Patents

Literature

156results about How to "Improve the qualified rate of flaw detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

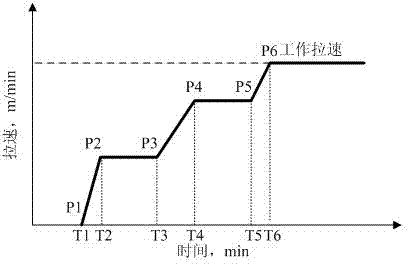

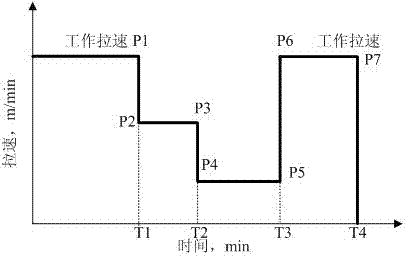

Method for increasing flaw detection yield of continuous casting sheet head billet and tail billet

ActiveCN103586433AImprove internal qualityImprove the qualified rate of flaw detectionMetallurgyContinuous casting

The invention discloses a method for increasing the flaw detection yield of a continuous casting sheet head billet and a tail billet. The flaw detection yield of the head billet and the tail billet is increased by improving internal quality of casting billets in the casting process and after the casting stopping process and optimizing technological operation. According to the method, through technological optimization and control under the unstable state condition, the internal quality of the head billet and the internal quality of the tail billet are improved, and then the flaw detection yield of steel sheets is increased. The method is suitable for the field of sheet billet continuous casting, and has significant economical value and practical significance in improving the quality of the casting billets under the continuous casting billet unstable state condition, and especially in improving the quality of variety steel and the material yield.

Owner:NANJING IRON & STEEL CO LTD

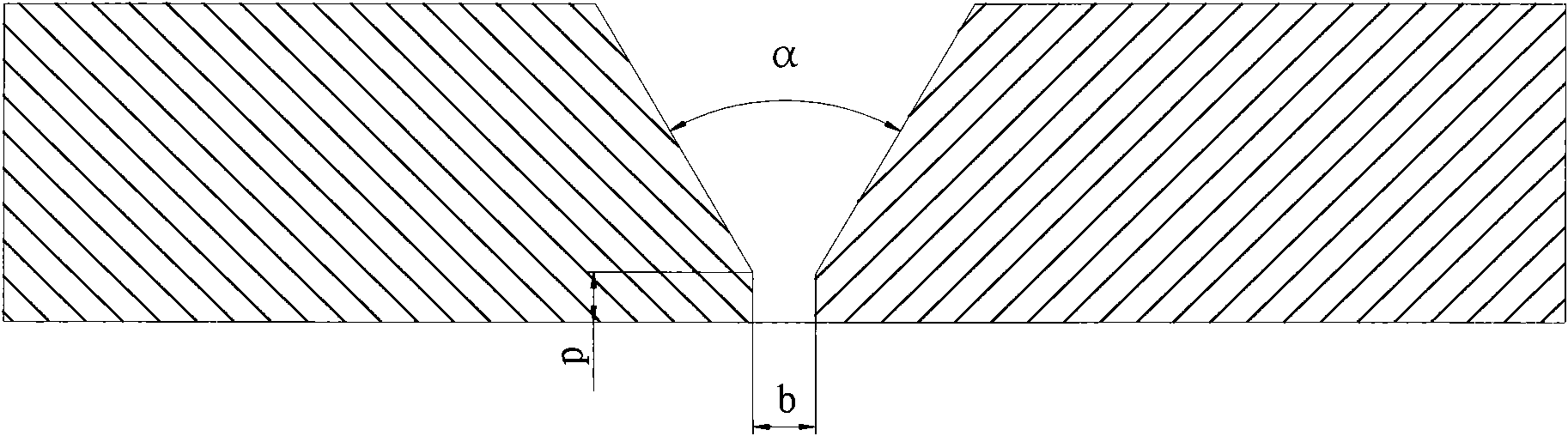

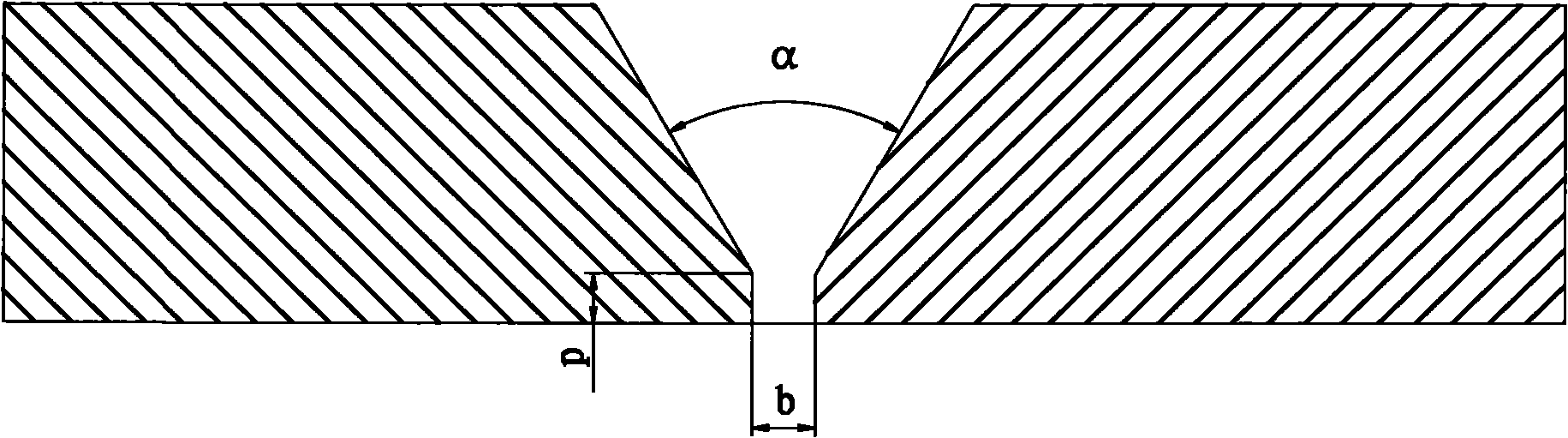

Welding process of 12Cr1MoV high-pressure pipeline CO2 semiautomatic or automatic gas shielded welding

InactiveCN101850460AHigh qualified rate of welding seam flaw detectionStable welding qualityArc welding apparatusWelding/soldering/cutting articlesSteel tubeWeld seam

The invention relates to a welding process of 12Cr1MoV high-pressure pipeline CO2 semiautomatic or automatic gas shielded welding, which comprises the following steps of: processing two welded steel pipes into a V-shaped bevel, and fixing the two welded steel pipes by a clamp; heating by an electric heater, preserving heat through heat-preserving cotton, and preheating a joint; immediately carrying out pairing and positioned welding on the welded joint; carrying out manual tungsten argon arc welding priming coat welding by using a solid welding wire TIG-R31; keeping the interlayer temperature between 200 DEG C and 300 DEG C, and carrying out multilayer multi-pass welding by adopting melting pole automatic or semiautomatic CO2 gas shielded welding; and carrying out heat processing after welding. The welding efficiency of the invention is 2-3 times that of welding rod arc welding, and the welding cost is 50% of that of the welding rod arc welding; the qualified rate of welding seam flaw detection is high, and the welding quality is stable.

Owner:中国石化集团第五建设公司

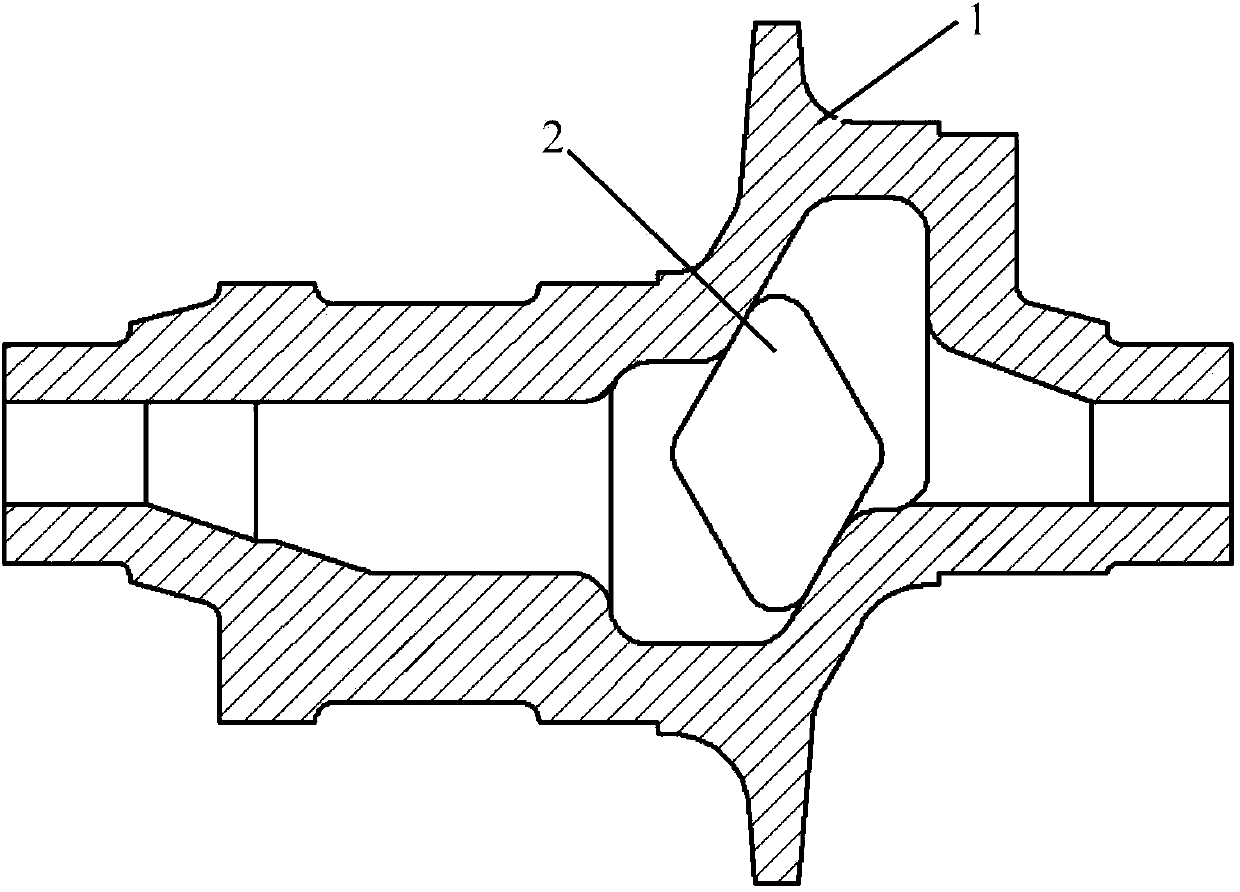

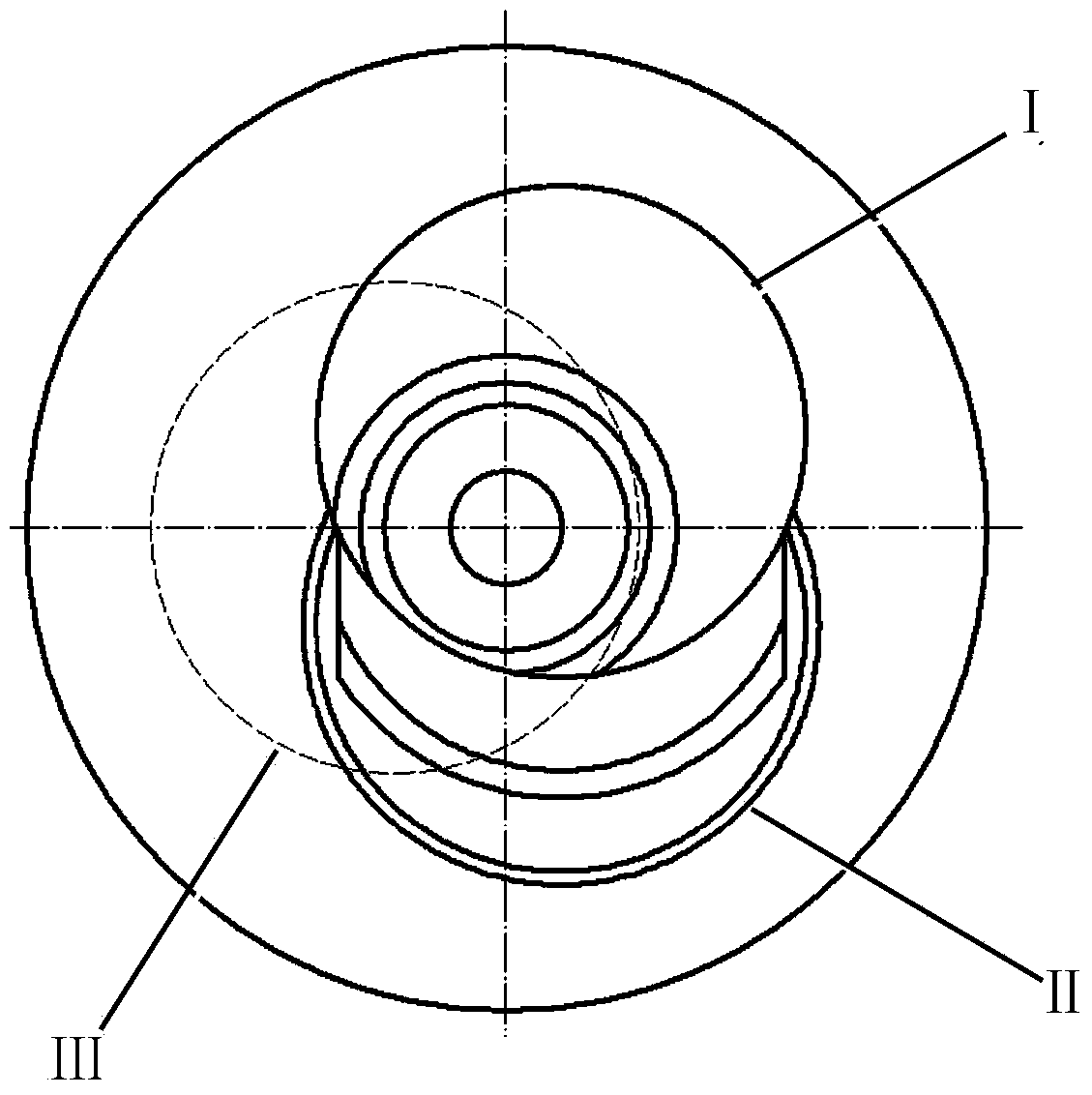

Casting method of hollow crankshaft of slurry pump

ActiveCN103624218APrevent core breakage or deformationImprove the qualified rate of flaw detectionFoundry mouldsFoundry coresRebarSlag

The invention discloses a casting method of a hollow crankshaft of a slurry pump. A casting model is utilized. The casting method comprises the following steps: manufacturing an actual sample and a core box of the hollow crankshaft; installing a sand discharge box, a large open riser, a slag collector and a pouring channel, opening open and hidden air holes in a sand mold, and arranging anti-cracking ribs in a turning part I and a turning part III; manufacturing a sand core and a core head mold body, manufacturing a core bar main rod, forming two groups of via holes in the core bar main rod, and welding a steel round positioning ring in each via hole; welding multiple reinforcing supports on the core bar main rod by reinforcing steel bars, winding a straw rope and a gas exhaust rope on the core bar main rod, putting a core bar into the core box, and filling sand for hardening; spraying paint; assembling the box; pouring; opening the box and spraying sand; polishing and repairing; normalizing; carrying out secondary sand spraying; and processing shaft holes in two end heads of the hollow crankshaft, thereby casting the hollow crankshaft of the slurry pump. The method provided by the invention can effectively prevent the structure defect of shrinkage cavity or shrinkage porosity partially.

Owner:BAOJI PETROLEUM MASCH CO LTD

Stainless steel sheet welding method capable of controlling deformation

InactiveCN101693328ABeautiful shapeImprove the qualified rate of flaw detectionWelding/cutting auxillary devicesAuxillary welding devicesSheet steelWeld seam

The invention relates to a method for welding steel sheets, in particular to a stainless steel sheet welding method capable of controlling deformation, which comprises the following steps: (a) grooves are processed in positions to be welded on two groups of stainless steel sheets; (b) two pieces of parallel flat steel are put on the surface of a workbench, the two groups of stainless steel sheets are respectively arranged above the flat steel and respectively use the flat steel as a fulcrum, the ends of which the grooves are processed on the two groups of stainless steel sheets are butted with each other, and the other end of each group of stainless steel sheets contacts the surface of the workbench; (c) two groups of pressure plates are respectively arranged above the steel sheets positioned on both sides of each piece of flat steel, and a weight block is arranged on the middle part of each of the two groups of pressure plates; (d) the two groups of stainless steel sheets are welded along the butted groove from above the stainless steel sheets; (e) and the weight blocks and the pressure plates are removed, and the stainless steel sheets with single welded surfaces are taken out. The method has the advantages of simple operation, convenient welding, small welding deformation, attractive formed appearance of welding seams, high splicing speed and high qualification rate for PT fault detection.

Owner:ZHEJIANG DADI STEEL STRUCTURE

Thick steel plate and manufacturing method thereof

The invention discloses a thick steel plate and a manufacturing method thereof, and belongs to the field of ferrous metallurgy. The method comprises the following steps of molten iron KR pre-desulfuration, converter smelting, LF refining, RH vacuum treatment, wire feeding, flexible stirring, plate blank continuous casting, plate blank reheating, rough rolling, intermediate blank temperature holding cooling, precision rolling, ACC quick cooling, steel plate straightening and stacking slow cooling, wherein in the plate blank reheating stage, the temperature is 1120-1220 DEG C, and the in-furnacetime is longer than or equal to 1.0 min / mm; in the rough rolling stage, the temperature is 1000-1080 DEG C, and the thickness of an intermediate blank after rolling is larger than 2.5 times that of asteel plate; in the precision rolling stage, the temperature is lower than or equal to 900 DEG C, the finish rolling temperature is 780-820 DEG C, and the total compression ratio in the stage is larger than or equal to 60%; in the cooling stage, the finish cooling temperature is 300-400 DEG C, and the cooling rate is 10+ / -5 DEG C / s. The steel plate manufactured through the method comprises the following chemical components of, by mass percent, 0.06-0.09% of C, 0.10-0.30% of Si, 1.40-1.70% of Mn, 0.020-0.060% of Al, 0.03-0.05% of Nb, 0-0.020% of Ti, 0-0.30% of Cr, 0-0.016% of P, 0-0.005% of S,0-0.080% of N and the balance Fe and inevitable impurity elements, the carbon equivalent Ceq is equal to [C+Mn / 6+(Cr+Mo+V) / 5+(Cu+Ni) / 15] and smaller than or equal to 0.42%, the welding crack sensitivity index CEpcm is equal to [C+Si / 30+(Mn+Cu+Cr) / 20+Ni / 60+Mo / 15+V / 10+5B] and smaller than or equal to 0.20%, and the applicable thickness of the steel plate is 40-70 mm.

Owner:ZHANGJIAGANG HONGCHANG STEEL PLATE CO LTD +1

Manufacturing method for casting metal lithium target

InactiveCN105349952AEliminate stomataEliminate shrinkageVacuum evaporation coatingSputtering coatingLithiumLiquid metal

Provided is a manufacturing method for casting a metal lithium target. A casting die for metal lithium is prepared according to the needed size, a stainless steel liner tube is located in the middle of the die, and cooling liquid can be injected into the stainless steel liner tube; liquid metal lithium is injected into a sandwich layer between the die and the stainless steel liner tube, and after the liquid metal lithium is solidified and formed, a metal lithium rotating target of the target size is formed through outline processing. The bottom-to-top directional solidification manner is adopted, the process is simple and convenient, and the high-purity metal lithium target which is small in grain size and high in compactness can be manufactured by eliminating air holes and shrinkage cavities in the metal lithium target. Casting conditions are optimized in the casting process, the flaw detection yield of the metal lithium target can be increased, and therefore the metal lithium target can be better applied to electrochromic glass.

Owner:GEMCH MATERIAL TECH SUZHOU

Rare earth element-containing uncoated weather-resistant steel and preparation method thereof

The invention provides a rare earth element-containing uncoated weather-resistant steel and a preparation method thereof, and belongs to the technical field of weather-resistant steels. The respectivecontent and the ratio of chemical components Cr, Ni, Cu, Mo, Re and Ca are optimized to control the X value to be equal to or more than 0.3 and equal to or less than 1.0, where X is a ratio of (20 Re+ 50 Ca) to (1.5 Cr + Ni + Cu + 1.2 Mo). The weather-resistant steel has the advantages of significant reduction of the number of inclusions of various welds, significant reduction of the size of thewelds, significant reduction of the crack tendency of the welds, great improvement of the quality of welding metallurgy and improvement of the flaw detection qualified rate when welded; and appropriate amounts of Si, Ni, Cr and Cu are added to make the atmospheric corrosion resistance index I to be equal to or more than 6.5, and addition of appropriate amounts of Y and Mo improves the weather resistance, so the wear-resistant steel has good resistance to the atmospheric corrosion and maintains excellent mechanical properties.

Owner:YANSHAN UNIV

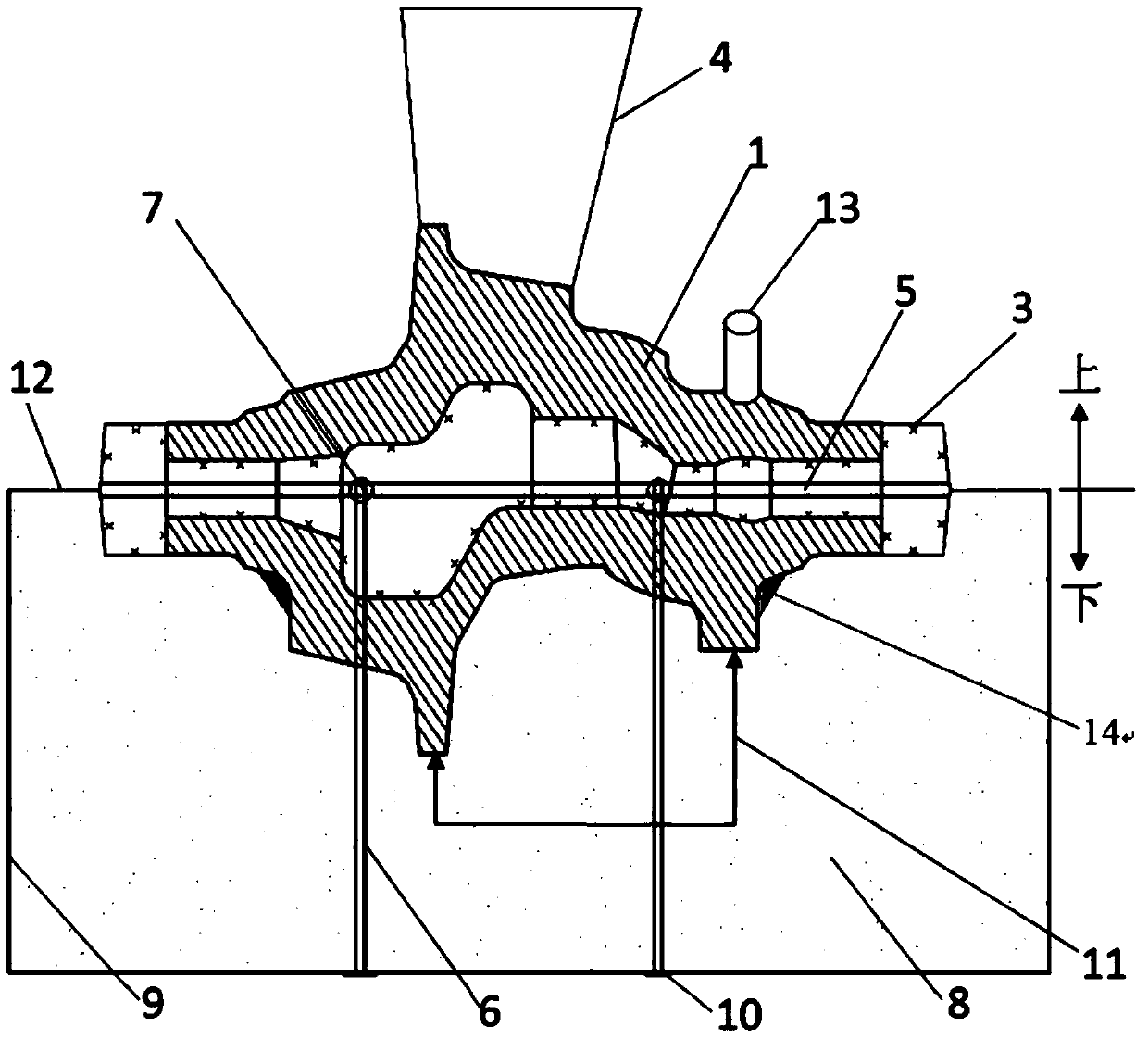

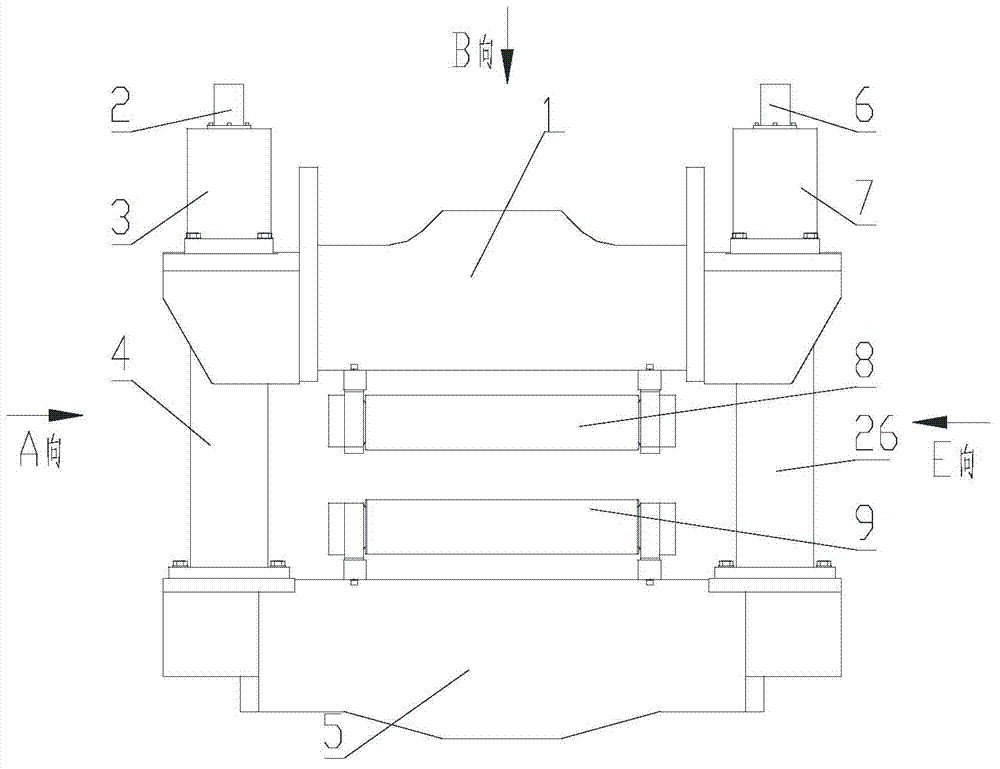

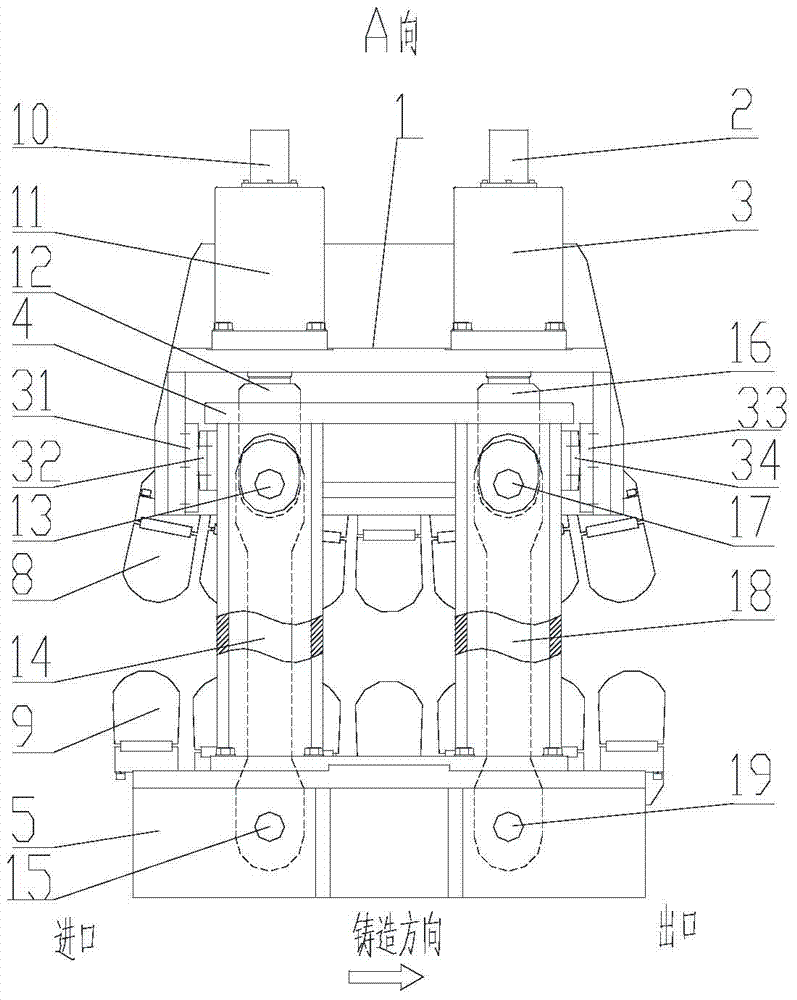

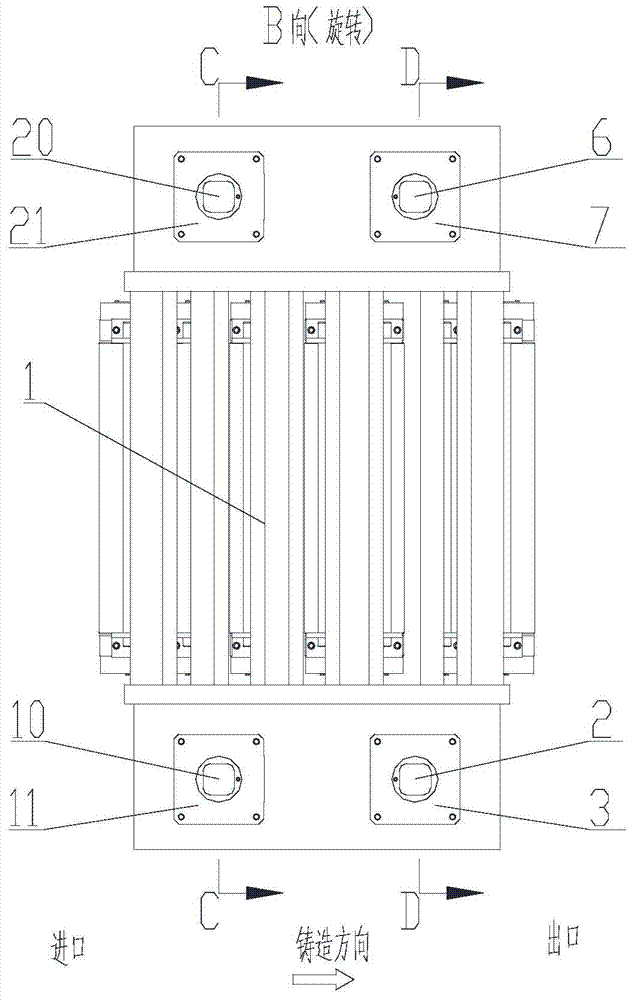

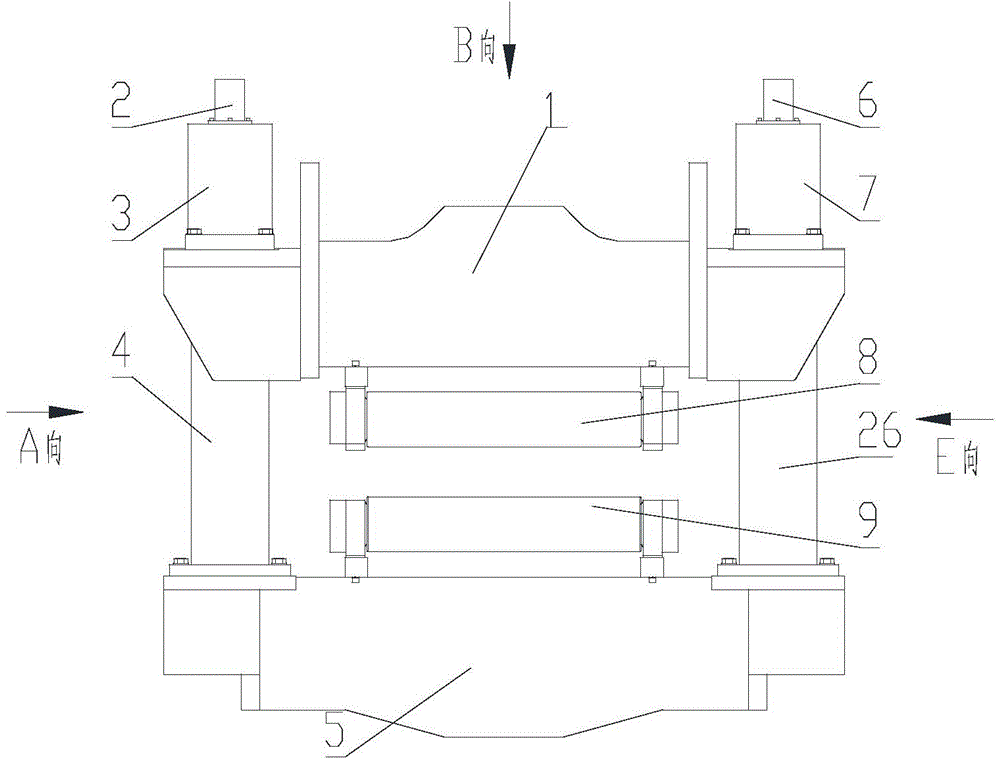

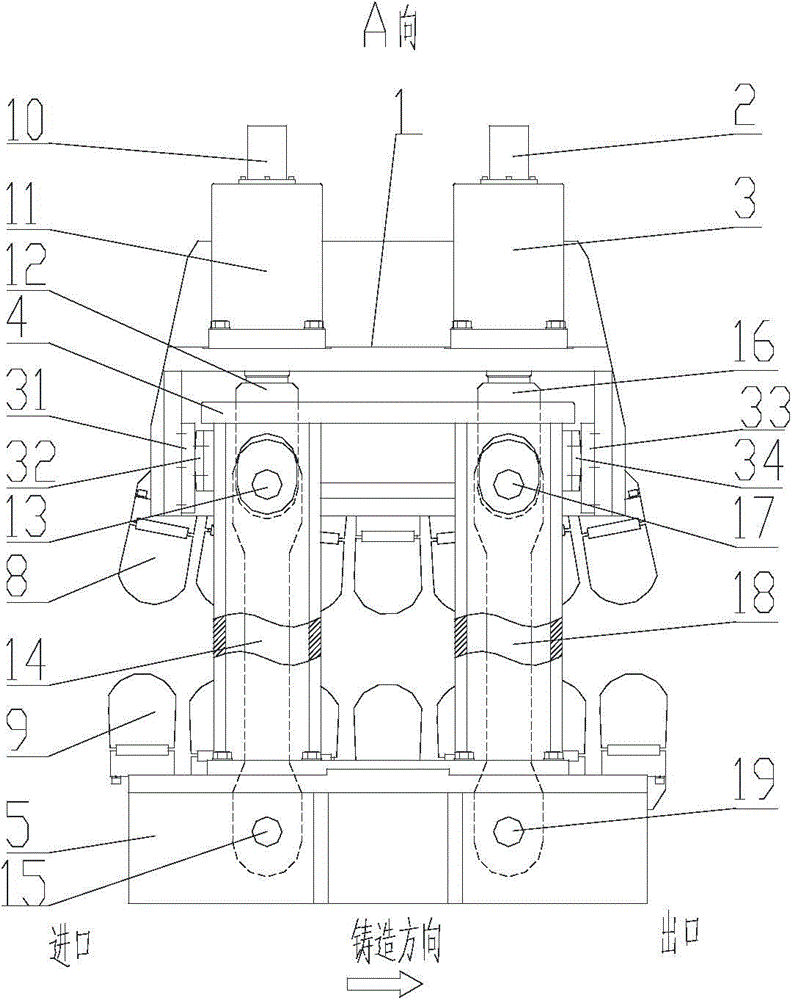

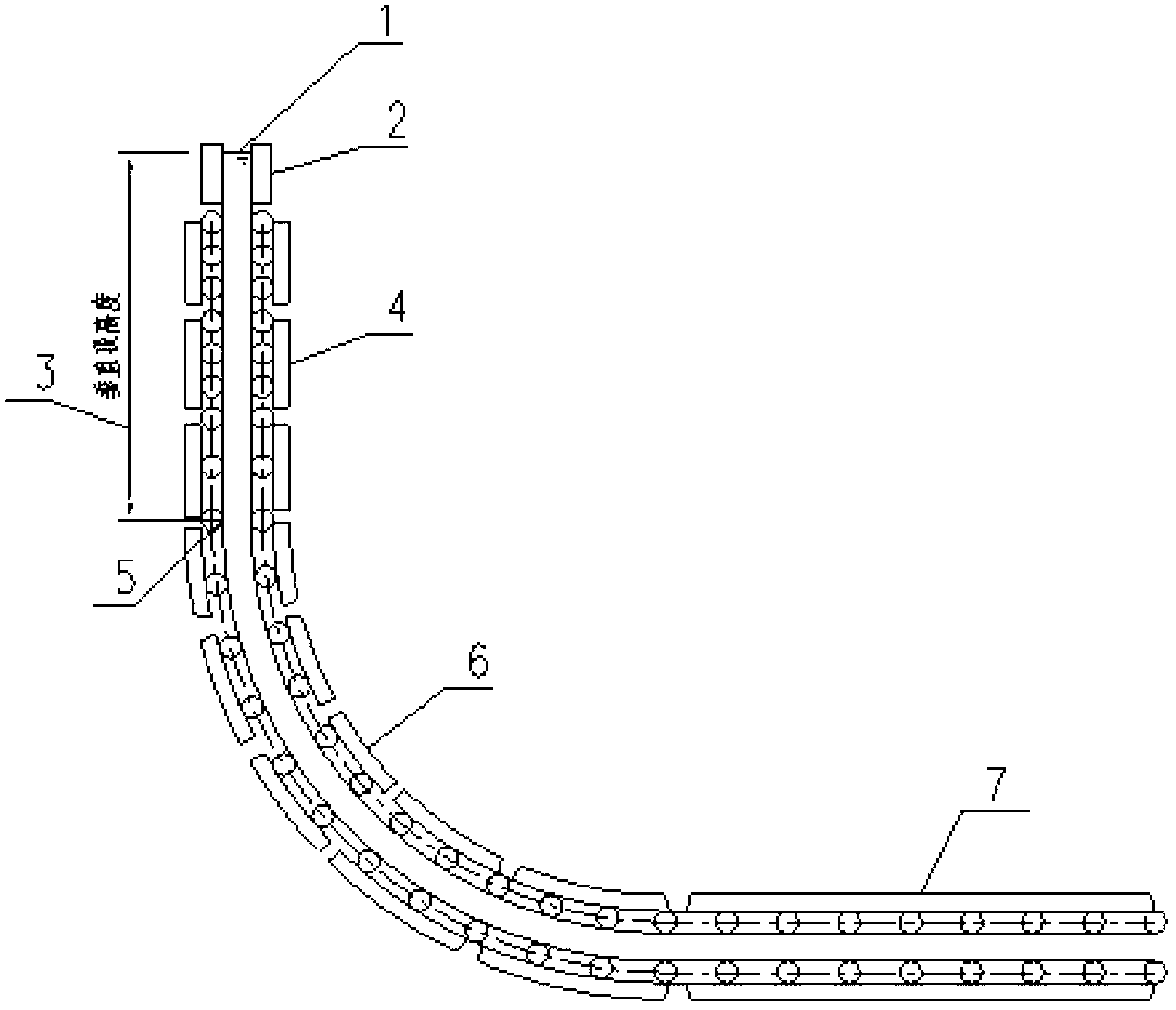

Sector segment structure capable of compositely pressing continuous casting solidification tail end of extra-thick plate

The invention provides a sector segment structure capable of compositely pressing the continuous casting solidification tail end of an extra-thick plate. An inner arc roller, an outer arc roller, an upper frame, a lower frame and side frames have enough strength and rigidity, four sensors and four oil cylinder assemblies are installed in the parts, the stretching or retraction strokes of the first oil cylinder assembly, the second oil cylinder assembly, the third oil cylinder assembly and the fourth oil cylinder assembly are controlled by detecting the first displacement sensor, the second displacement sensor, the third displacement sensor and the fourth displacement sensor, and then the opening degree between the inner arc roller and the outer arc roller of a sector segment is controlled, and the continuous casting solidification tail end of the extra-thick plate can be compositely pressed.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

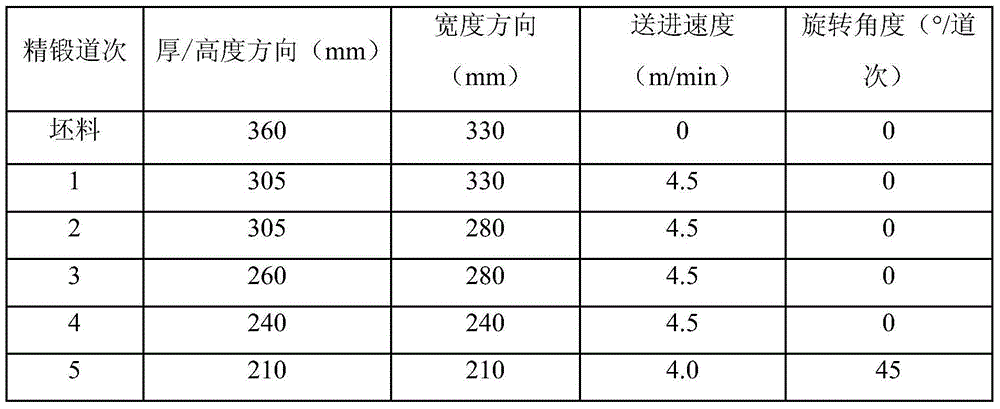

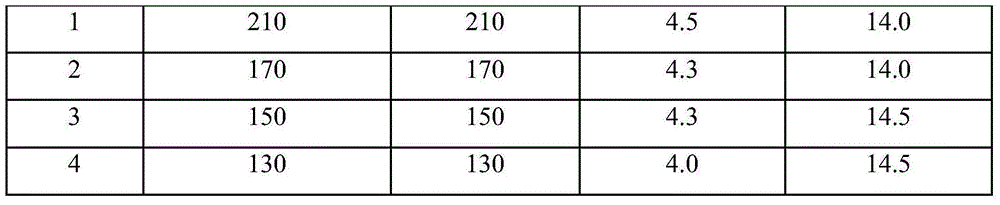

Forging method for high temperature alloy GH4169 round rod

ActiveCN104785690AImprove the qualified rate of flaw detectionForging hammersSuperalloyHot Temperature

The invention belongs to the field of high temperature alloy forging, and particularly relates to a forging method for a GH4169 round rod. According to the forging method for the high temperature alloy GH4169 round rod, a twice-heating production mode is adopted, in first heating, an intermediate billet is formed by adopting a flat hammer to conduct hammer cogging, and in second heating, a product with needed specifications is formed by adopting a bruting hammer to conduct precision forging. By means of the forging method for the high temperature alloy GH4169 round rod, the problems that forging cracking is prone to occurring due to the fact that the temperature drops too fast in using an existing forging technology, and the surface quality is poor and the center strain of the whole forging process is insufficient due to the fact that matching of the precision forging technology is unreasonable are solved, a surface spiral thread of the forged round rod is greatly reduced, and the flaw detection yield is greatly improved.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Y55 mark free-cutting steel plate and manufacture method thereof

The invention discloses a Y55 mark free-cutting steel plate and a manufacture method thereof. The steel plate comprises the following chemical components by weight percent: 0.50-0.58% of C, 0.05-0.15% of Si, 0.70-1.10% of Mn, less than or equal to 0.040% of P, 0.050-0.150% of S, 0.010-0.020% of Ti, 0.0015-0.0040% of Ca, and less than or equal to 0.015% of Alt. The manufacture method comprises the following steps that: desulfuration is not performed on molten iron in a converter, wherein the oxygen content is controlled at 30-70ppm; the temperature of a tundish is 1505-1525 DEG C, and the plate blank pull speed is 0.70-1.0m / min; the total heating time is controlled according to 0.95-10.5min / mm of the thickness of a casting blank; the initial blanking temperature is 1000-1050 DEG C, and the final rolling temperature is greater than or equal to 980 DEG C; and the steel plate is slowly cooled after hot rolling, wherein the slow cooling time is more than or equal to 48h. According to the invention, the steel plate is good in cutting performance, and the manufacture method is high in production efficiency.

Owner:XINYU IRON & STEEL CO LTD

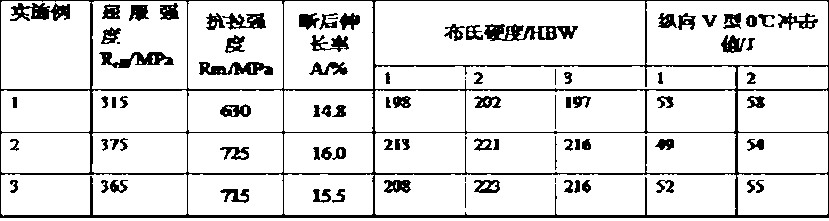

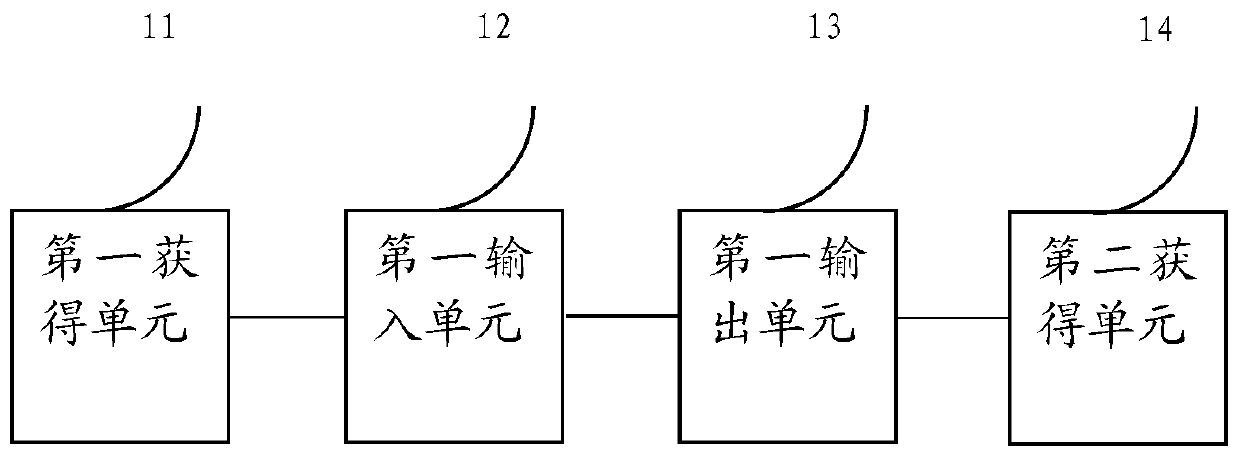

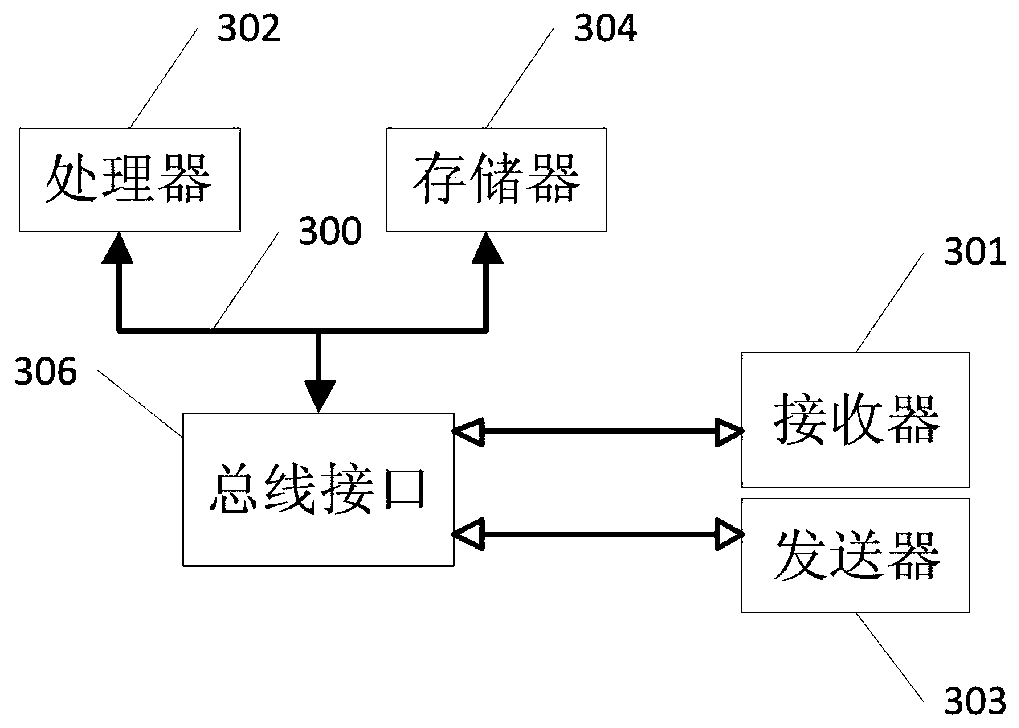

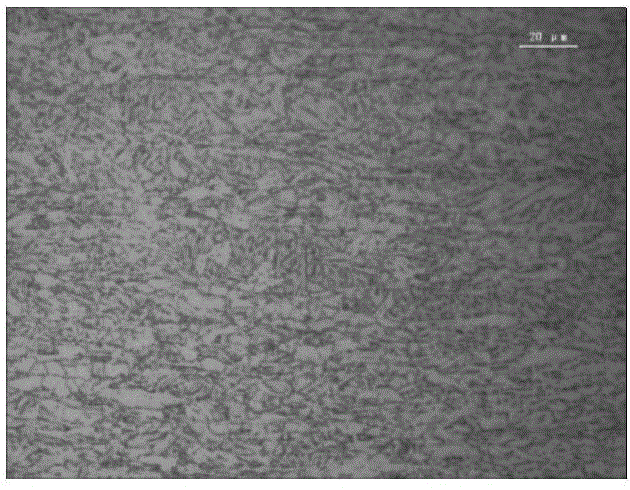

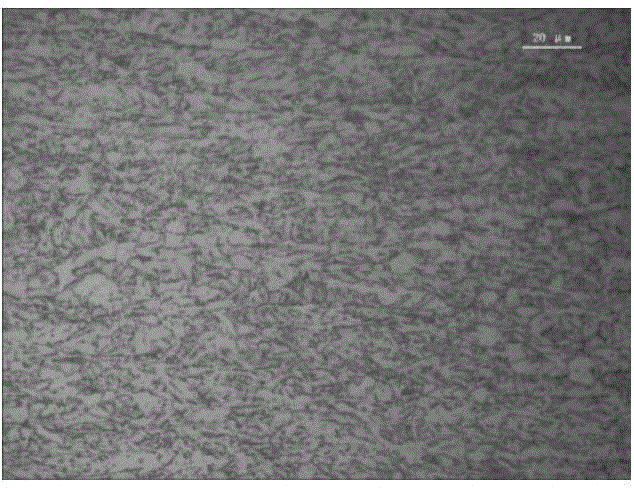

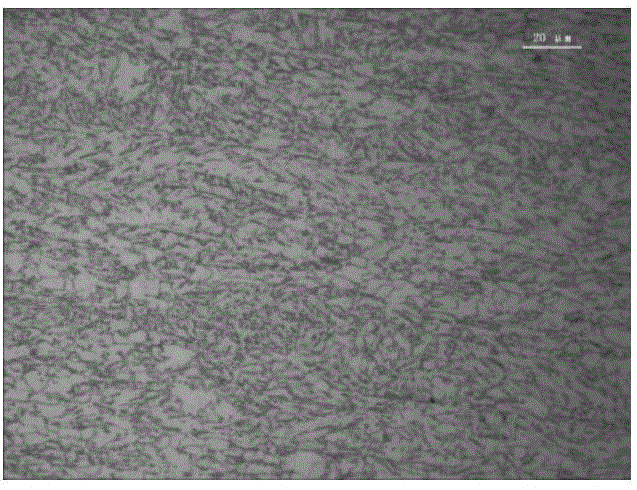

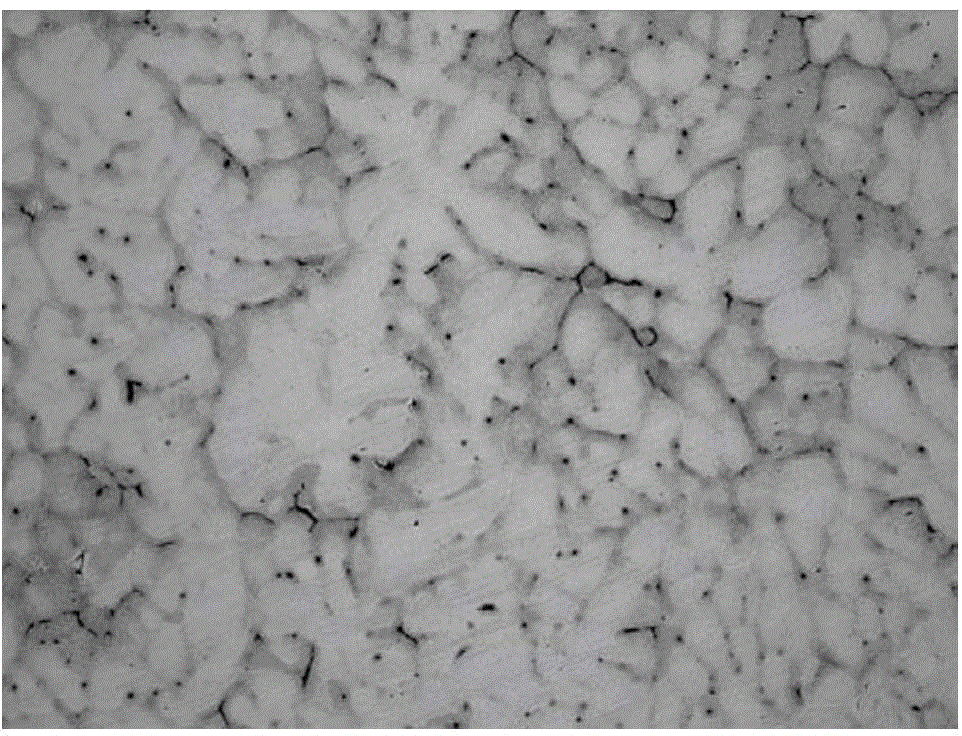

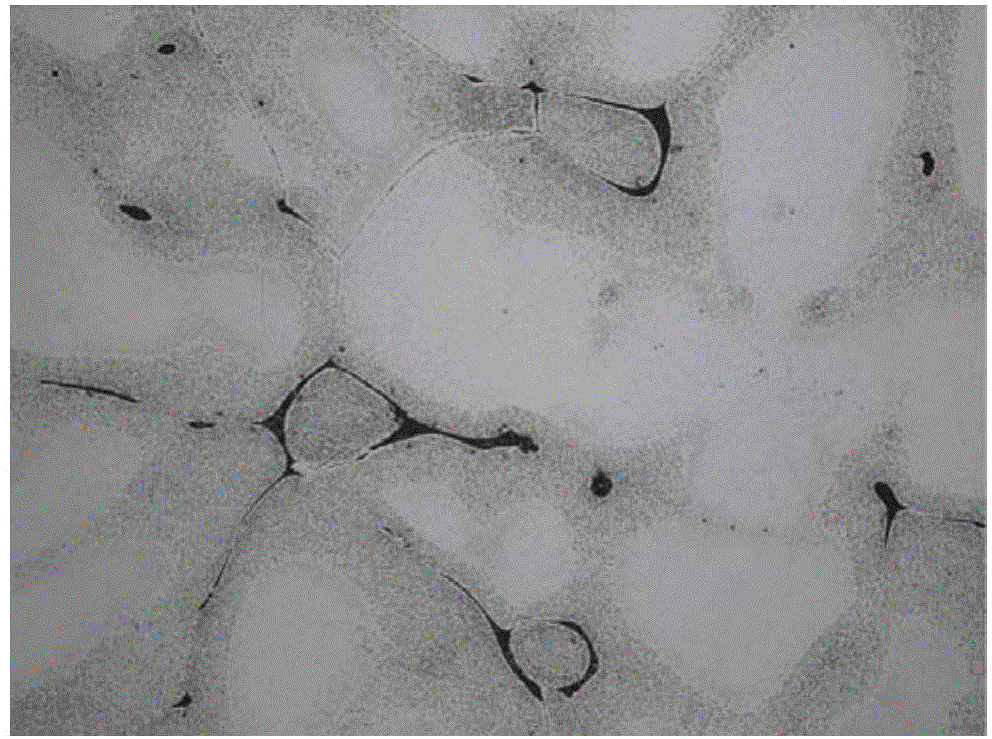

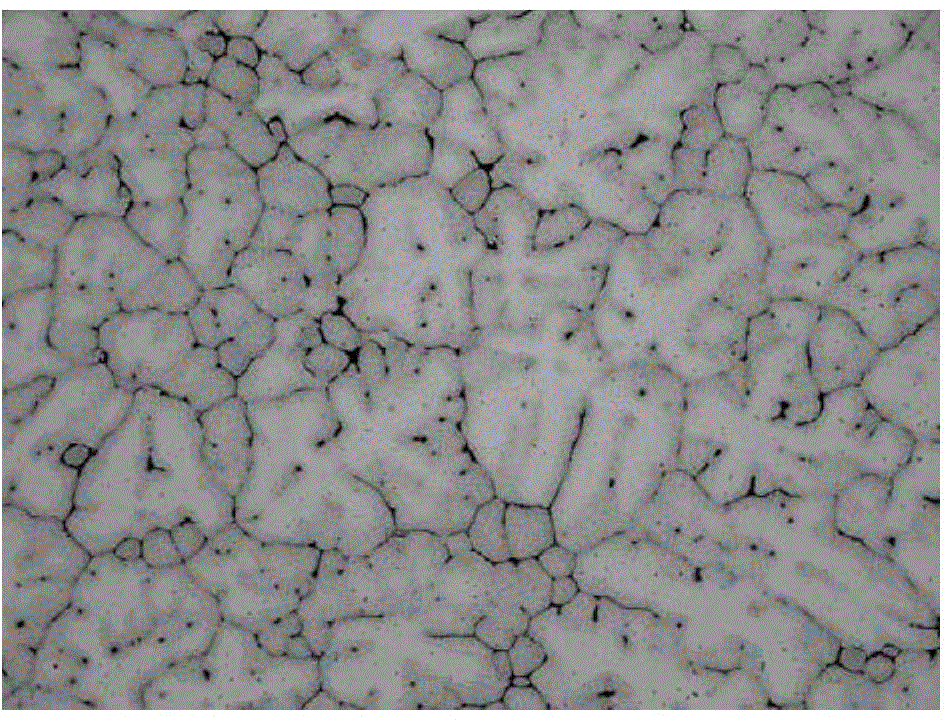

Method and device for improving continuous casting flaw detection qualification rate

ActiveCN110490862AImprove the qualified rate of flaw detectionGuarantee internal qualityImage enhancementImage analysisComputer scienceContinuous casting

The embodiment of the invention provides a method and device for improving the continuous casting flaw detection qualification rate. The method comprises the steps that obtained continuous casting billet image information is input into a training model, the training model is obtained through training of multiple sets of training data, and each set of training data in the multiple sets of trainingdata comprises the continuous casting billet image information, identification continuous casting billet center metallographic structure label information and preset inclusion index information; output information of the training model is obtained, and the output information comprises continuous casting billet center metallographic structure information and inclusion information corresponding to the continuous casting billet image information; according to the continuous casting billet center metallographic structure information and the inclusion information corresponding to the continuous casting billet image information, the continuous casting billet image information are screened and filtered to obtain standard continuous casting billet image information with qualified flaw detection, thereby achieving the technical effects of improving the flaw detection qualification rate of the continuous casting billet, reducing the inclusion content, ensuring the internal quality of the continuous casting billet and reducing the production cost.

Owner:LIANFENG STEEL (ZHANGJIAGANG) CO LTD

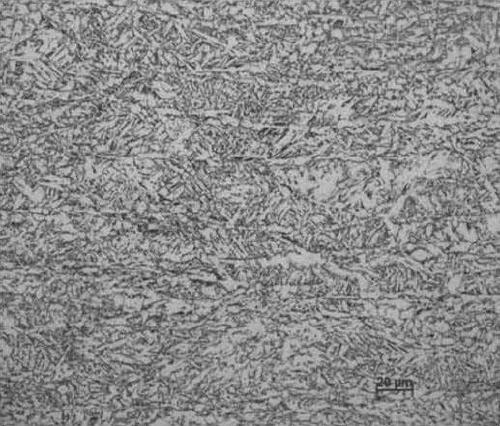

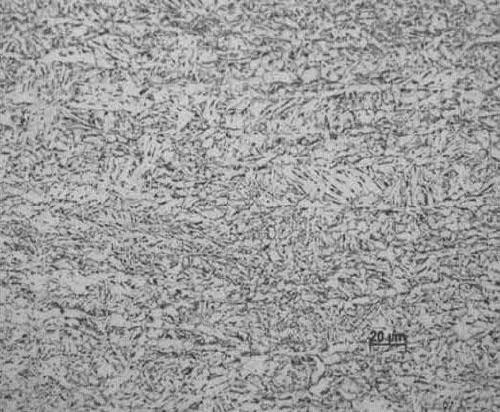

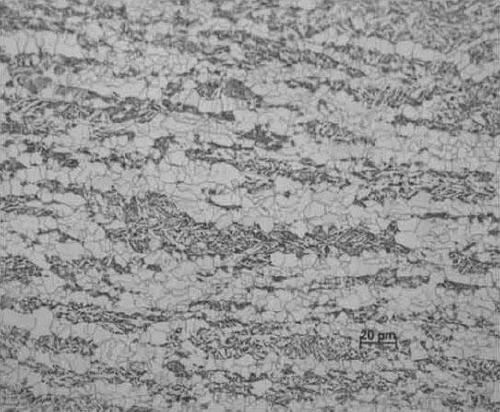

Super-thick pipeline steel plate with excellent low-temperature toughness and production method

The invention relates to a super-thick pipeline steel plate with excellent low-temperature toughness and a production method. The technical scheme is as follows: P is less than or equal to 0.006%, S is less than or equal to 0.002%, N is less than or equal to 0.0040%, H is less than or equal to 0.00015%, O is less than or equal to 0.0020%, the sum of N,O,H,S and P is less than or equal to 100 ppm, the trace element Sn is less than or equal to 0.015%, the trace element Pb is less than or equal to 0.005%, the trace element Sb is less than or equal to 0.010%, the trace element Bi is less than or equal to 0.005%, the radioactive element intensity is lower than 100 Bq / gram, fineness of various non-metallic inclusions is smaller than or equal to 1.5 grade, and the sum is smaller than or equal to 4.0. Crystal grains are refined, the inherent structure texture of the steel plate is eliminated, the performance uniformity of the super-thick steel plate is guaranteed, technological difficulties that toughness is difficult to match and the thickness direction performance is non-uniform during production of super-thick pipeline steel are broken through, the tiny and uniform acicular ferrite structure is obtained, and the steel plate is good in strength, excellent in series low-temperature toughness and high in uniformity.

Owner:SHANDONG IRON & STEEL CO LTD

Method for producing extremely-thick carbon die steel plate

ActiveCN106694549AIncreasing the thicknessImprove the qualified rate of flaw detectionAuxillary arrangementsMetal rolling arrangementsSheet steelSlow cooling

The invention provides a method for producing an extremely-thick carbon die steel plate. According to the method, roughness of the to-be-compounded surface of each mother blank is larger than 7.0 microns; a vacuum electron beam welder is adopted, and the vacuum degree of a vacuum chamber is larger than 2*10<2>Pa; spot welding is performed at first, then welding in the sequence from short edges to long edges is carried out, the welding current is 100-800mA, the speed is 6-10mm / min, and the depth of fusion is 20-60mm; a composite blank is heated, and the temperature rises at the speed of 5-10 DEG C / min below 700 DEG C; the temperature rises at the speed of 10-30 DEG C / min above 700 DEG C, and heat preservation lasts for 4-7h when the composite blank is heated to 1180-1220 DEG C; the rolling starting temperature of the composite blank is 1130-1150 DEG C, the roller speed is 16-20r / min, the rolling reduction in the first three passes is larger than 40mm, and the finished rolling temperature is higher than 900 DEG C; and as for steel plate slow cooling, a stacking mode of 'down-paving and up-covering' of the hot steel plate is adopted, the slow cooling temperature is 400-500 DEG C, and time is longer than 24h. By the adoption of the method, the thickness specification of the carbon die steel plate produced through a continuous casting can be increased to 400mm or above, and the flaw detection percent of pass and yield of the steel plate are both increased.

Owner:ANGANG STEEL CO LTD

Fan-shaped segment structure and method for realizing continuous casting, solidification and tail end composite pressing of super-thick plate

The invention discloses a fan-shaped segment structure and a method for realizing continuous casting, solidification and tail end composite pressing of a super-thick plate. An inner arc roller, an outer arc roller, an upper framework, a lower framework, a side framework I and a side framework II have sufficient strength and rigidity; four sensors and four oil cylinder assemblies are arranged in the components; the extension or retraction strokes of a first oil cylinder assembly, a second oil cylinder assembly, a third oil cylinder assembly and a fourth oil cylinder assembly are controlled by detecting a first displacement sensor, a second displacement sensor, a third displacement sensor and a fourth displacement sensor, so that the opening degree between the inner arc roller and the outer arc roller of a fan-shaped segment is controlled. The conventional pressing amount and a large compressing amount are implemented according to the solid fractions of different casting blanks, so that continuous casting, solidification and tail end composite pressing of the super-thick plate are realized.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

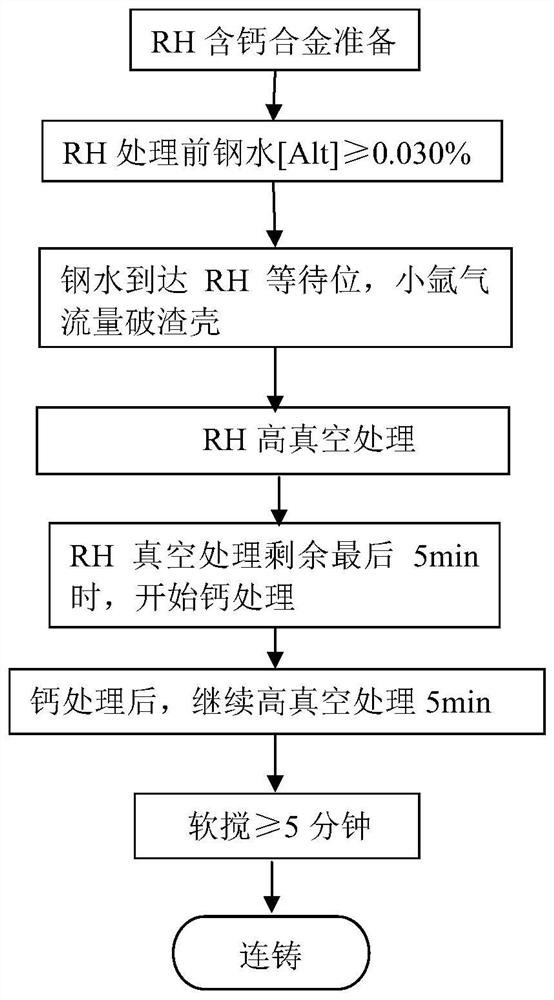

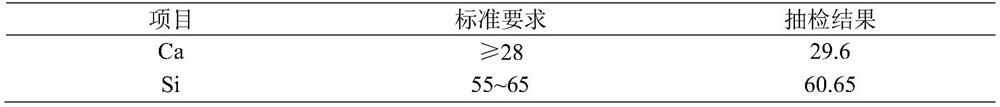

A Calcium Treatment Method in the Vacuum Process of Rh Refining Furnace

ActiveCN110042202BImprove the qualified rate of flaw detectionSolve secondary oxidationCalcium handlingEconomic benefits

The invention discloses a calcium treatment method in the vacuum process of an RH refining furnace. Through the vacuum cycle treatment process of the RH vacuum refining furnace, the RH alloy silo is used to add a calcium-containing alloy to the molten steel circulating in a vacuum chamber to modify molten steel inclusions and calcium treatment. The process is stable and controllable. After the treatment, the calcium composition of molten steel is controlled stably and accurately. The calcium recovery rate reaches more than 20%. The molten steel inclusions are fully denatured. The invention successfully solves the problem of secondary oxidation caused by the tumbling and exposure of molten steel when the pure calcium wire is fed after the vacuum treatment of the RH refining furnace, stabilizes the calcium treatment effect, reduces the content of inclusions, improves the cleanliness of the molten steel and passes the flaw detection of the finished steel plate The production rate is reduced, and the economic benefit is greatly improved.

Owner:NANJING IRON & STEEL CO LTD

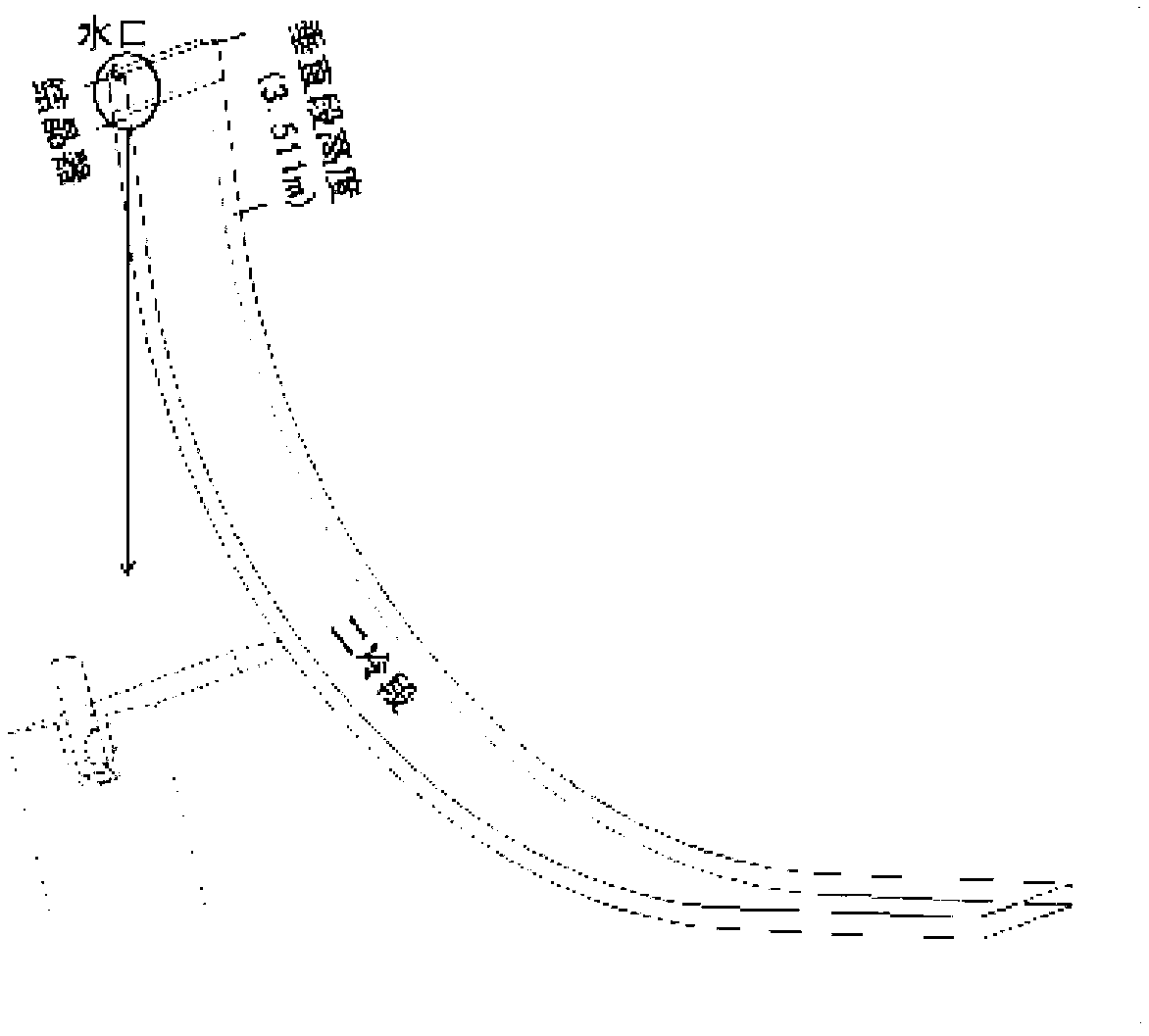

Method for removing inclusions by means of determining height of vertical section of continuous casting machine for extra-thick slabs

The invention discloses a method for removing inclusions by means of determining the height of a vertical section of a continuous casting machine for extra-thick slabs, and relates to the field of manufacture of extra-thick slabs. The method includes performing simulation calculation by the aid of a three-dimensional solidification heat transfer and flow coupling simulation model and an inclusion movement simulation model; finding a relation among a floating rate and the distribution condition of the inclusions inside a casting blank and the height of the vertical section in a continuous casting procedure; accurately determining the height of the vertical section of the continuous casting machine in order to meet requirements of high floating rate and uniform distribution of the inclusions inside the casting blank in the continuous casting procedure; and setting the vertical section on the continuous casting machine for the extra-thick slabs according to the height. The method has the advantage that damage of the inclusions to the quality of the casting blank is reduced, and the fault detection qualified rate of extra-thick plates which are manufactured by means of rolling the extra-thick slabs is increased.

Owner:CISDI ENG CO LTD

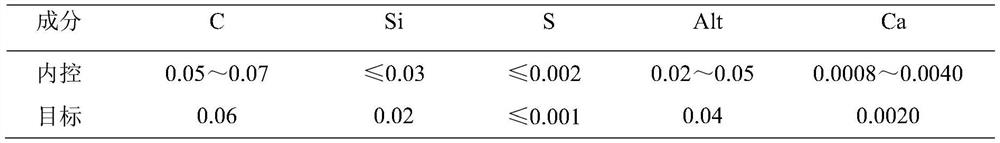

Continuous casting process for boiler pipe steel resistant to sulphuric acid dew point corrosion

The invention relates to a continuous casting process for boiler pipe steel resistant to sulphuric acid dew point corrosion. A full-protecting pouring mode is adopted during continuous casting. A long nozzle argon sealing protecting casting mode is adopted from a steel ladle to a tundish. An integrated built-in submersed nozzle protecting casting mode is adopted from the tundish to a crystallizer. Molten steel in the tundish uses molten steel covering agents. Continuous temperature measurement is carried out on the tundish. Full-automatic liquid surface detection is carried out on the liquid surface of the crystallizer in the continuous casting process. The continuous casting pulling rate is automatically controlled according to the superheat degree of the tundish. Automatic water distribution is carried out for the crystallizer and secondary cooling. The crystallizer uses special casting powder for the boiler pipe steel resistant to sulphuric acid dew point corrosion in the casting process. By means of the continuous casting process for the boiler pipe steel resistant to sulphuric acid dew point corrosion, the surface cracks of rolled metal can be largely reduced, and the flaw detection rate and yield are greatly increased.

Owner:NANJING IRON & STEEL CO LTD

Sectionalize heating technique in high alloy cold roller blank manufacture

The invention discloses a sectionwise heating technology in high alloy cold roller blank manufacture, which sets heating temperature of 1200-1220deg C before roller blank is forged. The heating processes comprise stages: first, keeping temperature for five hours and processing it with pressure drawing and prepressing; second, keeping temperature for seven hours and then processing it with metal gathering and forging; third, returning to furnace to keep temperature for eight hours. The invention can eliminate or reduce strip carbide grade efficiently in the course of roller blank manufacture.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

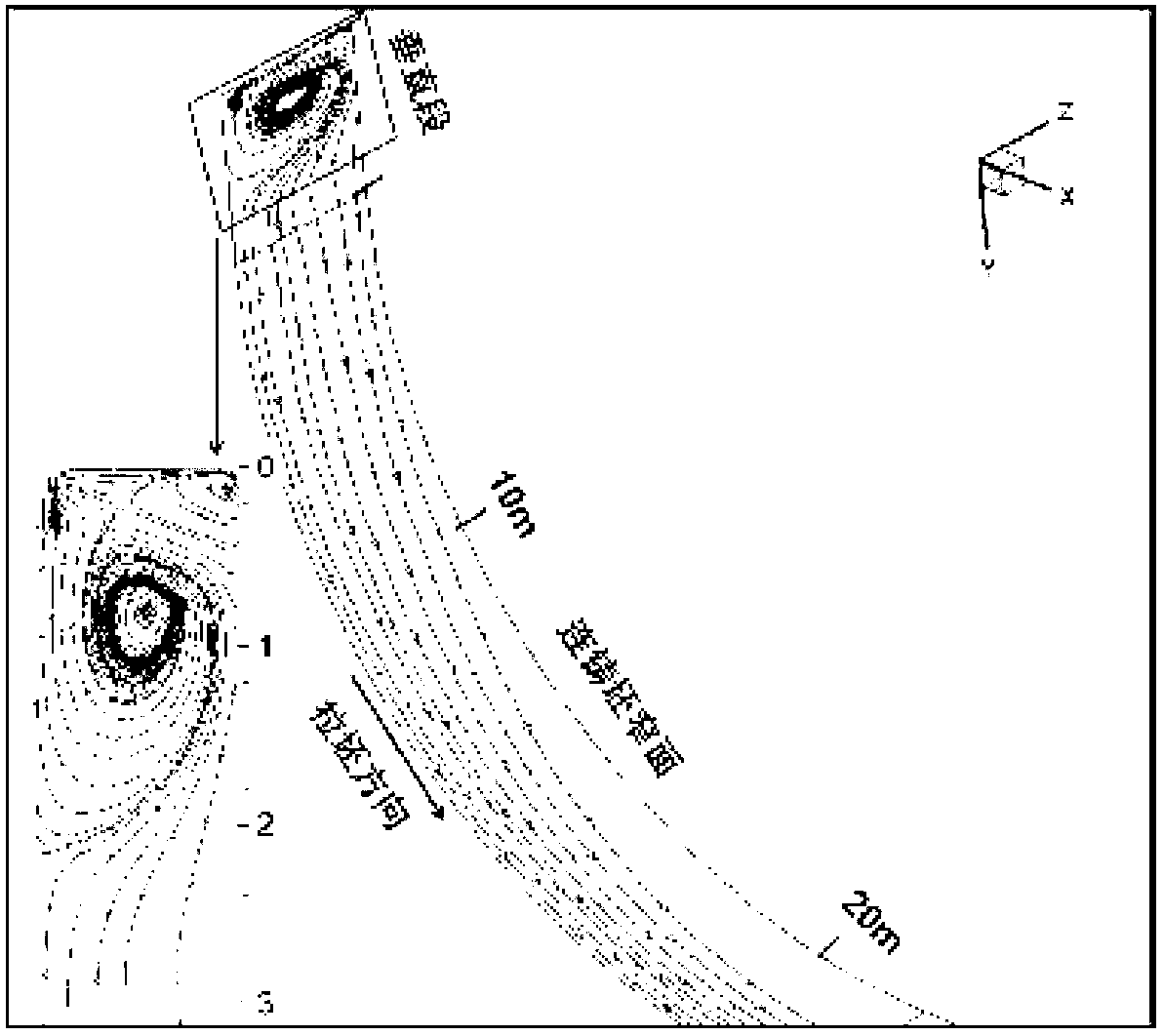

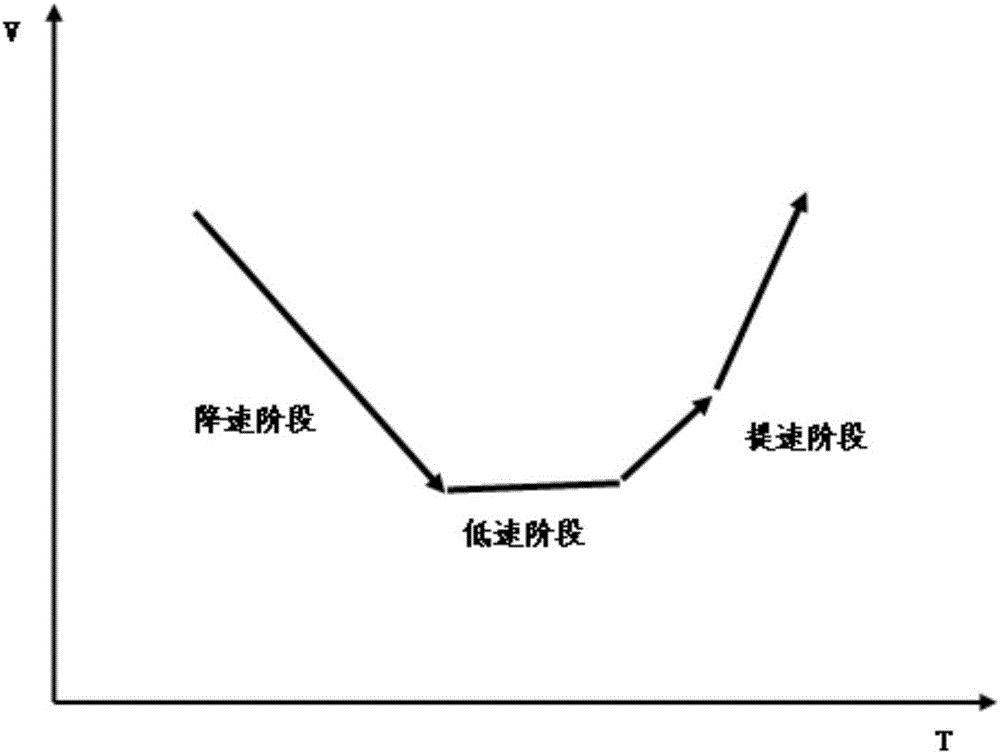

Wide and thick plate continuous casting machine dry capping method

The invention relates to a wide and thick plate continuous casting machine dry capping method, and belongs to the technical field of continuous casting technologies. The wide and thick plate continuous casting machine dry capping method particularly comprises the following steps and parameters that in the speed reduction stage, according to the actual measurement tundish tons, in cooperation the tundish measurement actual liquid level, the pull speed is reduced to 0.25 m / min; in the low-speed and constant-speed running stage, according to the tundish tons and the actual measurement liquid level, when the depth of the liquid face of molten steel in a tundish ranges from 100 mm to 300 mm, a plug bar is closed, meanwhile, the pull speed is reduced to 0.15 m / min to 0.2 m / min, and low-speed running is kept; and in the speed increasing process, the blank tail is pulled out of a crystallizer, and the pull speed is increased to a target pull speed. The wide and thick plate continuous casting machine dry capping method has the beneficial effects that slag is not wasted, slag fishing is avoided, low-speed weak-cold control is achieved, and therefore the effective improvement of the tail blank quality is achieved, the tail blank flaw detection yield is improved, the tail blank waste cutting amount is reduced, and the metal yield is improved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

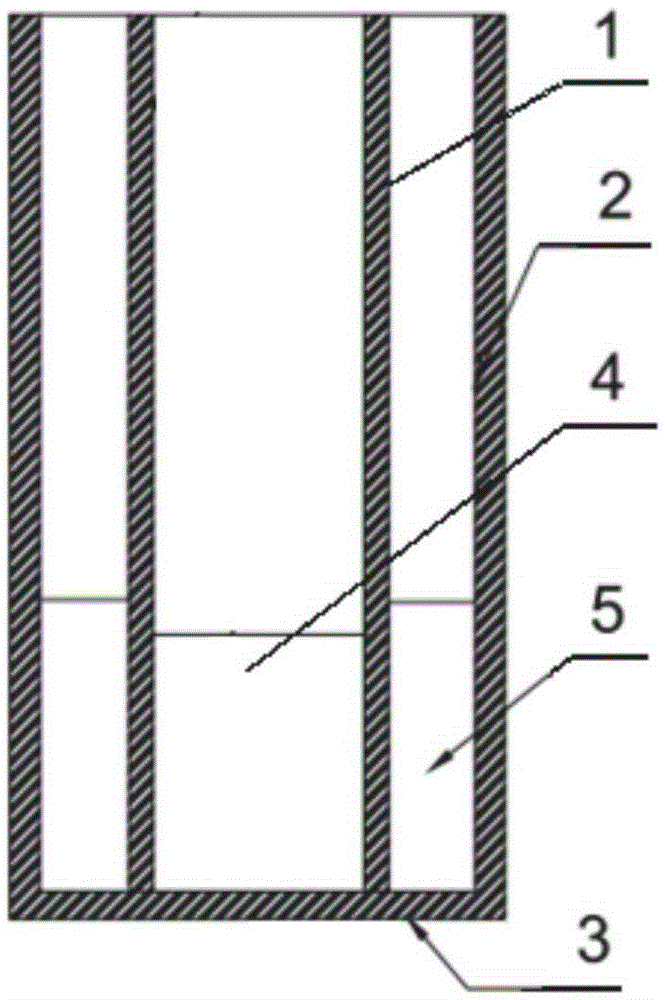

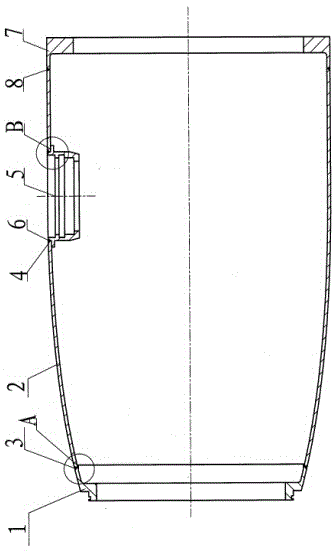

Destressing warhead-curve-shaped aluminum alloy thin-walled cylinder and machining process of destressing warhead-curve-shaped aluminum alloy thin-walled cylinder

ActiveCN104084771AImprove the qualified rate of flaw detectionImprove welding strengthCurve shapeWeld strength

The invention discloses a destressing warhead-curve-shaped aluminum alloy thin-walled cylinder and a machining process of the destressing warhead-curve-shaped aluminum alloy thin-walled cylinder. The destressing warhead-curve-shaped aluminum alloy thin-walled cylinder and the machining process solve the problems that an existing thin-walled cylinder is not thorough in destressing and the welding strength of weld joints can be easily lowered due to machining. The destressing warhead-curve-shaped aluminum alloy thin-walled cylinder comprises a warhead-curve-shaped thin-walled cylinder body (2), a front flange (1) and a rear flange (7). A front annular weld joint (3) in the perpendicular direction is arranged between an annular groove (10) of an annular cylinder body (9) arranged on the side face of the rear end of the front flange (1) and the front end of the warhead-curve-shaped thin-walled cylinder body (2). A hole base hole (4) is formed in the cylinder wall of the warhead-curve-shaped thin-walled cylinder body (2), and an positioning annular step (11) is arranged on the outer side wall of a hole base (5). The invention discloses an effective method for removing welding stress of the thin-walled cylinder. By means of the destressing warhead-curve-shaped aluminum alloy thin-walled cylinder and the machining process, surface residual tension of the thin-walled cylinder is effectively eliminated, the material structural strength is improved, and the fatigue life is prolonged.

Owner:SHANXI FENXI HEAVY IND

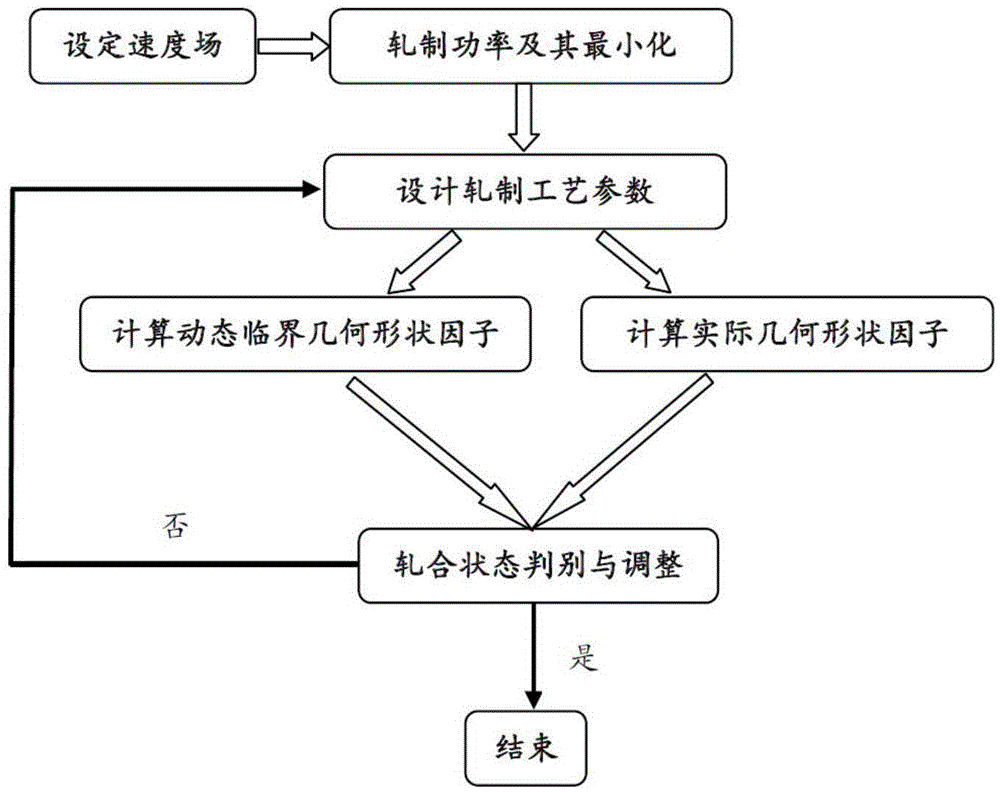

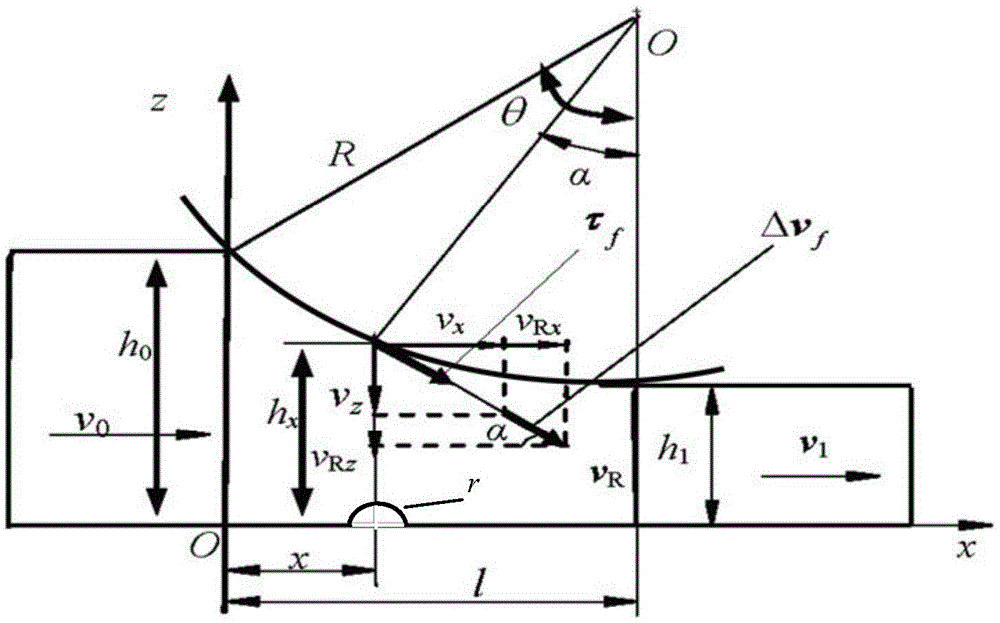

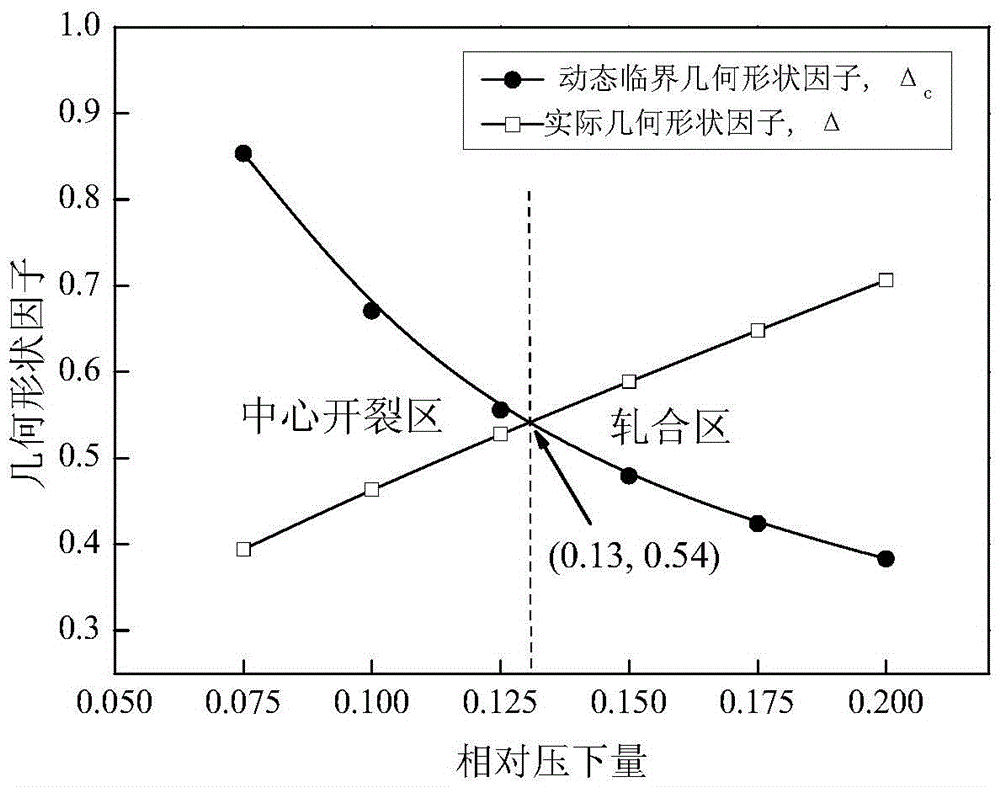

Control method of rolling of central hole defect of continuously-cast thick blank

InactiveCN105537269AImprove the qualified rate of flaw detectionRoll mill control devicesMetal rolling arrangementsStrain rateEngineering

The invention discloses a control method of rolling of a central hole defect of a continuously-cast thick blank. The method comprises steps as follows: (1) setting of a velocity field: a round hole defect-containing kinematically admissible velocity field and a strain rate field are set; (2) a rolling power total power function is established on the basis of the velocity field, and a minimum rolling power function is obtained; (3) design of rolling process parameters; (4) calculation of a dynamic critical geometrical shape factor; (5) calculation of an actual geometrical shape factor; (6) judgment and adjustment of the rolling state. The method depends on the rolling criterion of dynamic rolling parameters, and setting of the rolling process parameters per pass can be guided, so that the percent of pass of product flaw detection is increased.

Owner:SUZHOU UNIV

Steelmaking hydrogen control method

InactiveCN105969932AStable hydrogen control effectSmall fluctuations in hydrogen contentManufacturing convertersProcess efficiency improvementSteelmakingWater leakage

The invention provides a steelmaking hydrogen control method. Through much test and data analysis, the hydrogen content of molten steel produced in each procedure is detected and analyzed, and the various factors which may increase hydrogen in the steelmaking process are summarized. By optimizing the quality and proportion of furnace charge of a converter, improving the endpoint carbon content of the converter, reducing use of water-containing materials, strictly controlling water leakage of a flue and an oxygen lance, carrying out alloy and protective slag baking, prolonging the slow cooling time of casting blanks and the like, the average hydrogen content in the steel is lowered by 2.04 ppm and becomes 4-6 ppm. The quality of the casting blanks is remarkably improved, the crack and flaw detection defects of the steel grade not subjected to vacuum treatment are greatly reduced, and the flow defection percent of pass of steel plates is improved to 99.3% from original 98.5%.

Owner:SHANDONG IRON & STEEL CO LTD

Preparation process of aviation aluminum alloy ingot and aluminum alloy ingot

The invention provides a preparation process of an aviation aluminum alloy ingot. The preparation process of the aviation aluminum alloy ingot comprises the following steps: (A) mixing a Cu source, an Mg source, a Zn source, a Ti source, a Zr source and an Al source, then smelting to obtain a smelted product; (B) sequentially degassing, filtering and refining the smelted product obtained in the step (A) on line to obtain an on-line processed product; (C) casting the on-line processed product obtained in the step (B) to obtain an aviation aluminum alloy ingot blank, wherein the casting rate is 8-14mm / min; (D) carrying out homogenizing treatment on the aviation aluminum alloy ingot blank obtained in the step (C) to obtain the aviation aluminum alloy ingot. According to the preparation process, the proper casting rate is adopted; the flaw detection eligibility rate of the aluminum alloy can be increased; experimental results show that the flaw detection eligibility rate of aluminum alloy 7050 and aluminum alloy 7A85 prepared by the preparation process of the aviation aluminum reaches 97-99%.

Owner:SOUTHWEST ALUMINUM GRP

Hot top casting process of 7050 aluminum alloy and 7050 aluminum alloy ingot

The invention provides a hot top casting process of a 7050 aluminum alloy. The process comprises the following steps: (A) mixing a Cu source, a Mg source, a Zn source, a Ti source, a Zr source and a Al source, and then performing smelting to obtain a smelted material; (B) sequentially performing online degassing, online filtration and online refining on the smelted material obtained in the step (A) to obtain an online treatment product; and (C) performing casting on the online treatment product obtained in the step (B) to obtain the 7050 aluminum alloy, wherein the casting speed is 8-14mm / min. The hot top casting process provided by the invention adopts an appropriate casting speed and can be used for improving the flaw detection qualified rate of the aluminum alloy, and experimental results show that the flaw detection qualified rate of the 7050 aluminum alloy prepared by the hot top casting process of aviation aluminum, provided by the invention, is 97-99%.

Owner:SOUTHWEST ALUMINUM GRP

Manufacturing method of martensitic stainless steel seamless pipe with high concentricity

ActiveCN109513766AImprove the qualified rate of flaw detectionImprove surface qualityMartensitic stainless steelHeat treating

The invention discloses a manufacturing method of a martensitic stainless steel seamless pipe with high concentricity. The manufacturing method comprises the following steps that a bar billet is manufactured; a central through hole is drilled; the central hole is bored precisely; an outer circle is subjected to finish turning to ensure concentricity; a first pass of cold rolling is carried out; acold rolled pipe is cleaned; the rolled pipe is annealed; a next pass of cold rolling is carried out; a finished product of the rolled pipe is heated; finishing of the finished pipe is carried out; and nondestructive test of the finished pipe is carried out. The manufacturing method is simple and practical, reasonable in cost and good in cost performance, and the finished X12Cr13 martensitic stainless steel pipe has high concentricity, it is ensured that various performance completely meet the use requirements, and the manufacturing method is suitable for mass production.

Owner:南通金尼新材料科技有限公司

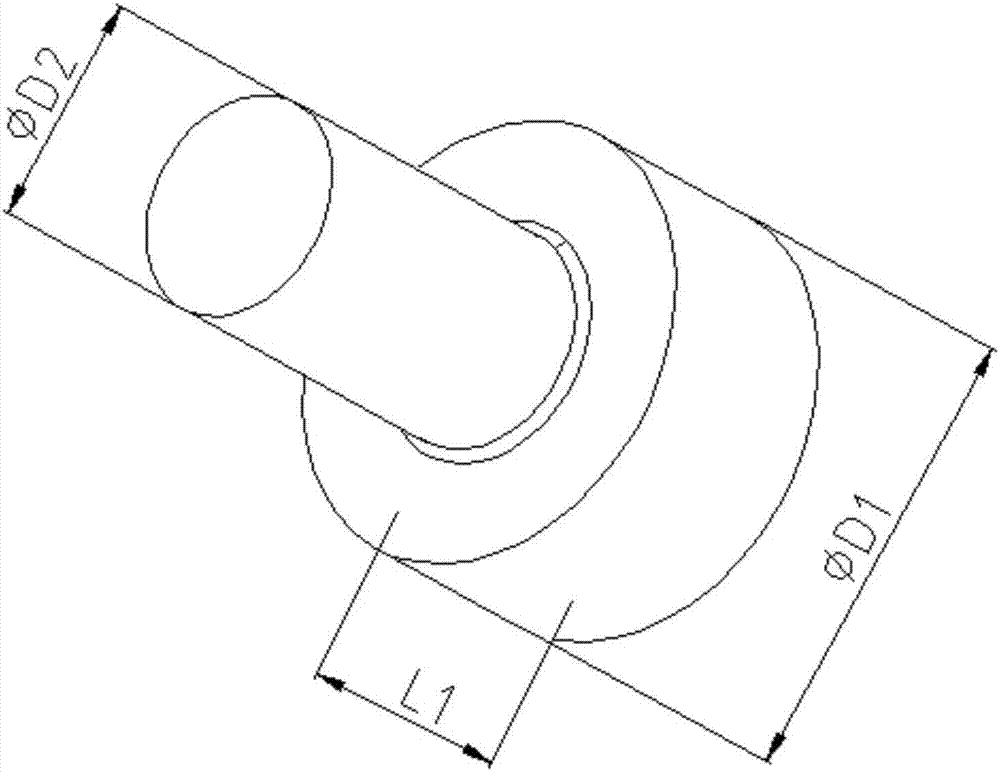

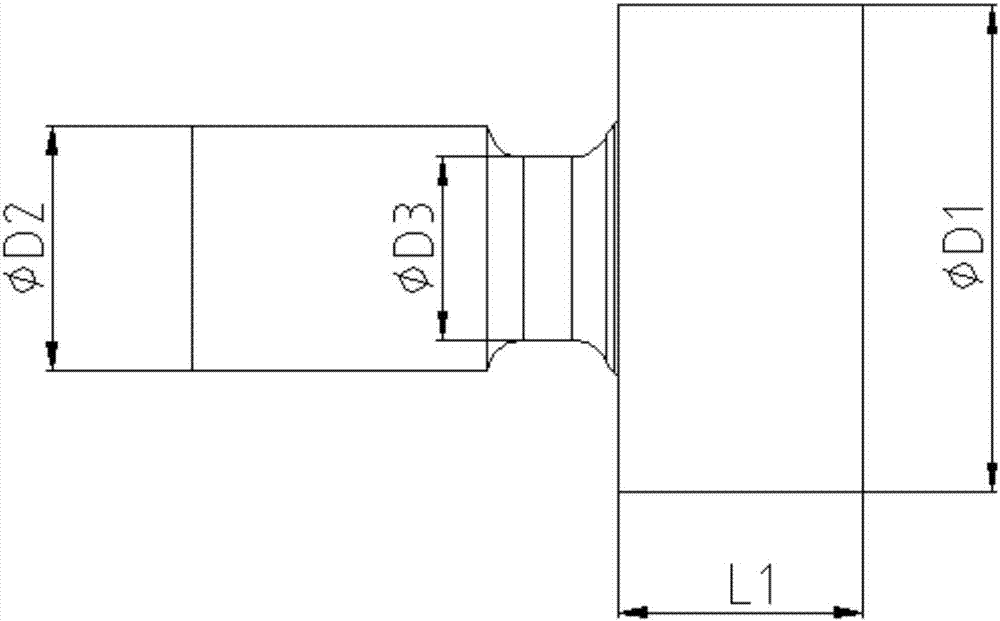

Forging forming technology of straight-shank double hooks

InactiveCN107537969AIncrease profitImprove the qualified rate of flaw detectionHooksLoad-engaging elementsPass rateEngineering

The invention discloses a forging forming technology of straight-shank double hooks and belongs to the technical field of forging and pressing formation. The forging forming technology of the straight-shank double hooks comprises the following steps that firstly, round steel with the diameter being D and the length being L is selected; secondly, the diameter becomes D1 through heading; thirdly, the part with the length being L1 is measured out from the lower end of the forged piece to be used as a hook body, and the part above the part, from the position of the L1, of the forged piece is usedas a hook shank, forging and drawing are conducted on the hook shank, the drawn section is divided into two sections with different diameters from top to bottom, the diameter of the upper section is D2, and the diameter of the lower section is D3; fourthly, the hook body at the lower end of the forged piece is forged to be a cylinder perpendicular to the upper end of the forged piece, and the diameter of the cylinder is D3; fifthly, the two ends of the cylinder at the lower end of the forged piece are drawn, and the two ends of the cylinder become cones; sixthly, the hook shank at the upper end of the forged piece is drawn to be round steel in a preset diameter; and seventhly, the two ends of the hook body are bent, and a double-hook blank is manufactured. By the adoption of the forging forming technology of the straight-shank double hooks, the utilization rate of raw materials is greatly improved, the flaw detection yield of workpieces is greatly improved, at least two working procedures of an original machining manner are omitted, the energy consumption is reduced, and efficiency is improved.

Owner:XUZHOU DACHANGSHI ENG MACHINERY

Low-cost production process for increasing fault detection qualification rate of Q345R steel plates

ActiveCN103509925AImprove the qualified rate of flaw detectionLow costTemperature control deviceManufacturing convertersTemperingMetallurgy

The invention relates to a low-cost production process for increasing the fault detection qualification rate of Q345R steel plates. The process mainly comprises the following steps: performing molten iron feeding with the content of S less than or equal to 0.010%, performing converter tapping with the total oxygen content controlled to be less than or equal to 20 ppm, and performing LF refining with the content of S controlled to be less than or equal to 0.005%; when the steel plate thickness is more than or equal to 60 mm or the compression ratio is less than or equal to 10, performing on-line shearing and RH refining, wherein the degree of vacuum is less than or equal to 5.0 mbar, and the maintaining time is more than or equal to 12 min; when the product thickness is controlled to be 12-80 mm, controlling the fine rolling temperature to be 1020-870 DEG C and the finish rolling temperature to be 820-830 DEG C, and discharging and cooling after the self-tempering temperature is controlled to be 700-680 DEG C; when the product thickness is less than or equal to 60 mm and the discharge temperature is more than or equal to 350 DEG C, shearing after stacking for slow-cooling for 72 h. The production process achieves the purpose of increasing the fault detection qualification rate of Q345R steel plates with low cost through the procedures of scientific and reasonable distribution and control of sulfur, deep deoxidation, RH refining, steel plate stacking for slow-cooling and the like.

Owner:NANJING IRON & STEEL CO LTD

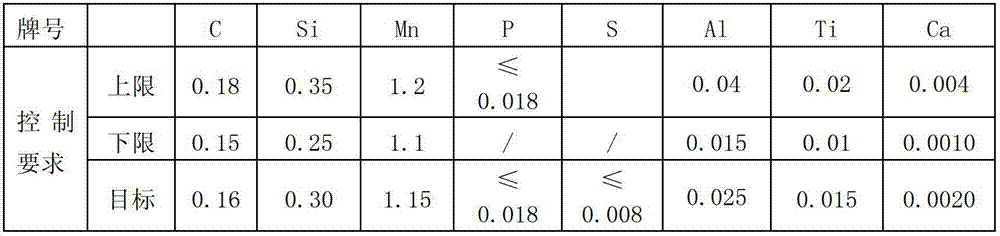

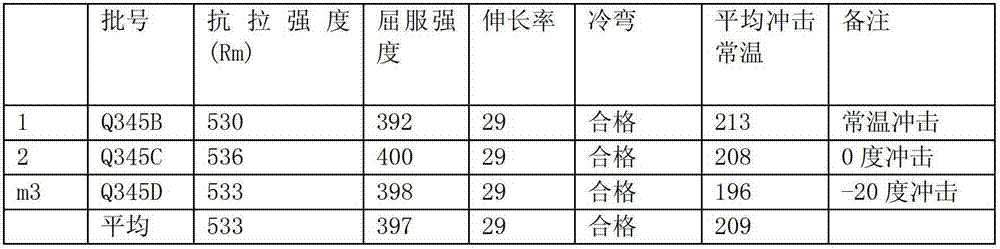

Production method for controlling fault detection defect of medium thick plate Q345 steel

InactiveCN103031490AImprove the qualified rate of flaw detectionImproving the pass rate of strong flaw detection of steelThick plateSlag

The invention provides a production method for controlling fault detection defect of medium thick plate Q345 steel. The composition design is: 0.15-0.18% of C, 0.25-0.35% of Si, 1.1-1.2% of Mn, equal to or less than 0.018% of P, equal to or less than 0.008% of S, 0.025-0.04% of Al, 0.015-0.02% of Ti, and 0.002-0.004% of Ca; an Al-Ca refining agent is added during LF refining, the Al-Ca reining agent is began to feed into a steel ladle when the temperature reaches 1530 DEG C, and the addition amount is 0.5-1.0kg / t steel; the S content of the pretreated molten iron is 0.001-0.002%, and the tapping temperature of a converter is kept at 1620 DEG C to 1630 DEG C; the Al2O3 content of refined slag of an LF refining furnace is 30-35%, the delivery of current is 10min to 15min, and the final molten steel nitrogen content is 0.002-0.004%; and the molten steel liquid level of a casting pot is controlled to be 500mm to 550mm, and the steel ladle long nozzle is protected by argon seal, thus the nitrogen content of the continuous casting molten steel is enhanced by 0.0003-0.0008%, and the molten steel continuous casting temperature is 1525 DEG C to 1535 DEG C.

Owner:宝钢集团八一钢铁股份有限公司

Method for improving internal quality of steel plate

InactiveCN102344990AImprove the qualified rate of flaw detectionSimple methodHydrogen contentSlow cooling

The invention discloses a method for improving the internal quality of a steel plate, which comprises the following steps that: (1) covering agents in big and intermediate bags are baked before an LF furnace smelts, so the water contents of the covering agents in big and intermediate bags are reduced to be lower than 0.5%; (2) after a slab is cut, stacking for slow-cooling is carried out, wherein the temperature of the stacking for slow-cooling is 800-950 DEG C, the time of the stacking for slow-cooling is more than 48h, so the hydrogen content in a casting blank is lower than 3PPm; and (3) the finished steel plate with the thickness of 18-70mm is air-cooled to 260-500 DEG C, stacking for slow-cooling is quickly carried out on the steel plate in a cooling bed area, when the temperature of the stacking for slow-cooling is 260-500 DEG C, the stacking number of the steel plates is not less than 8, the time of the stacking for slow-cooling on the steel plate with the thickness of 30-70mm is longer than 48h, the time of the stacking for slow-cooling on the steel plate with the thickness of 18-30mm is longer than 24h, so the hydrogen content of the finished steel plate is smaller than 1PPm. Under the conditions of no RH or VD vacuum treatment equipment, special hydrogen diffusion equipment and the like or not using the vacuum treatment equipment for reducing the cost, through reducing the hydrogen content in the steel, the crack which is caused by the hydrogen in the center of the steel plate is prevented from being produced, and the flaw detection acceptability of the steel plate is improved.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

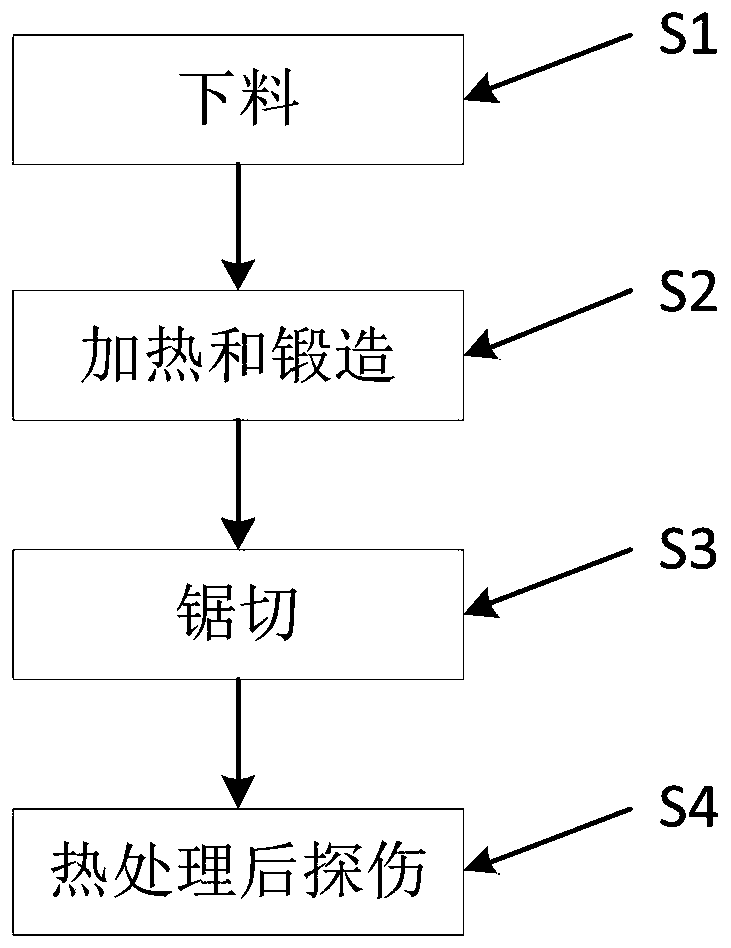

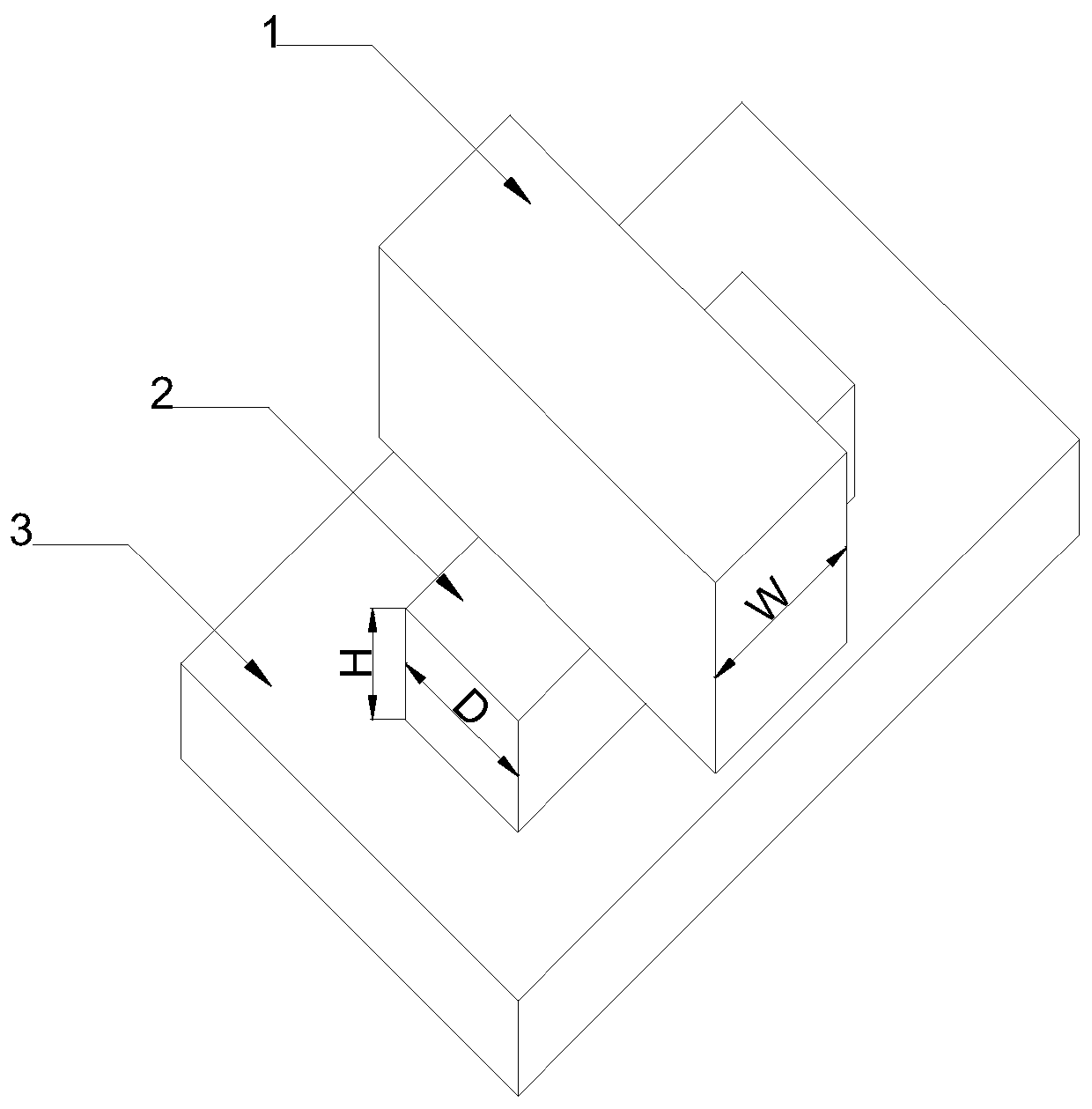

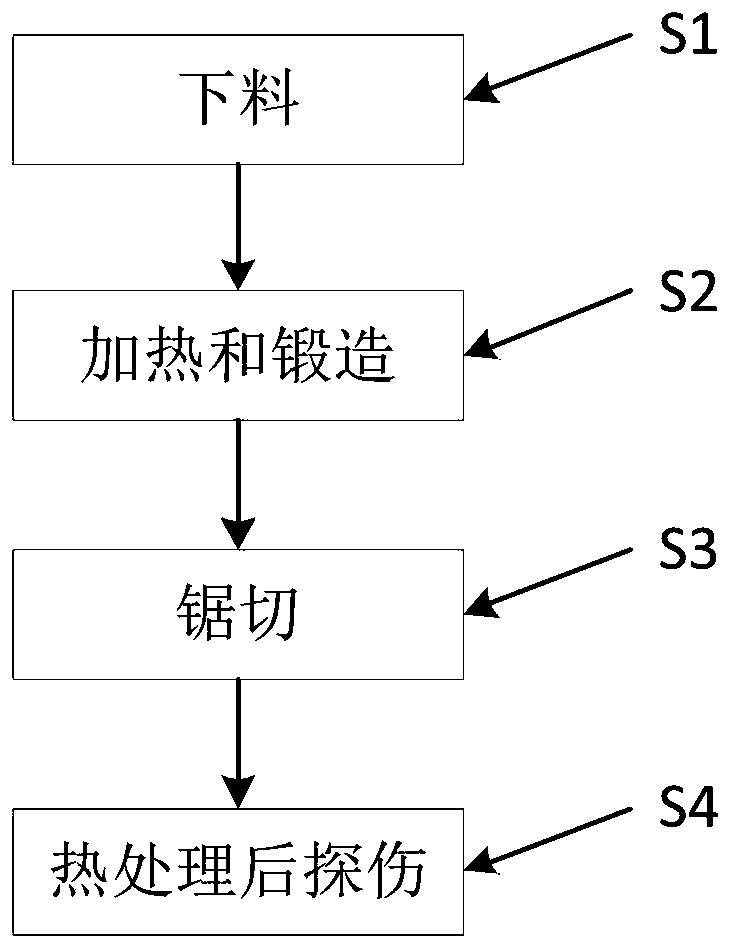

Forging method of improving qualified rate in flaw detection of aluminum alloy disk forging

ActiveCN109909410AImprove the qualified rate of flaw detectionSolve the impact of unqualified flaw detectionHandling devicesDiameter ratioHeat treated

The invention relates to a forging method of improving the qualified rate in flaw detection of an aluminum alloy disk forging. The forging method comprises the following steps of S1, blanking: the diameter of a rod is D, the rod is sawn in a length direction of the rod into multiple blanks, and the diameter ratio of the diameter D of each blank and the diameter d of a forging is larger than or equal to 1.5; S2, heating and forging: firstly, after being heated, the blanks are squared and drawn in axial directions of the blanks respectively, and finally, forgings are chamfered and rounded; S3, sawing: the forgings are sawn in length directions of the forgings; and S4, flaw detection after heat treatment. In the forging method, upsetting is not performed during forging, the blanks are directly drawn in the original axial direction to the required size, and the influence of unqualified flaw detection caused by an uneven flow line is solved.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com