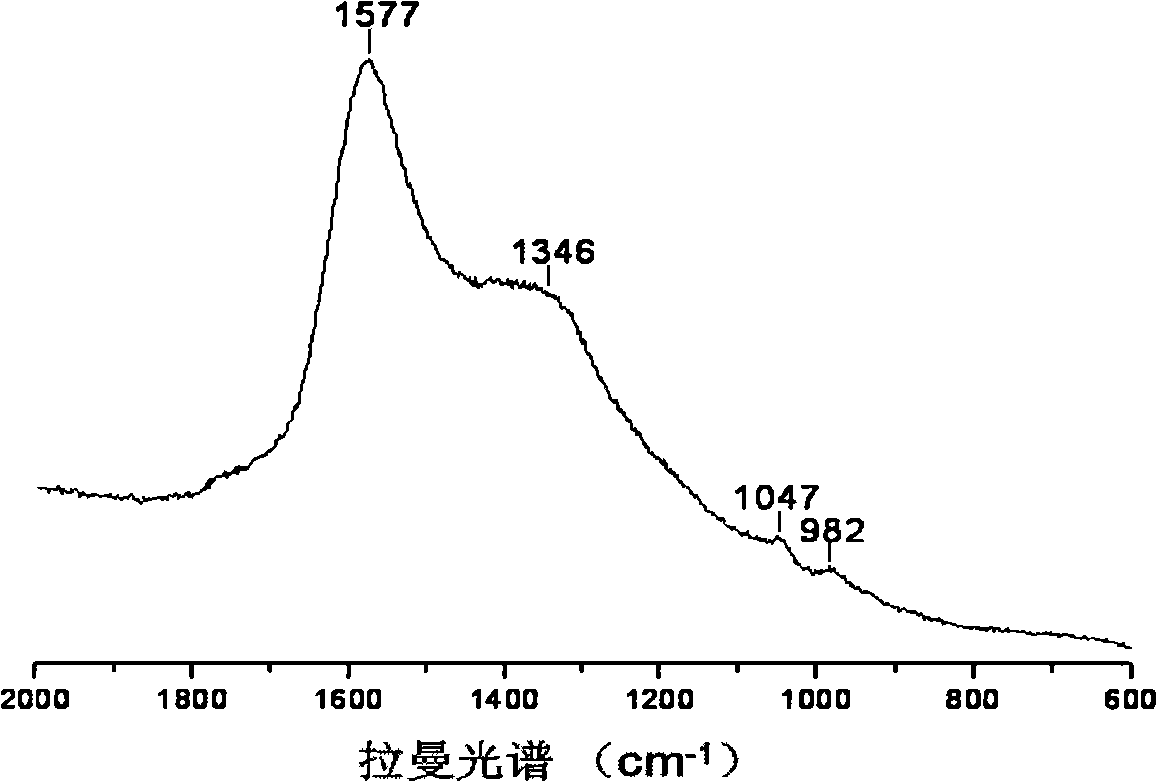

[0022] Step (1) Preparation of modified carbon nanotubes: with the method of in-situ inverse emulsion polymerization, the specific formula is to add 1.2 milliliters of pyrrole, 1.32 grams of ammonium persulfate and 6 grams of hexadecylbenzene to 2 milligrams of carbon nanotubes In a mixture of sodium sulfonate, and in an inert atmosphere of argon, under ultrasonic or stirring conditions, react at 0°C for 8 hours, and form a core-shell structure material with carbon nanotubes as the core and an organic layer as the shell after drying. The test results are as follows: figure 1 It is the Raman spectrogram of MWCNT@PPy described in step (1). It can be seen that there are characteristic peaks of MWCNT@PPy at 1577, 1346, 1047, and 982 wavenumbers.

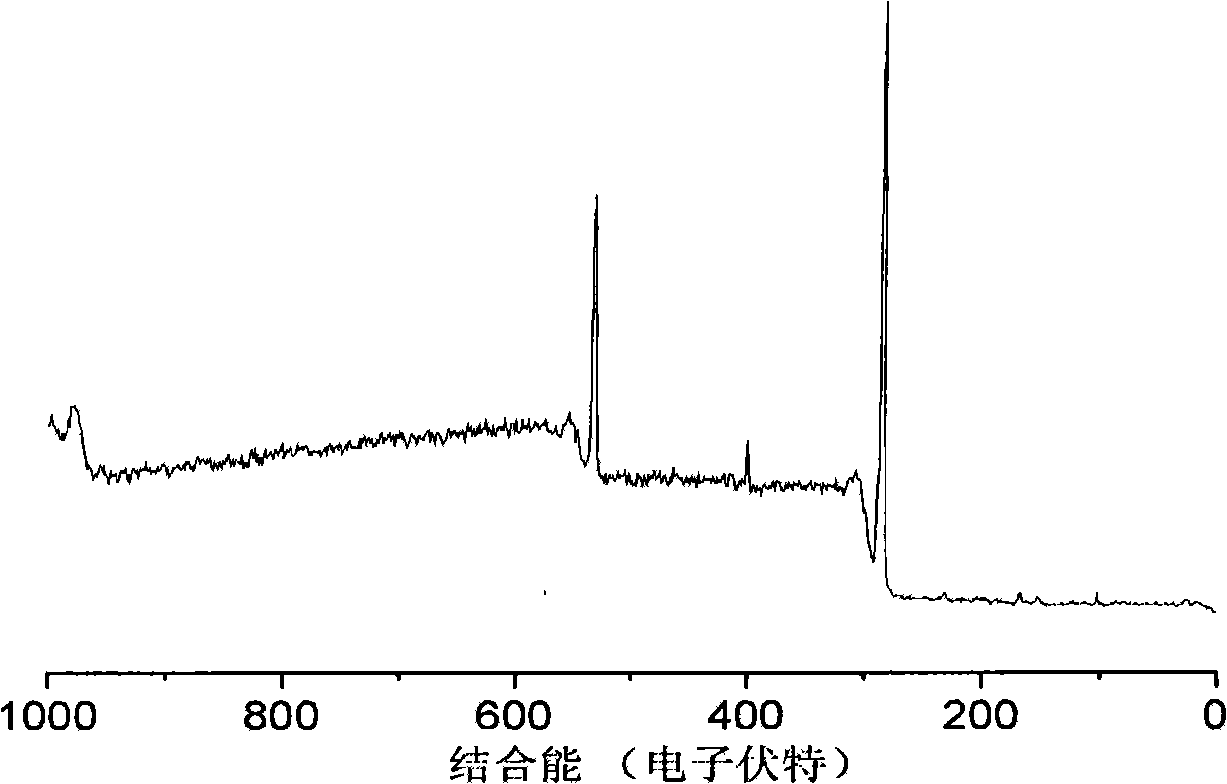

[0023] figure 2 It is the X-ray photoelectron spectrum diagram of the modi...

Embodiment 1

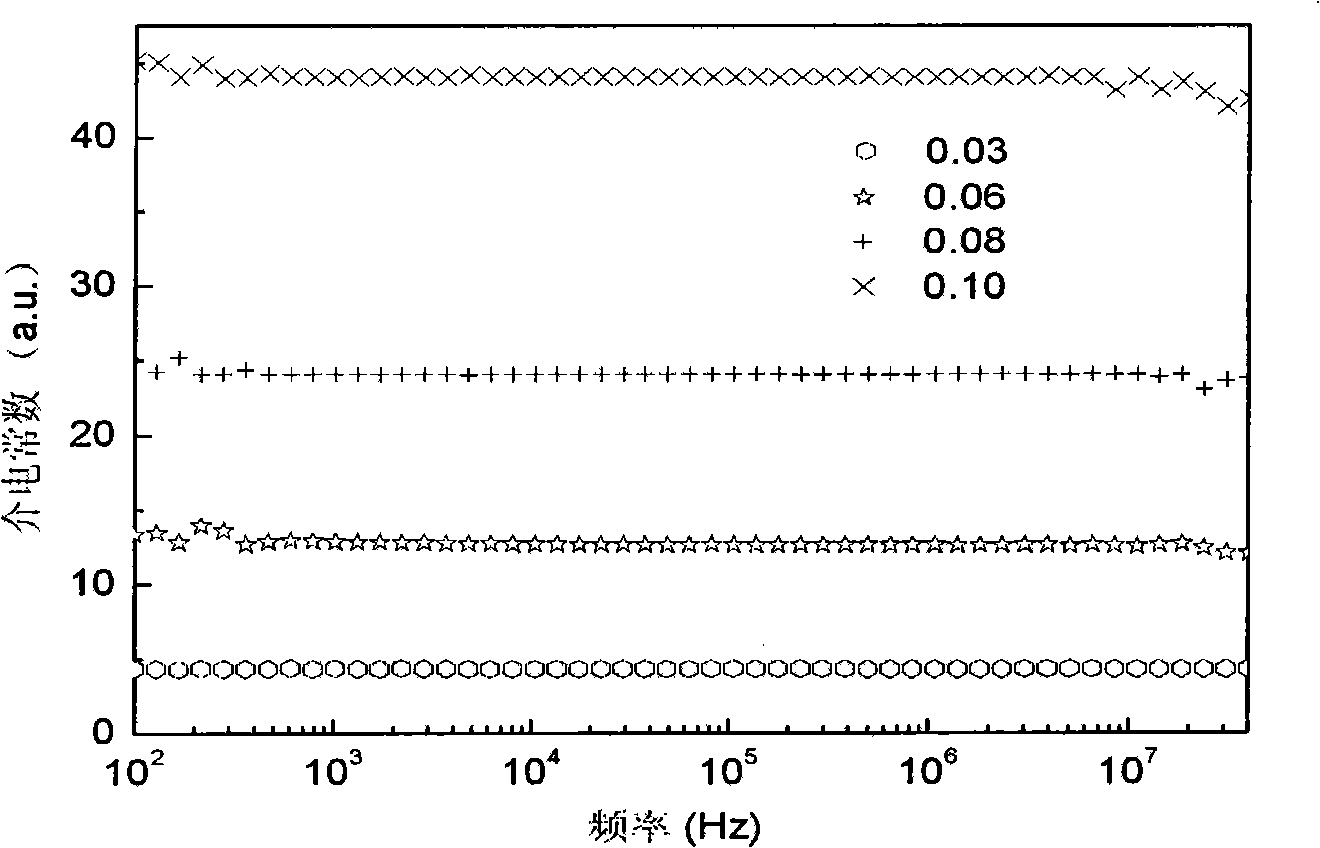

[0029] Weigh 1 gram of polystyrene, and dissolve it in 10 ml of ethyl acetate solution with stirring. Then weigh 0.03 gram of the modified carbon nanotubes described in the above step (1) and join in 10ml ethyl acetate solution to carry out ultrasonic operation for 0.5 hour (using 800W power, ultrasonic 1min, intermittent 5s mode), then mix with poly Mix the ethyl acetate solution of styrene, and under the protection of argon, stir evenly at room temperature, cast to form a film, dry at room temperature, vacuum dry, and then place it in an environment with a temperature of 150 ° C and a pressure of 10 MPa for 20 minutes to form , and finally placed in a normal temperature and pressure environment for 20 minutes to set the shape, that is, a modified carbon nanotube / polystyrene composite material with high energy storage density (denoted as 0.03MWCNT@PPy / PS).

Embodiment 2

[0031] Weigh 1 gram of polystyrene, and dissolve it in 10 ml of ethyl acetate solution with stirring. Then weigh 0.06 gram of the modified carbon nanotubes described in the above step (1) and join in 15ml of ethyl acetate solution for 1.0 hour ultrasonic operation (800W power, ultrasonic 1min, intermittent 5s mode), and then mix with poly Mix the ethyl acetate solution of styrene, and under the protection of argon, stir evenly at room temperature, cast into a film, dry at room temperature, vacuum dry, and then place it in an environment with a temperature of 160 ° C and a pressure of 12.5 MPa for 20 minutes Molding, and finally placed in an environment of normal temperature and pressure for 20 minutes to set the shape, that is, a composite material with high energy storage density of modified carbon nanotubes / polystyrene (denoted as 0.06MWCNT@PPy / PS).

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com