Dynamic balance automatic welding device

An automatic welding and automatic technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as high production cost, large welding current, waste, etc., to reduce frequent replacement time, stable welding quality, and working environment. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

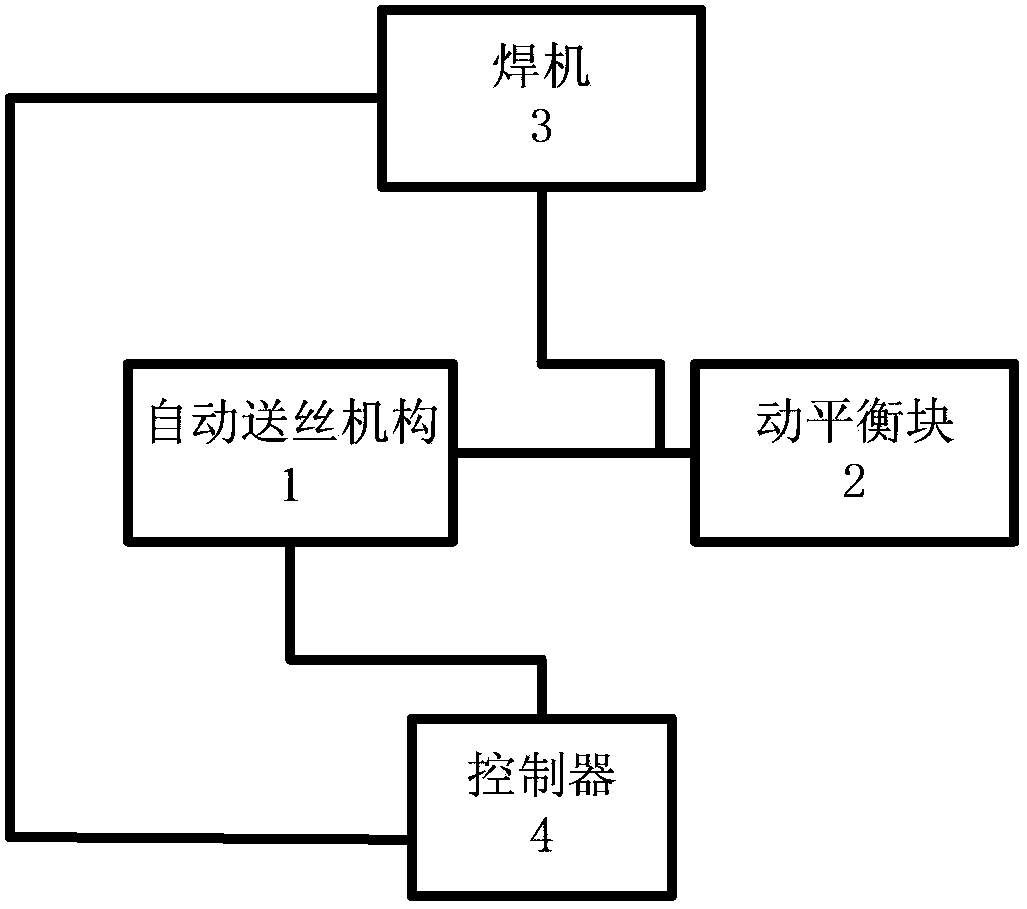

[0026] Such as figure 1 As shown, a dynamic balancing automatic welding device includes an automatic wire feeding mechanism 1, a dynamic balancing block 2, a welding machine 3 and a controller 4, the automatic wire feeding mechanism 1 is aligned with the welding place of the dynamic balancing block 2, and the Described welding machine 3 is aimed at the welding wire of automatic wire feeding mechanism 1, and described controller 4 is connected with automatic wire feeding mechanism 1, welding machine 3 respectively;

[0027] The controller 4 controls the automatic wire feeding mechanism 1 to align with the welding place of the dynamic balance block 2, controls the welding machine 3 to perform welding, and automatically loads the welding wire during the welding process, and leaves the automatic wire feeding mechanism 1 after welding is completed. Dynamic balance block 2.

[0028] The welding machine 3 is a CO2 welding machine. The controller 4 controls the feeding amount of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com