Nano-Al2O3 modified biopolymer material and preparation method thereof

A biopolymer and nanotechnology, applied in the field of polypropylene, can solve the problems of hindering widespread use, low elongation at break, low melt strength, etc., and achieve the effects of improving strength and toughness, improving material performance, and improving agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

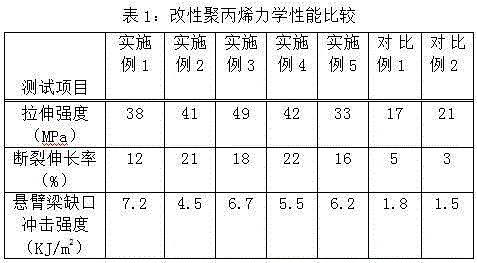

Examples

Embodiment 1

[0025] Add 1g of solid titanate coupling agent TMC-201 into 10mL of isopropanol, ultrasonicate for 10min (ultrasonic frequency 80Hz) to form a homogeneous solution, add 15g of nano-Al 2 o 3 After reacting for 2 hours, filter and dry in vacuum at 30°C for 14 hours to obtain modified nano-Al 2 o 3 Material.

[0026] 90kg P(3HB-co-4HB), 10kg modified nano Al 2 o 3 Materials, 0.2 kg of phenolic heat stabilizer 1010, 0.2 kg of lubricant EBS were melted, mixed and dispersed in a twin-screw extruder with a length-to-diameter ratio of 40:1, and all raw materials were blended and extruded to obtain nano-Al 2 o 3 Modified biopolymer materials. The processing temperature during preparation was 150°C.

Embodiment 2

[0028] Add 2g of solid titanate coupling agent TMC-201 into 40mL of isopropanol, ultrasonicate for 20min (ultrasonic frequency 90Hz) to form a uniform solution, add 60g of nano-Al 2 o 3 After reacting for 3 hours, filter and dry in vacuum at 50°C for 20 hours to obtain modified nano-Al 2 o 3 Material.

[0029] 80kgP (3HB-co-4HB), 20kg nano Al 2 o 3 Materials, 0.1kg lubricant zinc stearate, 0.1kg lubricant calcium stearate, 0.25 kg phenolic heat stabilizer 1010 are melt mixed and dispersed in a twin-screw extruder with a length-to-diameter ratio of 56:1, and all raw materials are After mixing, extruding and granulating, nano-Al 2 o 3 Modified biopolymer materials. The processing temperature during preparation was 130°C.

Embodiment 3

[0031] Add 1g of solid titanate coupling agent TMC-201 into 3mL of isopropanol, ultrasonicate for 3min (ultrasonic frequency 60Hz) to form a homogeneous solution, add 10g of nano-Al 2 o 3 After reacting for 1 hour, filter and dry in vacuum for 8 hours at 25°C to obtain modified nano-Al 2 o 3 Material.

[0032] 97kg polypropylene, 3kg nanometer Al 2 o 3 Materials, 0.3kg phenolic heat stabilizer 1010 and 0.3kg lubricant EBS, were melt mixed and dispersed in a twin-screw extruder with a length-to-diameter ratio of 35:1, and all raw materials were blended and extruded to obtain nano-Al 2 o 3 Modified biopolymer materials. The processing temperature during preparation was 160°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com