Ultra-fine grained HPB300 hot-rolling optical disc stripe reinforcing steel bar and preparation method thereof

A technology of ultra-fine grain and disk, applied in the field of ferrous metallurgy, can solve the problems of high and low temperature performance, no description of aging performance, low Mn content, high process cost, etc., to improve passivation corrosion resistance, reduce alloying cost, good toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

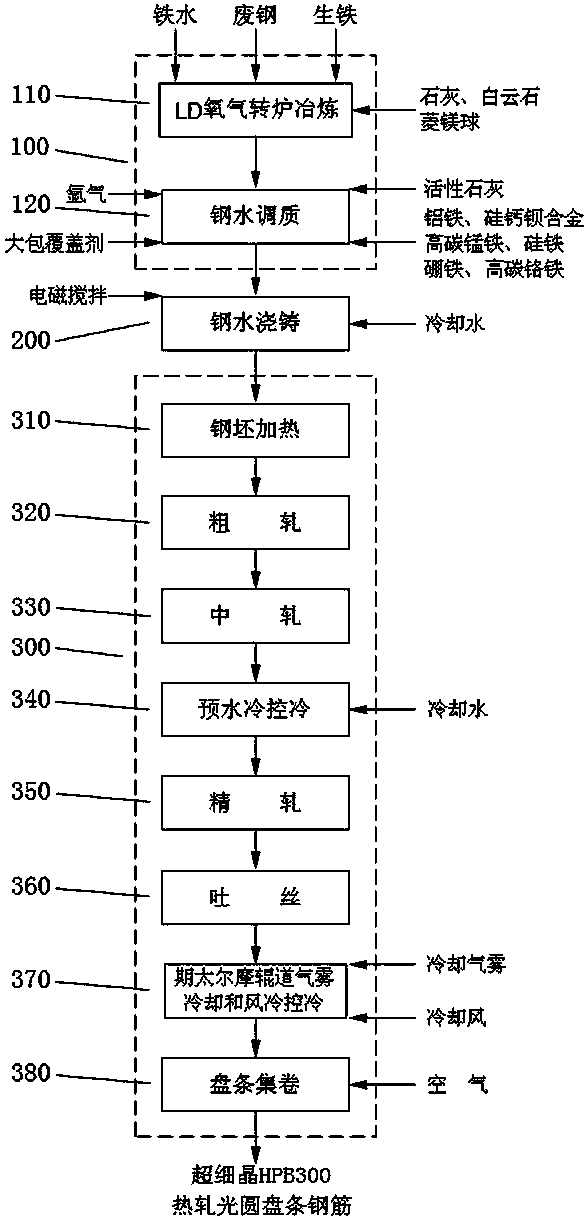

[0020] as attached figure 1 As shown, the preparation method of the ultrafine-grained HPB300 hot-rolled round wire rod steel bar of the present invention includes molten steel smelting, molten steel casting, billet controlled rolling and controlled cooling process, specifically comprising:

[0021] A. Molten steel smelting: Add molten iron, scrap steel and pig iron into the LD oxygen converter, conventional top-bottom compound blowing, add lime, dolomite and magnesite balls according to the conventional amount for slagging, control the end carbon ≥ 0.08wt%, and tap The temperature is less than 1640 ℃; before tapping, add active lime to the bottom of the ladle; when tapping, argon is blown at the bottom of the ladle. Ferromanganese, ferrosilicon, ferroboron and high-carbon ferrochrome are added to the molten steel in the ladle when the amount of molten steel reaches 3 / 4; after tapping, blow argon to the molten steel for 4 to 5 minutes; Conventional large bag covering agent;

...

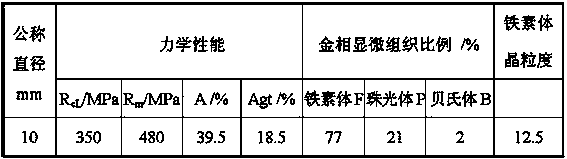

Embodiment 1

[0040] A. Molten steel smelting: After adding molten iron, scrap steel and pig iron into the LD oxygen converter, carry out conventional top-bottom compound blowing, add lime, dolomite and magnesite balls according to the conventional amount to make slag; control the end point carbon to 0.08wt%, and tap the steel The temperature is 1638°C, and the rate is 2.5kg / t before tapping 钢 The amount of active lime is added to the bottom of the ladle; when the steel is tapped, the argon is blown at the bottom of the ladle, the flow rate of the argon gas is controlled at 30NL / min, and the argon blowing time is 5 minutes. Add the following substances: according to 0.8kg / t 钢 The amount of aluminum and iron in the following mass ratio is added: Al 53.5wt%, the rest is Fe and unavoidable impurities; according to 1.0kg / t 钢 Add the following mass ratio of silicon-calcium-barium alloy: Si 52.5wt%, Ca 11.5wt%, Ba 12.5wt%, Al 3.5wt%, the rest is Fe and unavoidable impurities; according to 1.5kg / ...

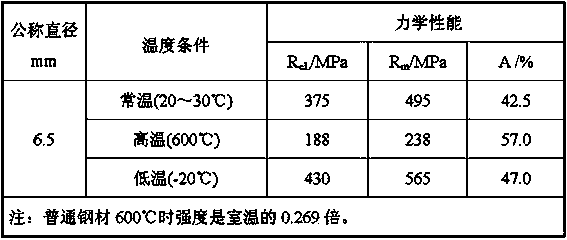

Embodiment 2

[0053]A. Molten steel smelting: After adding molten iron, scrap steel and pig iron into the LD oxygen converter, carry out conventional top-bottom compound blowing, add lime, dolomite and magnesite balls according to the conventional amount for slagging; control the end point carbon to 0.09wt%, and produce The steel temperature is 1636°C, 2.5kg / t before tapping 钢 The amount of active lime is added to the bottom of the ladle; when the steel is tapped, the argon is blown at the bottom of the ladle, the flow rate of the argon gas is controlled at 40NL / min, and the argon blowing time is 4 minutes. Add the following substances: according to 1.0kg / t 钢 The amount of aluminum and iron in the following mass ratio is added: Al 53.5wt%, the rest is Fe and unavoidable impurities; according to 1.0kg / t 钢 Add the following mass ratio of silicon-calcium-barium alloy: Si 52.5wt%, Ca 11.5wt%, Ba 12.5wt%, Al 3.5wt%, the rest is Fe and unavoidable impurities; according to 2.8kg / t 钢 The amount o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com