Patents

Literature

34results about How to "Improve thermomechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flameproof polyacrylonitrile fibre and method for preparing same

ActiveCN1566421AGood physical and mechanical propertiesImprove flame retardant performanceMonocomponent synthetic polymer artificial filamentArtifical filament manufactureSolventSilane coupling

The invention discloses a flame-proof polyacrylonitrile fiber and its manufacturing method. Said fiber comprises at least 5%-25% by polyacrylonitrile weight of APP flame retardant, or APP flame retardant treated by silane coupler or titanate coupler, furthmore, comprises pentaerythritol, bi-pentaerythritol and like polyhydric alcohol compound, which has a APP-to-polyhydric alcohol ratio ranging from 2 to 3.8 by wt / wt. The method for manufacturing said fiber includes: crossblending the flame retardant with the inorganic solvent spinning dope of polyacrylonitrile, which is obtained by one-step method or two-step method to prepare crossblending spinning dope, then spinning, washing, drafting and thermal sizing by using current technique of making acrylon with inorganic solvent spinning line. The invention applies cheap, non-poisonous and high efficient inorganic additive flame retardant APP to spin flame retardant acrylon, as a result, crossblending spinning dope with good spinnability and fiber with high flame retardancy is obtained.

Owner:CHINA PETROLEUM & CHEM CORP +2

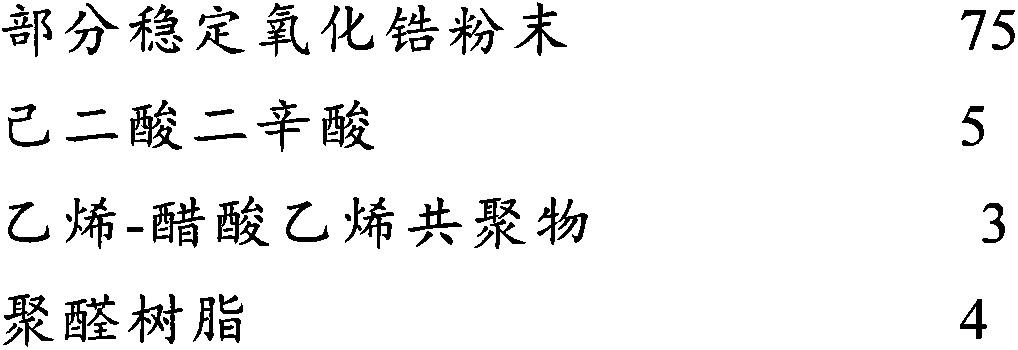

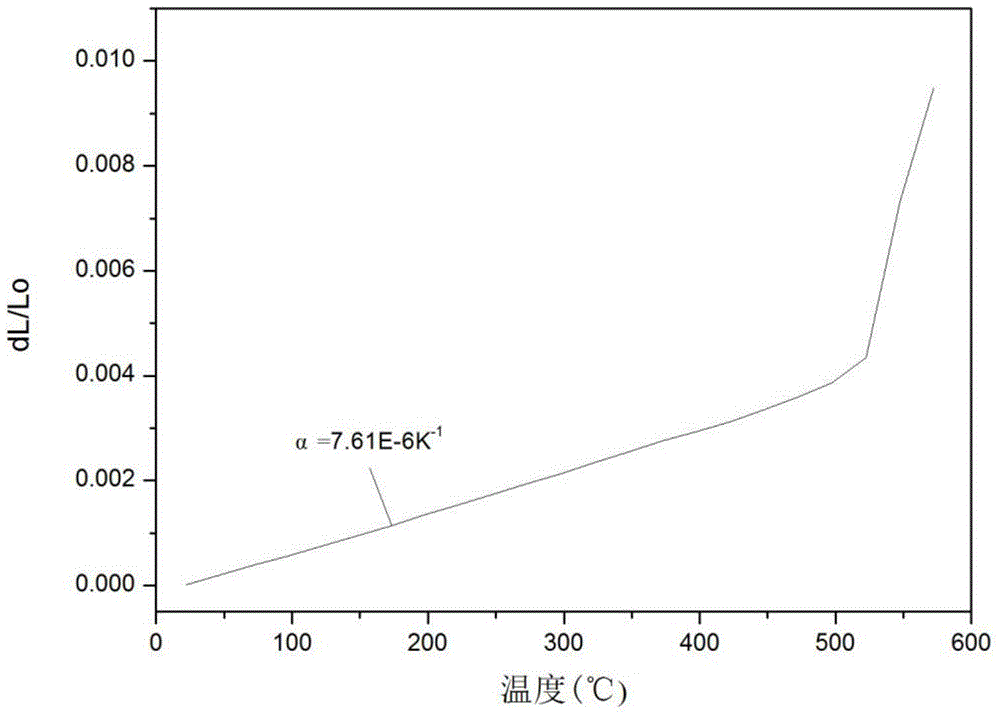

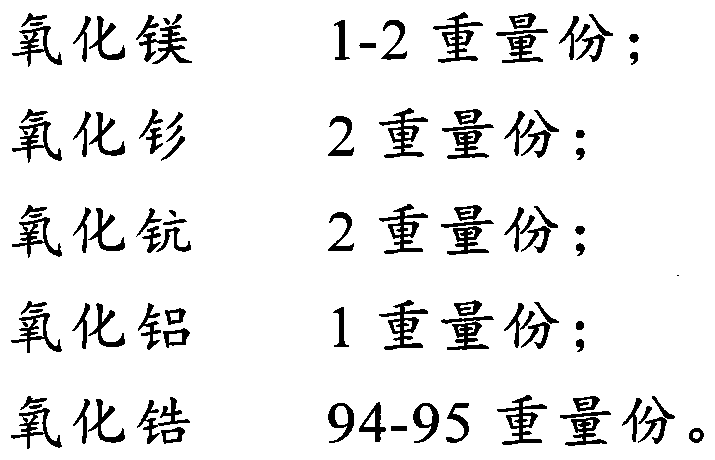

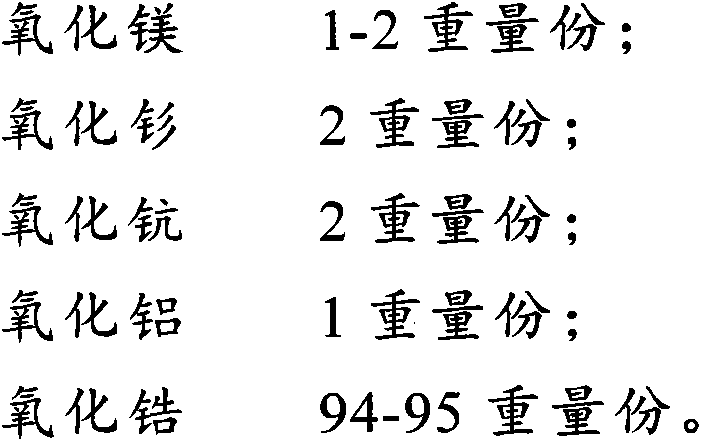

Method for manufacturing high-strength zirconia ceramic core insert

ActiveCN104961462AExcellent coefficient of linear expansionImprove thermomechanical propertiesBenzenePolystyrene

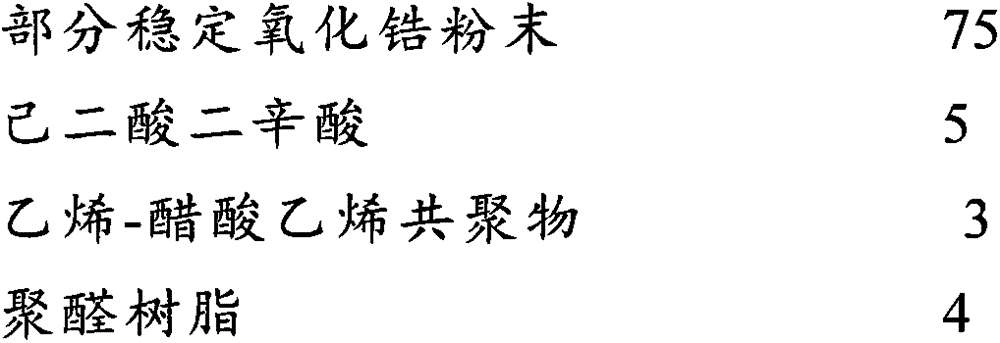

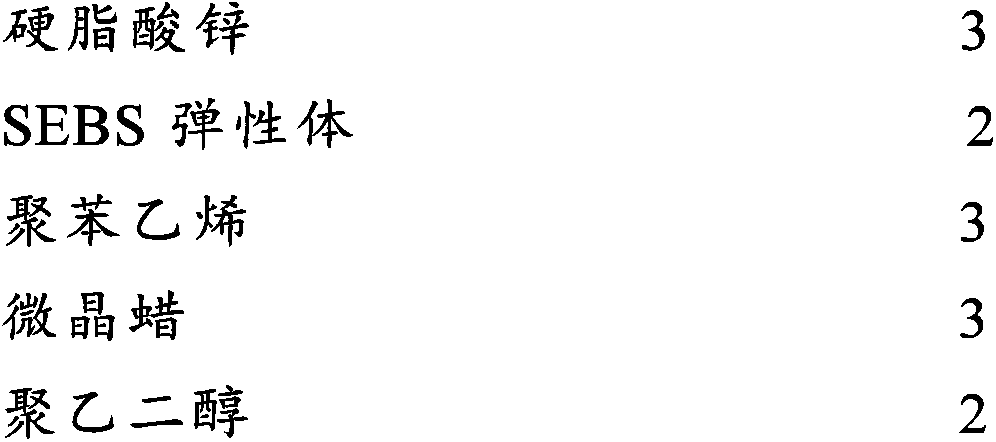

The invention provides a method for manufacturing a high-strength zirconia ceramic core insert and a method for preparing part of zirconia stabilizing powder for the high-strength zirconia ceramic core insert. According to the method for manufacturing the high-strength zirconia ceramic core insert, firstly, scandia and cerium oxide are made to react with zirconia, nano titania and aluminum oxide are mixed at the same time, so that the linear expansion coefficient and thermal stress performance which are more excellent than that of pure zirconia ceramic are obtained, in this way, the material can have high strength, high tenacity and excellent thermal shock resistance, and deformation is unlikely to occur; secondly, an SEBS elastomer, polrvinyl benzene, aldehyde resin and the like are inserted into part of zirconia stabilizing powder for polymerization, so that an interspersed network structure is formed, a stable structural system is obtained, and deformation is unlikely to occur; thirdly, the aldehyde resin and the polrvinyl benzene are taken as main binding agents, in this way, the strength of formed blank is high, conformality is good, the degreasing speed is high, and the precision is high; fourthly, stearate radical is removed during sintering of zinc stearate, so that the zinc stearate is oxidized into zinc oxide, and thus the strength of the core insert is improved.

Owner:NINGBO BRIGHT PHOTOELECTRIC TECH

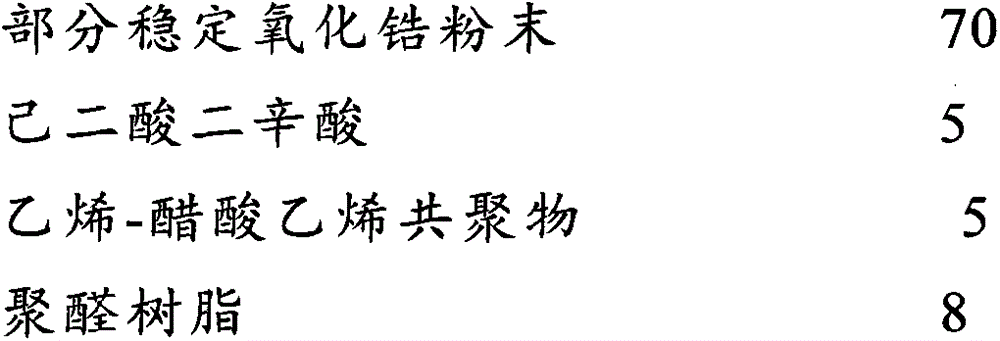

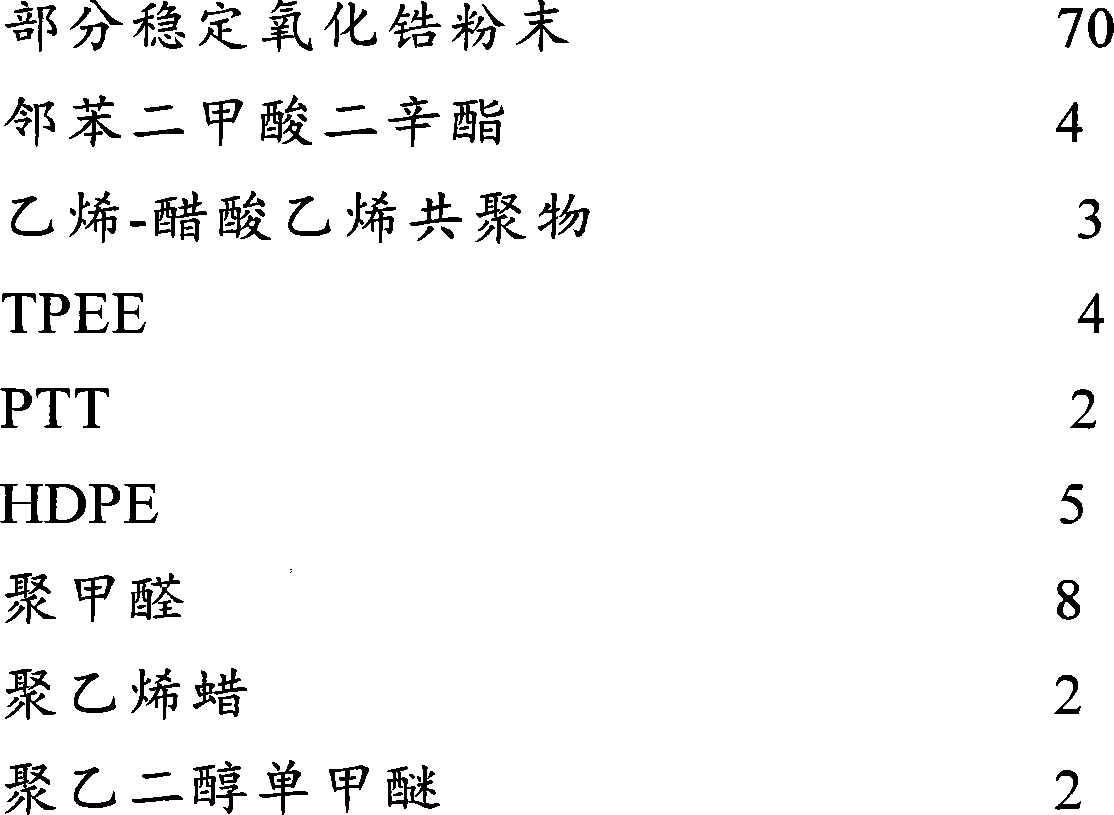

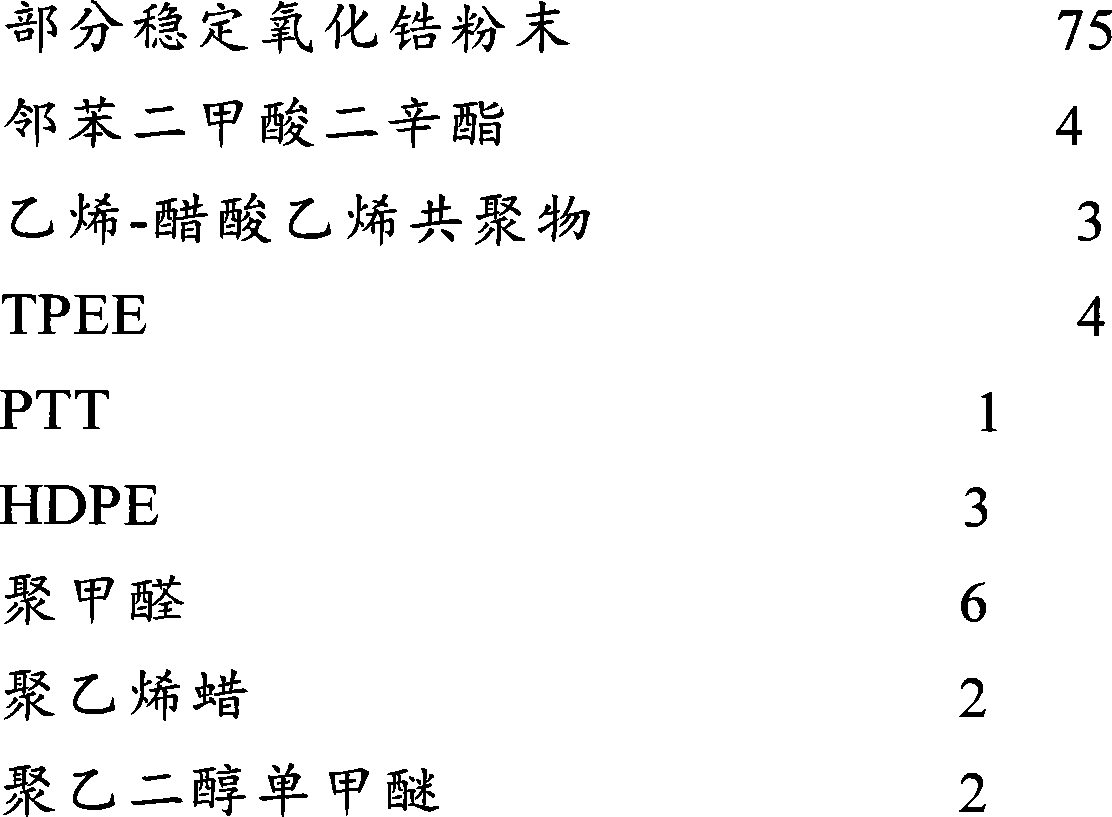

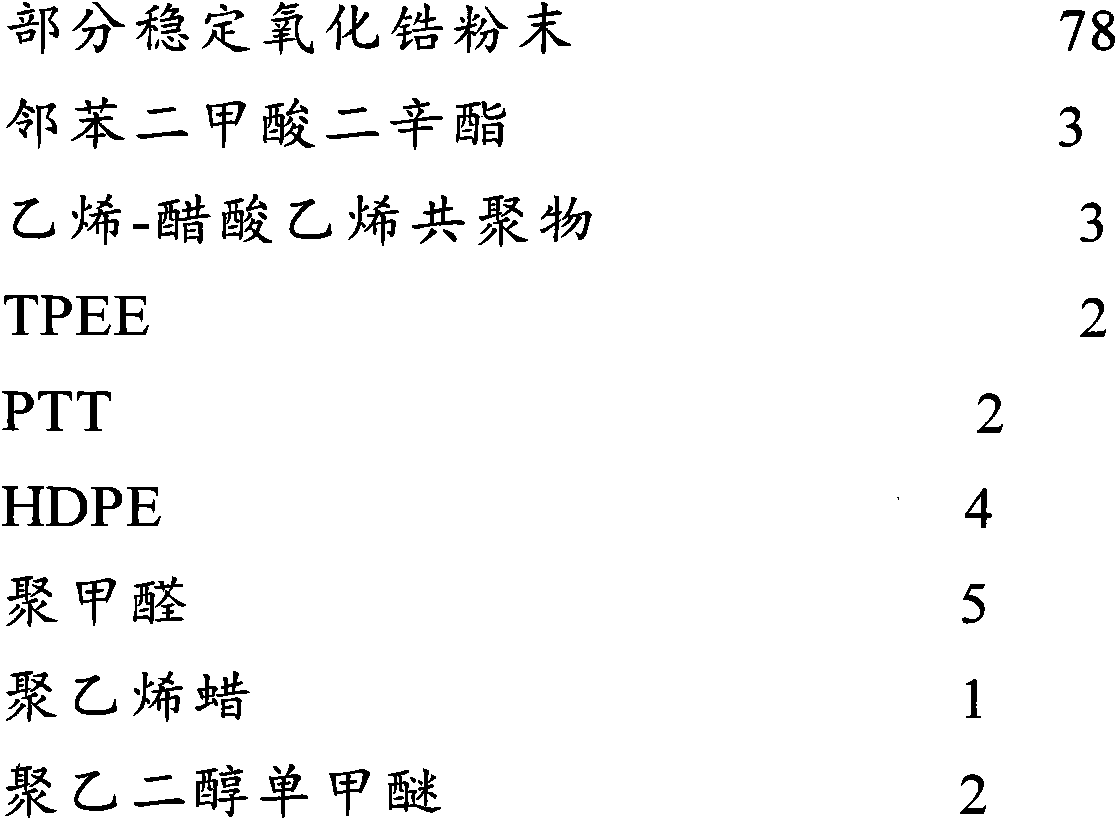

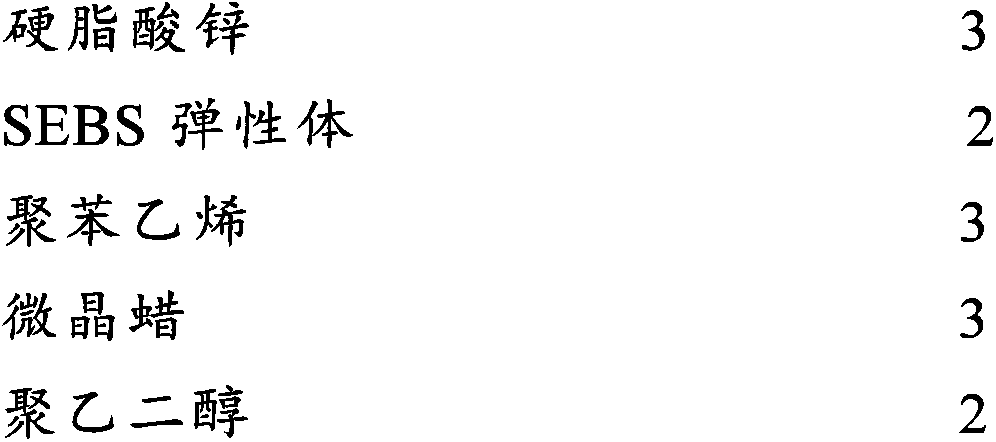

Preparation method of high-precision ceramic ferrule

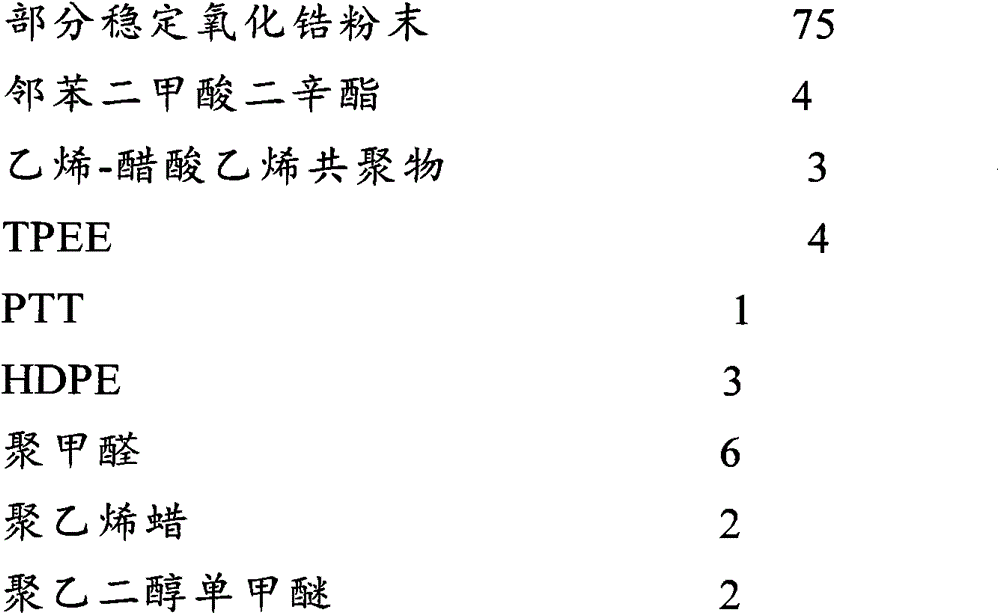

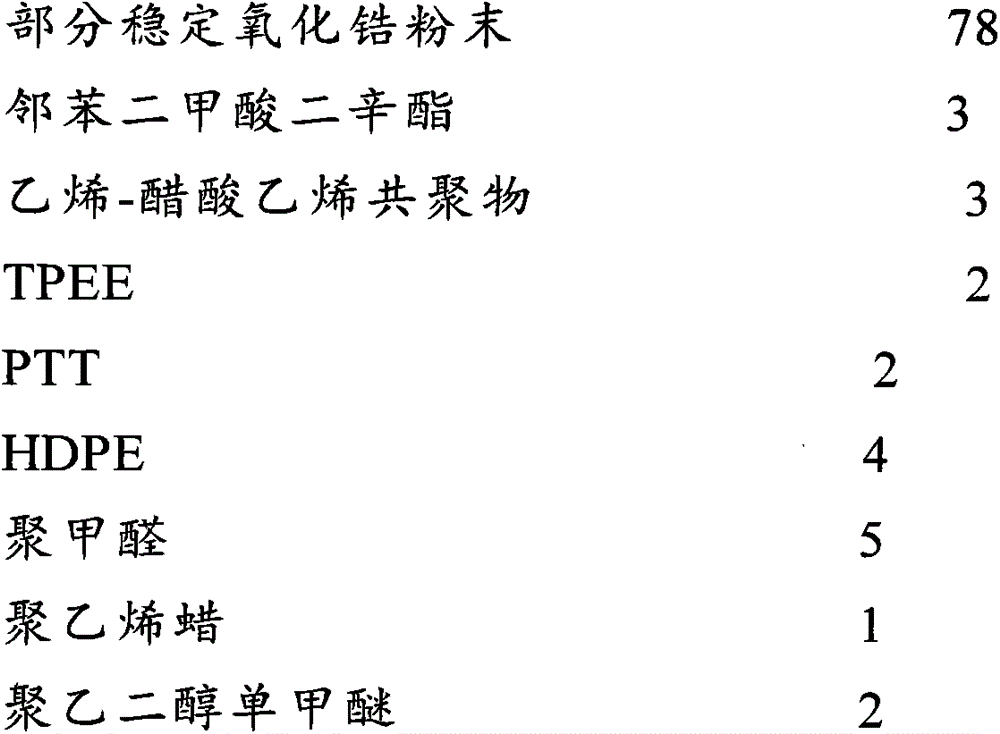

The invention provides a preparation method of a high-precision ceramic ferrule and a preparation method of partially stabilized zirconium oxide powder for the high-precision ceramic ferrule. The preparation methods provided by the invention have the following advantages: firstly, silicon oxide, molybdenum oxide, zinc oxide, scandium oxide and holmium oxide are adopted, so that the thermal stress property of partially stabilized zirconium ceramic is high, the thermo-mechanical property of zirconium oxide is improved, and the ferrule material can be higher in strength, high in thermal shock resistance, low in deformation possibility and free from cracking; secondly, through an ethylene-vinyl acetate copolymer, TPEE, PTT, HDPE, polyformaldehyde and the like are polymerized in an interpenetrated manner to form an interpenetrated network structure, so that the obtained ceramic ferrule is low in deformation possibility and relatively high in precision; thirdly, an adopted organic binding agent has high liquidity, so that the ceramic ferrule is high in homogeneity and free from cracking; finally, due to the sequence of adding the organic binding agent during mixed refining, the feeding rheological property can be relatively high, a blank material can be easier to degrease, and then the prepared ceramic ferrule can be prevented from cracking.

Owner:NINGBO BRIGHT PHOTOELECTRIC TECH

Photosensitive resin and preparation method thereof

InactiveCN107759750AShort curing timeShorten the development cycleAdditive manufacturing apparatusSpecial designLight cure

The invention discloses photosensitive resin and a preparation method thereof. The photosensitive resin is prepared by the following components in part by weight: 10-60 parts of organic silicone resinpowder, 5-15 parts of an organic solvent, 10-50 parts of a silane coupling agent, 0.5-3 parts of a catalyst, 0.1-10 parts of metal alkoxide, 0.1-10 parts of a complexing agent, 0.1-5 parts of a photo-initiator and 5-40 parts of an active diluent. The photosensitive resin prepared according to the formula has the advantages of low system viscosity and good fluidity; a used light-cured 3D printer is of an ordinary model without special design. The photosensitive resin disclosed by the invention is suitable for a DLP or SLA type 3D printer, and a printed model has a certain strength and can be converted into ceramics after high-temperature processing.

Owner:SHENZHEN UNIV

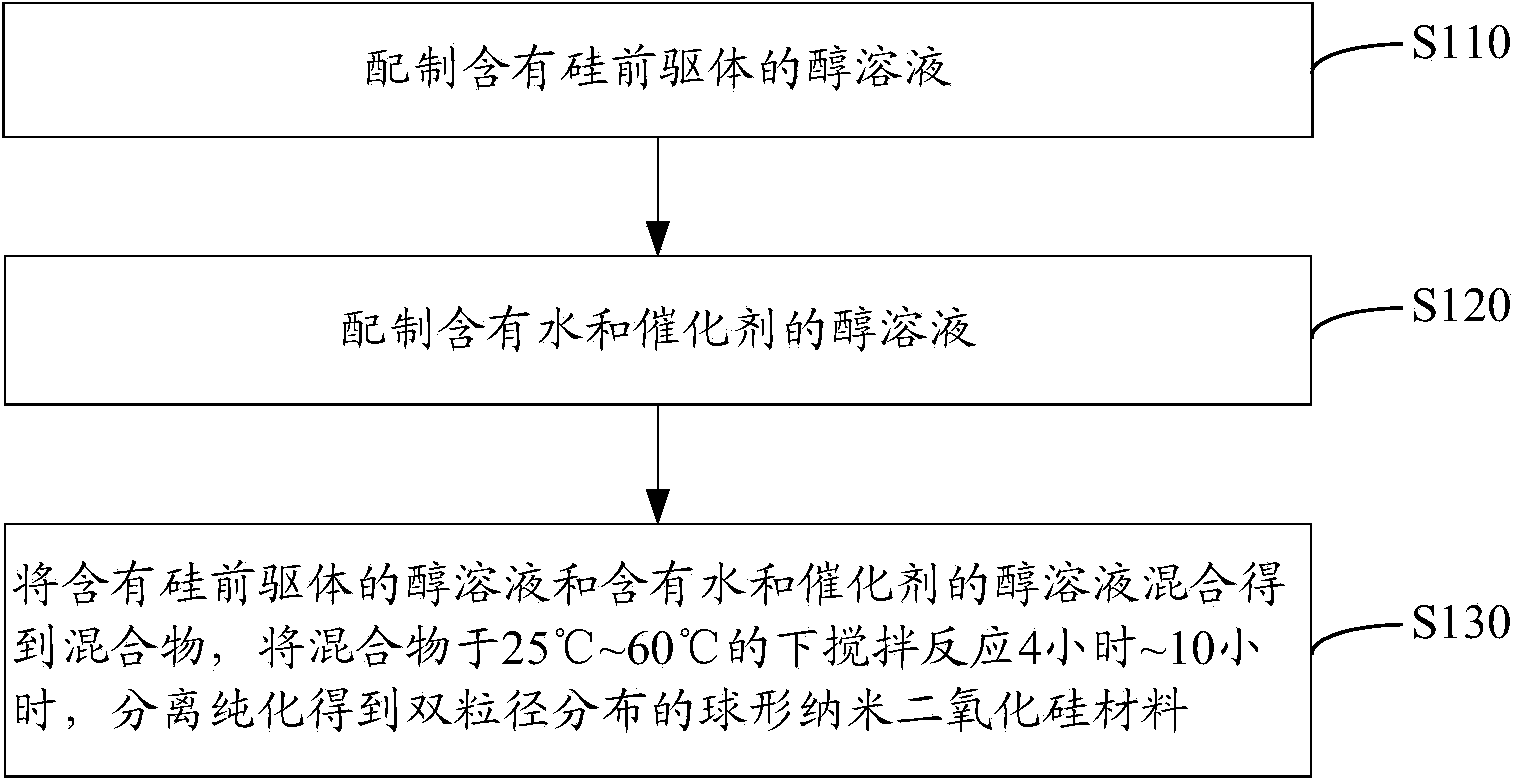

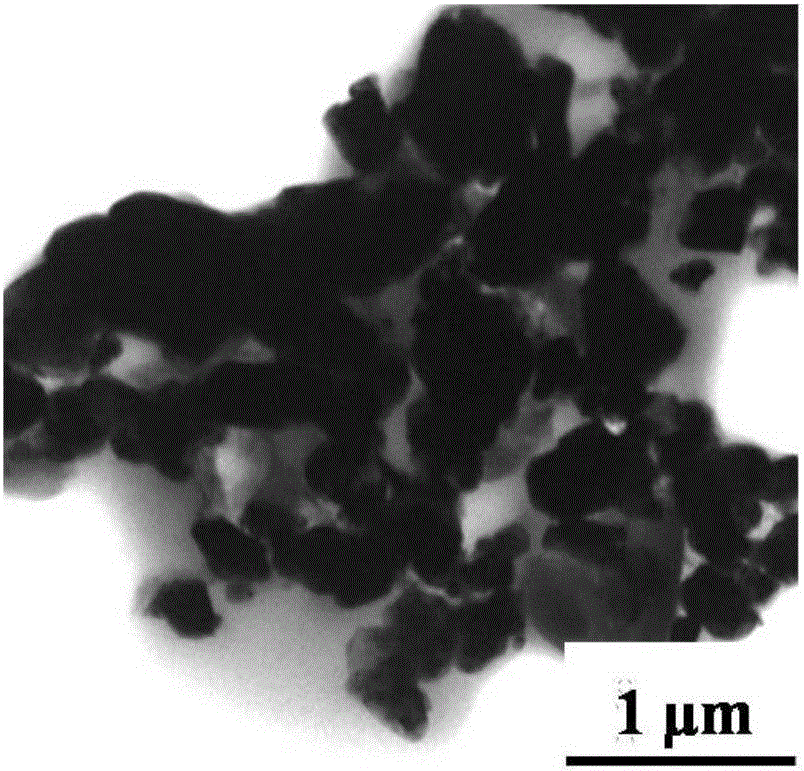

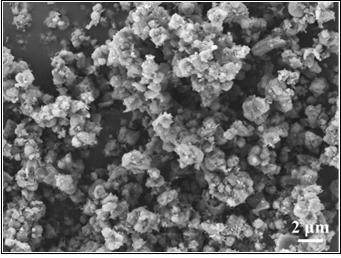

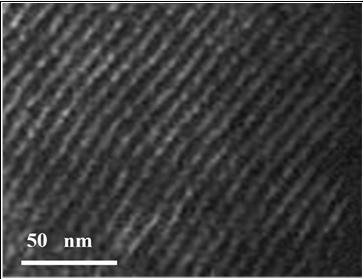

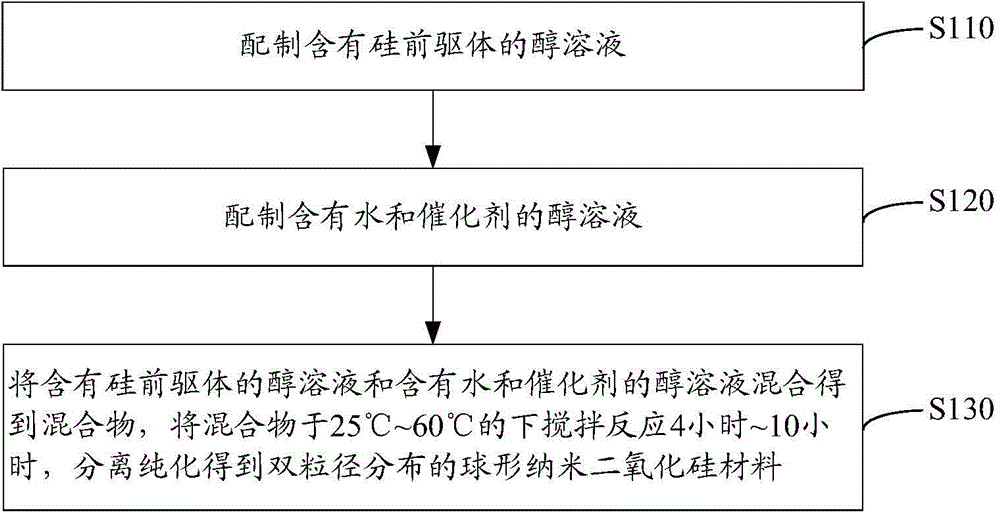

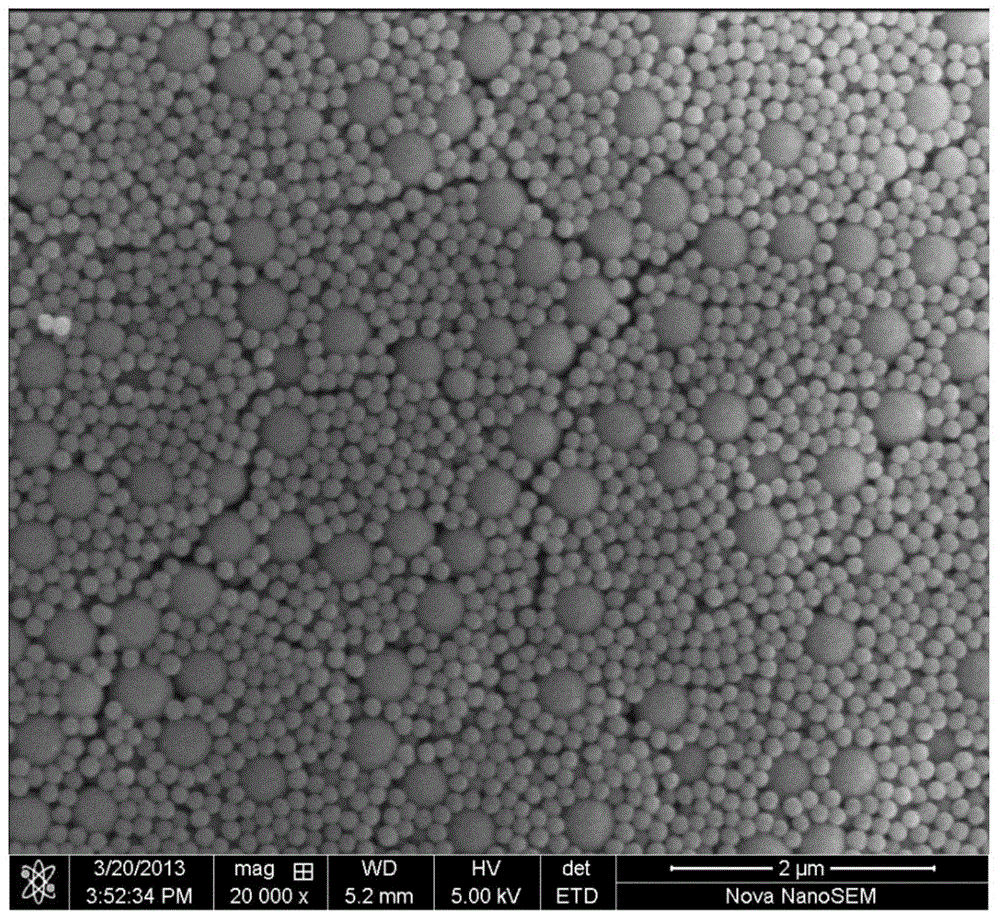

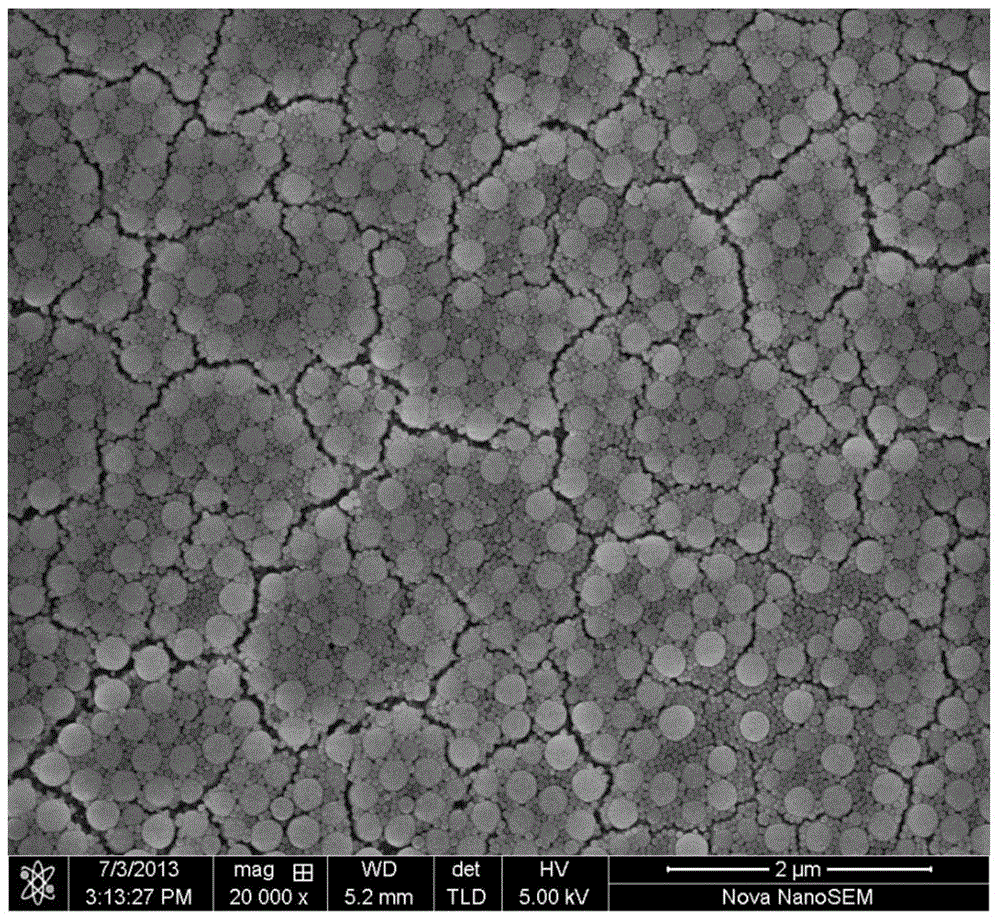

Spherical nano-silica material with dual particle size distribution and preparation method thereof

ActiveCN103864082AImprove thermomechanical propertiesSimple processMaterial nanotechnologySilicaChemical physicsSilicon dioxide

The invention relates to a spherical nano-silica material with dual particle size distribution and a preparation method thereof. The preparation method of the spherical nano-silica material with dual particle size distribution comprises the following steps: preparing an alcoholic solution containing a silicon precursor; preparing an alcoholic solution containing water and a catalyst; and mixing the alcoholic solution containing the silicon precursor and the alcoholic solution containing water and the catalyst to obtain a mixture, stirring the mixture to react for 4-10 hours at 25-60 DEG C, and separating and purifying to obtain the spherical nano-silica material with dual particle size distribution. Experiments prove that the preparation method of the spherical nano-silica material with dual particle size distribution can be used for preparing the spherical nano-silica material with dual particle size distribution in situ. The preparation method disclosed by the invention is simple in process and capable of preparing the spherical nano-silica material with dual particle size distribution in a large scale, so that the thermomechanical performance of an electronically-packaged composite is improved.

Owner:SHENZHEN INST OF ADVANCED TECH

Lightweight brake wheel disk for high speed train

InactiveCN106838064AObvious weight loss effectEasy to brakeBraking discsFriction liningCarbon compositesHigh concentration

The invention discloses a lightweight brake wheel disk for high speed train, comprising a frictional disk made of carbon / ceramic frictional material and a framework disk of carbon-carbon composite material; the frictional disk and the framework disk are bonded to each other and fixedly connected through a rivet, and connected with a wheel through the framework disk. The brake disk is composed of the frictional disk made of carbon / ceramic material and the framework disk made of carbon-carbon material; the whole density is about one third of forged steel, and the wheel disk has obvious weight reducing effect of the brake system and better high temperature performance and brake efficiency; the lightweight brake wheel disk cannot be corroded in the high-concentration oxygen, and the brake performance is greatly improved, thus the carbon-ceramic brake disk can replace the service life of two steel brake disks, and the maintaining cost is greatly reduced.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

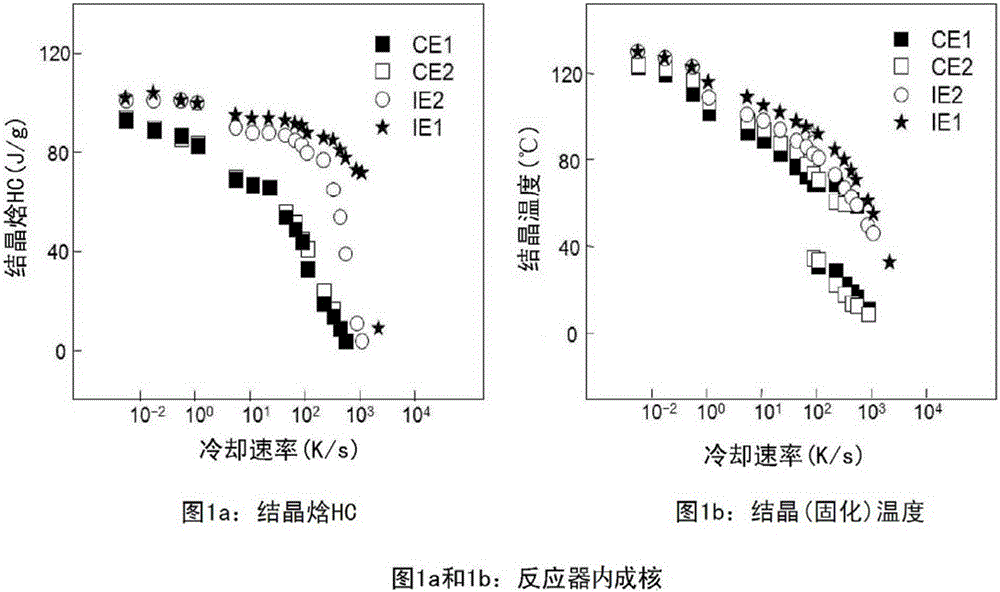

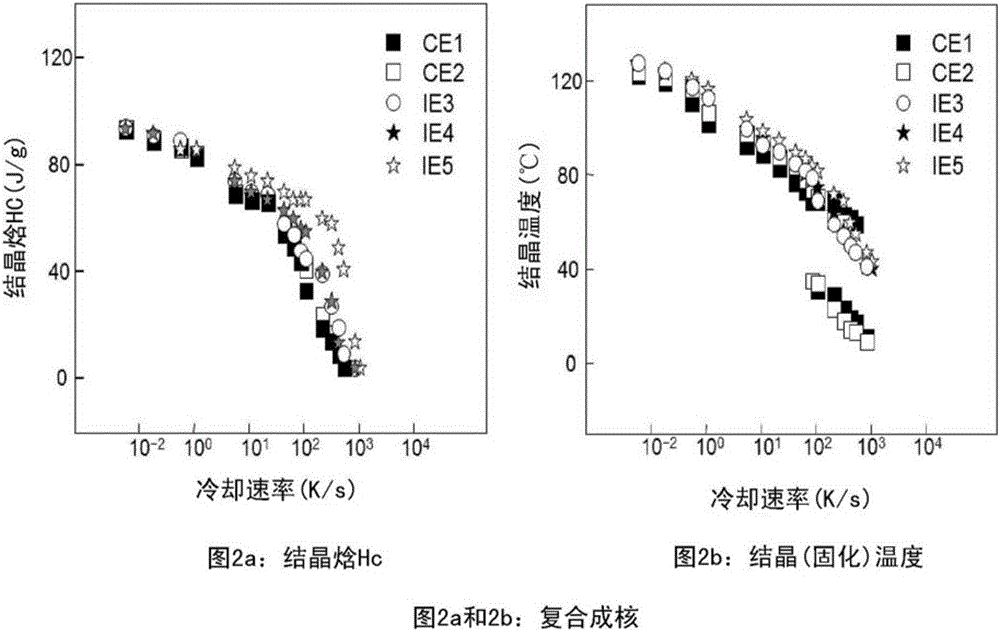

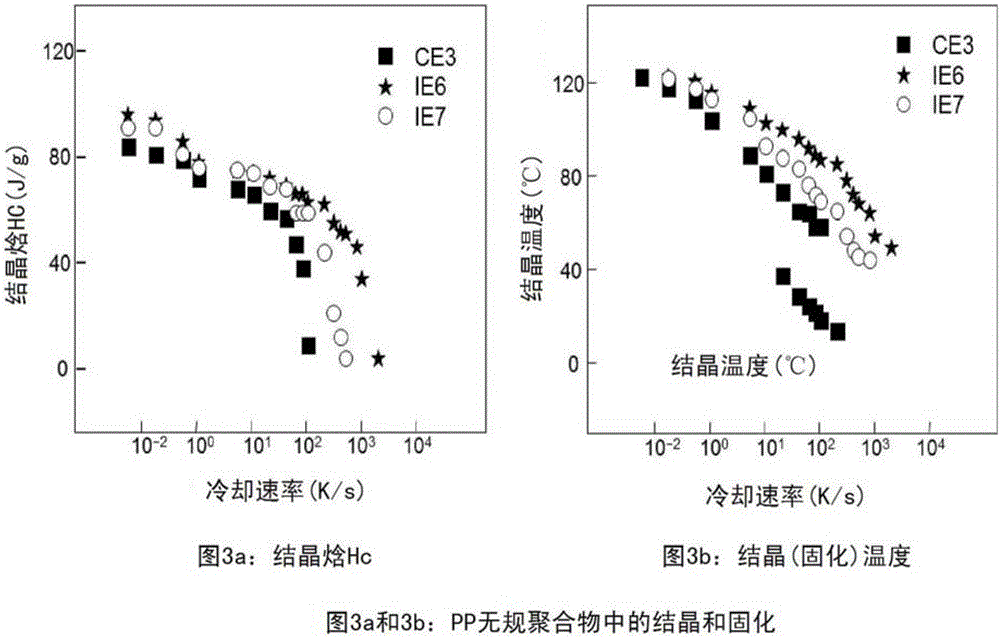

Process for the preparation of an alpha-nucleated polypropylene

ActiveCN106795305AImprove thermomechanical propertiesGood thermomechanical propertiesPolymer sciencePolypropylene

The present invention presents a new method for preparation of an alpha-nucleated crystalline polypropylene based on polymeric nucleating agents and very high cooling rates, further the alpha-nucleated crystalline polypropylene based on polymeric nucleating agents derived thereof and its use in final articles derivable thereof.

Owner:BOREALIS AG

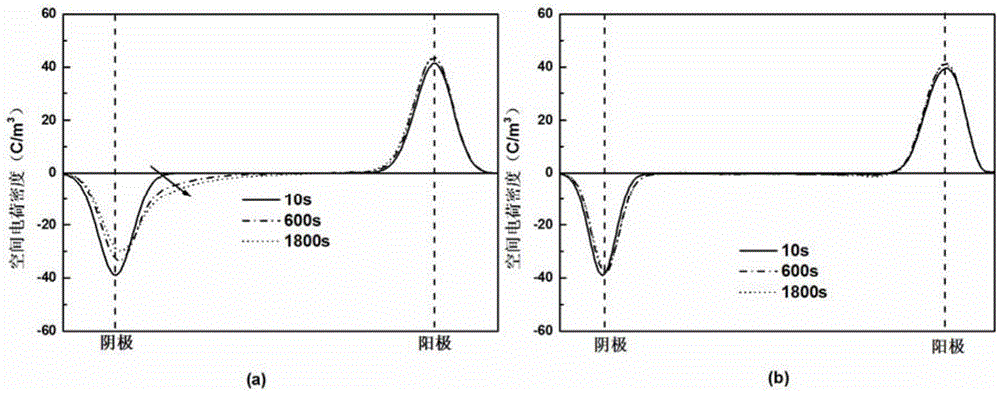

Preparation method for recyclable high-voltage direct-current cable material with function of inhibiting space charge

InactiveCN104927190AImprove thermomechanical propertiesEnhanced inhibitory effectPlastic/resin/waxes insulatorsElastomerProcedure Agents

The invention relates to a preparation method for a recyclable high-voltage direct current cable material with the function of inhibiting space charge, and belongs to the technical field of transmission equipment. The preparation method comprises the following steps: mixing isotatic polypropylene, an elastomer, an antioxidant, a fire retardant and a processing aid for 6-10 minutes under the conditions that the temperature is 190-200 DEG C, and the revolving speed is 40-60 r / min to prepare the high-voltage direct current cable material, wherein the ratio of isotatic polypropylene to the elastomer is 1:(0-0.7), and isotatic polypropylene and the elastomer are 100 parts by weight, the antioxidant is 0.5-1 part by weight, the fire retardant is 2-5 parts by weight, and the processing aid is 0.5-1 part by weight. The recyclable high-voltage direct-current cable material takes a mixture of a thermoplastic polymer material and the elastomer as the raw material, the melting point of the polymer material is higher than or equal to 150 DEG C, and the content of octylene in the elastomer is smaller than 14%. The recyclable high-voltage direct-current cable material has the advantages that under the condition that the thermomechanical properties of thermoplastic resin are improved, the space charge of the recyclable high-voltage direct-current cable material can be inhibited well, the recyclable high-voltage direct-current cable material can be recycled after the design lifetime is reached, and environment is not damaged.

Owner:TSINGHUA UNIV

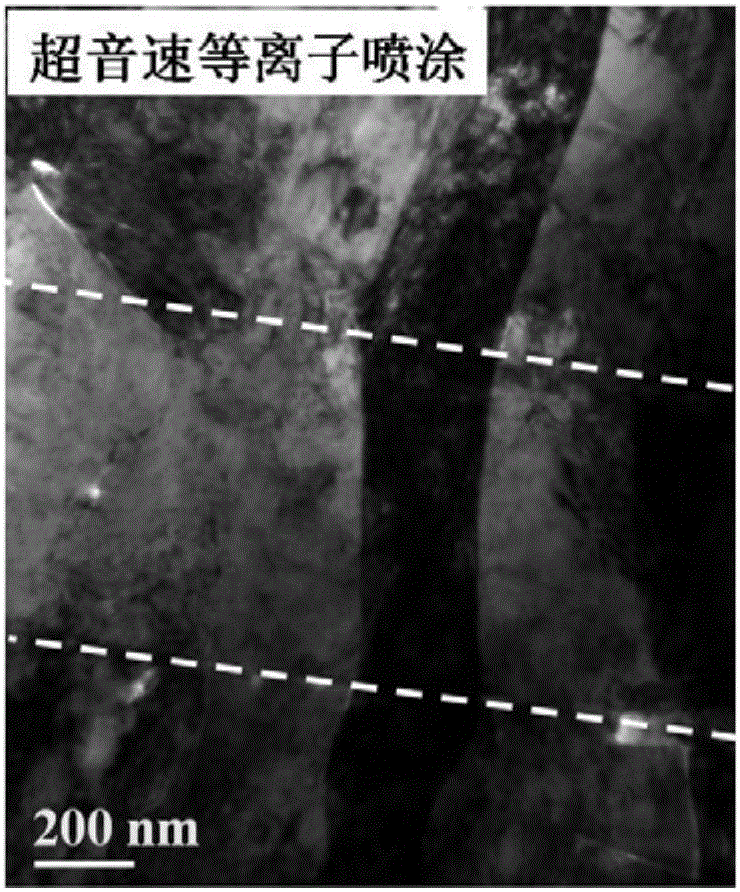

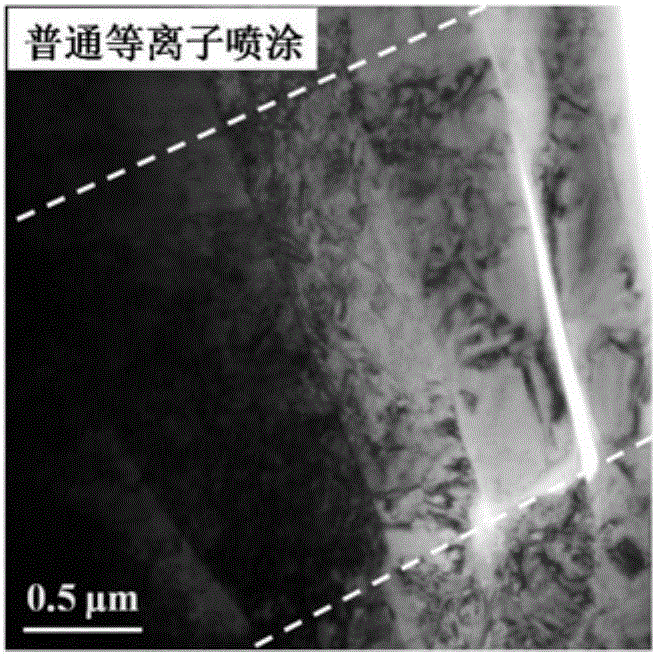

Preparation method of YSZ thermal barrier coating of sheet micro-nano column crystal structure

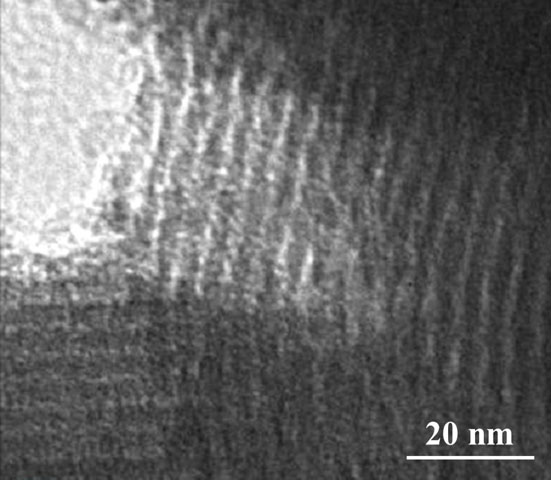

InactiveCN105970145AIncrease cooling rateImprove structural stabilityMolten spray coatingEfficient propulsion technologiesMicroscopic scaleSupersonic speed

The invention discloses a preparation method of a YSZ thermal barrier coating of a sheet micro-nano column crystal structure. The average thickness of laminated structures (or spreading sheets) formed in different embodiments is measured, so that the thickness of each spreading sheet of the obtained supersonic speed plasma spray coating is approximately one third that of a common plasma spray coating. The structure of the supersonic speed plasma spray coating is represented through a field emission scanning electronic microscope, so that a double-mode microstructure with submicron crystals and nanocrystals coexisting therein appears inside each spreading sheet; and the content of different submicron crystals and nanocrystals inside each spreading sheet is further disclosed through a thermal etching displaying method and a quantitative statistic method.

Owner:XI AN JIAOTONG UNIV

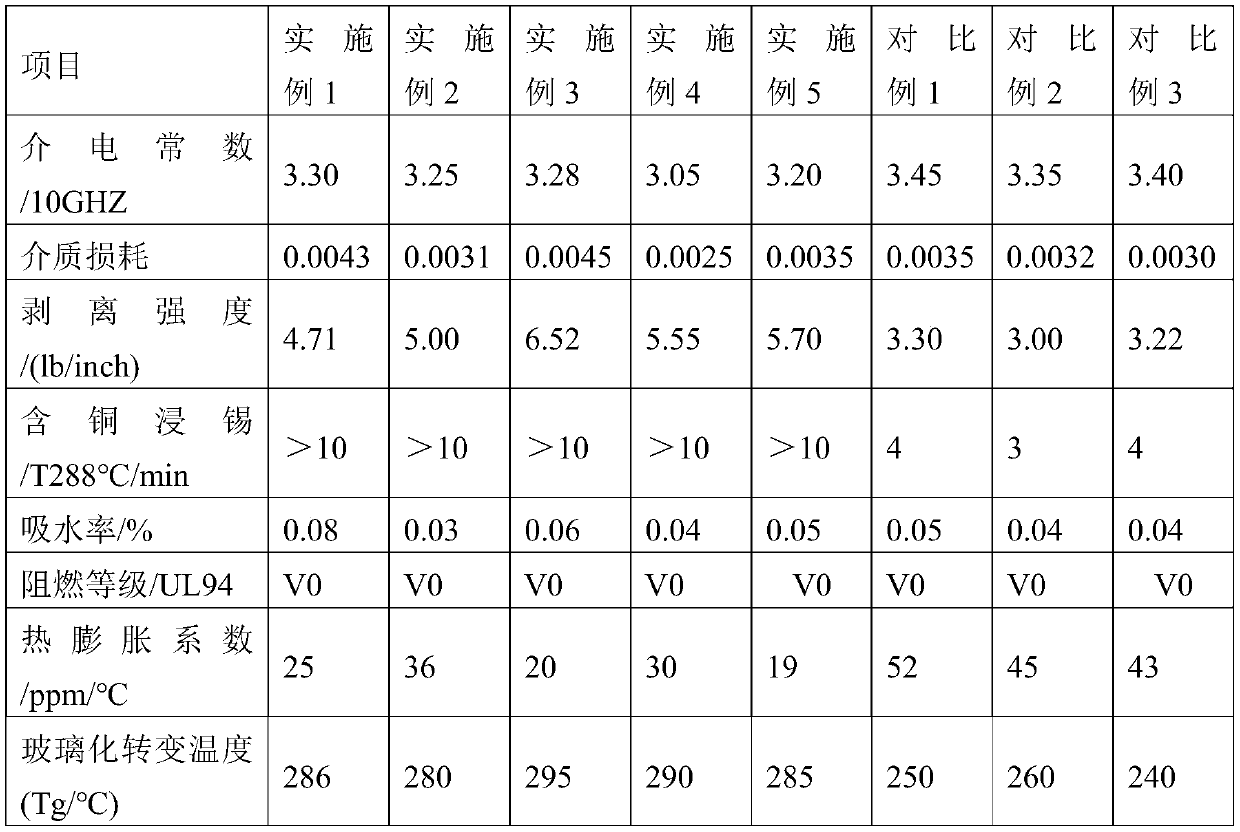

Multifunctional modified resin blended prepreg hydrocarbon composition, application thereof and method for preparing high-frequency and high-speed copper-clad plate by adopting prepreg hydrocarbon composition

ActiveCN111378243ALow dielectric constantSmall dielectric lossLamination ancillary operationsLaminationPolymer scienceButadiene Dioxide

The invention discloses a multifunctional modified resin blended prepreg hydrocarbon composition and an application thereof, and a method for preparing a high-frequency high-speed copper-clad plate byusing the prepreg hydrocarbon composition. The prepreg hydrocarbon composition comprises the following components: 20-60 parts of multifunctional modified resin; 25 to 65 parts of an inorganic filler; 10 to 50 parts of a flame retardant; 0.1 to 10 parts of an antioxidant; and 2-10 parts of a cross-linking agent. The multifunctional modified resin is one or more of a hydroxyl modified polybutadiene polymer, a hydroxyl modified polybutadiene-styrene copolymer, sulfydryl modified polybutadiene, polyether modified polybutadiene, an isoprene-styrene copolymer, a styrene-butadiene-styrene copolymerand a butadiene-acrylonitrile copolymer. The special multifunctional modified resin blended prepreg hydrocarbon composition for the high-frequency copper-clad plate provided by the invention has thecharacteristics of low dielectric constant, low dielectric loss, excellent heat resistance, good thermal mechanical properties, extremely low water absorption and stable performance.

Owner:无锡睿龙新材料科技有限公司

Preparation method of degradation acidity-adjustable self-enhanced polyester/ordered mesoporous degradable bone repair material as well as product and application thereof

InactiveCN109157680AOvercomes the disadvantage of performance degradation caused by molecular weight lossTo overcome the disadvantage of performance degradationTissue regenerationProsthesisPolyesterSilicon oxide

The invention relates to a preparation method of a degradation acidity-adjustable self-enhanced polyester / ordered mesoporous degradable bone repair material as well as a product and application thereof. The self-enhanced and degradation acidity-adjustable composite material is prepared by taking a degradable polyactic acid-based ternary random copolymer as a matrix and a modified ordered mesoporeas an enhancer. The preparation method comprises preparation of a PLLA surface modified MCM-41 mesoporous silicon oxide and preparation of a polyester / PLLA-NH-MCM-41 composite material. In the productobtained by the method, the mesoporous materials are dispersed uniformly into an organic matrix, the two-phase interface compatibility is high, the mechanical property of the polyester base is greatly improved and the pH can be maintained in a neutral range in a degradation process. The obtained product can meet the requirement of clinical application. The preparation process is simple and controllable, small in adding amount of nanometer materials and easy to process and form; and the product has high mechanical strength and stable performance and can serve as a bone repair material of a weight-bearing bone part with relatively high requirements on properties and indexes.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

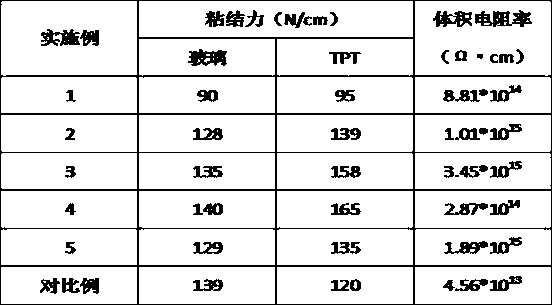

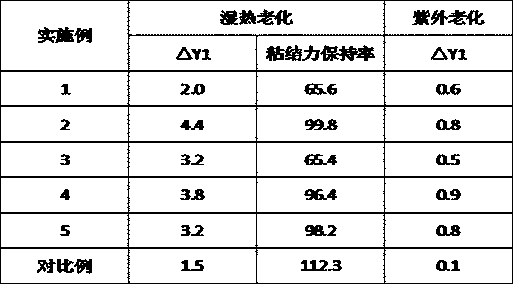

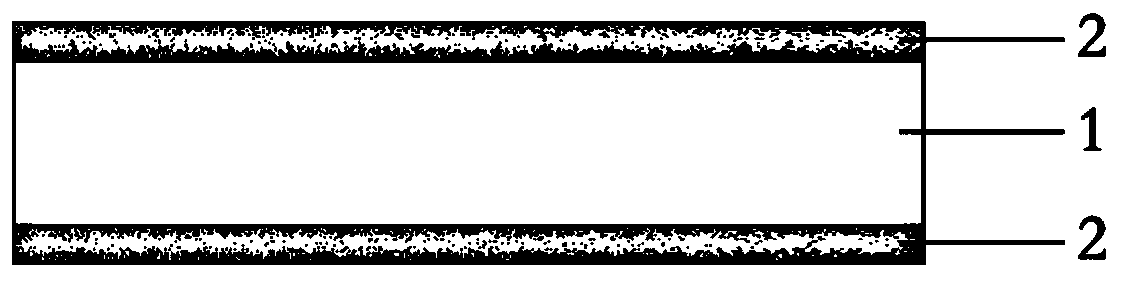

Preparation method of polyolefin packaging film for solar cell module

InactiveCN109206653AExtends free radical lifeLow monomer residueFinal product manufacturePhotovoltaic energy generationPolyolefinElectrical battery

The invention belongs to the technical field of solar packaging materials, in particular to a preparation method of a polyolefin packaging film for a solar cell module. the preparation method comprises the following steps: (1) adding raw materials into a stirring device, uniformly mixing, then adding into a single-screw extruder to carry out reaction extrusion, controlling the extrusion temperature of the screw extruder to be 80-100 DEG c and the screw rotating speed of 20-30 rpm, then extruding, casting and cooling to form a film; and (2) carrying out radiation treatment on the surface of oneside of the prepared packaging film in the step (1), and finally cutting and winding to obtain the polyolefin packaging film for the solar cell module; an anti-oxidant, an ultraviolet light absorbentand a light stabilizer are added to prevent the composition from being subjected to yellowing caused by transition thermal oxidative degradation in the blending extrusion process, so that yellowing and aging of the packaging film can be effectively prevented at the beginning of production of the packaging film, the aging and yellowing resistance of the packaging film after being subjected to solar radiation in the using process can be also improved.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

Method for improving medium-temperature mechanical property of Mg-Al series magnesium alloy pressure castings

The invention discloses a method for improving the medium-temperature mechanical property of Mg-Al series magnesium alloy pressure castings. The method comprises the steps of die-cast formation of magnesium alloy subjected to smelting and aging treatment of the pressure castings subjected to die-cast formation and is characterized in that the aging treatment is directly carried out on the pressure castings after die-cast formation; Pb and Sn are added in the smelting process of the magnesium alloy. The method has the advantages that the Pb and the Sn have the grain refinement effect on structures of the Mg-Al series magnesium alloy pressure castings, the Pb can reduce precipitation of harmful discontinuous second-phase Mg17Al12 and enhance precipitation of beneficial continuous second-phase Mg17Al12 after the aging treatment, and the Sn can form high-melting-point Mg2Sn particles for being precipitated with Mg in the aging process. According to the method, the aging heat treatment is directly carried out instead of being carried out after solution treatment, and therefore the problem that bubbles are generated on the surfaces of the magnesium alloy pressure castings because the temperature is excessively high in the solution treatment process can be avoided.

Owner:CHONGQING UNIV

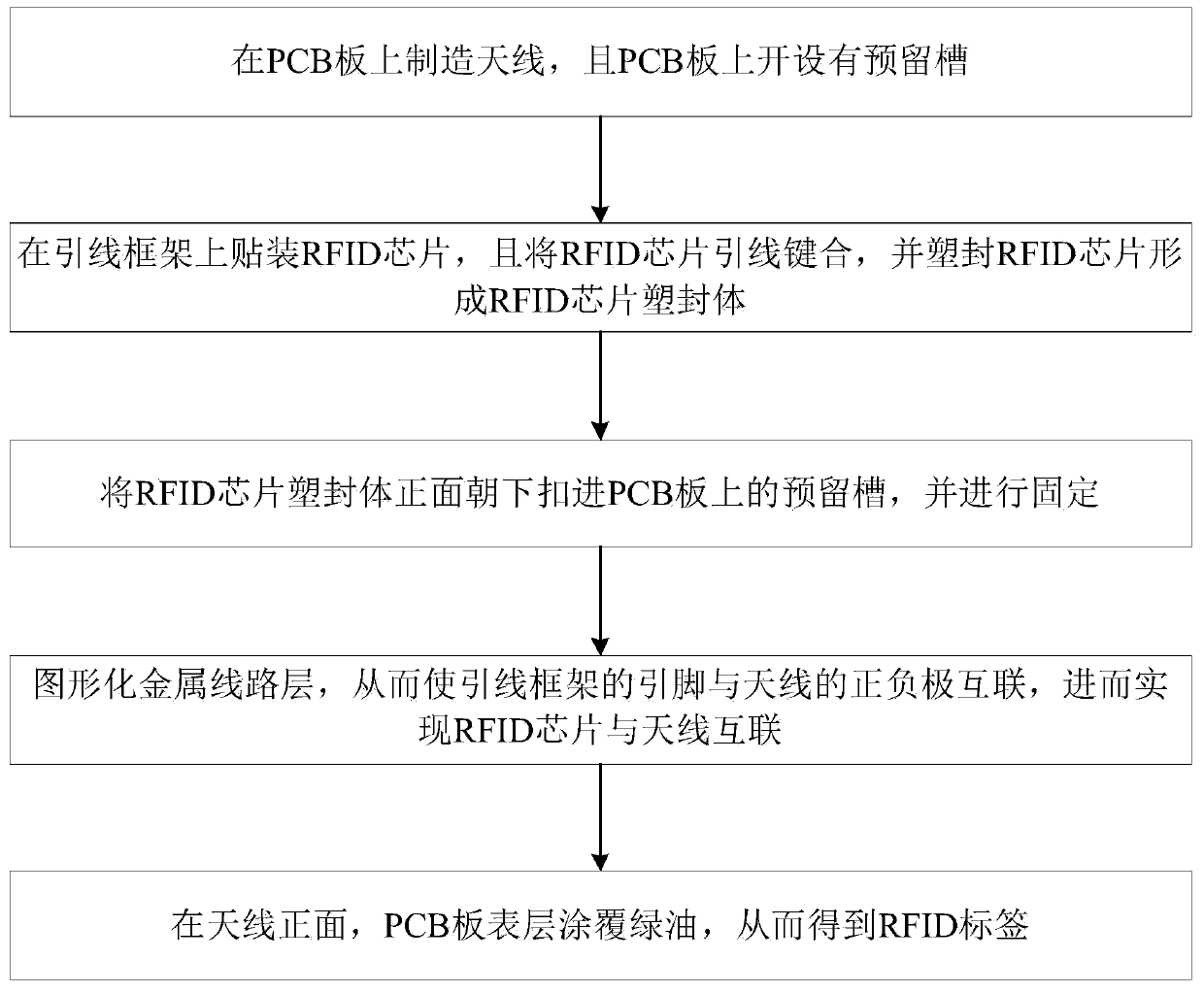

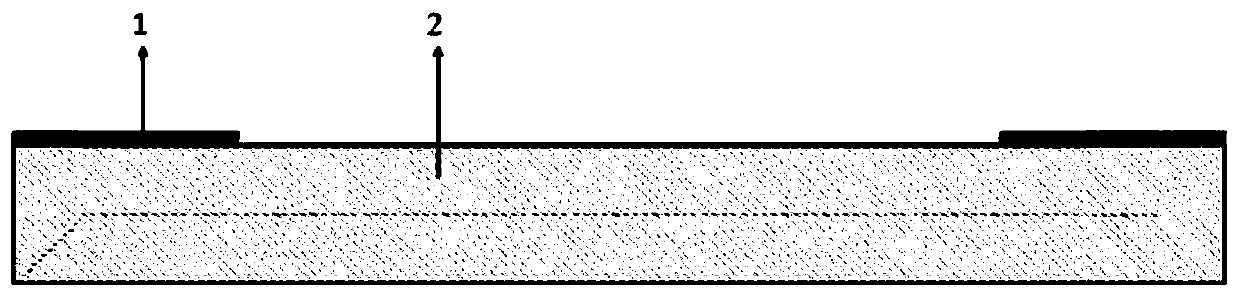

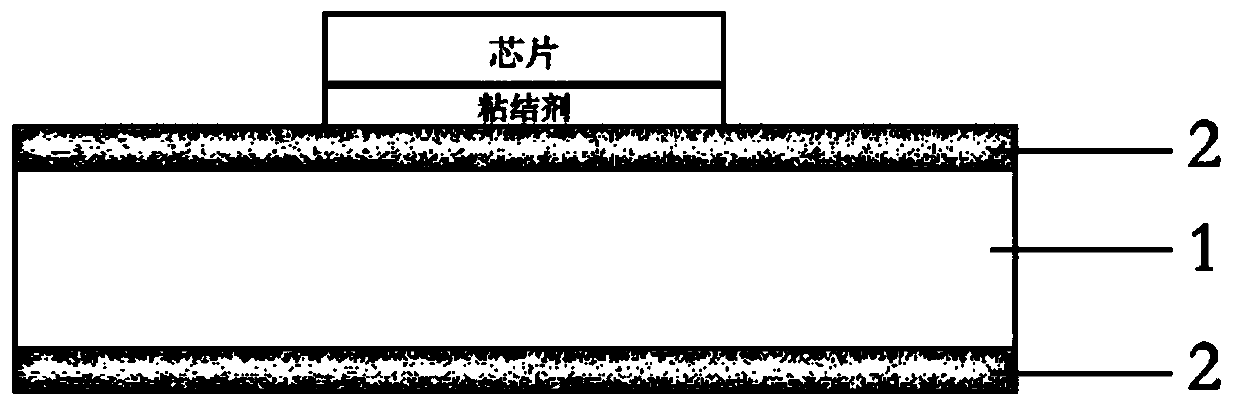

Embedded RFID tag packaging method

InactiveCN110571161AEmbedded packagingAchieve miniaturized packagingSemiconductor/solid-state device detailsSolid-state devicesSurface layerLead bonding

The invention discloses an embedded RFID tag packaging method, which comprises the steps of manufacturing an antenna on a PCB, and forming a reserved groove in the PCB; mounting an RFID chip on a leadframe, performing lead bonding on the RFID chip, and plastically packaging the RFID chip to form an RFID chip plastic package body; buckling the RFID chip plastic package body into the reserved groove in the PCB in a mode of enabling the front of the RFID chip plastic package body to face downwards, and fixing the RFID chip plastic package body; patterning a metal circuit layer, enabling pins ofthe lead frame to be interconnected with the positive electrode and the negative electrode of the antenna, and thus realizing the interconnection between the RFID chip and the antenna; and coating thefront of the antenna and the surface layer of the PCB with green oil to obtain an RFID tag. Therefore, the embedded RFID tag packaging method provided by the invention can meet the requirement of thin and high-reliability packaging.

Owner:BEIJING SMARTCHIP MICROELECTRONICS TECH COMPANY +2

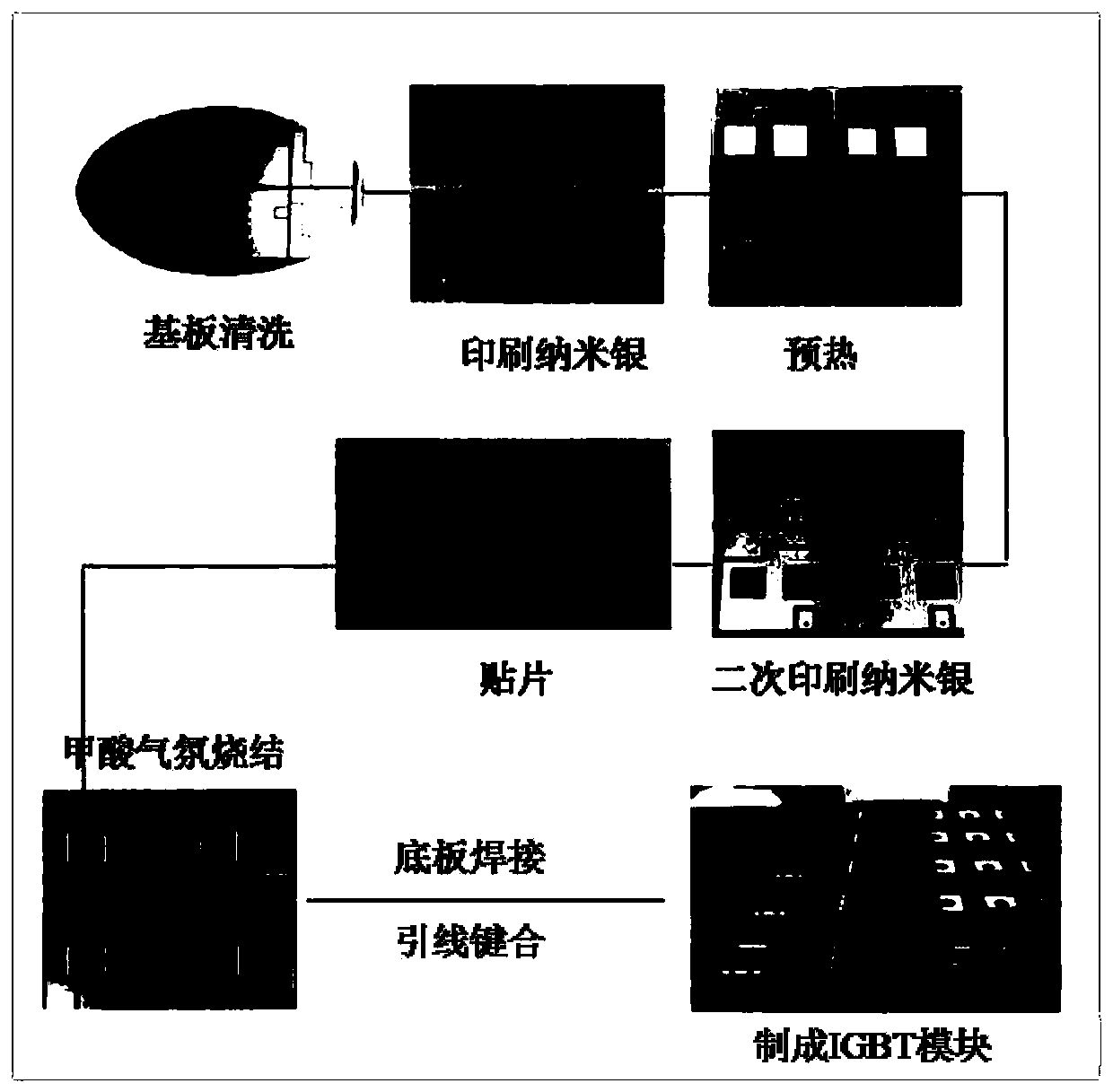

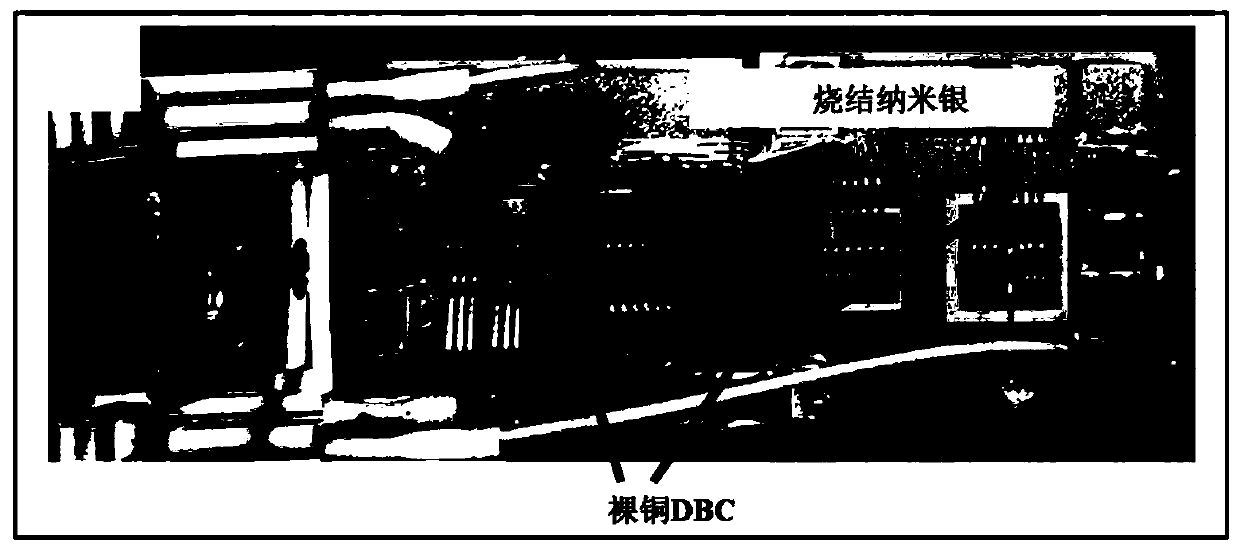

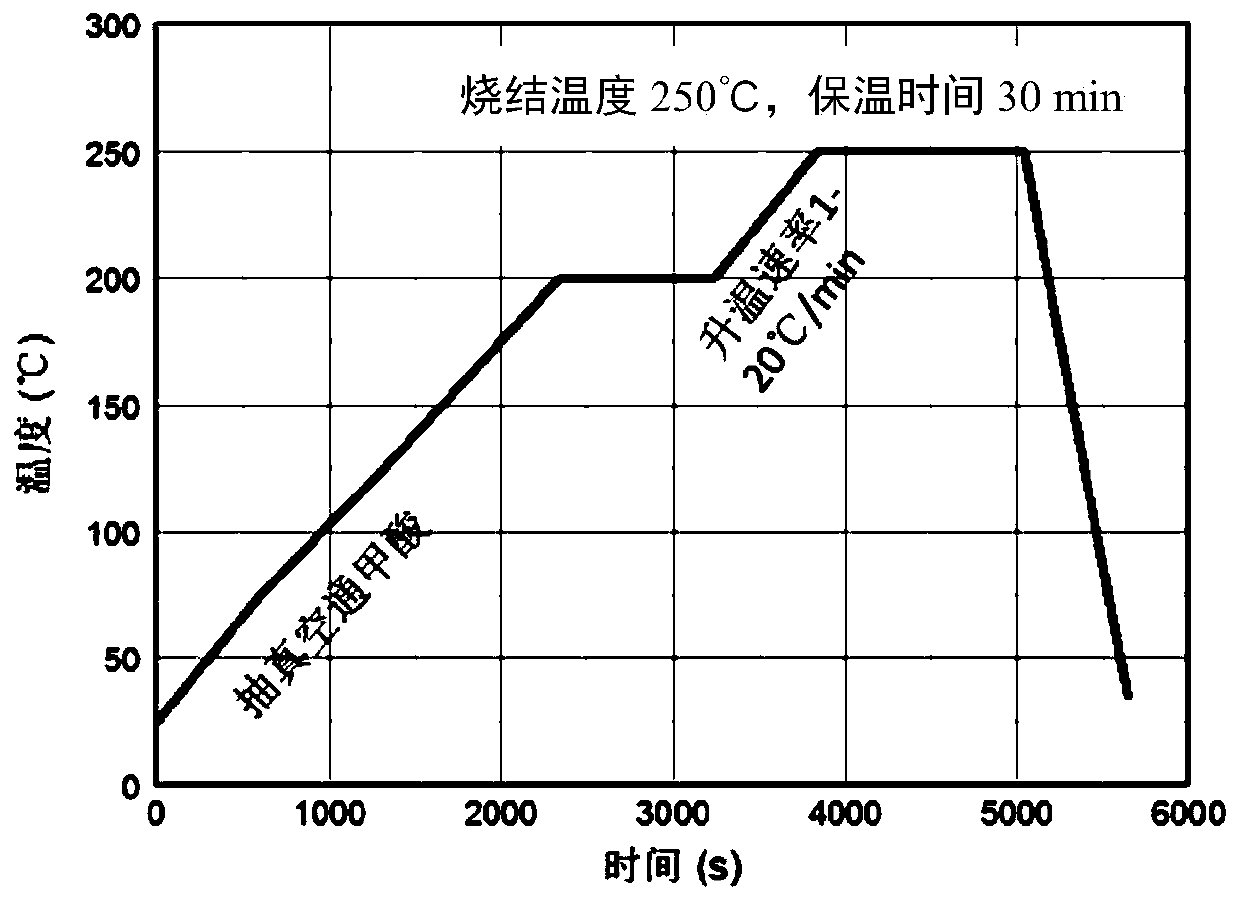

A kind of nanometer silver solder paste connects the power module manufacturing method of bare copper DBC

ActiveCN107871675BImprove reliabilitySuitable connectionSolid-state devicesSemiconductor/solid-state device manufacturingStencil printingDBc

The invention relates to a method for manufacturing a power module for connecting bare copper DBCs with nano-silver solder paste, including a cleaning process, a solder paste printing process, a patch process, and a sintering process; the cleaning process uses ultrasonic oscillation to clean the bare copper DBC, and the solder paste The printing process adopts stencil printing to realize the printing of nano-silver solder paste, and the nano-silver is printed twice; the placement process adopts placement machine placement; the sintering process adopts vacuum reflow furnace sintering to obtain formic acid oxygen-free atmosphere, and control the sintering temperature and temperature rise rate. It can not only realize the densified connection between the nano-silver solder paste and the bare copper DBC, but also prevent the oxidation of the bare copper DBC. The invention does not require special equipment, the processing procedure is convenient and easy, and the process is simple. It is suitable for realizing the connection between the power chip and the bare copper substrate or the copper-clad substrate through the nano-silver solder paste, which ensures the reliability of the subsequent wire bonding and improves the The reliability of the power module has greatly promoted the application of nano-silver solder paste in the packaging of power semiconductor modules.

Owner:TIANJIN UNIV

Spherical nano-silica material with double particle size distribution and preparation method thereof

ActiveCN103864082BImprove thermomechanical propertiesSimple processMaterial nanotechnologySilicaAlcoholSilicon dioxide

The invention relates to a spherical nano-silica material with dual particle size distribution and a preparation method thereof. The preparation method of the spherical nano-silica material with dual particle size distribution comprises the following steps: preparing an alcoholic solution containing a silicon precursor; preparing an alcoholic solution containing water and a catalyst; and mixing the alcoholic solution containing the silicon precursor and the alcoholic solution containing water and the catalyst to obtain a mixture, stirring the mixture to react for 4-10 hours at 25-60 DEG C, and separating and purifying to obtain the spherical nano-silica material with dual particle size distribution. Experiments prove that the preparation method of the spherical nano-silica material with dual particle size distribution can be used for preparing the spherical nano-silica material with dual particle size distribution in situ. The preparation method disclosed by the invention is simple in process and capable of preparing the spherical nano-silica material with dual particle size distribution in a large scale, so that the thermomechanical performance of an electronically-packaged composite is improved.

Owner:SHENZHEN INST OF ADVANCED TECH

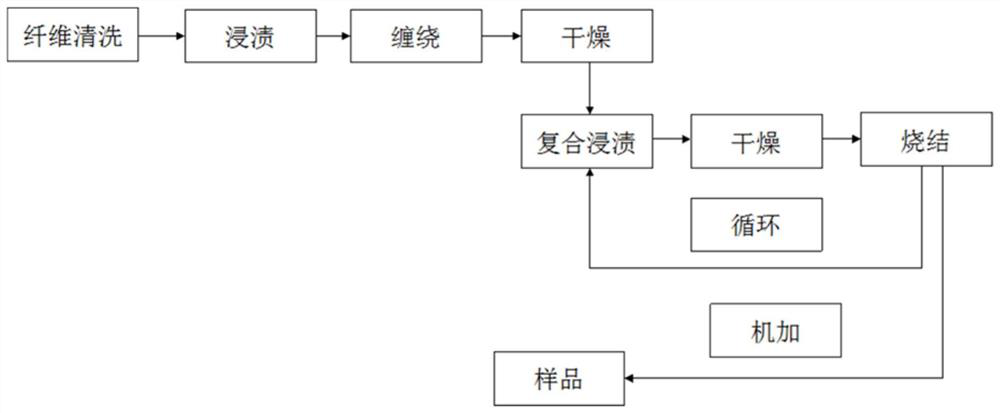

Method for preparing fiber reinforced ceramic matrix composite material

The invention relates to a method for preparing a fiber reinforced ceramic matrix composite material. The method comprises the following steps: 1) pretreating fibers to remove epoxy resin on the surfaces of the fibers; 2) impregnating the pretreated fibers in the sol to obtain completely impregnated fibers; (3) winding the impregnated fibers on a core mold, and drying; 4) sequentially carrying out composite dipping, drying, composite dipping, drying and sintering on the dried sample piece; and 5) repeating the step 4) for multiple times to obtain the fiber reinforced ceramic matrix composite material. The ceramic-based composite material with high fiber volume content is prepared by combining a fiber winding process and a sol-gel method, so that the time can be saved, the mechanization can be improved, the production cost can be reduced, and the fiber volume content can be improved by changing the fiber type, the ceramic matrix, the particle size distribution and fiber orientation of sol for impregnation and a winding mode. The thermal mechanical property of the fiber reinforced ceramic matrix composite material is adjusted.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

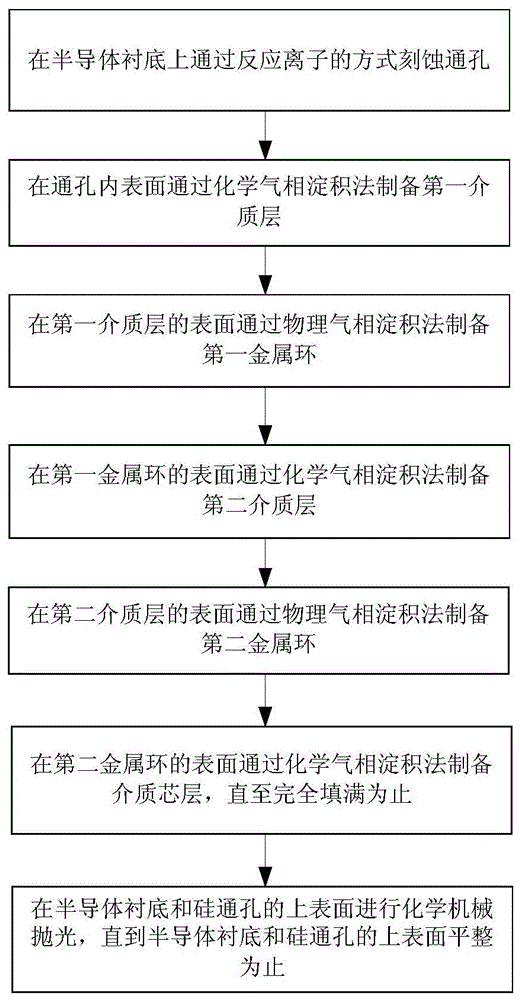

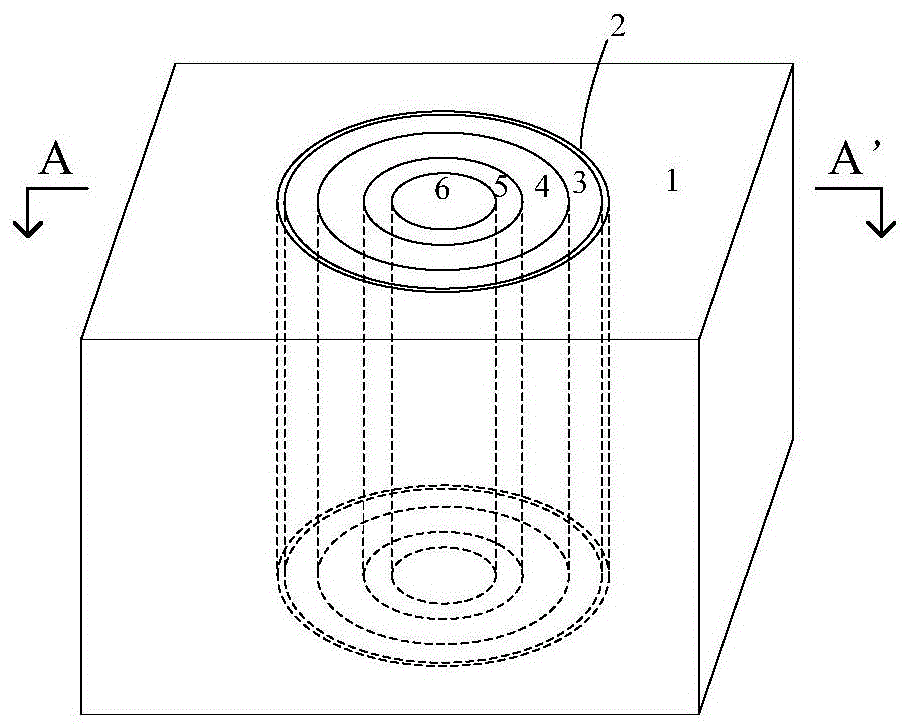

A double-ring through-silicon via structure and its manufacturing method

InactiveCN104201165BRealize the function of shielding noise signalHigh Frequency Signal IntegritySemiconductor/solid-state device detailsSolid-state devicesDielectric layerSemiconductor

The invention relates to a double-ring silicon through silicon via structure and a manufacturing method thereof. The double-ring silicon through silicon via structure comprises a semiconductor substrate, a first dielectric layer, a first metal ring, a second dielectric layer, a second metal ring and a dielectric core layer sequentially from outside to inside. The manufacturing method of the double-ring silicon through silicon via structure includes: (1) forming a through via in the semiconductor substrate by etching; (2) preparing the first dielectric layer on the inner surface of the through via; (3) preparing the first metal ring on the surface of the first dielectric layer; (4) preparing the second dielectric layer on the surface of the first metal ring; (5) preparing the second metal ring on the surface of the second dielectric layer; (6) preparing the dielectric core layer on the surface of the second metal ring until fullness is achieved; (7) performing chemical mechanical polishing on the upper surfaces of the semiconductor substrate and the through silicon via. By adoption of the first metal ring which is arranged outside and grounded, a function of shielding noise signals is realized, and high integrity of high-frequency signals is achieved; by adoption of the second metal ring arranged inside, thermal stress is reduced, and thermo-mechanical property is improved.

Owner:XIAN UNIV OF TECH

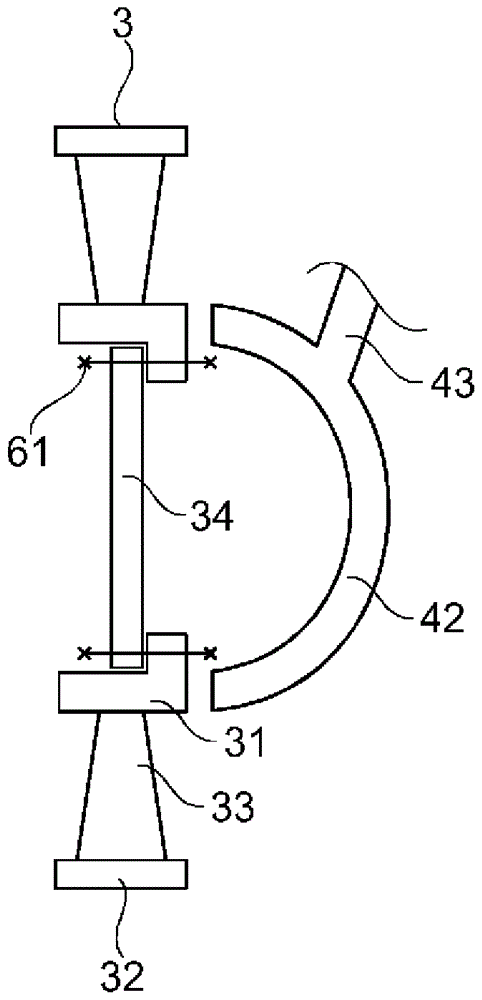

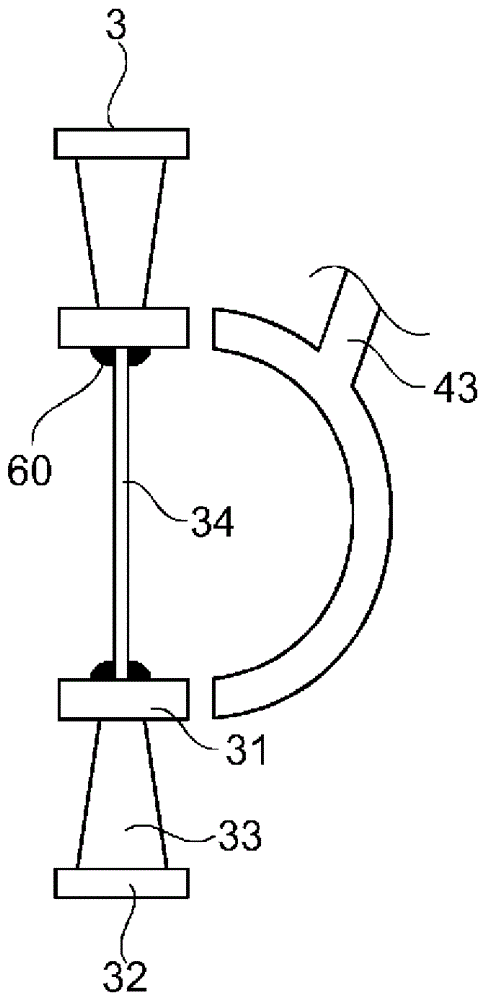

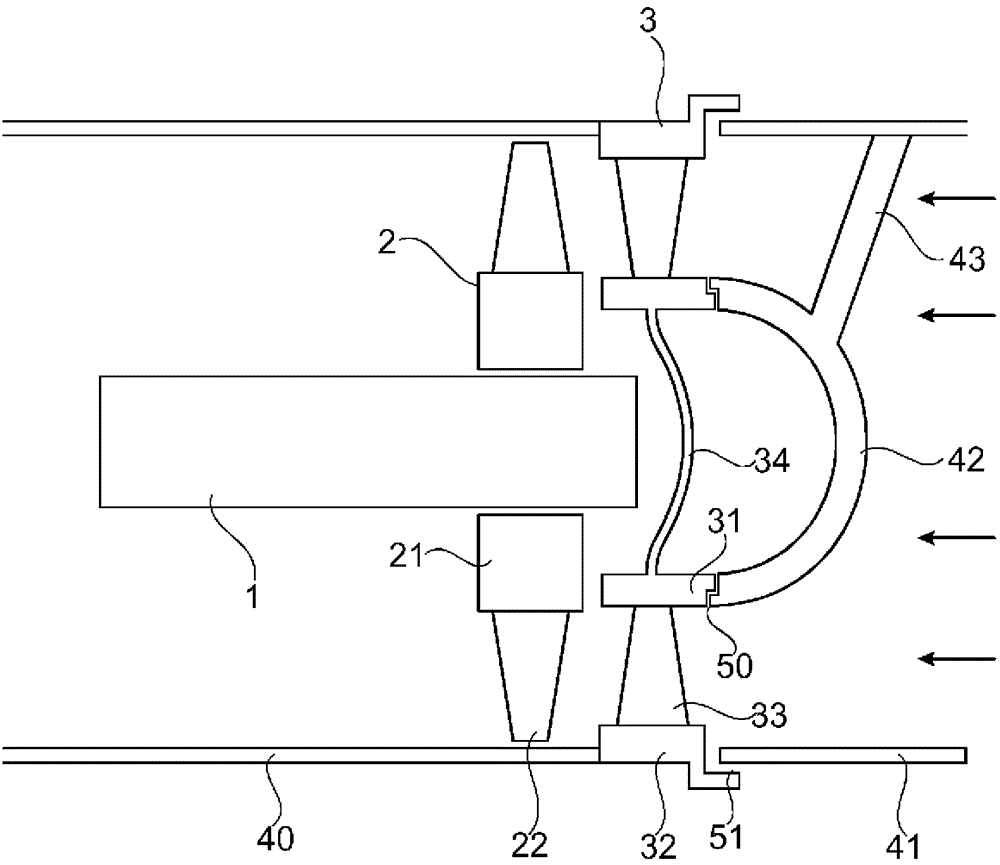

Exhaust gas turbine with closed nozzle ring

The invention relates to an exhaust gas turbine having a shaft (1) and a turbine wheel (2), and which has an internally closed nozzle ring (3). The nozzle ring (3) has guide blades (33) and an inner ring (31) that lies radially inside in relation to the guide blade (33). An inner surface of the nozzle ring (3) bounded by the inner ring (31) is filled out by a cover (34) and sealed in regard to the exhaust gas flow, such that the inner surface is closed in regard to a throughflow of the exhaust gas. Thus, the sealing point between the nozzle ring (3) and an inner gas inlet housing (42) is omitted and is transferred to a technically simpler seal between the nozzle ring (3) and the cover (34).

Owner:TURBO SYST SWITZERLAND LTD

Flameproof polyacrylonitrile fibre and method for preparing same

InactiveCN1297697CGood physical and mechanical propertiesImprove flame retardant performanceMonocomponent synthetic polymer artificial filamentArtifical filament manufacturePolymer sciencePentaerythritol

The invention discloses a flame-proof polyacrylonitrile fiber and its manufacturing method. Said fiber comprises at least 5%-25% by polyacrylonitrile weight of APP flame retardant, or APP flame retardant treated by silane coupler or titanate coupler, furthmore, comprises pentaerythritol, bi-pentaerythritol and like polyhydric alcohol compound, which has a APP-to-polyhydric alcohol ratio ranging from 2 to 3.8 by wt / wt. The method for manufacturing said fiber includes: crossblending the flame retardant with the inorganic solvent spinning dope of polyacrylonitrile, which is obtained by one-step method or two-step method to prepare crossblending spinning dope, then spinning, washing, drafting and thermal sizing by using current technique of making acrylon with inorganic solvent spinning line. The invention applies cheap, non-poisonous and high efficient inorganic additive flame retardant APP to spin flame retardant acrylon, as a result, crossblending spinning dope with good spinnability and fiber with high flame retardancy is obtained.

Owner:CHINA PETROLEUM & CHEM CORP +2

A method for improving the medium-temperature mechanical properties of mg‑al magnesium alloy die castings

InactiveCN105420649BImprove the mechanical properties at medium temperatureImprove grain refinement effectSolution treatmentSmelting process

The invention discloses a method for improving the medium-temperature mechanical property of Mg-Al series magnesium alloy pressure castings. The method comprises the steps of die-cast formation of magnesium alloy subjected to smelting and aging treatment of the pressure castings subjected to die-cast formation and is characterized in that the aging treatment is directly carried out on the pressure castings after die-cast formation; Pb and Sn are added in the smelting process of the magnesium alloy. The method has the advantages that the Pb and the Sn have the grain refinement effect on structures of the Mg-Al series magnesium alloy pressure castings, the Pb can reduce precipitation of harmful discontinuous second-phase Mg17Al12 and enhance precipitation of beneficial continuous second-phase Mg17Al12 after the aging treatment, and the Sn can form high-melting-point Mg2Sn particles for being precipitated with Mg in the aging process. According to the method, the aging heat treatment is directly carried out instead of being carried out after solution treatment, and therefore the problem that bubbles are generated on the surfaces of the magnesium alloy pressure castings because the temperature is excessively high in the solution treatment process can be avoided.

Owner:CHONGQING UNIV

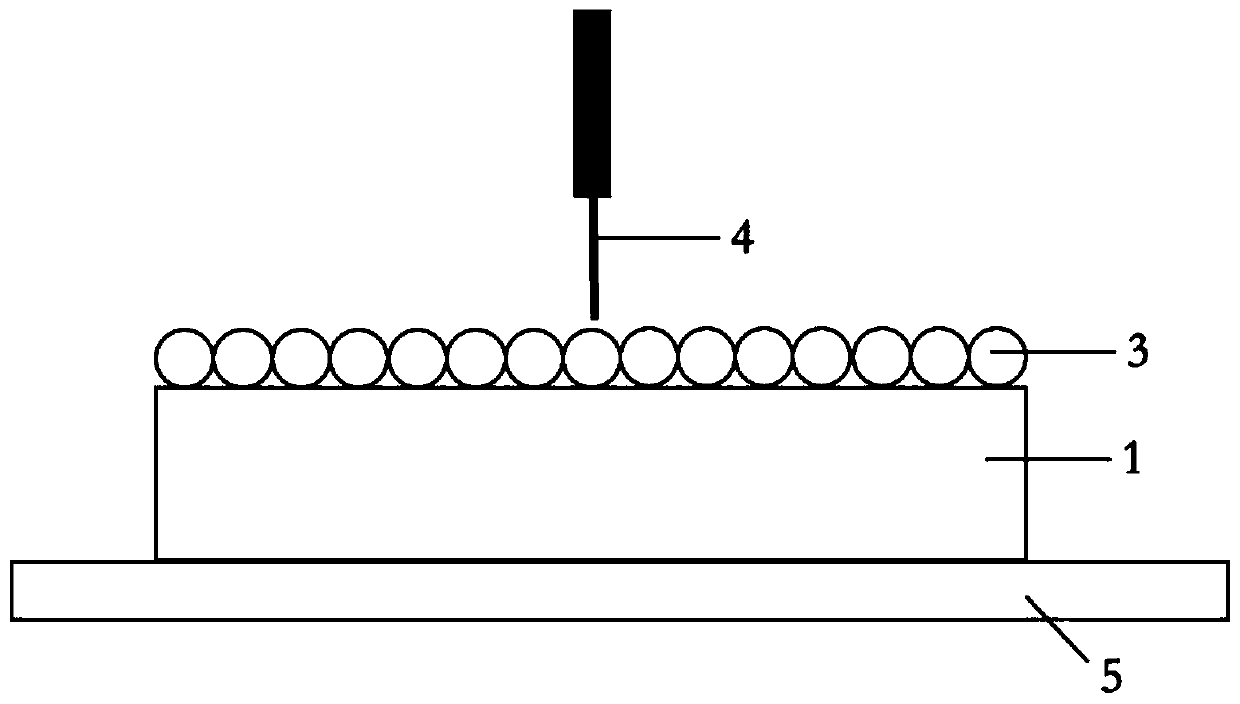

Silicon carbide surface-enhanced aluminum heat dissipation substrate and manufacturing method thereof

InactiveCN110957228AUniform deformationIncrease stiffnessSemiconductor/solid-state device detailsSolid-state devicesThermal dilatationDevice material

The invention belongs to the technical field of electronic packaging, and particularly relates to a silicon carbide surface-enhanced aluminum heat dissipation substrate and a manufacturing method. Nanometer silicon carbide ceramic particles are evenly spread on the surface of an aluminum substrate, the nanometer silicon carbide ceramic particles are sintered through laser beams or electron beams,and the surface of the aluminum substrate is evenly covered with a formed silicon carbide layer; and the nanometer silicon carbide particles at the interface permeate into the surface layer of the aluminum material to form firm interface connection. The overall thermal expansion coefficient of the aluminum heat dissipation substrate is reduced, the hardness and strength are improved, warping is reduced, thermal fatigue failure and crack generation and expansion are reduced, the thermal mechanical property of the aluminum heat dissipation substrate is improved, the aluminum heat dissipation substrate is applied to the field of electronic packaging, and the reliability of a semiconductor device can be improved.

Owner:FUDAN UNIV

A kind of preparation method of high-precision ceramic ferrule

The invention provides a preparation method of a high-precision ceramic ferrule and a preparation method of partially stabilized zirconium oxide powder for the high-precision ceramic ferrule. The preparation methods provided by the invention have the following advantages: firstly, silicon oxide, molybdenum oxide, zinc oxide, scandium oxide and holmium oxide are adopted, so that the thermal stress property of partially stabilized zirconium ceramic is high, the thermo-mechanical property of zirconium oxide is improved, and the ferrule material can be higher in strength, high in thermal shock resistance, low in deformation possibility and free from cracking; secondly, through an ethylene-vinyl acetate copolymer, TPEE, PTT, HDPE, polyformaldehyde and the like are polymerized in an interpenetrated manner to form an interpenetrated network structure, so that the obtained ceramic ferrule is low in deformation possibility and relatively high in precision; thirdly, an adopted organic binding agent has high liquidity, so that the ceramic ferrule is high in homogeneity and free from cracking; finally, due to the sequence of adding the organic binding agent during mixed refining, the feeding rheological property can be relatively high, a blank material can be easier to degrease, and then the prepared ceramic ferrule can be prevented from cracking.

Owner:NINGBO BRIGHT PHOTOELECTRIC TECH

A kind of preparation method of high-strength zirconia ceramic ferrule

The invention provides a method for manufacturing a high-strength zirconia ceramic core insert and a method for preparing part of zirconia stabilizing powder for the high-strength zirconia ceramic core insert. According to the method for manufacturing the high-strength zirconia ceramic core insert, firstly, scandia and cerium oxide are made to react with zirconia, nano titania and aluminum oxide are mixed at the same time, so that the linear expansion coefficient and thermal stress performance which are more excellent than that of pure zirconia ceramic are obtained, in this way, the material can have high strength, high tenacity and excellent thermal shock resistance, and deformation is unlikely to occur; secondly, an SEBS elastomer, polrvinyl benzene, aldehyde resin and the like are inserted into part of zirconia stabilizing powder for polymerization, so that an interspersed network structure is formed, a stable structural system is obtained, and deformation is unlikely to occur; thirdly, the aldehyde resin and the polrvinyl benzene are taken as main binding agents, in this way, the strength of formed blank is high, conformality is good, the degreasing speed is high, and the precision is high; fourthly, stearate radical is removed during sintering of zinc stearate, so that the zinc stearate is oxidized into zinc oxide, and thus the strength of the core insert is improved.

Owner:NINGBO BRIGHT PHOTOELECTRIC TECH

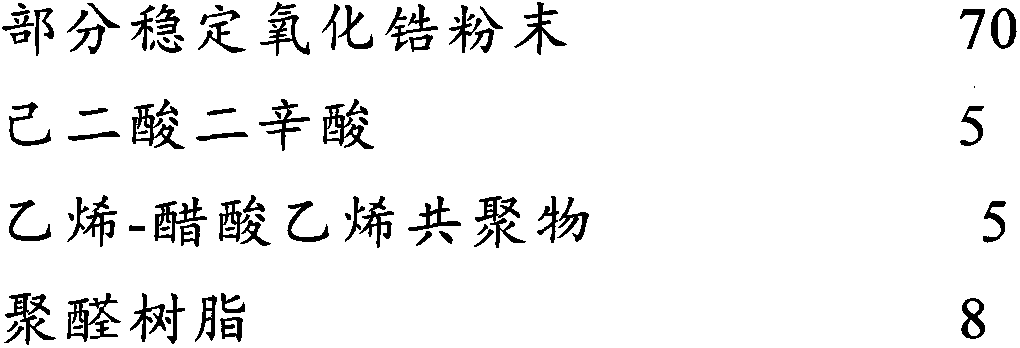

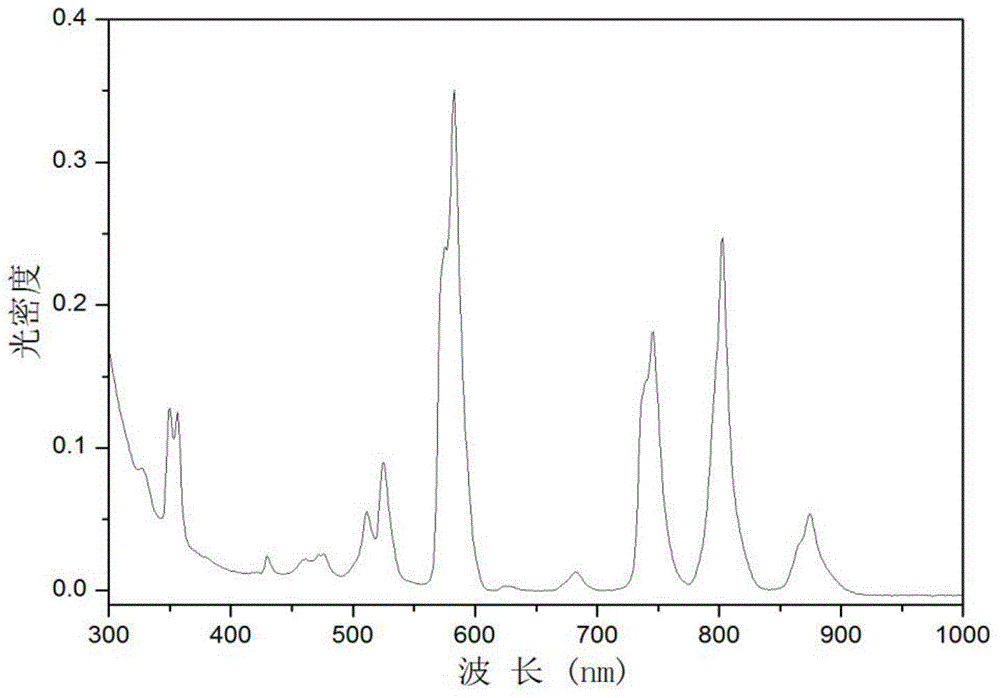

Phosphate-silicate laser neodymium glass with thermal shock resistance, and preparation method thereof

InactiveCN104860534ASmall coefficient of thermal expansionImprove fracture toughnessHigh fracturePhosphate

The invention discloses phosphate-silicate laser neodymium glass with thermal shock resistance, and a preparation method thereof. The glass is composed of 40-56mol% of P2O5, 8-22mol% of SiO2, 15-20mol% of Al2O3, 10-15mol% of MgO, 10-15mol% of Li2O, 0.2-3mol% of Nd2O3, and 0-0.3mol% of Sb2O3. The phosphate-silicate laser neodymium glass has relatively low thermal expansion coefficient, relatively high fracture toughness and relatively high thermal conductivity. The glass can withstand higher thermal shock and is prevented from being damaged. The glass also has a moderate stimulated emission cross section and a relatively long fluorescence lifetime, thus is widely applied as a gain medium in a repetition-frequency large-energy laser system.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

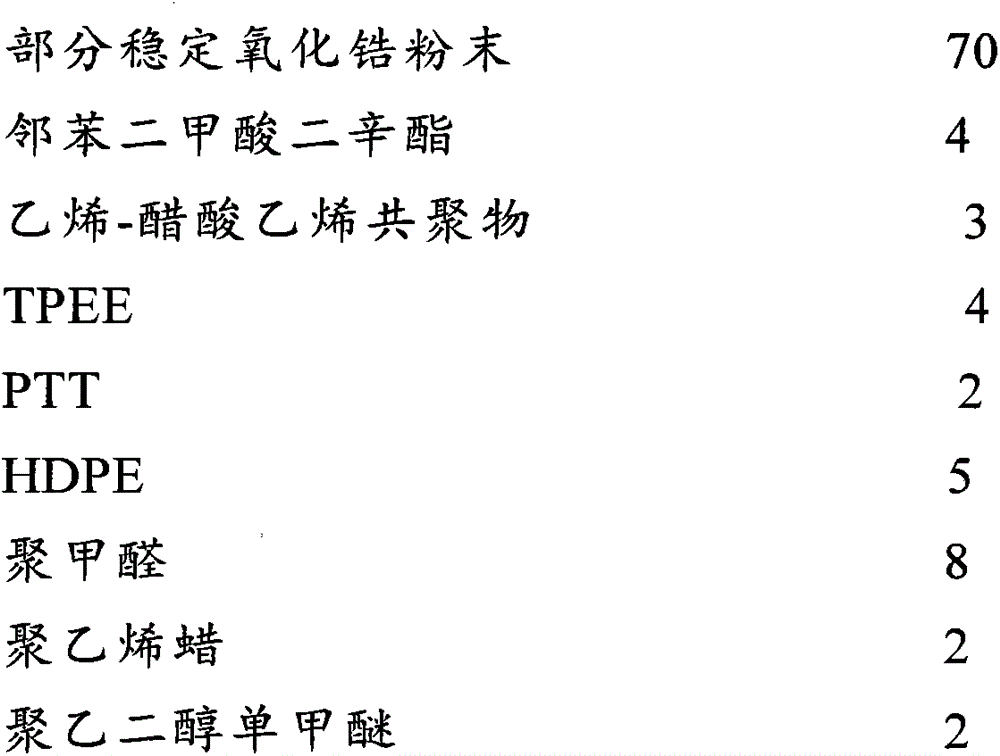

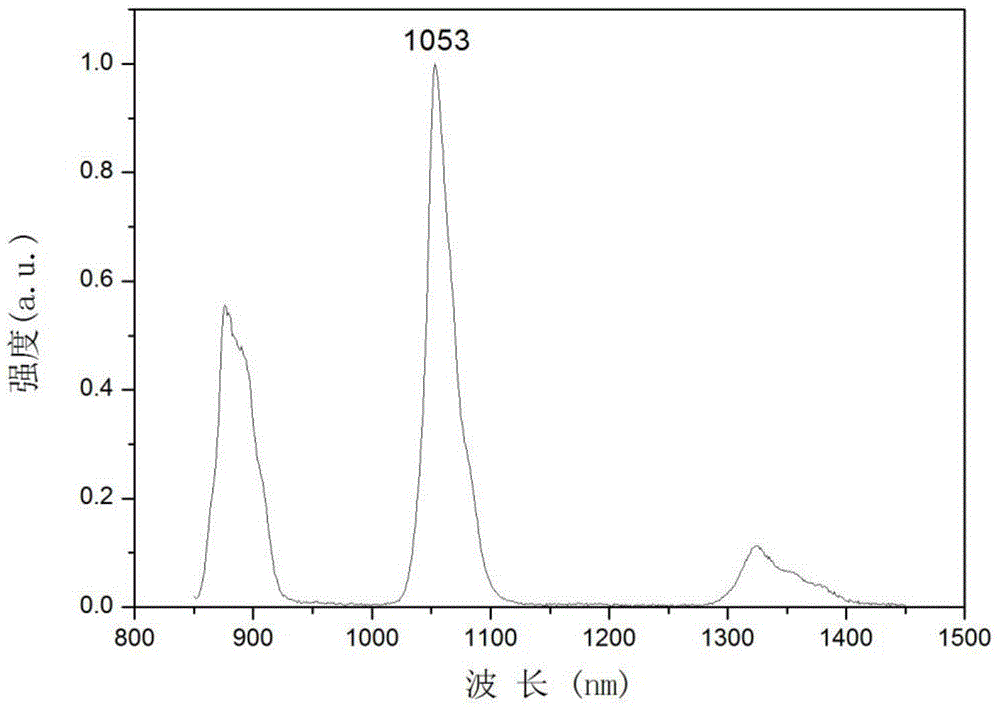

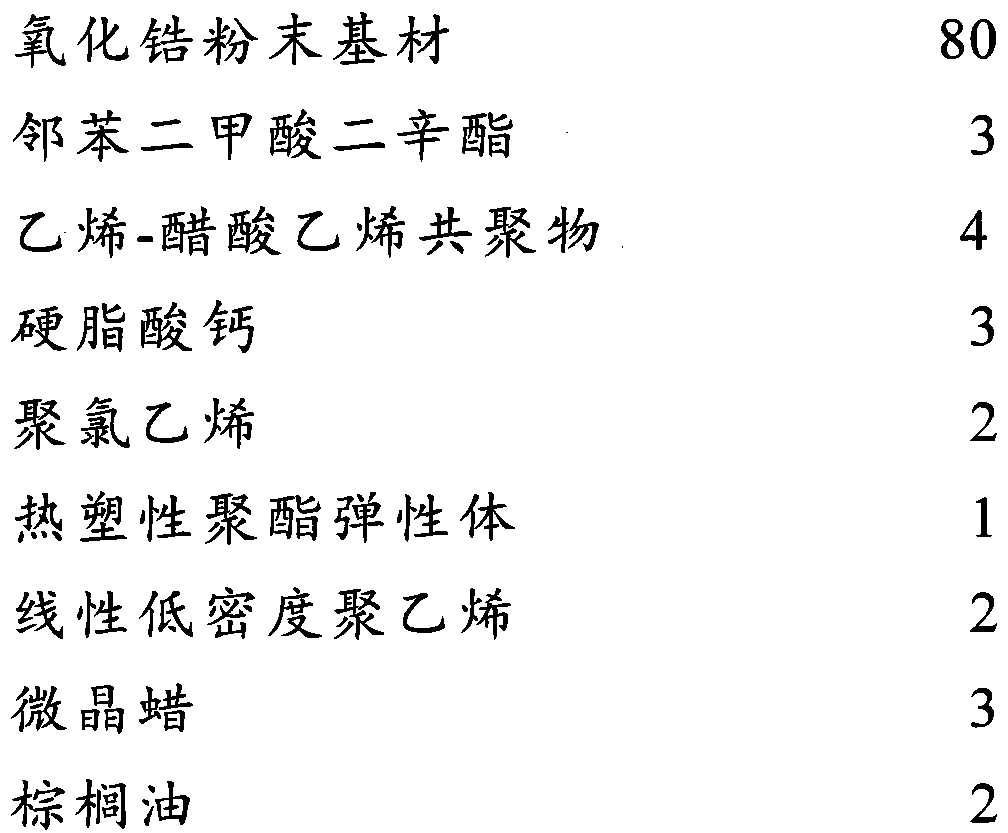

A kind of preparation method of anti-aging zirconia ceramic ferrule

The invention provides a method for preparing an anti-aging zirconia ceramic insert core, a zirconia powder composite base material and a method for preparing the same. Samarium oxide takes effect with zirconia to achieve the stabilizing effect and has a synergistic effect with magnesium oxide, aluminum oxide and scandium oxide, the thermal mechanical performance of zirconia is improved, so that the zirconia ceramic insert core has high strength and toughness and excellent thermal shock resistance. On the other hand, an ethylene-vinyl acetate copolymer causes thermoplastic polyester elastomer, polyvinyl chloride and linear low density polyethylene to interpenetrate in zirconia ceramic to be polymerized to form an interpenetrating network structure and obtain a stable structure system; dioctyl phthalate serves as a plasticizer, microcrystalline wax, palm oil and calcium stearate serve as auxiliary adhesives, so that an injection molding material is good in mobility, high in demolding performance and short in degreasing cycle, the strength of formed green bodies is guaranteed, the zirconia ceramic insert core obtained after sintering has high strength and anti-aging performance, and the pass rate is improved.

Owner:NINGBO BRIGHT PHOTOELECTRIC TECH

an electrical connector

ActiveCN105390842BImprove conductivityHigh strengthContact member cases/bases manufactureCoupling contact membersManganeseEngineering

The invention belongs to the field of electrical and signal connection technologies, and particularly relates to an electrical connector. The electrical connector comprises an inner conductor, an installation board and a shell body, and is characterized in that: the inner conductor is made of copper alloy, and is composed of the following components by weight: 0.012 to 0.043% of cobalt, 0.034 to 0.045% of vanadium, 0.038 to 0.045% of manganese, 0.078 to 0.088% of zinc, 0.12 to 0.20% of silicon, 0.020 to 0.032% of samarium, 0.032 to 0.042% of titanium, 0.022 to 0.034% of tin, 0.045 to 0.056% of nickel, and the balance being copper. The inner conductor adopted by the electrical connector has excellent conductive performance and high strength, the tensile strength thereof reaches 610 to 635Mpa, the conductivity ranges from 81 to 83.5% IACS, and the softening-resistant temperature reaches 455 to 468 DEG C.

Owner:NINGBO TALENLY ELECTRONICS TECH CO LTD

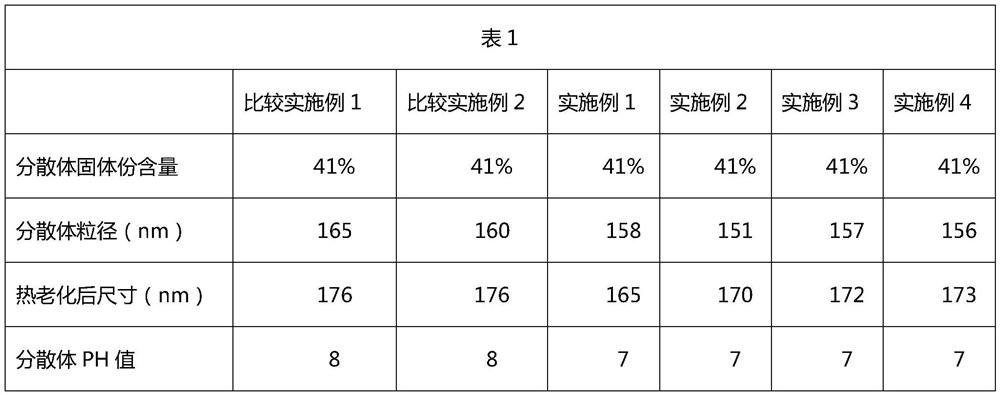

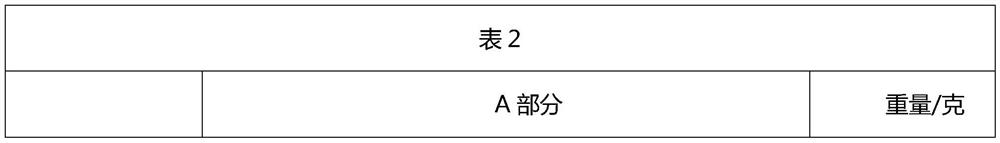

Thermosetting polymer aqueous dispersion as well as preparation method and application thereof

InactiveCN112708035AStable storageHigh selectivityAnti-corrosive paintsGraft polymer adhesivesPolymer scienceCoating system

The invention discloses a thermosetting polymer water-based dispersion as well as a preparation method and application thereof, relates to a preparation method of the thermosetting polymer water-based dispersion, and particularly relates to a method for directly introducing hybrid resin containing glycidyl ether active reaction groups through covalent bond reaction in a polymerization process of polyurethane and an acrylic monomer, and further preparing the aqueous dispersion capable of being crosslinked at room temperature. The aqueous dispersion is storage stable and contains functional groups of a monoglycidyl ether crosslinkable at room temperature. In the crosslinking reaction process with different amine curing agents, the film forming uniformity is good, and the selectivity universality to the amine curing agents is high. The aqueous dispersion can be widely applied to a waterborne coating system, can be used as a single component, and can also be cross-linked with a common amine curing agent at room temperature, so that the thermal mechanical property, chemical resistance and corrosion resistance of a coating are effectively improved.

Owner:上海朗派新材料科技有限公司

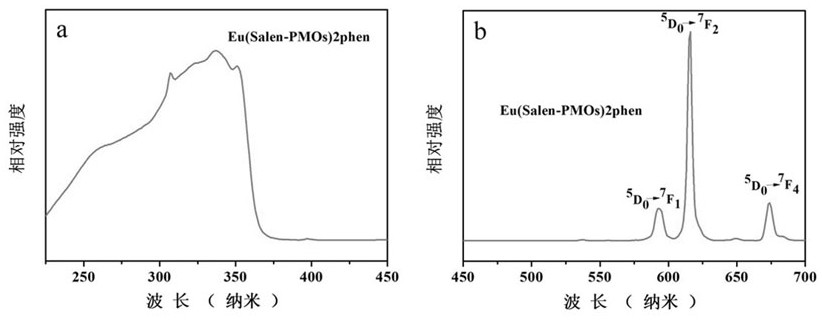

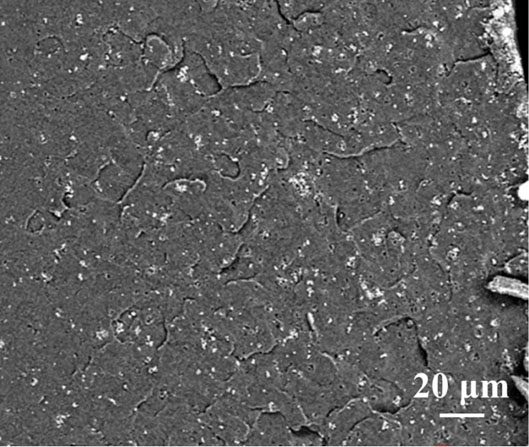

Preparation, product and application of fluorescently labeled polyester/periodic mesoporous bone filling composites with degradable rate

ActiveCN109568675BEvenly dispersedImprove interface compatibilityTissue regenerationProsthesisPolymer scienceNanoparticle

The invention relates to the preparation, product and application of a polyester / periodic mesoporous bone filling composite material whose degradation rate can be fluorescently marked. Firstly, rare earth periodic mesoporous nanoparticles with fluorescent properties were synthesized, then the rare earth periodic mesoporous nanoparticles were chemically modified with low molecular weight poly-L-lactic acid as a modifier, and finally added to the polyester matrix by solution blending middle. The product obtained by the above method and the application of the product as a composite bone filling material in bone repair are also provided. The fluorescent mesoporous material obtained by the method of the invention is evenly dispersed in the organic matrix, the mechanical properties of the polyester base are greatly improved, and the degradation behavior of the composite bone filling material can be monitored in real time. The preparation process is simple, and it can be used as a bone filling material for load-bearing bone parts with high performance index requirements. The obtained composite material can meet the requirement of clinical application.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

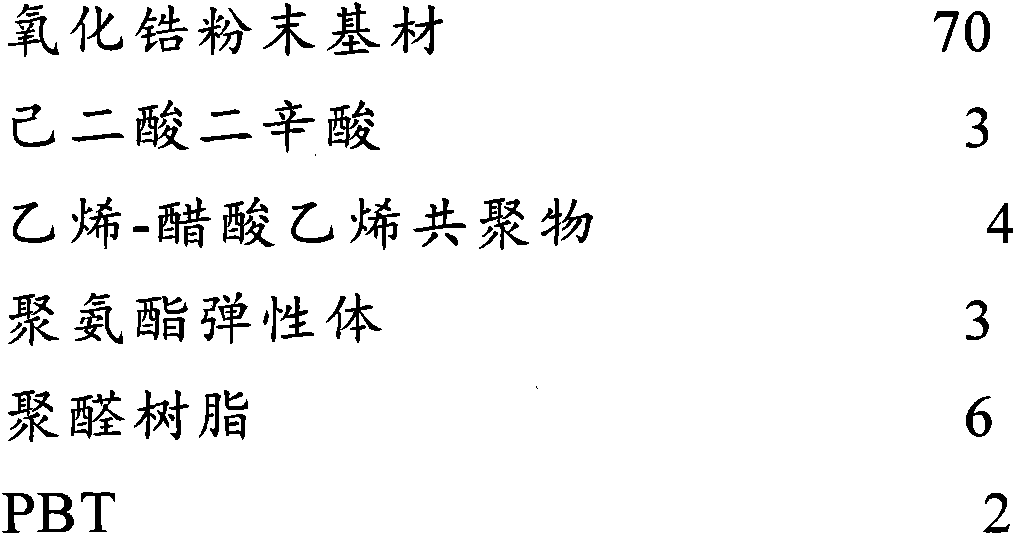

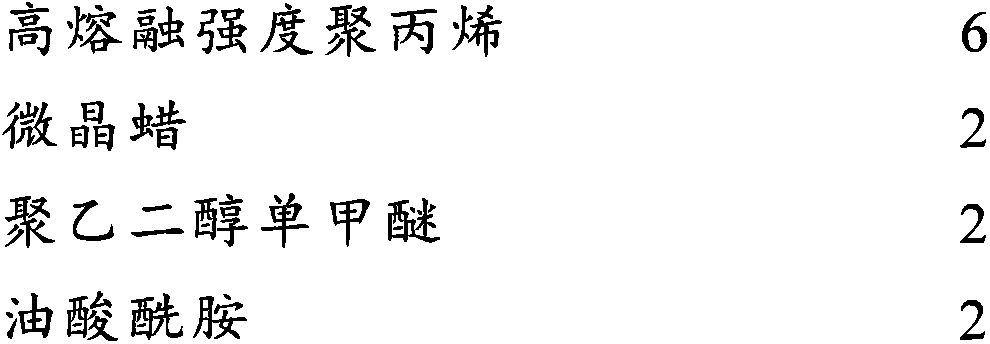

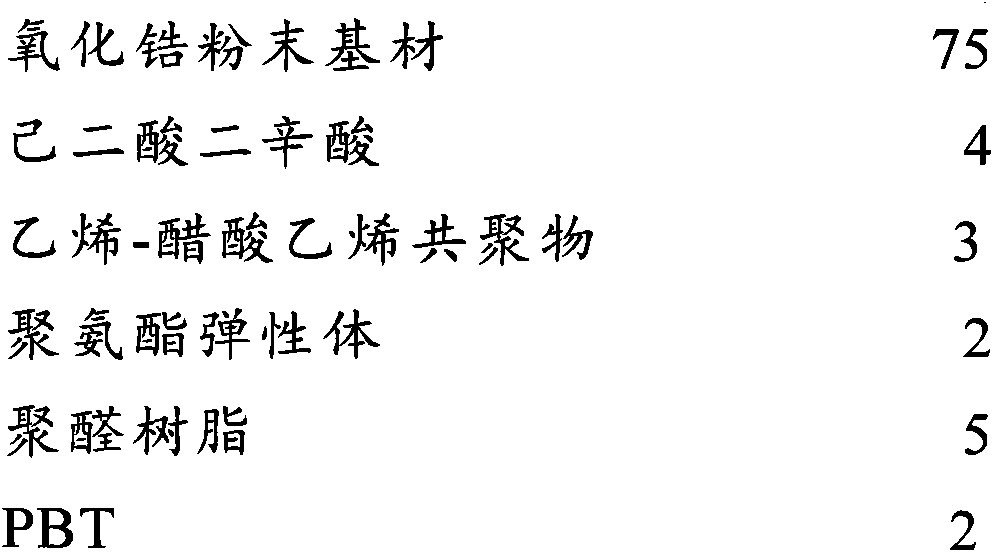

A kind of preparation method of zirconia ceramic ferrule

The invention provides a preparation method of a zirconia ceramic ferrule and a preparation method of a zirconia powder base material used for the zirconia ceramic ferrule. The titanium dioxide used in the present invention makes the material have excellent fluidity in the injection molding process, and the synergistic effect of magnesium oxide, zinc oxide and titanium oxide obtains better linear expansion coefficient and thermal stress performance than pure zirconia ceramics, and improves the entire system at the same time Excellent thermomechanical properties make the material have high strength. Second, ethylene-vinyl acetate copolymer has high elasticity and toughness. Polyurethane elastomer, polyacetal resin, high-melt strength polypropylene, etc. are interspersed in zirconia powder through ethylene-vinyl acetate copolymer to polymerize these organic The adhesive forms a structure that intersects the network very well, and a stable structural system is obtained, so that the formed ceramic ferrule is not easily deformed. Third, the polyaldehyde resin is used as an organic binder to make the molded body have high strength, good shape retention, fast degreasing speed and high precision.

Owner:NINGBO BRIGHT PHOTOELECTRIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com