Welding process of 12Cr1MoV high-pressure pipeline CO2 semiautomatic or automatic gas shielded welding

A gas shielded welding, 12cr1mov technology, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of high labor intensity of welders, low welding efficiency, non-fusion, etc., and achieve a high pass rate of weld flaw detection , The effect of stable welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] 12Cr1MoV high pressure pipeline CO 2 The detailed steps of the semi-automatic or automatic gas shielded welding process are as follows:

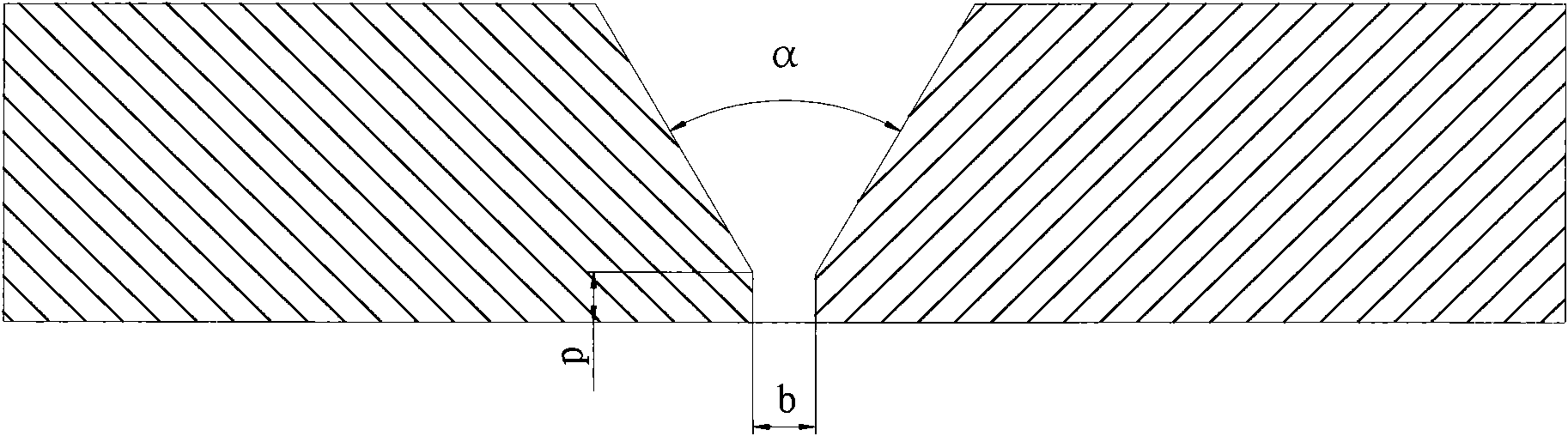

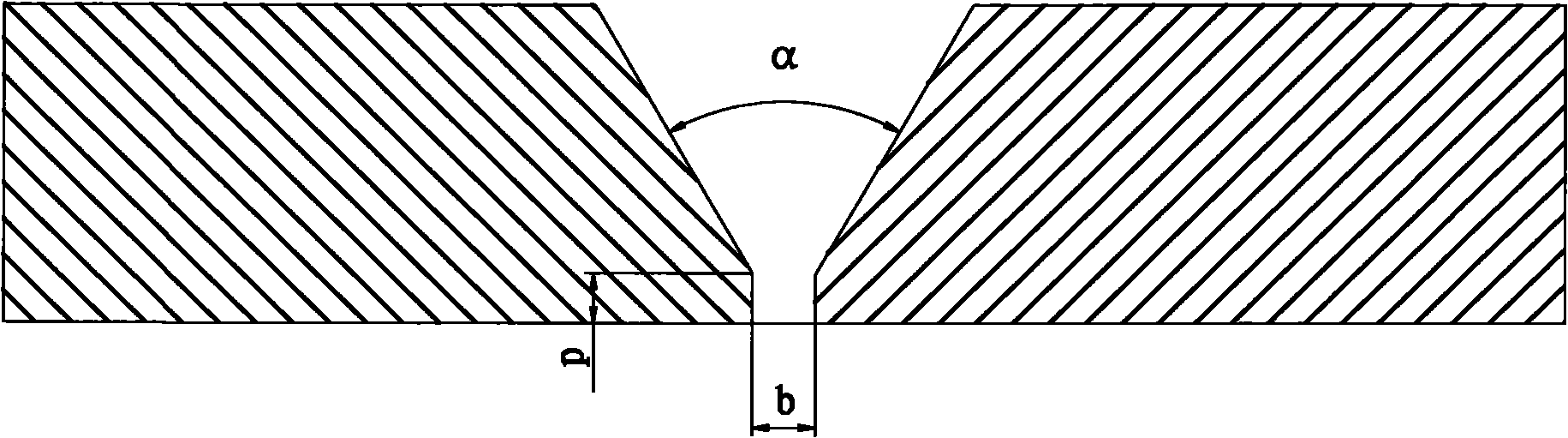

[0016] 1. Take the 12Cr1MoV high pressure tube of φ273×18mm, such as figure 1 The groove is processed in the shown groove form, the included angle of the groove is 55-60°, the blunt edge p is 0.5-1.0mm, and the gap b between the welding end faces of the two steel pipes is 2.0-3.0mm.

[0017] 2. Use the magnetic powder surface nondestructive testing method to detect the groove surface. If there is no crack, it is qualified, and clean up the dirt within 50-100mm of the groove surface of the two-phase welded steel pipe and the edges on both sides of the fracture;

[0018] 3. Fix the two-phase welded steel pipe with a fixture.

[0019] 4. The heating can be heated by flame, heating furnace or caterpillar, and thermal insulation cotton is used to preheat the joint. The preheating range is 3δ from the edge of the groove (δ- is the wall thickness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com