Forging method for high temperature alloy GH4169 round rod

A technology of GH4169 and high-temperature alloys, which is applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., and can solve problems such as increasing core deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] A forging method of high-temperature alloy GH4169 round bar:

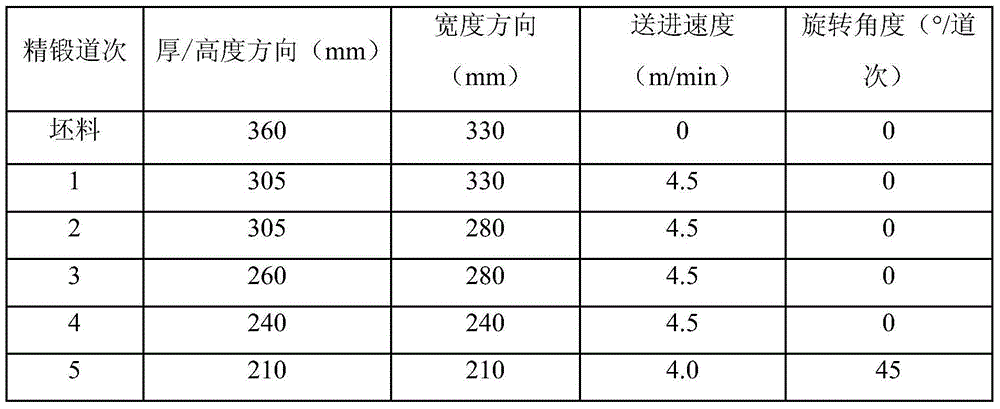

[0033] When using the radial forging unit to forge GH4169 round rods, two fires are used. The first fire uses flat hammers to forge blanks, and the second fire uses round hammers for precision forging into specifications; forging billets and precision forging processes As shown in Table 1 and Table 2, respectively. After the completion of forging, the surface quality of the specification product is good, no obvious spiral pattern is found, and no defect wave is found in the flaw detection, which meets the qualified requirements.

[0034] Table 1 Blanking process of GH4169 radial forging machine (flat hammer head)

[0035]

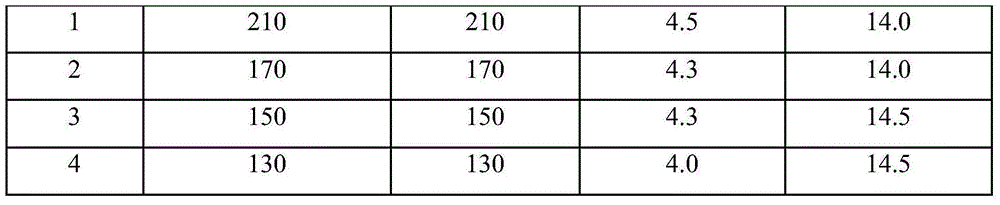

[0036] Table 2 GH4169 precision forging process (round hammer)

[0037]

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com