A kind of preparation method of zirconia ceramic ferrule

A zirconia ceramic and zirconia technology, applied in the field of preparation of zirconia ceramic ferrule, can solve the problems of easy deformation and low precision of the ferrule, and achieve the effects of improving thermomechanical properties, high precision and excellent linear expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The embodiment of the present invention discloses a method for preparing a zirconia ceramic ferrule, which includes the following steps:

[0038] Step a) mixing nano titanium dioxide, magnesium oxide, scandium oxide, samarium oxide, holmium oxide, zinc oxide and zirconium oxide, adding oleic acid after pre-calcination, mixing by ball milling, and obtaining a zirconium oxide powder substrate after sieving;

[0039] Step b) adding the zirconia powder base material and high-melt-strength polypropylene into an internal mixer, mixing and stirring, adding polyethylene glycol monomethyl ether, microcrystalline wax, oleic acid amide, and adding ethylene-vinyl acetate after stirring Stir the copolymer, PBT, polyurethane elastomer and polyaldehyde resin, heat up to 140-144°C, then add adipic acid dioctanoic acid, heat up to 160-180°C after stirring, cool after banburying, and obtain a gelatinous substance;

[0040] Step c) compressing the gelatinous substance into tablets, pulver...

Embodiment 1

[0085] Step 1, the nano-titanium dioxide of 1 weight part, the magnesium oxide of 2 weight parts, the scandium oxide of 1 weight part, the samarium oxide of 2 weight parts, the holmium oxide of 1 weight part, the zinc oxide of 1 weight part and 92 weight parts of After the zirconia is uniformly mixed, it is pre-sintered at 700° C. for 2 hours, and then 3 parts by weight of oleic acid are added for ball milling, mixing and sieving to obtain a zirconia powder base material.

[0086] The specific process of step 2 is as follows:

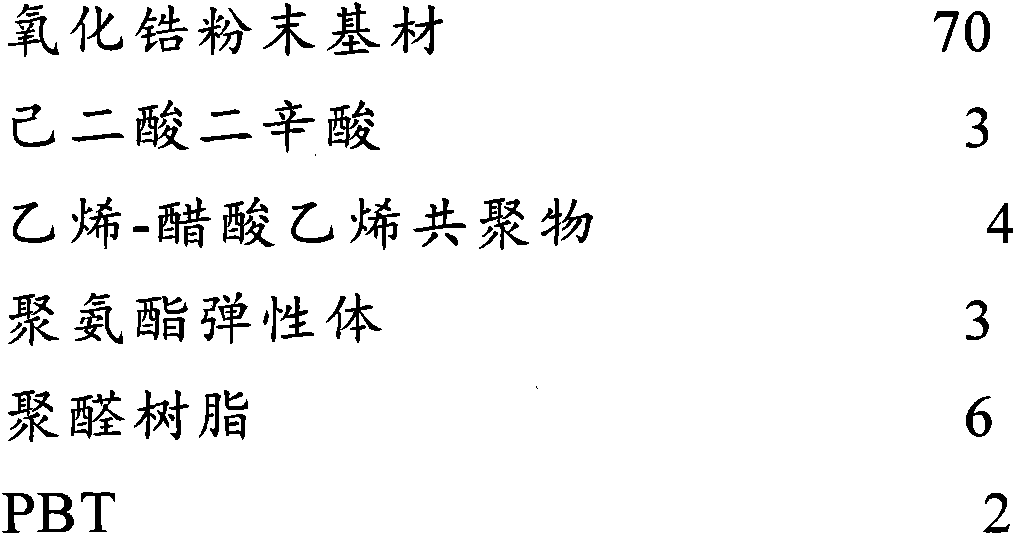

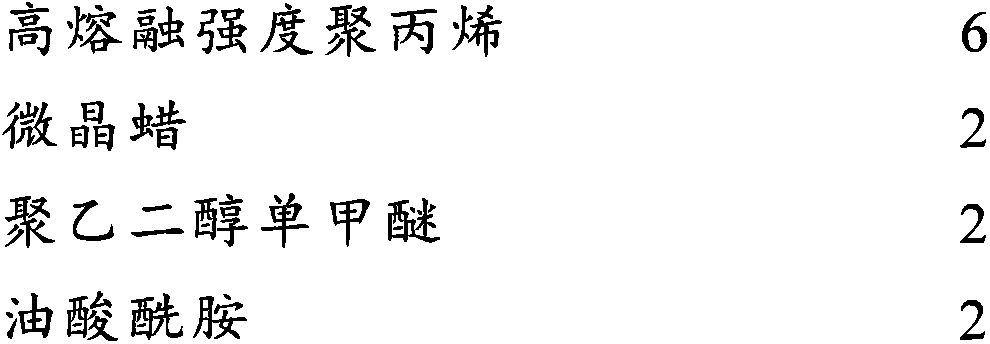

[0087] Step 2a, mixing the above-mentioned prepared zirconia powder substrate with organic carriers such as binder, surface active agent and plasticizer in a certain proportion, the raw materials used in this step include in parts by weight:

[0088]

[0089]

[0090] Raise the temperature of the internal mixer to 100°C, then add the above-mentioned weight parts of zirconia powder base material and high-melt-strength polypropylene into the above-m...

Embodiment 2

[0111] Step 1, the nano-titanium dioxide of 1 weight part, the magnesium oxide of 2 weight parts, the scandium oxide of 1 weight part, the samarium oxide of 2 weight parts, the holmium oxide of 1 weight part, the zinc oxide of 1 weight part and 92 weight parts of After the zirconia is uniformly mixed, it is pre-sintered at 680° C. for 1.5 hours, and then 4 parts by weight of oleic acid are added for ball milling, mixing and sieving to obtain a zirconia powder base material.

[0112] The specific process of step 2 is as follows:

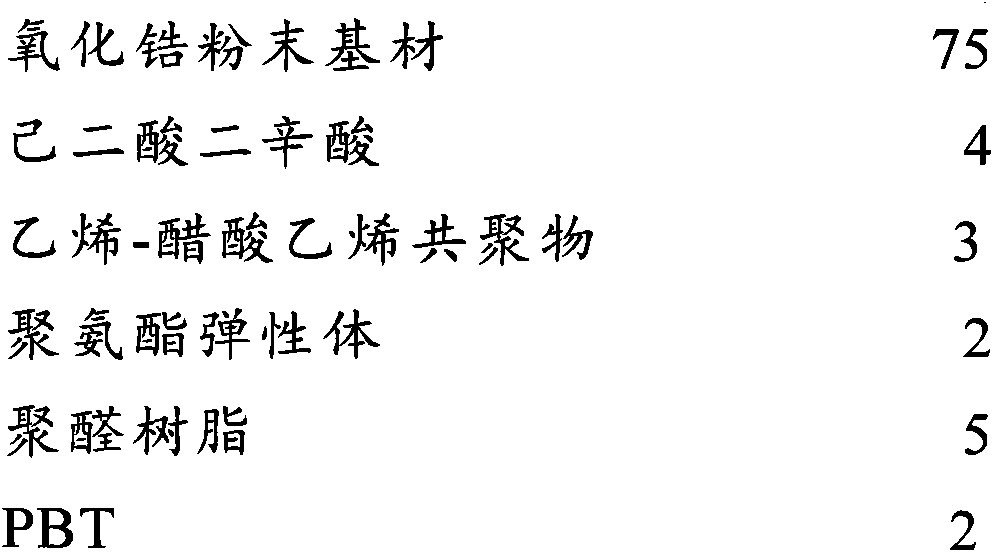

[0113] Step 2a, mixing the above-mentioned prepared zirconia powder substrate with organic carriers such as binder, surface active agent and plasticizer in a certain proportion, the raw materials used in this step include in parts by weight:

[0114]

[0115]

[0116] Raise the temperature of the internal mixer to 105°C, then add the above-mentioned weight parts of zirconia powder base material and high-melt-strength polypropylene into the above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com