Forging method of improving qualified rate in flaw detection of aluminum alloy disk forging

An aluminum alloy, pass rate technology, used in manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve problems such as uneven flow lines and easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

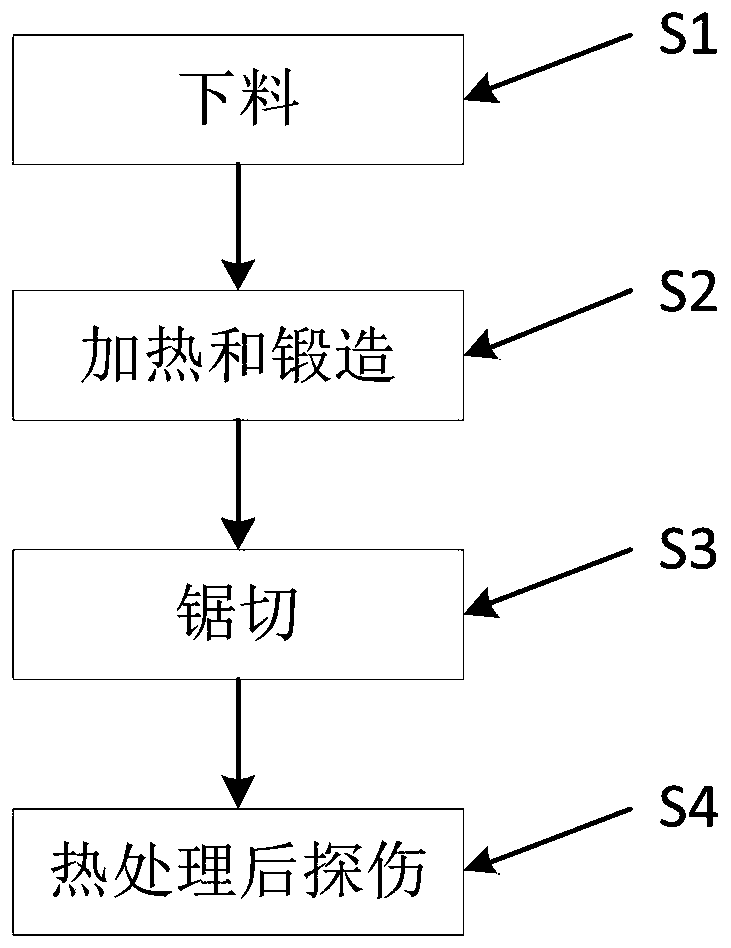

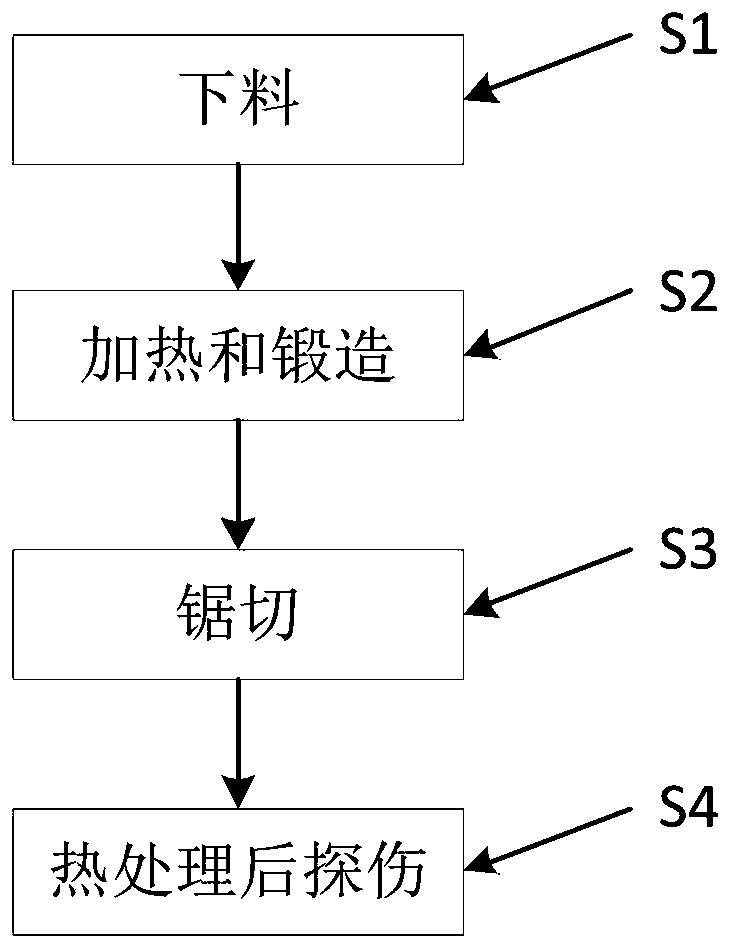

[0041] Embodiment: Forging The finished product size of the forging is required to be Φ200mm×100mm, that is, d=200mm.

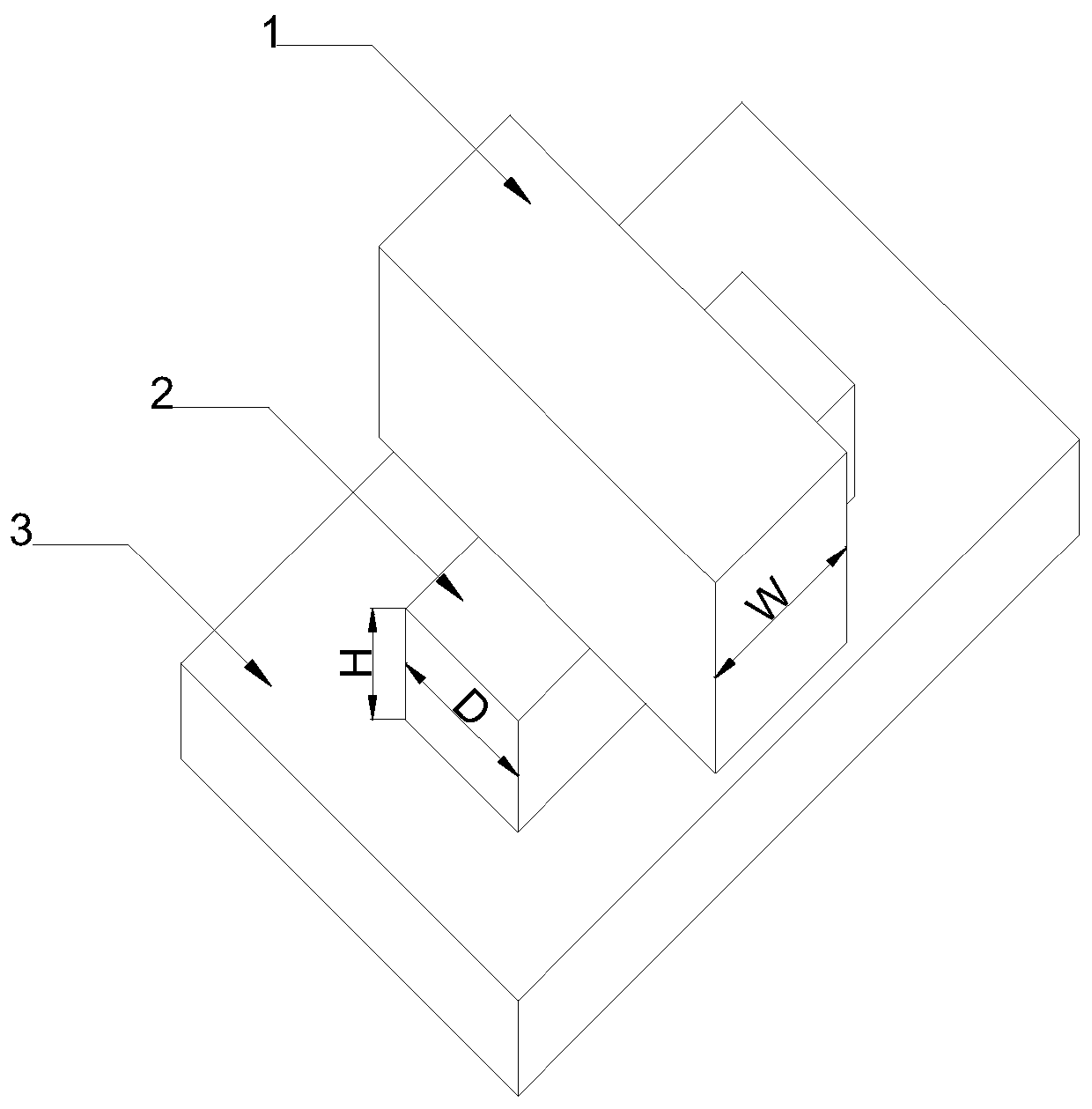

[0042] Step S1: unloading. The diameter of the bar is D, where D=300mm. Saw the bar along its length using a band saw, sawing into multiple billets 2 . The ratio of the width D of the blank 2 to the height H of the blank 2 is D / H=0.8. The diameter ratio of the diameter D of the blank 2 to the diameter d of the forging is 1.5.

[0043] Step S2: heating and forging. First, the billet 2 is put into a heating furnace and heated to 440°C±10°C. Then, the blank 2 is taken out, and squared and lengthened on the manipulator along the axial direction of the blank 2 . The manipulator includes a cart traveling mechanism, a clamp frame, a swing mechanism, a lifting mechanism, a rotating mechanism and a clamping mechanism. Lower anvil 3 is installed on the rotating mechanism. The tong frame adjusts the tong bar installed on the tong frame through the rising or falli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com