Preparation method of YSZ thermal barrier coating of sheet micro-nano column crystal structure

A thermal barrier coating, micro-nano technology, applied in coatings, metal material coating processes, air transportation, etc., can solve the problems of large thickness of the layered structure of the coating, low flying speed of droplets, and insufficient flattening. , to achieve the effect of improving thermomechanical properties, increasing flat rate, and increasing cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A preparation method of a thin-film micro-nano-column crystal structure YSZ thermal barrier coating of the present invention comprises the following steps:

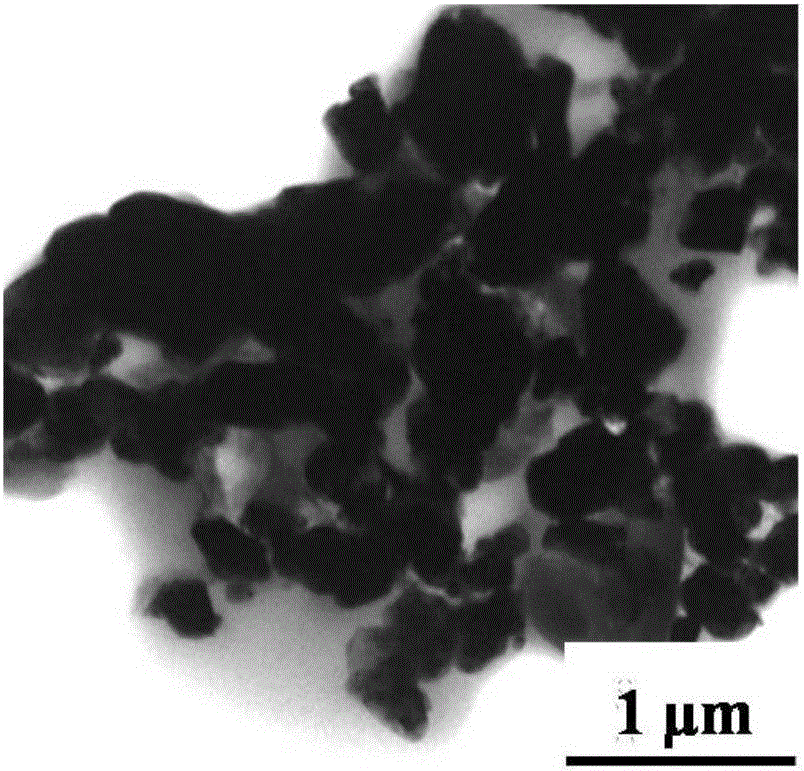

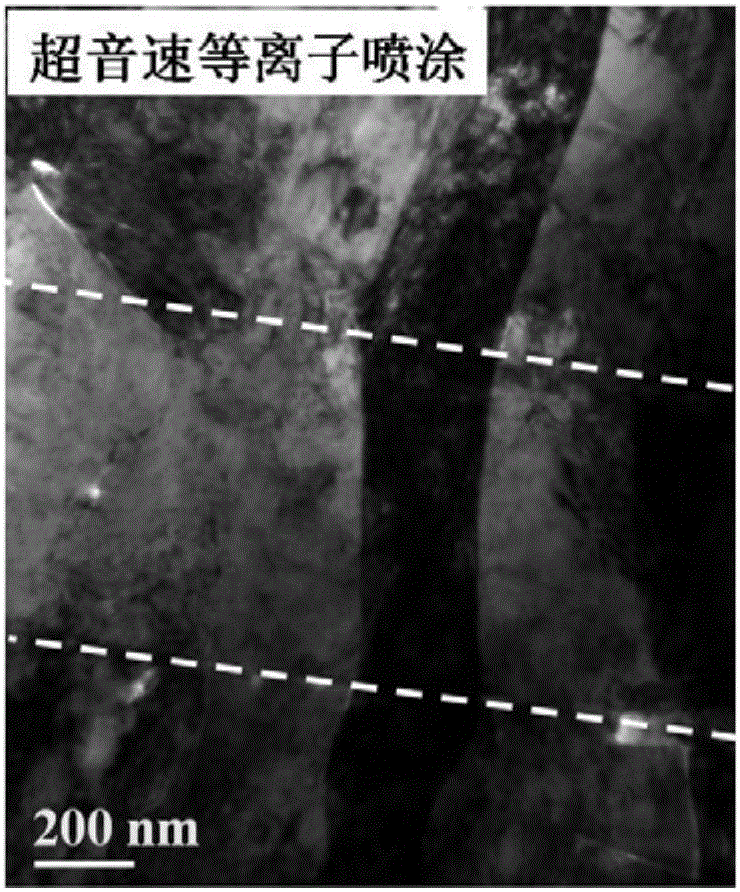

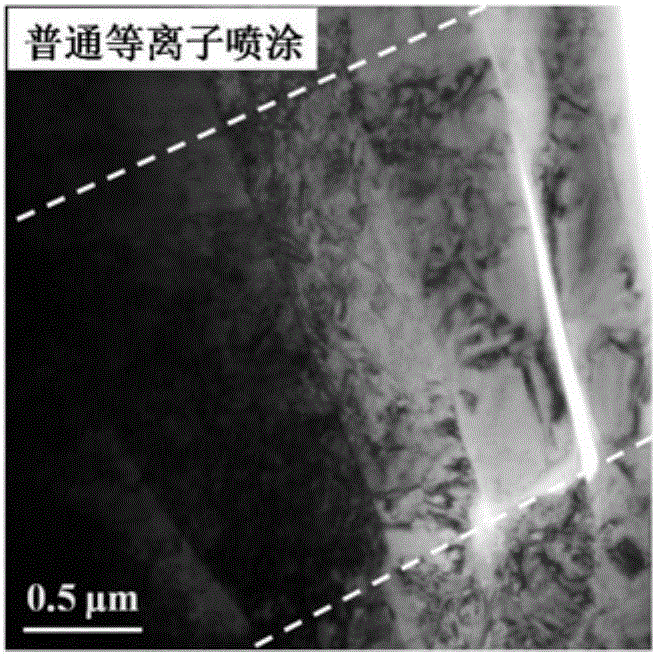

[0024] (1) All examples are as follows figure 1 The grain size shown is in the sub-micron level (100-900μm) yttrium oxide partially stabilized zirconia (YSZ) agglomeration powder is the raw material for spraying, the particle size after agglomeration is 10-50μm, and the mass fraction of yttrium oxide in the raw material is 5% to 8%; all examples in Table 1 use a supersonic plasma spray method with an internal powder feeding, single anode Laval nozzle to prepare YSZ coatings. During the spraying process, the back of the substrate is cooled by compressed air, and the temperature is controlled within the range of 100-200 °C. In the preparation process, the spraying process parameters are: arc current: 300-550A, arc voltage: 115-140V, main gas flow: 60-80slpm, secondary gas flow: 14-24slpm, spraying distance: 80-120mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com