Method for controlling medium-thick plate Q345 steel flaw detection defects

A Q345B, plate technology, used in the field of controlling the flaw detection of Q345 steel for medium and thick plates, and can solve problems such as unqualified flaw detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

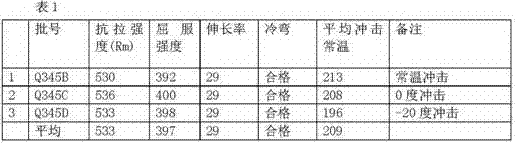

[0014] A method for controlling flaw detection defects of medium-thick plate Q345 steel, including optimizing the composition-weight ratio of Q345 steel: applicable steel type: Q345B, thickness: H=30mm, C 0.16, Si 0.30, Mn 1.15, P 0-0.018, S 0-0.008, Al0.025, Ti 0.015, Ca 0.0020; control of [MnS] inclusions in steel: the process route is: hot metal desulfurization treatment---120t converter---LF-slab continuous casting-heating furnace- -Medium plate rolling---ACC—collection; among them: (1) Desulfurization pretreatment of molten iron reduces the sulfur content of molten iron [S]2 o 3 51%, other ingredients 1.0%, cold consolidation by adding binder, adding 200kg of AL-Ca refining agent after converter tapping, LF refining final slag Al 2 o 3 The content is greater than 30%, the power transmission time is controlled within 10 minutes, and the nitrogen content of molten steel is less than 0.0040%; (4) Continuous casting protection casting, the temperature of molten steel in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com