Production method for controlling fault detection defect of medium thick plate Q345 steel

A production method, the technology of Q345B, is applied in the fields of steelmaking and smelting and casting billet casting, and can solve problems such as cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

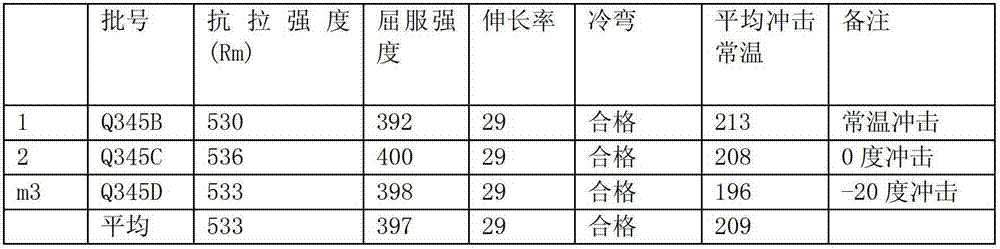

Examples

Embodiment

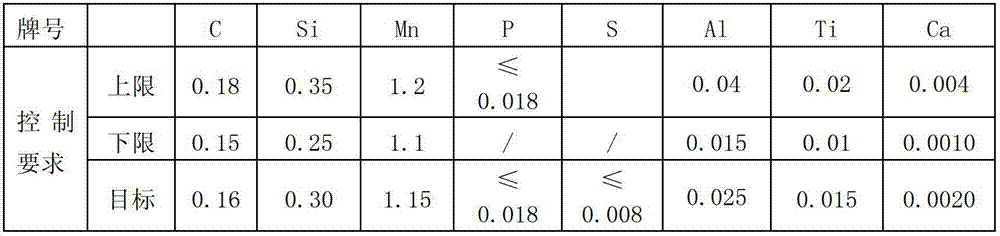

[0020] 1. Composition design: Applicable steel grade Q 345B / C / D, thickness H≤30mm; see Table 1 for composition.

[0021] Table 1 Optimized ingredients (%)

[0022]

[0023] From the data in the above table, it can be seen that the internal control chemical composition of the enterprise is adopted, which is stricter than the national standard, that is, the manganese content and sulfur content of the steel are reduced, and the inclusions of [MnS] are reduced.

[0024] 2. Control of [MnS] inclusions in steel

[0025] The process route is: hot metal desulfurization treatment--120t converter-LF--slab continuous casting-heating furnace-medium plate rolling--ACC-collection

[0026] Controlling the manganese content of molten steel through composition design can greatly reduce the generation of MnS inclusions. In addition, the following operations can also effectively reduce the generation of [MnS].

[0027] (1) The desulfurization pretreatment of molten iron reduces the sulfur c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com