Preparation method for recyclable high-voltage direct-current cable material with function of inhibiting space charge

A high-voltage DC, space charge technology, applied in organic insulators, plastic/resin/wax insulators, etc., can solve problems such as calculation and design difficulties, dielectric breakdown, etc., to achieve favorable space charge dissipation, good mechanical integrity, Effect of spherulite size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

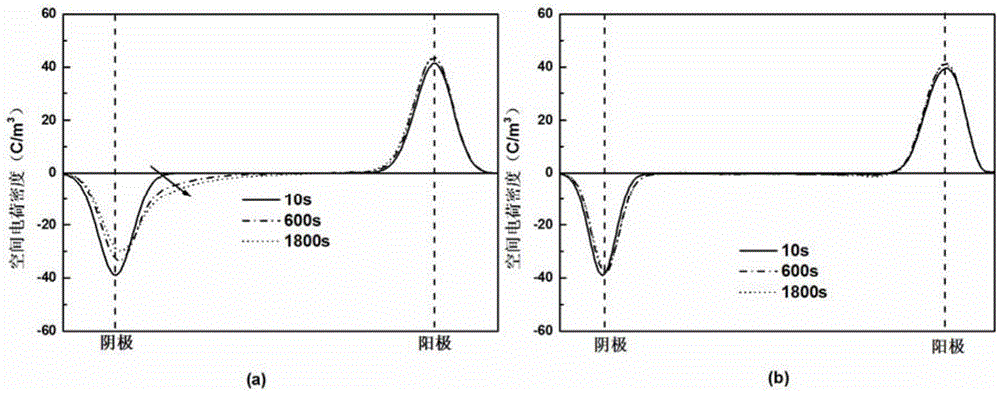

[0028] 30 grams of isotactic polypropylene, 20 grams of polyolefin elastomer Dow Engage POE 8842, 0.25 grams of antioxidant 1010, 1 gram of flame retardant magnesium hydroxide and 0.25 grams of processing aid glyceryl stearate, at 180 Mixing at ℃ for 6 minutes, with a rotation speed of 60r / min, a recyclable insulating material for high-voltage DC cables is obtained, and its space charge performance is shown in figure 1 (b).

[0029] The recyclable high-voltage DC cable material obtained in the above implementation examples of the present invention still has a suitable storage modulus at 90° C., indicating that its mechanical properties have been greatly improved. At the same time from figure 1 (b) It can be seen that the material has good space charge suppression ability. From the perspective of comprehensive performance, the material meets the requirements of recyclable wire and cable insulation, does not require cross-linking in the preparation process, and is a recyclable...

Embodiment 2

[0031] 35 grams of isotactic polypropylene, 15 grams of polyolefin elastomer Dow Engage POE 8842, 0.3 grams of antioxidant 2246, 1.5 grams of flame retardant low-water zinc borate and 0.3 grams of processing aid glyceryl stearate, in Kneading at 180°C for 6 minutes at a rotational speed of 40r / min to obtain a recyclable insulating material for high voltage direct current cables.

Embodiment 3

[0033] 30 grams of isotactic polypropylene, 20 grams of Dow Engage POE 8150 polyolefin elastomer and 0.4 grams of antioxidant 2246, 2 grams of flame retardant aluminum hydroxide and 0.4 grams of processing aid glyceryl stearate, at 180 Kneading for 8 minutes at a temperature of 50 r / min to obtain a recyclable insulating material for high-voltage direct current cables.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com