A kind of cold-rolled high-strength plastic product medium manganese steel with lower Mn content and preparation method thereof

A technology of high-strength plastic accumulation and manganese steel accumulation, applied in the field of automobile steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

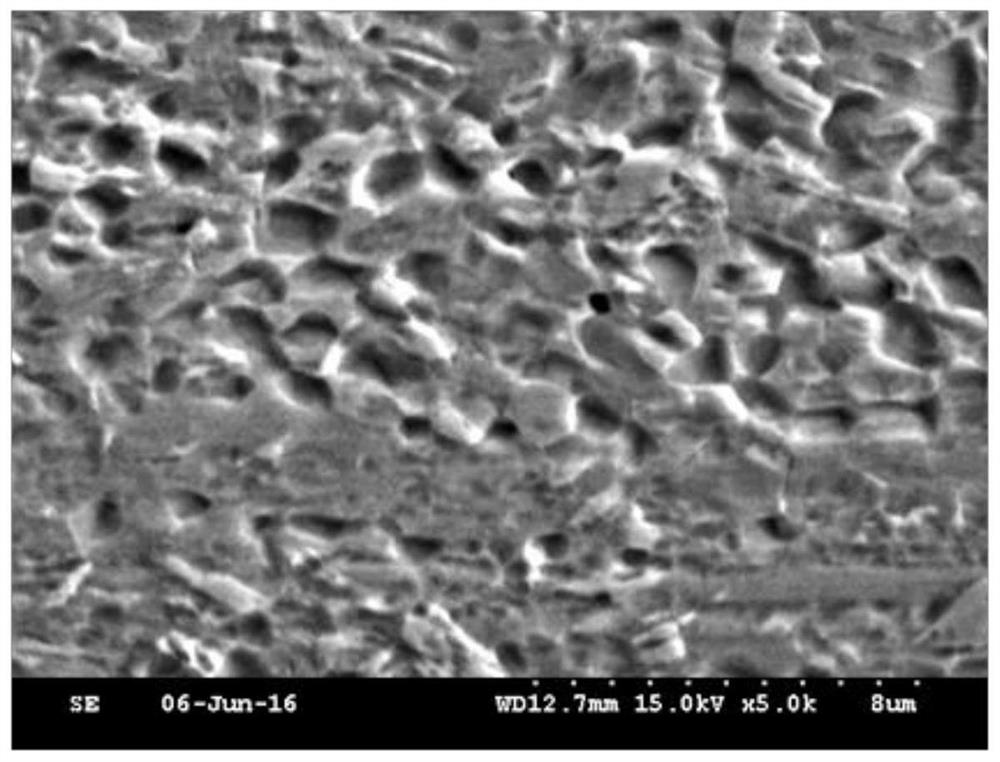

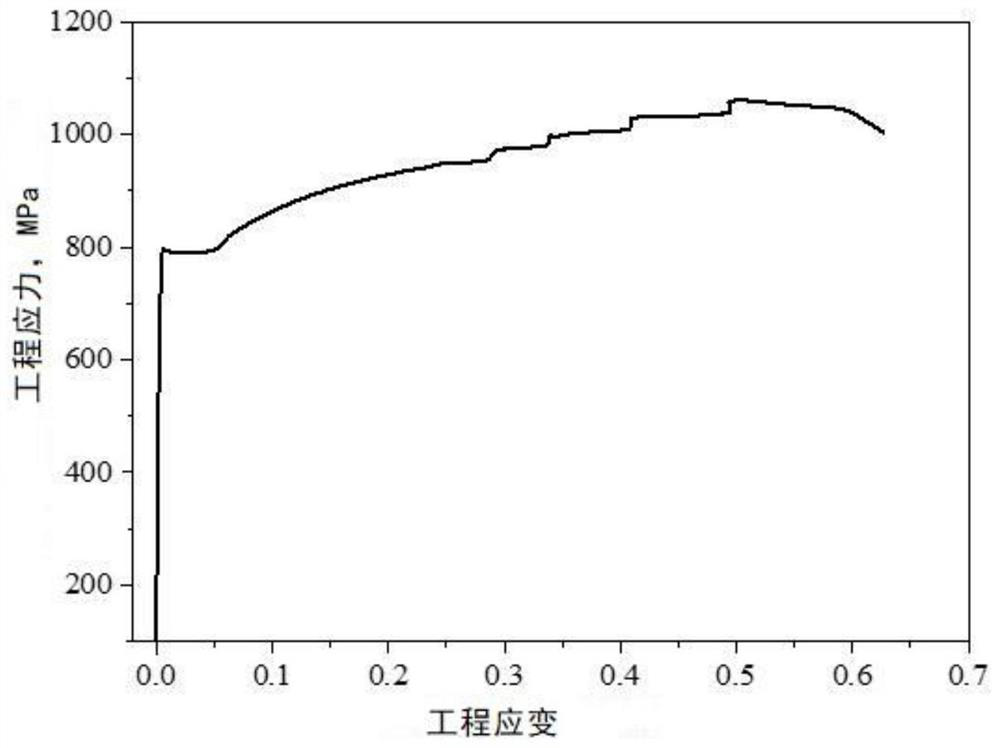

Image

Examples

preparation example Construction

[0034] The second aspect of the present invention provides a method for preparing the above-mentioned cold-rolled high-strength plastic-laminated medium-manganese steel with a lower Mn content, the steps comprising:

[0035] S1. Continuous casting of molten steel to produce slabs or mold castings to produce ingots. The chemical composition of molten steel includes: by weight percentage, C: 0.15-0.6%, Mn: 3.0-6.0%, Al: 1.0-3.0%, Si : 0-2.0%, Cr: 0-5.0%, Ni: 0-2.0%, the balance is Fe and unavoidable impurities;

[0036]S2. Hot rolling the billet or ingot obtained in step S1 after opening the billet. The hot rolling process includes: heating the billet to 1150-1250°C, soaking time for 1.5-2.5h, and hot rolling to a thickness through multiple passes It is a thin plate of 2-6mm, the final rolling temperature of the multi-pass hot rolling is not lower than 820°C, and the coiling is air-cooled to room temperature after rolling;

[0037] S3. Put the hot-rolled sheet or coiled sheet o...

Embodiment 1

[0042] This embodiment provides a cold-rolled high-strength ductile medium-manganese steel with a relatively low Mn content. The chemical composition is, by weight percentage, C: 0.45%, Mn: 5.0%, Al: 2.0%, Si: 0.3% , Cr: 0.7%, Ni: 0.4%, and the balance is Fe and unavoidable impurities.

[0043] The preparation method of the above-mentioned cold-rolled high-strength plastic product medium-manganese steel with lower Mn content, the steps include:

[0044] The steel billet is heated to 1200°C, soaking time is about 2 hours, hot rolled to a steel plate with a thickness of 4mm through multiple passes, the final rolling temperature is 820°C, and then coiled and air-cooled to room temperature.

[0045] The hot-rolled steel coils were put into a bell furnace for softening annealing, kept at 700°C for 20h, and then cooled to room temperature.

[0046] After pickling the hot-rolled annealed sheet, it is cold-rolled, and the cold-rolling reduction is 70%.

[0047] Put the cold-rolled s...

Embodiment 2

[0052] This embodiment provides a cold-rolled high-strength plastic-laminated medium-manganese steel with a relatively low Mn content. The chemical composition is, by weight percentage, C: 0.21%, Mn: 3.0%, Al: 1.2%, and Si: 1.5%. , Cr: 2.0%, Ni: 0.8%, V: 0.5%, B: 0.5%, and the balance is Fe and unavoidable impurities.

[0053] The preparation method of the above-mentioned cold-rolled high-strength plastic product medium-manganese steel with lower Mn content, the steps include:

[0054] The steel billet is heated to 1200°C, soaking time is about 2 hours, hot rolled to a steel plate with a thickness of 5mm through multiple passes, the final rolling temperature is 825°C, then coiled and air-cooled to room temperature.

[0055] The hot-rolled steel coils were put into a bell furnace for softening annealing, kept at 670°C for 24h, and then cooled to room temperature.

[0056] After pickling the hot-rolled annealed sheet, it is cold-rolled, and the cold-rolling reduction is 50%.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com