Patents

Literature

209results about How to "Eliminate the influence of human factors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cable tester

InactiveCN101241162AImprove versatilityReduce volumeFault locationTest efficiencyHuman–machine interface

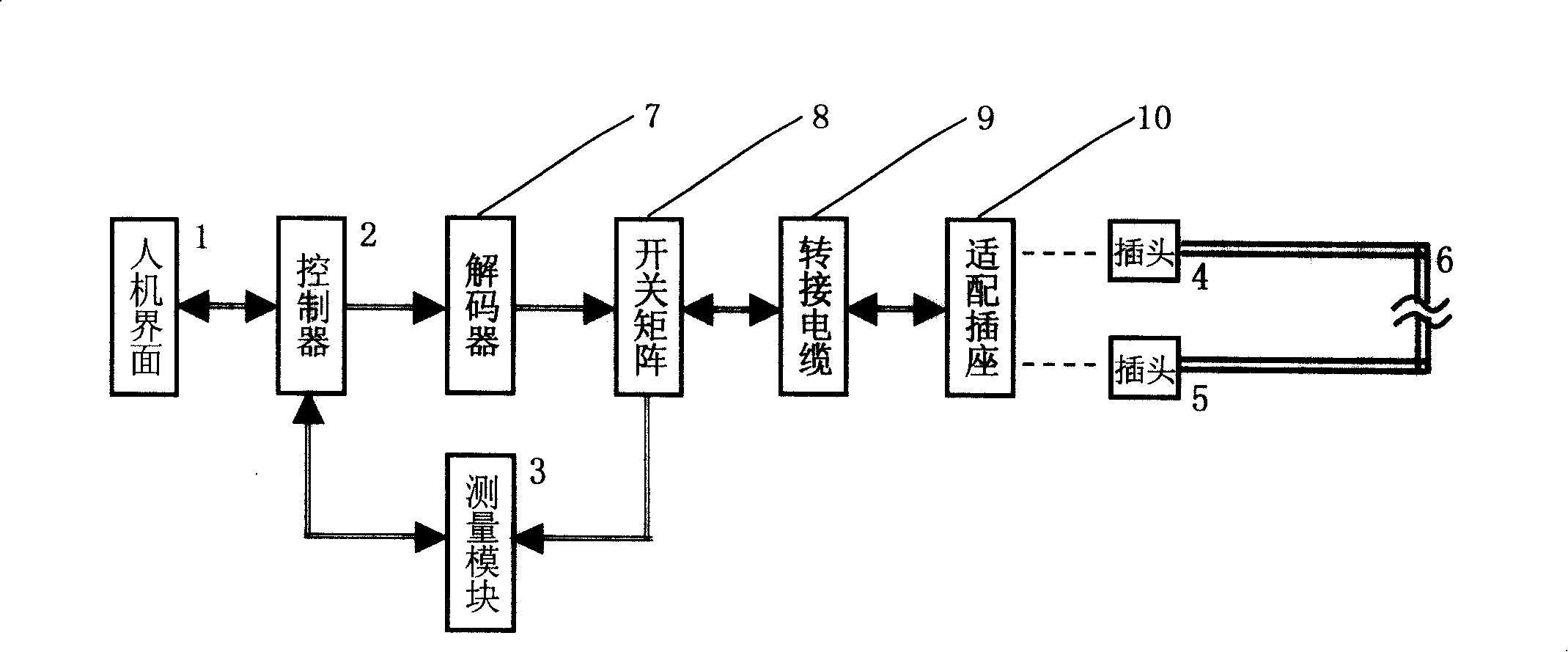

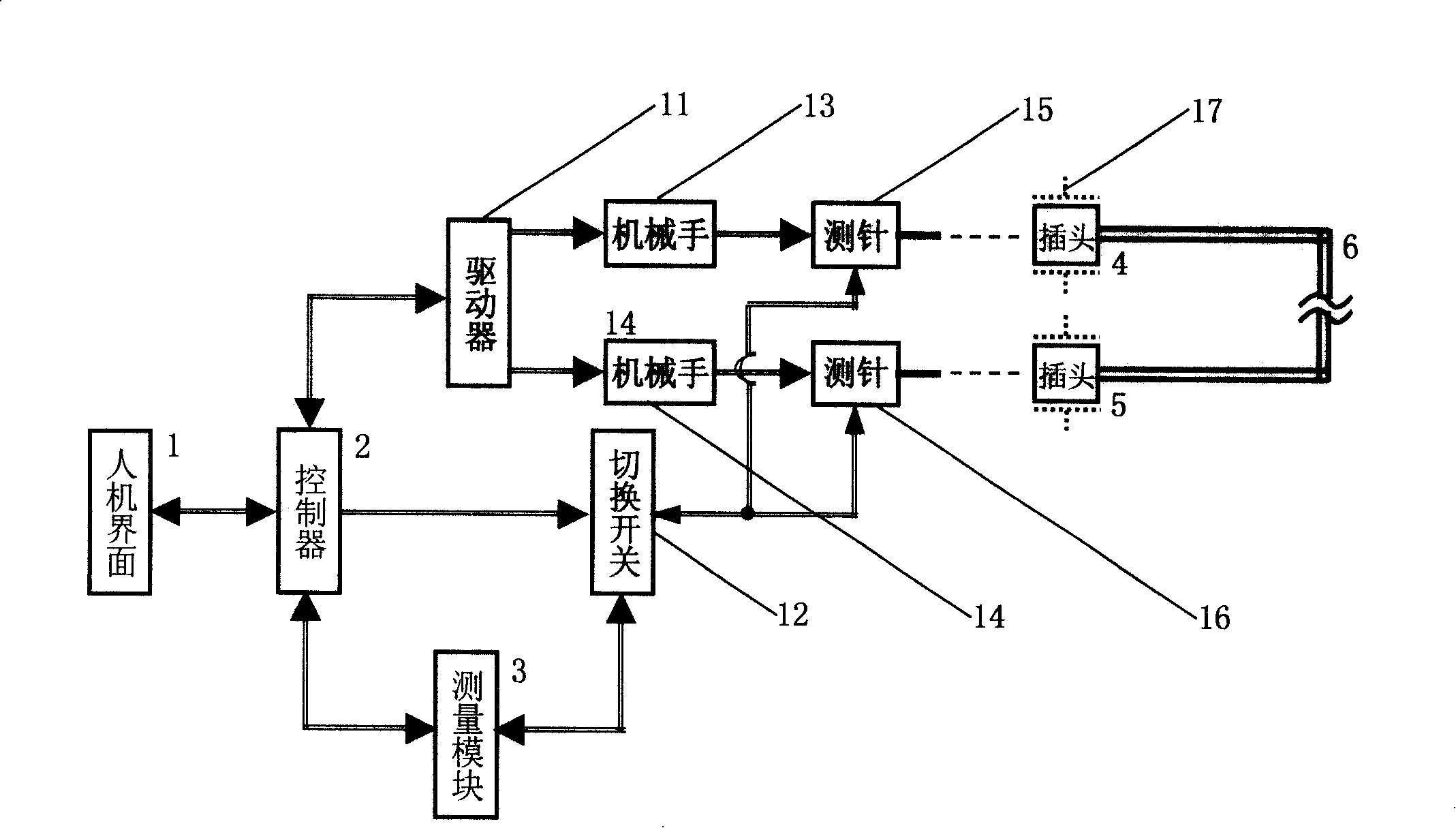

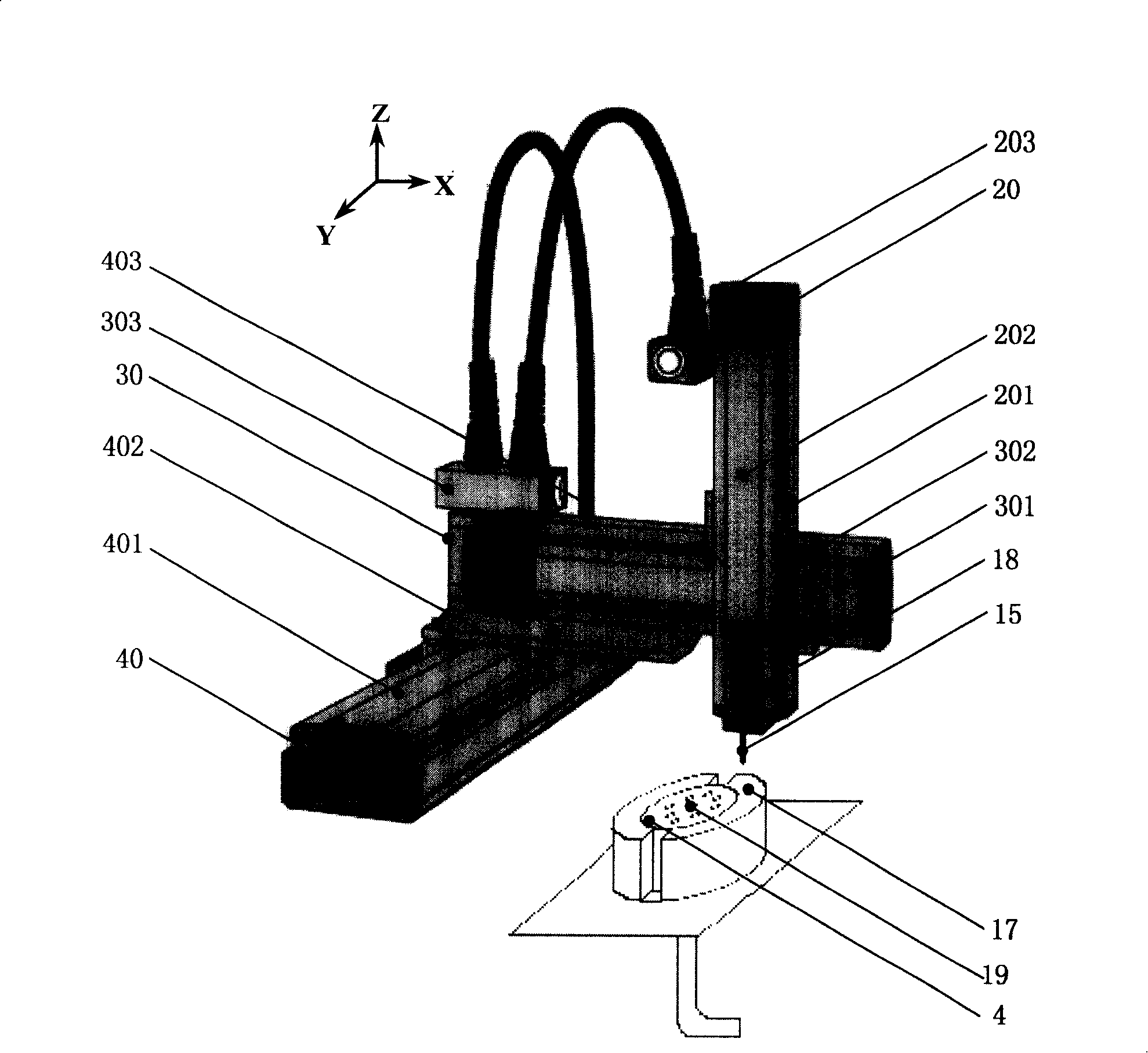

The present invention provides a device to detecting cable which comprises of controller, man-machine interface of I / O interface of controller and measuring module, also comprises of driver of I / O interface of controller, manipulator connected with driver, and measuring probe connected with manipulator. Controller and measuring module communicate with measuring probe by switch, and manipulator is 3-DOF manipulator. The problems that efficient of manual testing in background techniques is low, precision is bad, and cost is high because of testing system is used in a few testing are resolved. The present invention is used for detecting cable device or device connected with cable in process of research, produce, detection, usage and maintains, especially for detecting cable with different capability and specification in laboratory.

Owner:西安航力航电技术发展有限公司

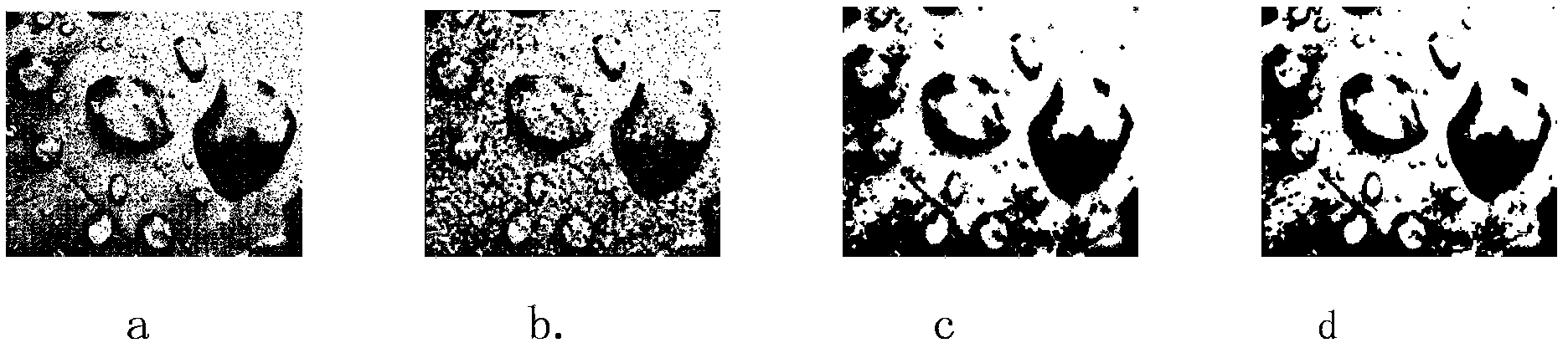

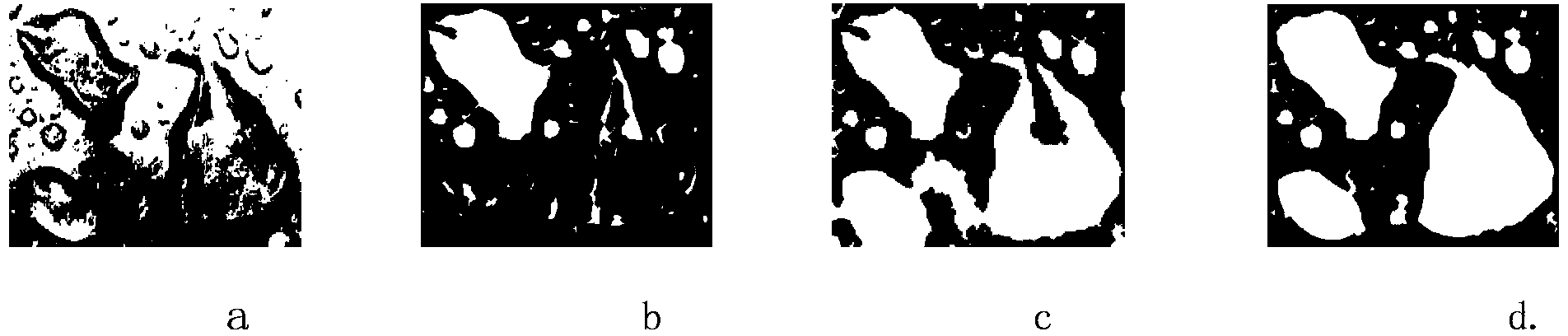

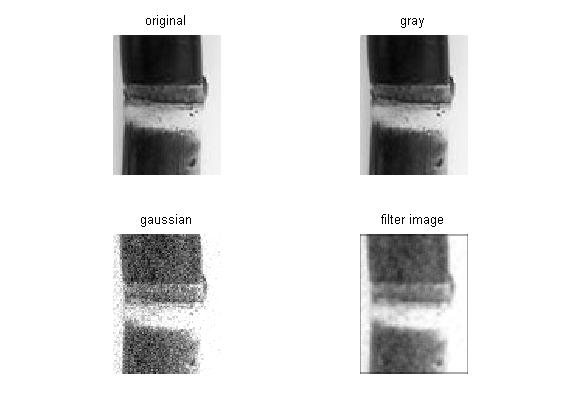

Method for automatically identifying hydrophobic grades of composite insulators

InactiveCN103440495AIncrease contrastLarge dynamic rangeImage enhancementCharacter and pattern recognitionComposite insulatorsSimulation

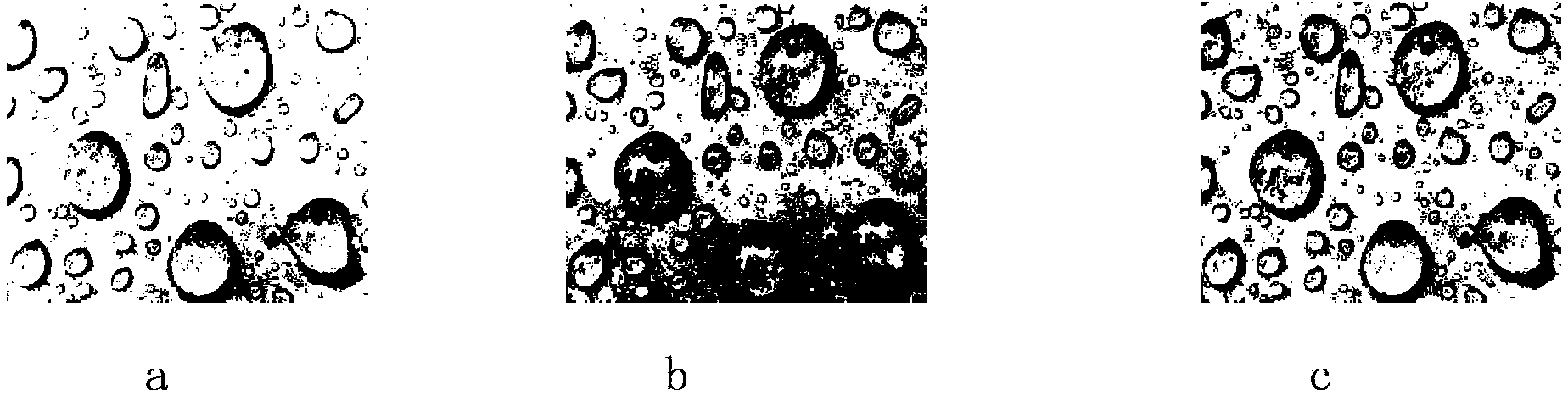

The invention belongs to the technical field of detection of performance of electric transmission line insulators, and discloses a method for automatically identifying hydrophobic grades of composite insulators. The method includes the steps of image enhancement, image filtering, image segmentation, image feature quantity extraction, neural network identification model establishment and the like. By analyzing hydrophobic images of the composite insulators, automatic identification of the hydrophobic grades of the composite insulators is achieved. Human factor influences are eliminated, the method is high in accuracy of the judgment result, easy to operate and capable of automatically identifying the hydrophobic grades of the insulators different in voltage grade, type, manufacturer, foul degree grade, operation age limit and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

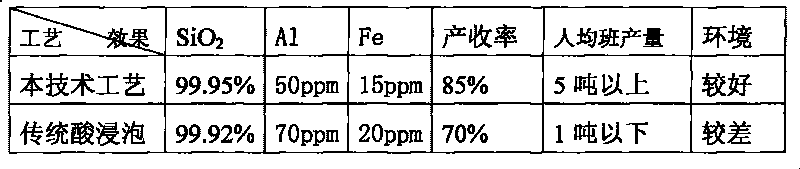

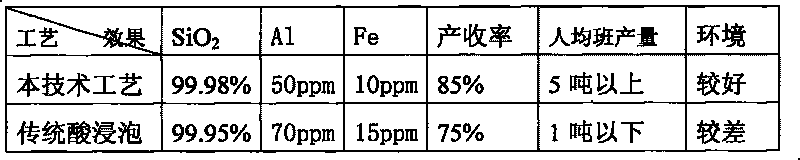

Autogenous grinding and impurity removing method of thermokalite in high-purity quartz sand production

InactiveCN101695680ARelieve stressReduce processing costsCleaning using liquidsWet separationResource utilizationGranularity

The invention relates to an autogenous grinding and impurity removing method of thermokalite in high-purity quartz sand production, which belongs to the technical field of quartz sand production. The method comprises the following steps: breaking quartz ores to reach lumpiness below 10 centimeters or granularity below 0.5 millimeter; uniformly inputting broken quartz lumps below 10 centimeters into an autogenous grinding machine (inputting quartz sand with the granularity being below 0.5 millimeter into a scrubbing machine), and meanwhile, adding an NaOH or Na2CO3 solution with a concentration of 1-2 percent according to a liquid-solid volume ratio of 0.5:1-2:1; at a temperature of 40-100 DEG C (90+ / -5 DEG C for the best), starting the autogenous grinding machine or the scrubbing machine to ensure that the quartz ores are mutually and autogenously ground so as to peel off impurities on the surfaces of the quartz ores; and washing the autogenously ground or scrubbed quartz by clear water or purified water until the pH value of the quartz reaches 7 after the washing. The invention can guarantee the product quality, obviously improve the resource utilization rate and the production efficiency, greatly reduce the pollutant discharge of the whole production process and reduce the cost of waste water treatment.

Owner:江苏阳山硅材料科技有限公司

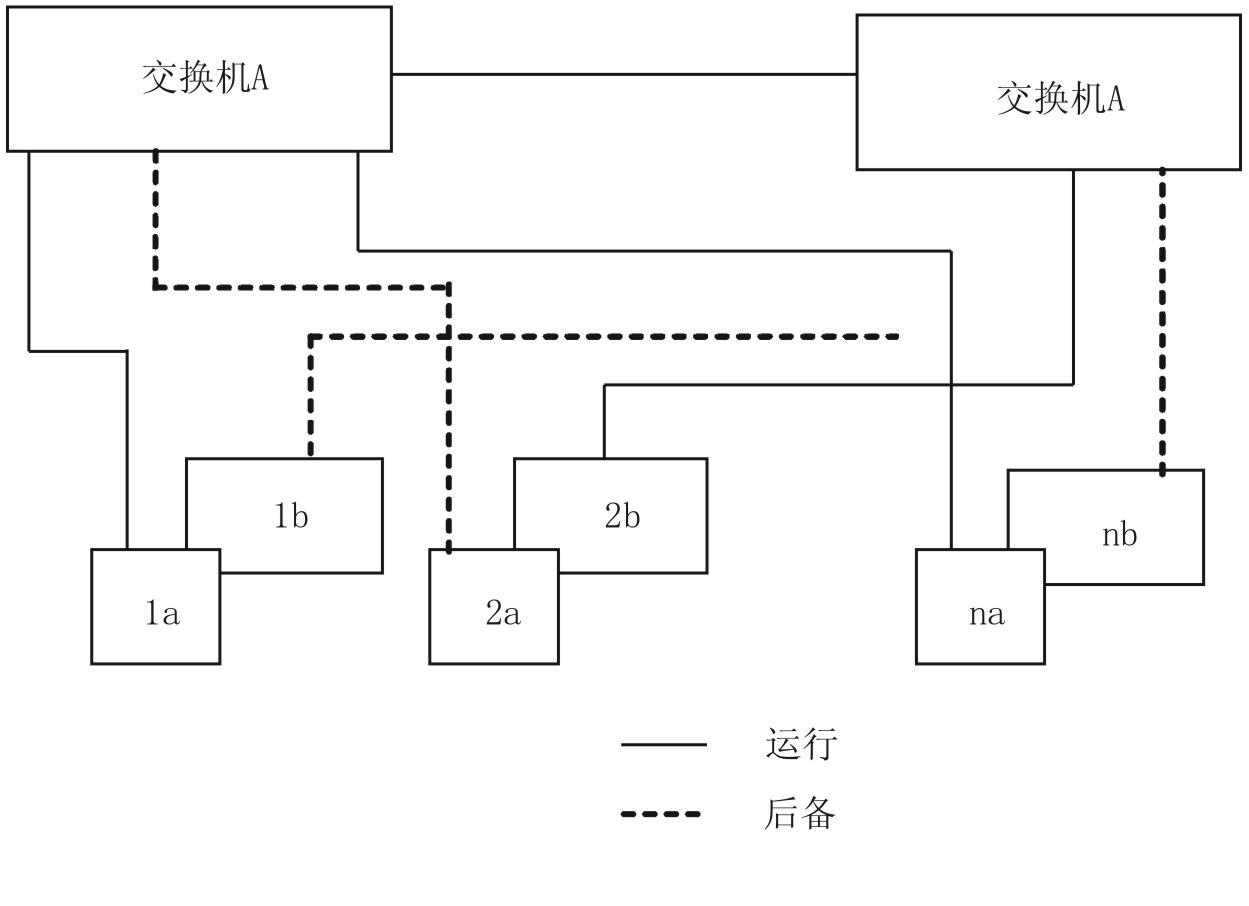

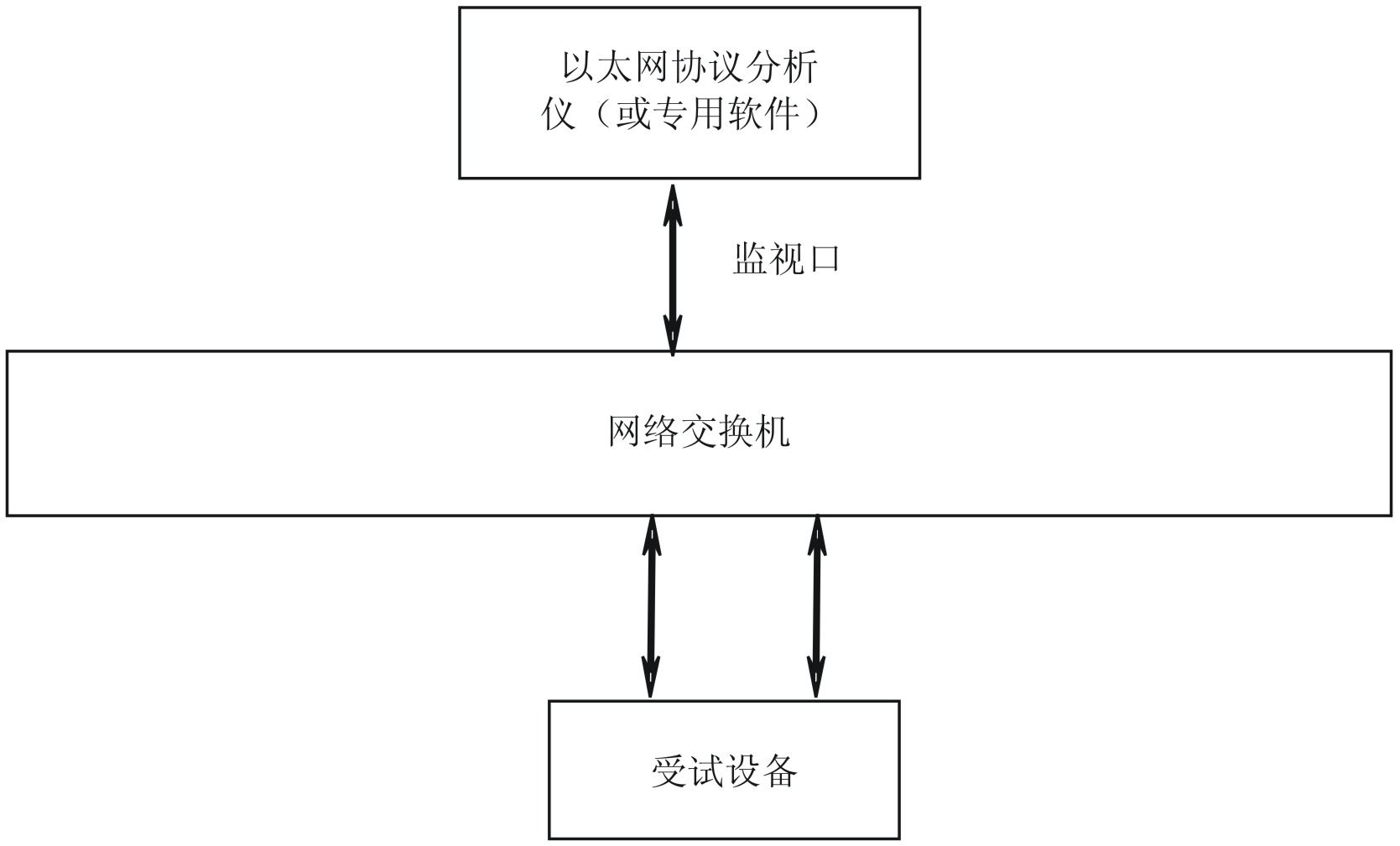

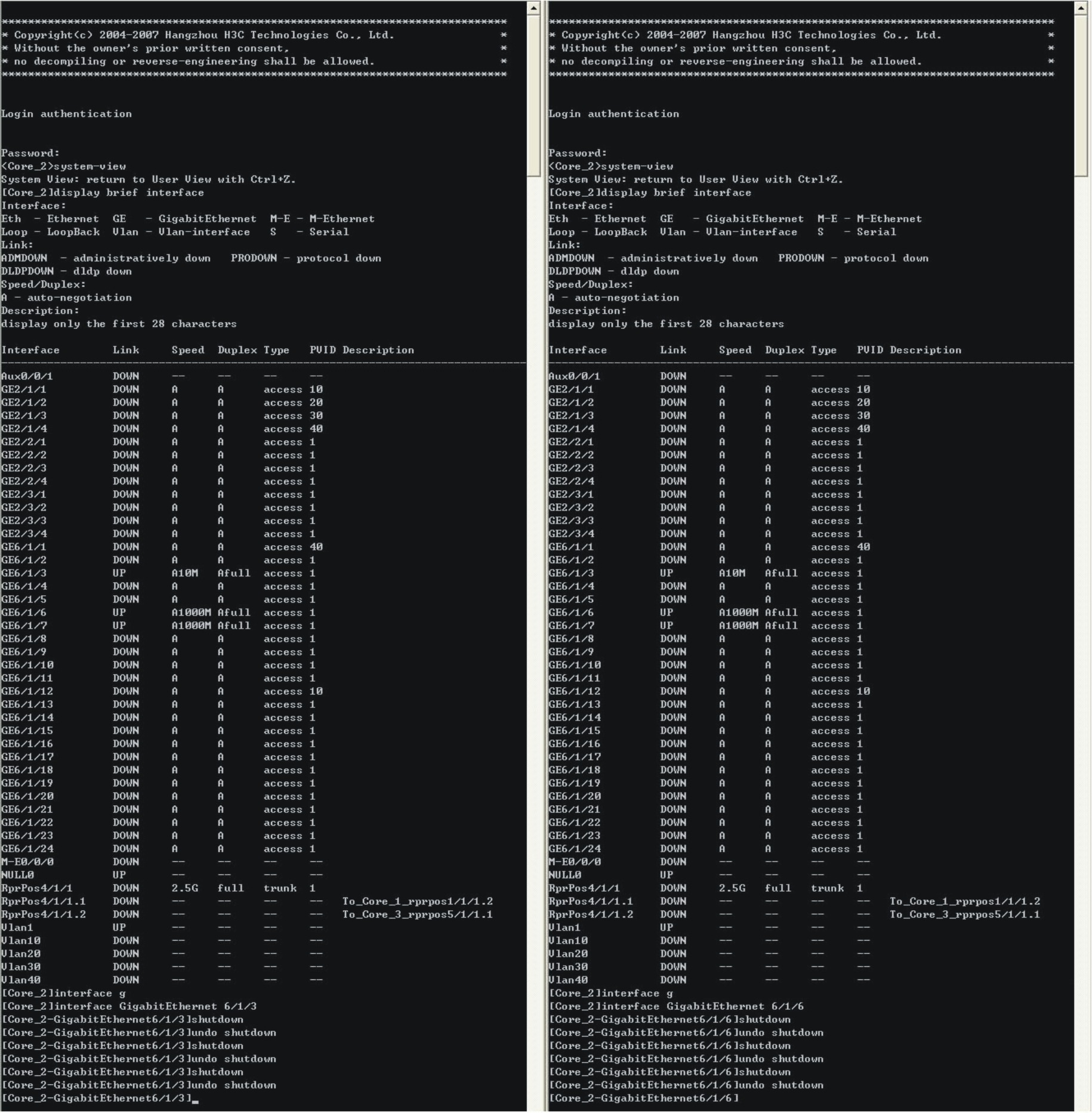

Dual-network-interface-card switching performance testing method for information integration system

ActiveCN102684946AReduce workloadReduce work intensityData switching networksAddress Resolution ProtocolNetwork connection

The invention discloses a dual-network-interface-card switching performance testing method for an information integration system. The method includes: firstly, connecting equipment under test and a network tester to a network switch of the information integration system; secondly, logging in the network switch, running the network tester for ARP (address resolution protocol) message transmission and message capturing, and alternately opening / closing corresponding ports of the switch; and finally, processing captured data message so that switching time is obtained. By the aid of the method, the defects due to manual plugging and unplugging of network connection cables traditionally are avoided, working efficiency is improved, equipment failure rate is decreased, test period is shortened, and manpower and material resources are reduced. Technically, the method is simple and clear in principle, process control is extremely simple, and work quality of dual-network-interface-card switching tests can be well guaranteed.

Owner:CHINA SHIP DEV & DESIGN CENT

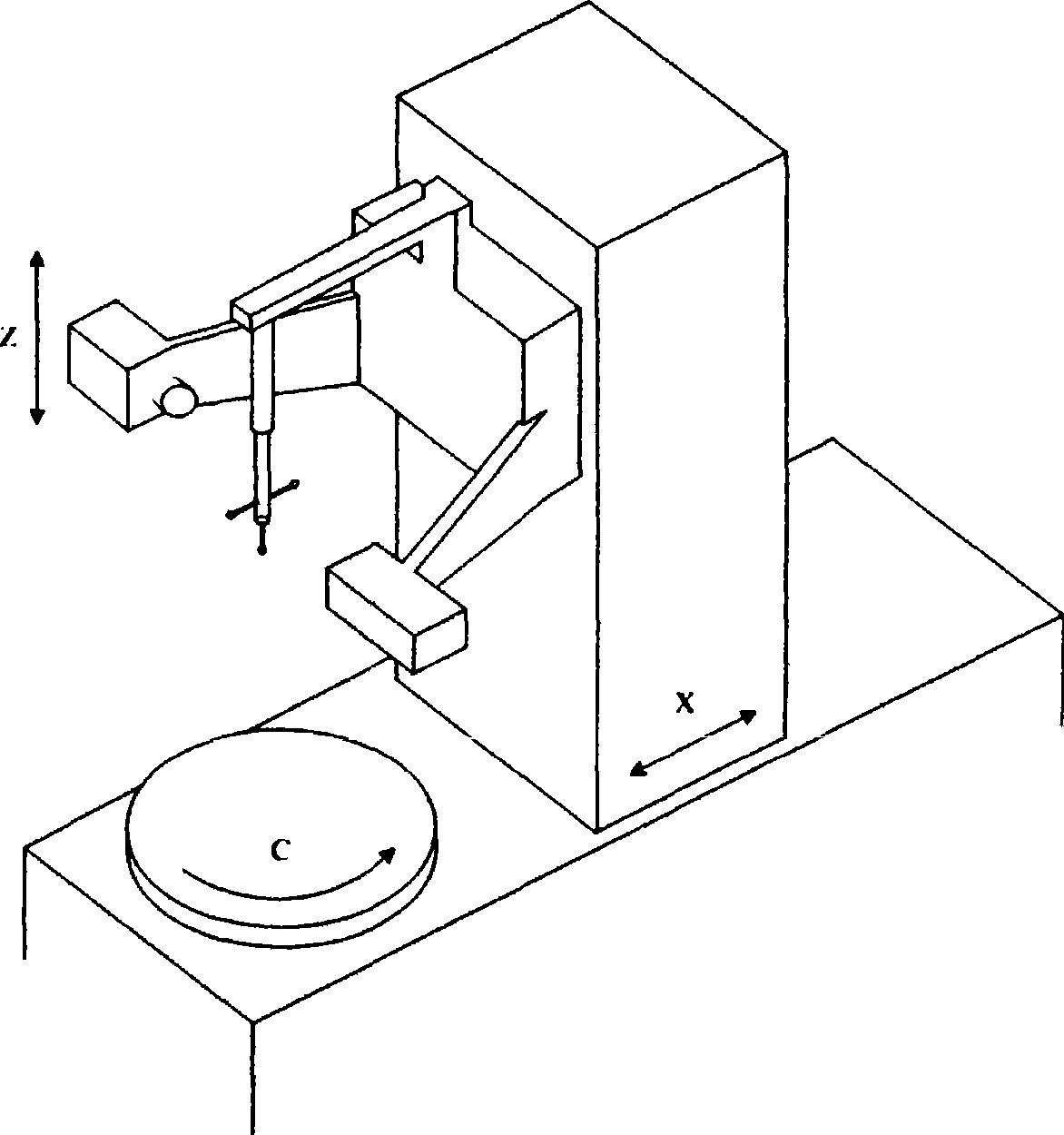

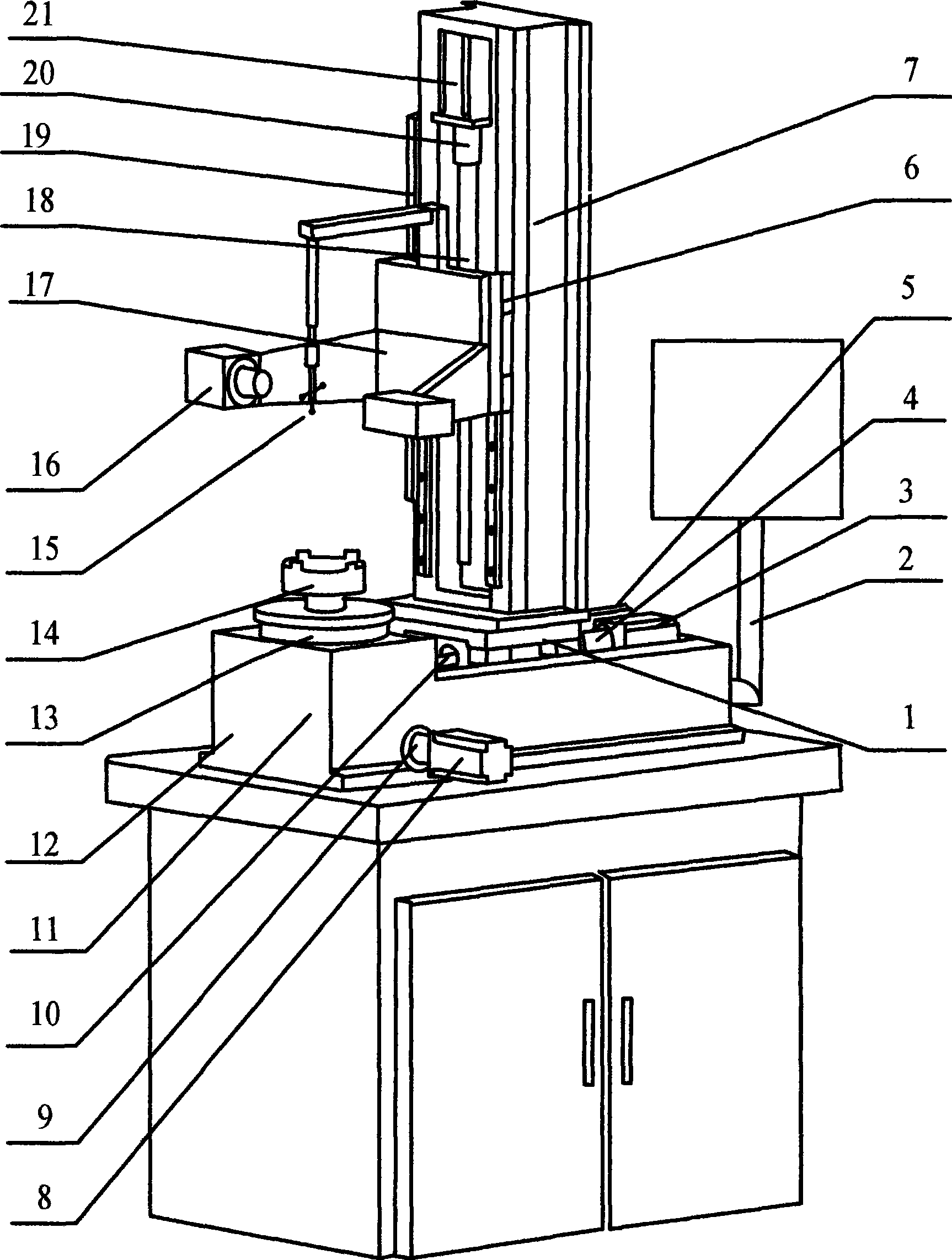

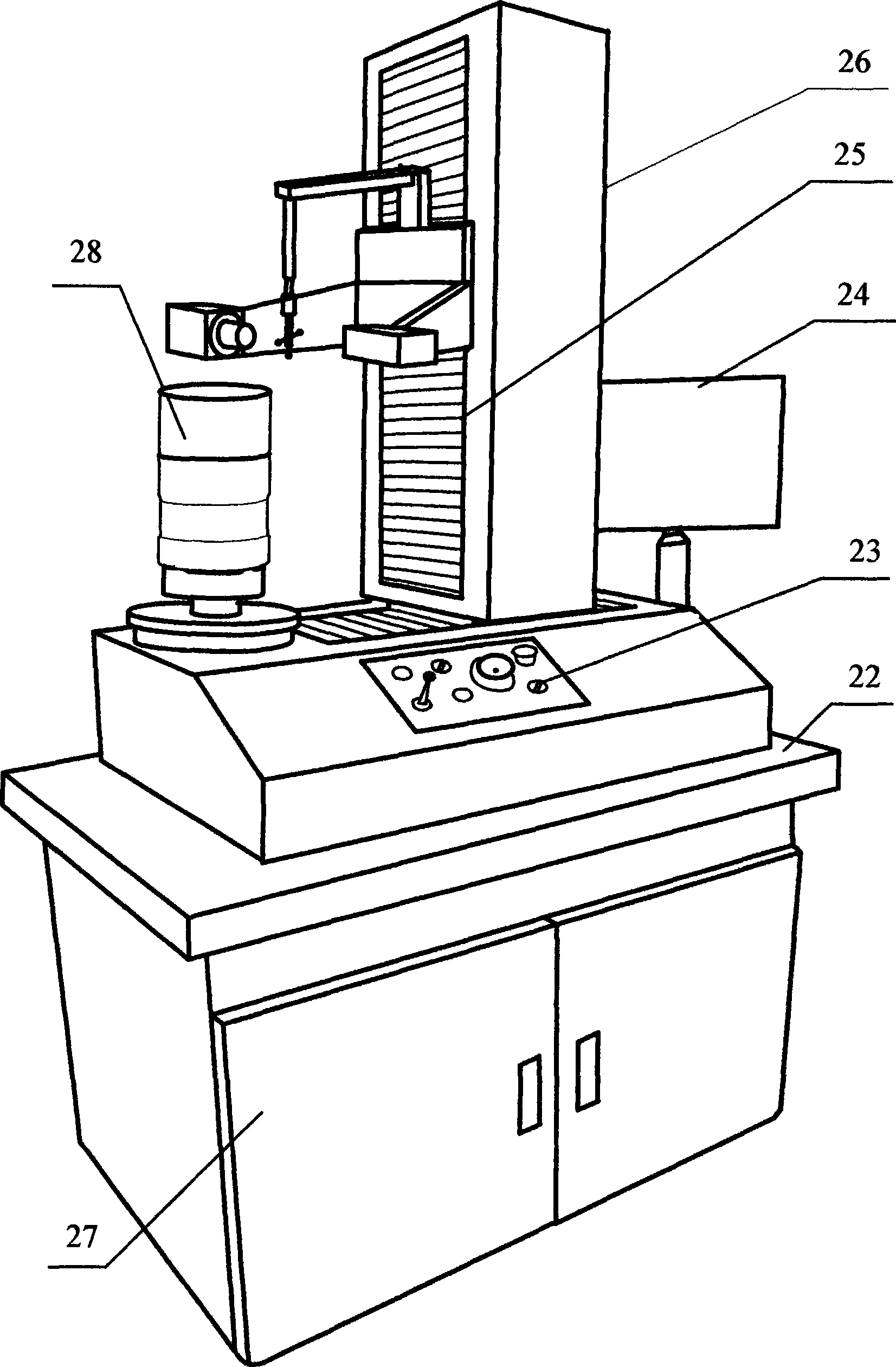

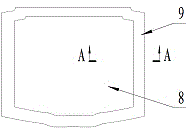

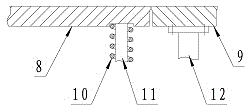

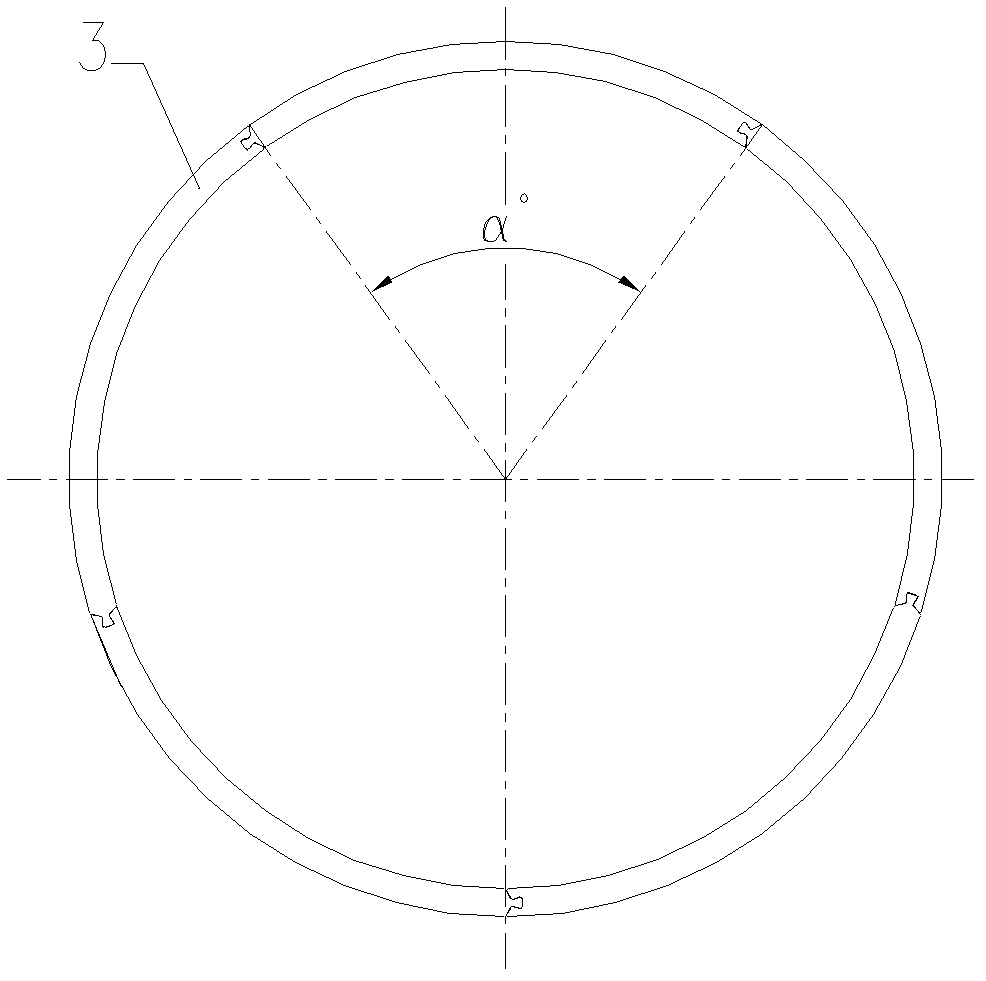

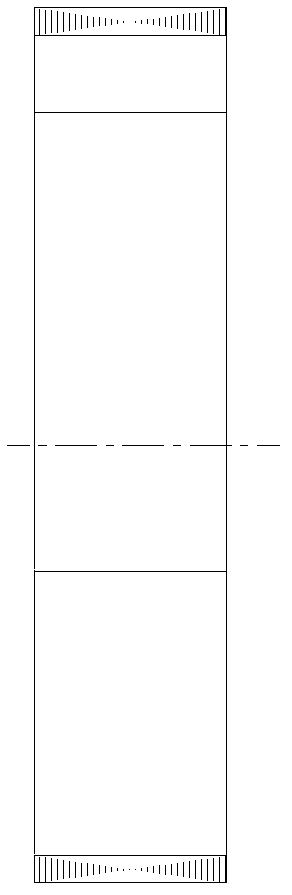

Cylinder liner intelligent detection device

InactiveCN101387495AImprove information processing abilityHigh degree of opennessUsing optical meansRotary stageDisplay device

The invention belongs to the technical field of instruments and meters, and particularly relates to a precise intelligent detecting device for a cylinder sleeve. The intelligent detecting device for the cylinder sleeve mainly comprises a base 12 in the X axis direction, a main shaft revolving stage 13 revolving in the C axis direction, an upright post 7 in the Z axis direction, an electric control cabinet 27, a marble platform 22, a measuring rack 17, a shell 26, a dust shield 25, an operation panel 23, a display 24 and a display supporting stem 2. The checking device has the characteristics of high precision, high efficiency and automatic detection, and is suitable for various cylinder sleeve products.

Owner:TIANJIN UNIV

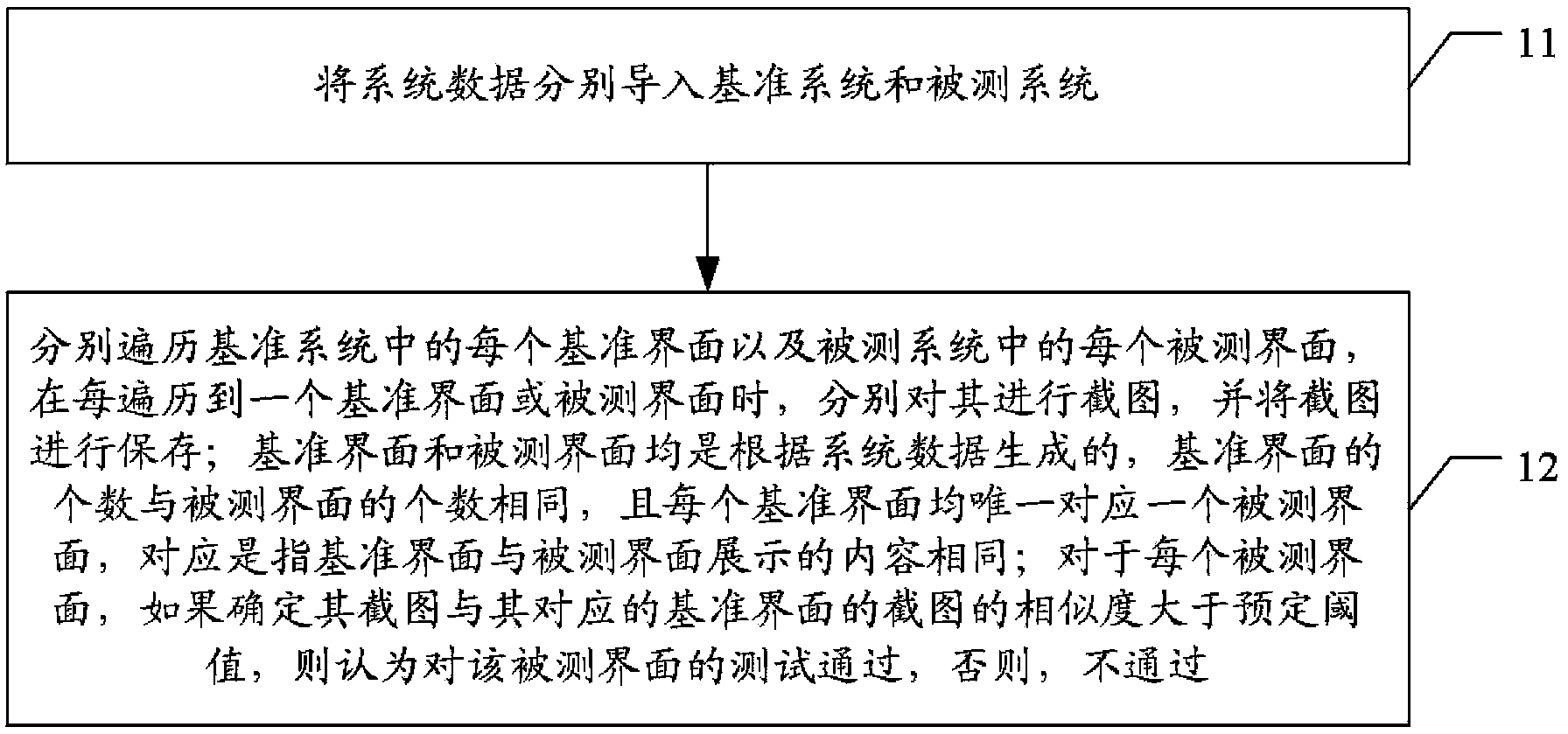

Interface testing method and device

InactiveCN103389937AImprove test efficiencyEliminate the influence of human factorsSoftware testing/debuggingComputer hardwareTest efficiency

The invention discloses an interface testing method and an interface testing device. The interface testing method comprises the following steps: introducing system data into a reference system and a tested system respectively; traversing each reference interface in the reference system and each tested interface in the tested system respectively, screen-shooting the interfaces respectively every time when an interface is traversed and saving screenshots, wherein both the reference interfaces and the tested interfaces are generated according to the system data, the number of the reference interfaces is the same as that of the tested interfaces, each reference interface uniquely corresponds to one tested interface, and the correspondence indicates that the contents displayed by the reference interface and the tested interface are the same; and for each tested interface, considering that the test of the tested interface is passed if the similarity of the screenshot of the interface and the screenshot of the corresponding reference interface is determined to be greater than a predetermined threshold value, and otherwise, considering that the test of the tested interface is not passed. By applying the scheme provided by the invention, the testing efficiency and the accuracy of a test result can be improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

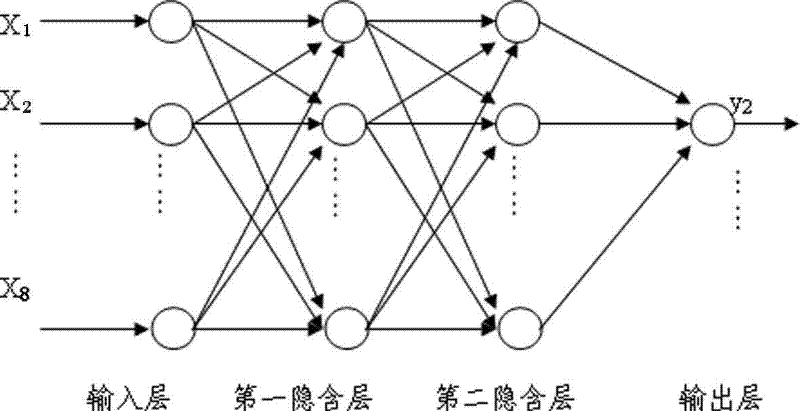

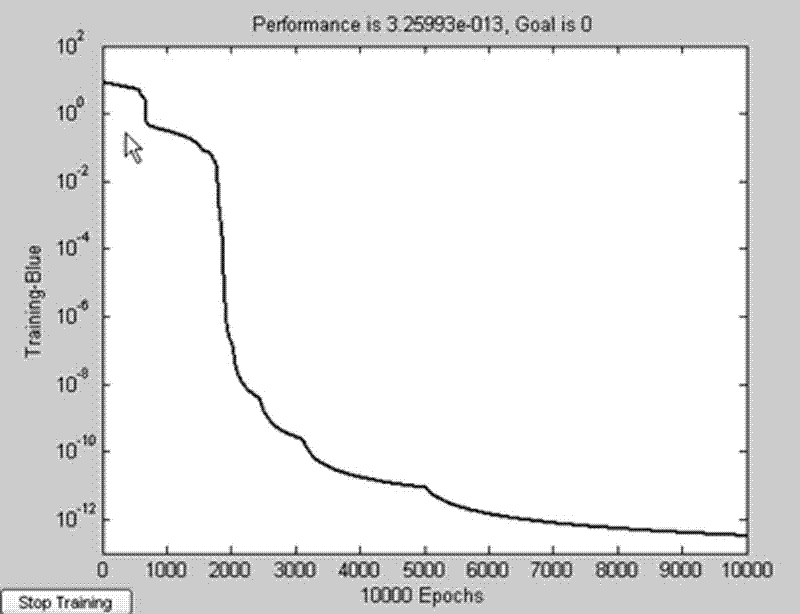

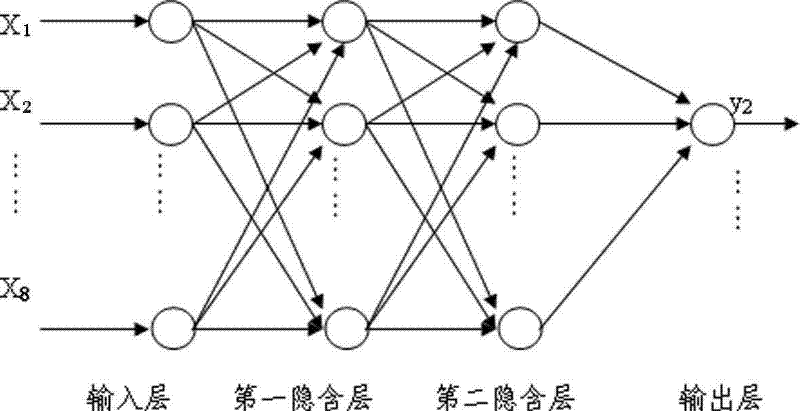

Mine shaft well engineering surrounding rock artificial intelligence stage division method

InactiveCN102496059AFit closelyMeet the practical application of engineeringBiological neural network modelsGround temperatureNerve network

The invention provides a mine shaft well engineering surrounding rocks artificial intelligence stage division method which comprises the following steps: (1) establishing a nerve network model, (2) training a sample set, (3) carrying out network training and (4) carrying out network simulation. The invention has the following advantages: a network system is simple in operation, influence of artificial factors can be eliminated, an interaction relation between factors can be automatically found, and with regards to a shaft well project which lacks a deep part stage division experience, the system can solve stability stage division of a rock well under complex conditions of high ground stress, high underground water pressure, high ground temperature and the like at a shaft well deep part and has a strong engineering application value.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

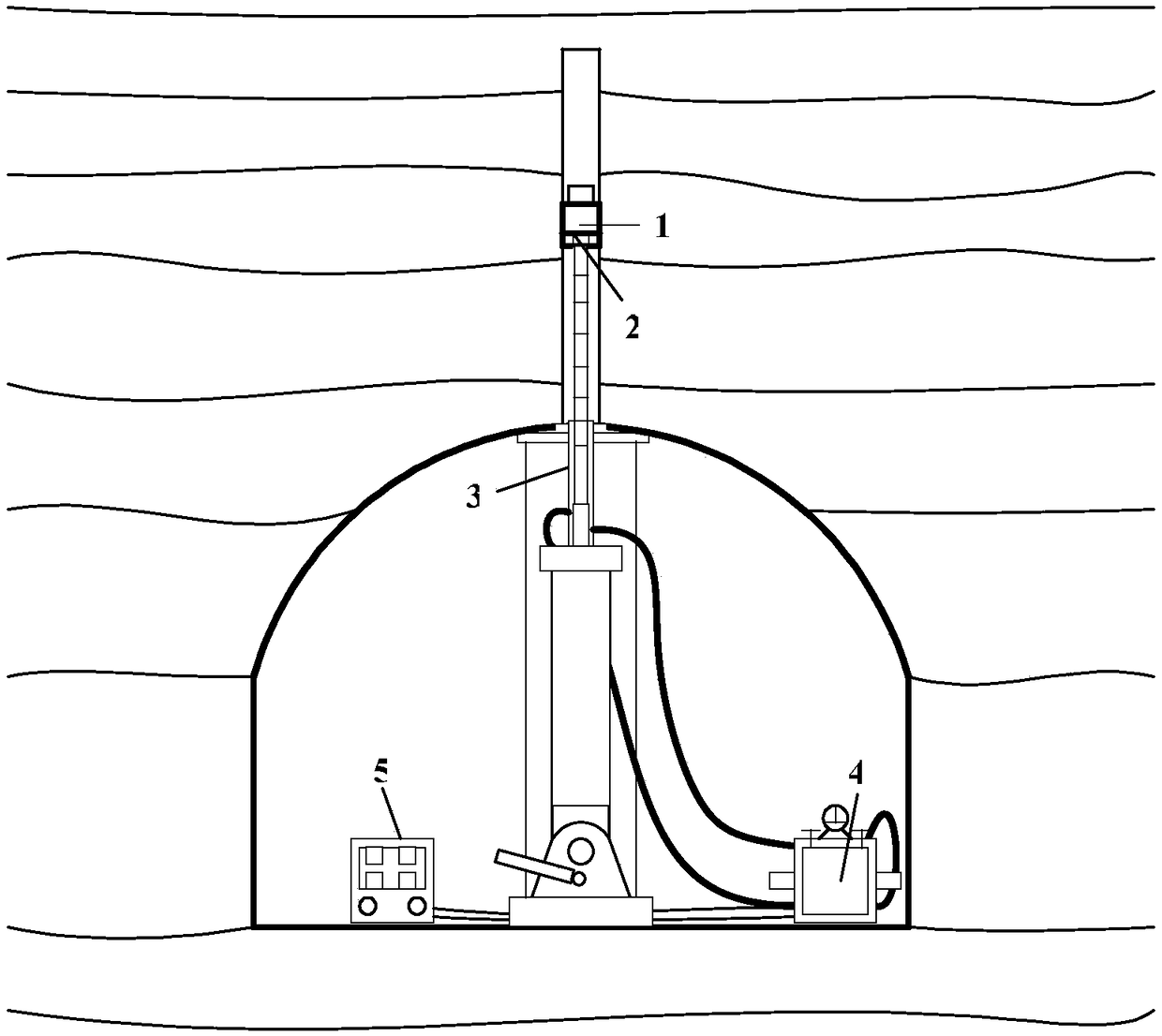

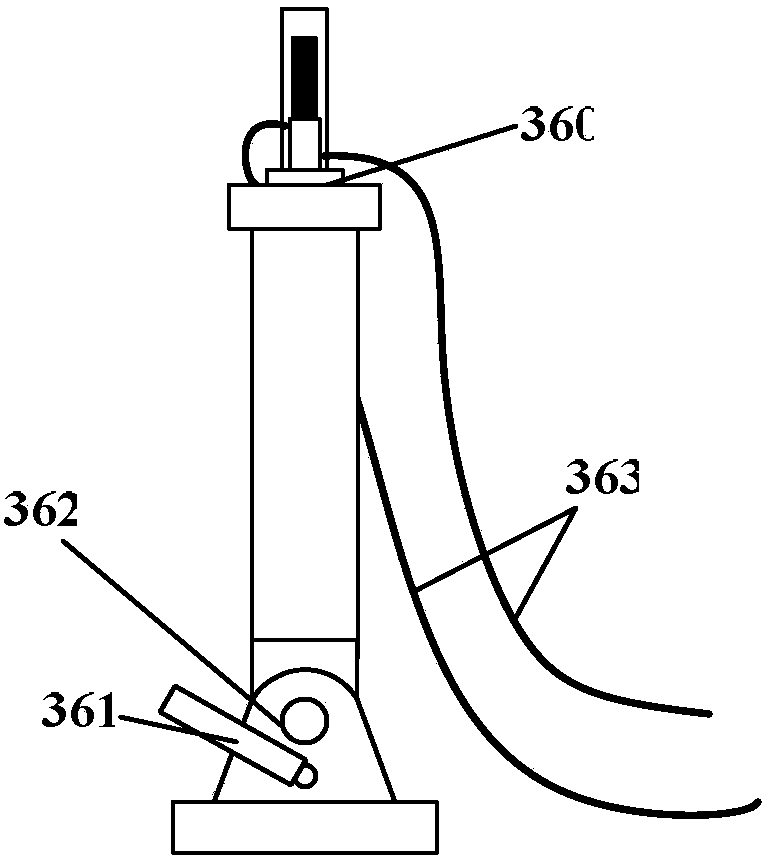

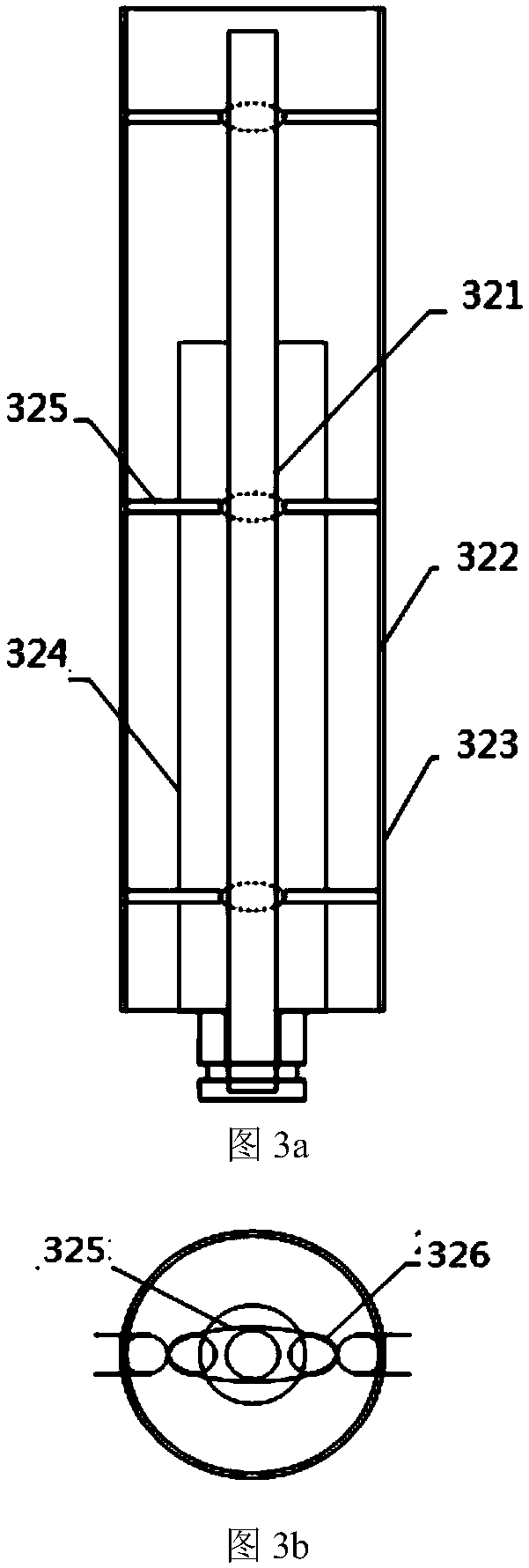

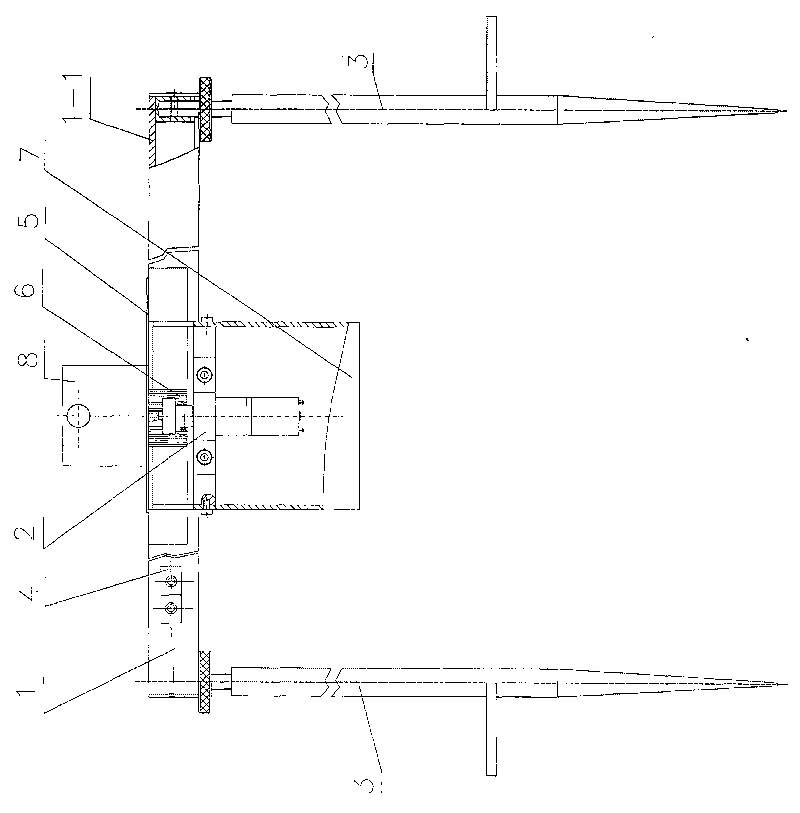

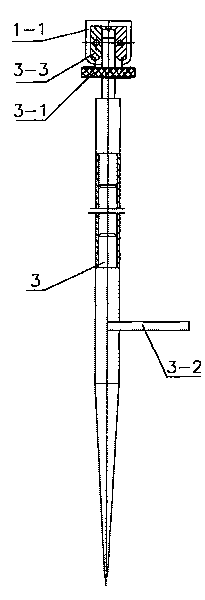

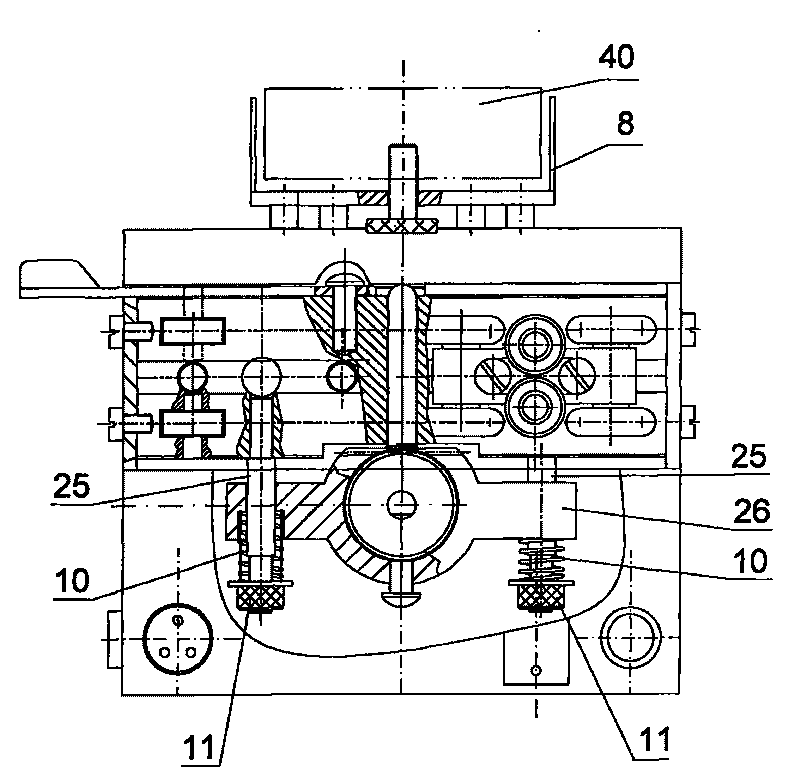

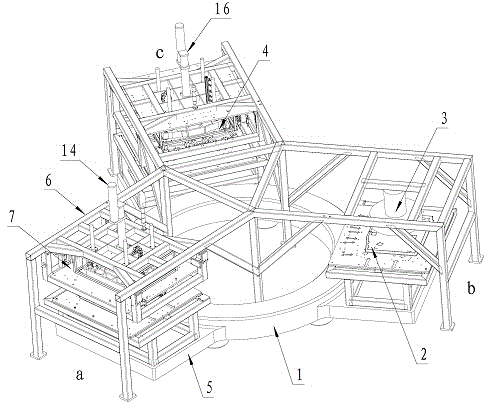

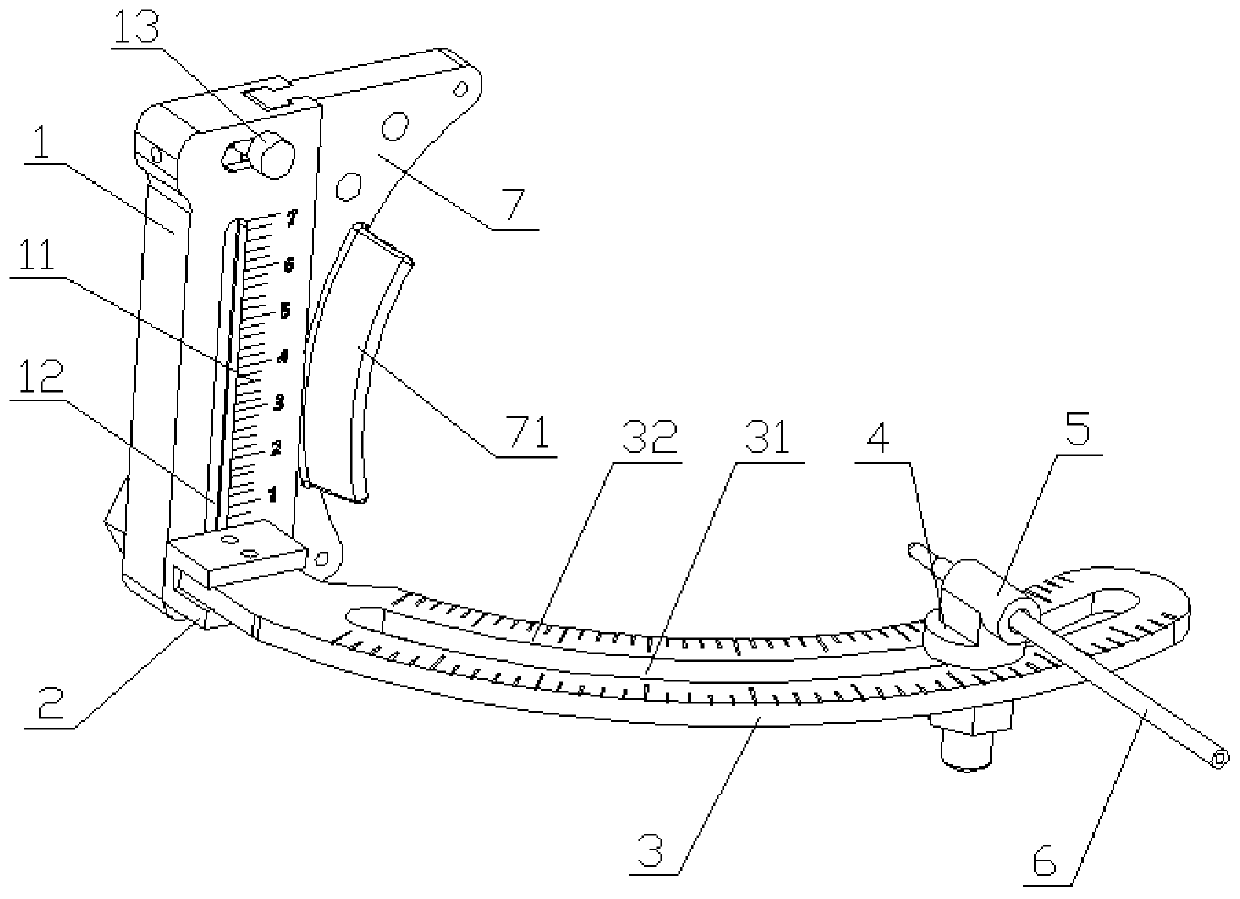

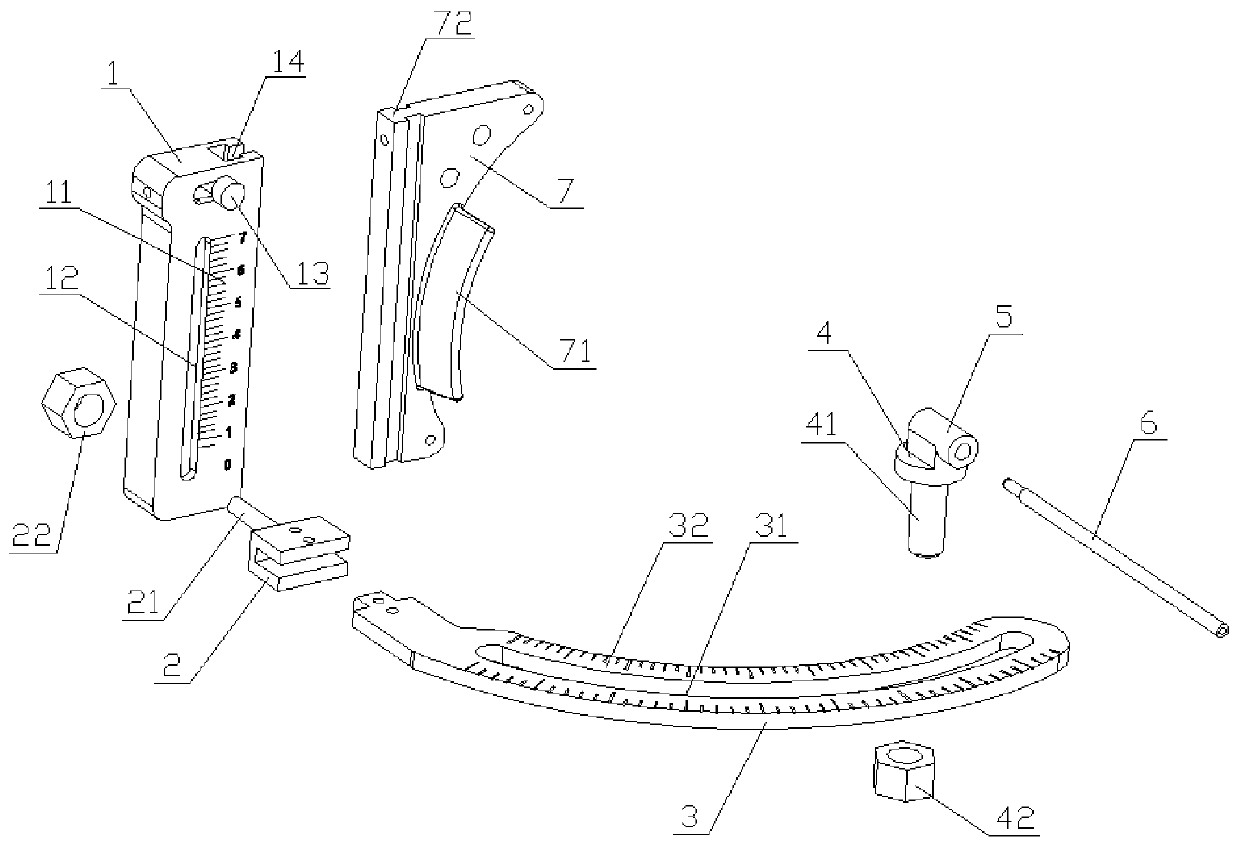

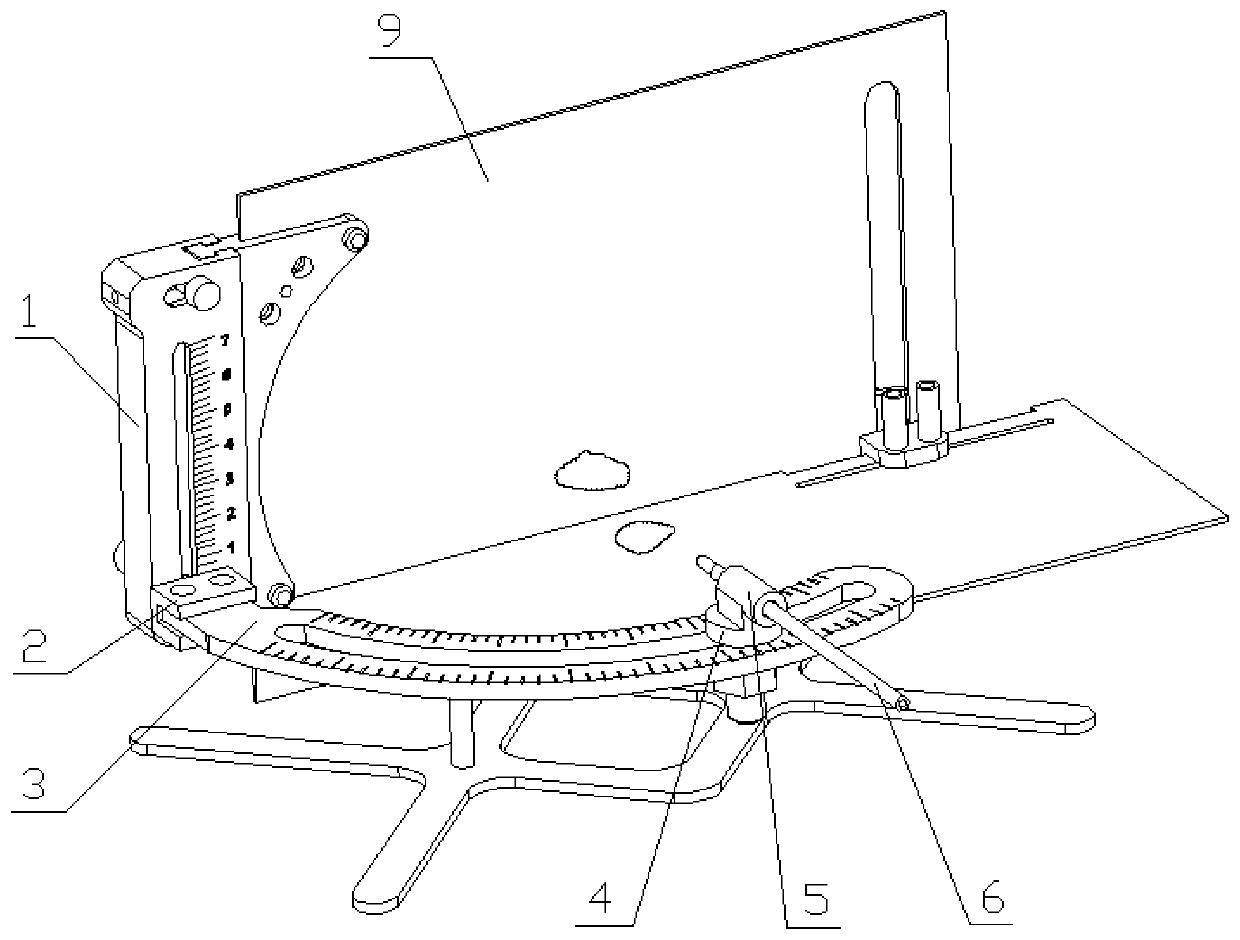

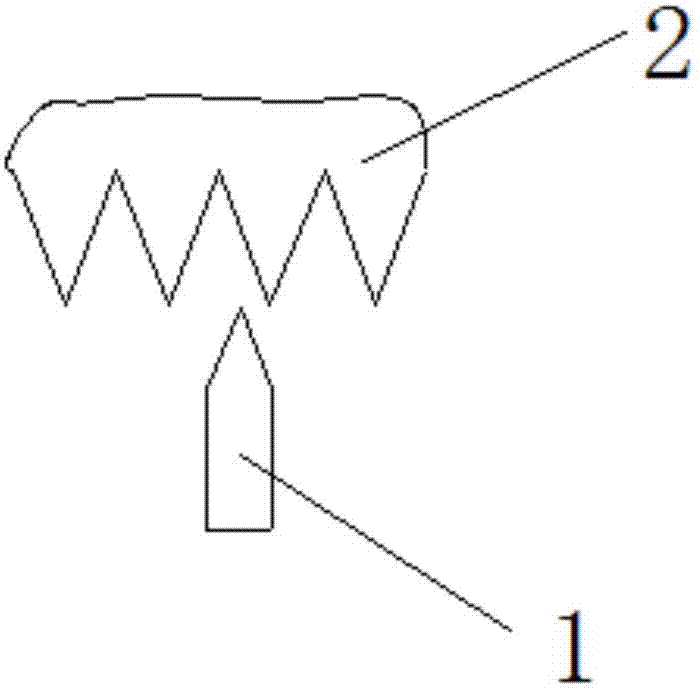

Drilling in-situ testing device for testing mechanical parameters of engineering rock mass and use method of drilling in-situ testing device

The invention discloses a drilling in-situ testing device for testing the mechanical parameters of an engineering rock mass and a use method of the drilling in-situ testing device. The device comprises a penetration sounding loading system, a multi-point testing rotational positioning system, a propelling support system, a hydraulic loading system and a control system. The penetration sounding loading system and the multi-point testing rotational positioning system are connected together through a bearing and can move along with a propelling lever of the propelling support system, and finally,the whole device is regulated and controlled through the hydraulic loading system and the control system. The device and the method drill and load and test the engineering rock mass in situ, the deformation and fracture characteristics of the rock mass having different lithological characters and different drilling depths and the load-displacement curve and data of a surrounding rock in the loading process are acquired, the relevant technical indexes and parameters are obtained through conversion, the device and the method are favorable for accurately simulating the numerical value and effectively designing the supporting scheme in the construction process, the supporting strength and the engineering strength are guaranteed, and the guarantee is provided for the safety construction of theengineering like rock and soil, water resources and hydropower, and mines.

Owner:SHANDONG UNIV OF SCI & TECH

Portable erosion gully measuring instrument

InactiveCN101718545AHigh measurement accuracyReduce workload and work intensityProfile tracingPhysicsLaser rangefinder

The invention relates to an instrument for measuring a soil erosion gully, which aims to provide a measuring instrument with the characteristics of high measuring accuracy, high measuring efficiency, automatic measurement of wireless transmitted data, convenient transport and lower cost. The invention has the technical scheme that the portable erosion gully measuring instrument comprises a control circuit, a battery, a stand, a trolley and a laser distance measuring instrument, wherein the stand is arranged on the ground of the erosion gully; the trolley is positioned on the stand and can move along the stand; the laser distance measuring instrument is installed on a wheel stand of the trolley, vertically measures the height of the ground soil, and transmits the measured data to terminal equipment in a wireless transmission mode; the stand comprises a horizontally suspended beam and supporting feet for supporting both ends of the beam; the trolley comprises a bearing structure and an actuating mechanism, wherein the bearing structure is used for hanging the wheel stand of the trolley, and the actuating mechanism acts with the stand to generate driving force to move the trolley; two supporting edges used as guide rails are produced on the beam; and the bearing structure comprises a plurality of pairs of rollers which are supported by the supporting edges and are positioned in an inner cavity of the beam.

Owner:ZHEJIANG INST OF HYDRAULICS & ESTUARY +1

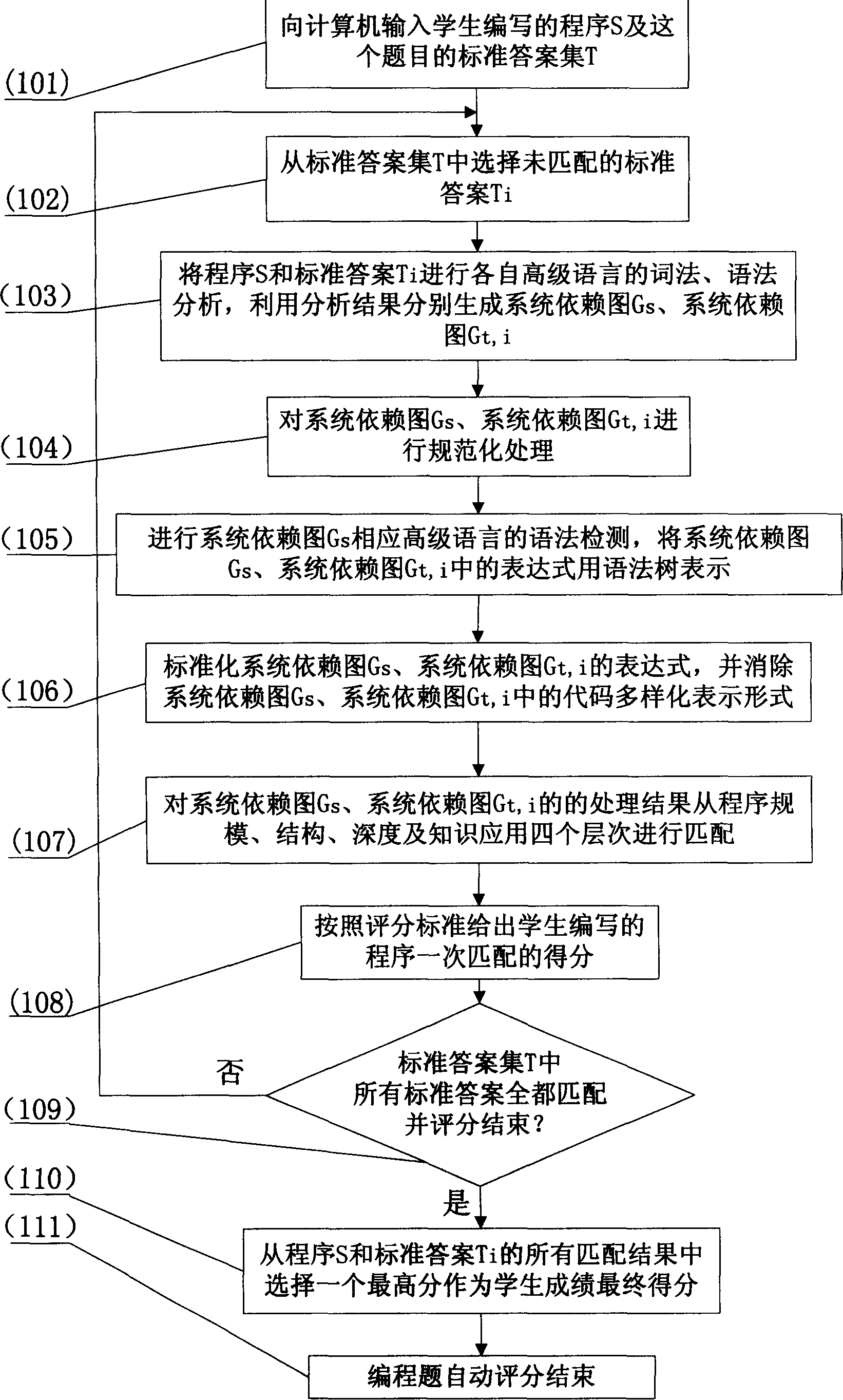

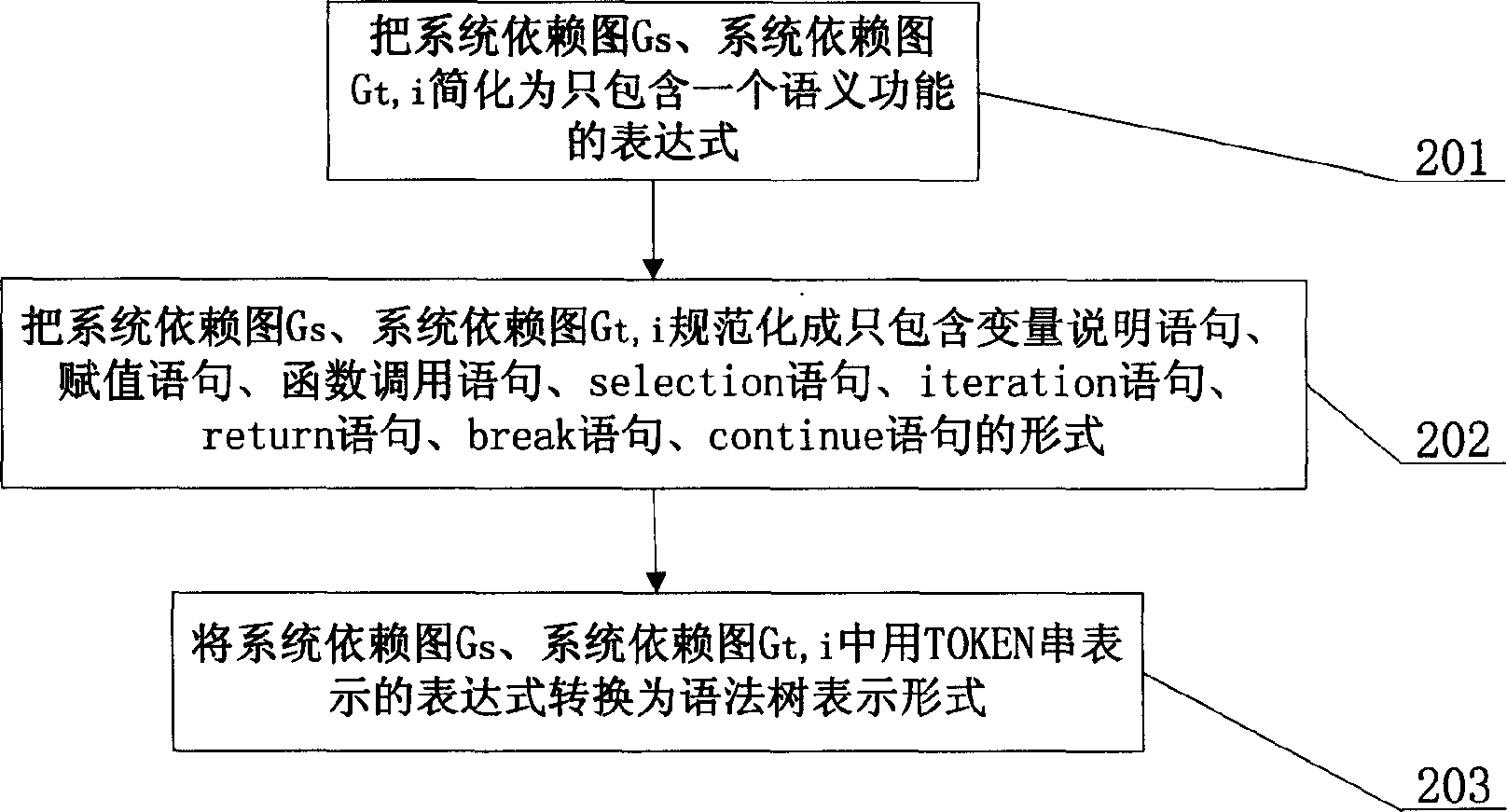

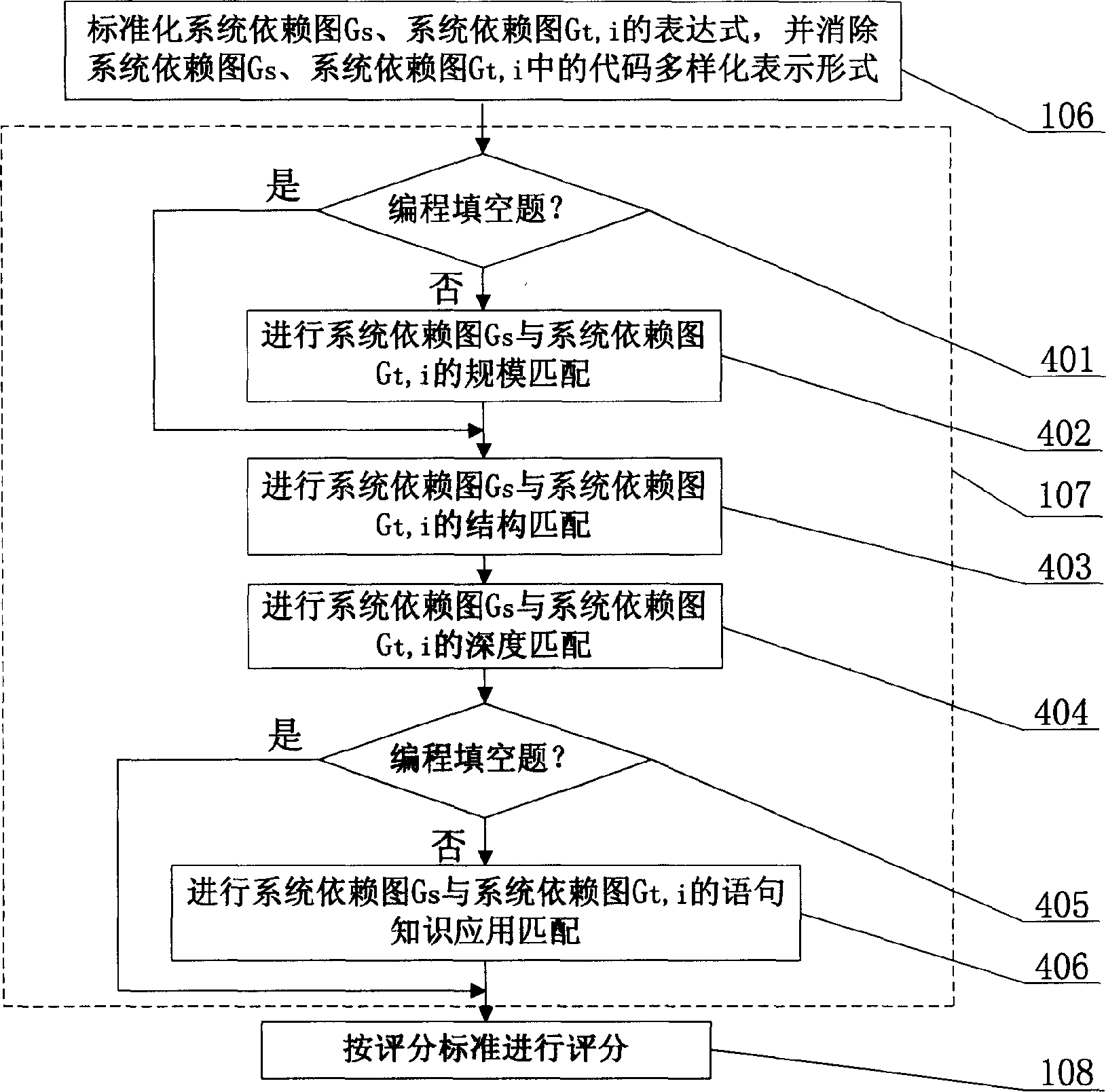

Method of automatic grading program design language editor topic

InactiveCN1598809AEliminate diverse representationsOvercome the limitations of grammatical errorsSpecial data processing applicationsTheoretical computer scienceProgram Design Language

The invention discloses an automatic grading method used in C, Pascal, Fortran and Basic programming subjects. Its steps include: input program (S) designed by students and standard key; respectively analyze grammar and accidence of program (S) and standard key (Ti) and generate system dependency graph (Gs), (Gt.i); Normalize the two graphs; represent the two graphs in syntax tree to eliminate code diversification; match process result in scale, construction, depth and knowledge application four layers; give once matching score (108) and select the highest score from all matching results of (S) and (Ti) as the final score (110). With a full consideration of kinds of grading factors, the invention has a higher precision than manual grading.

Owner:HARBIN INST OF TECH

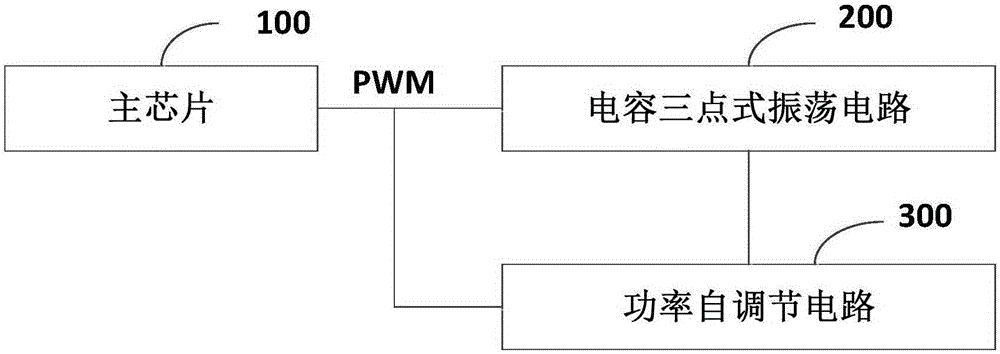

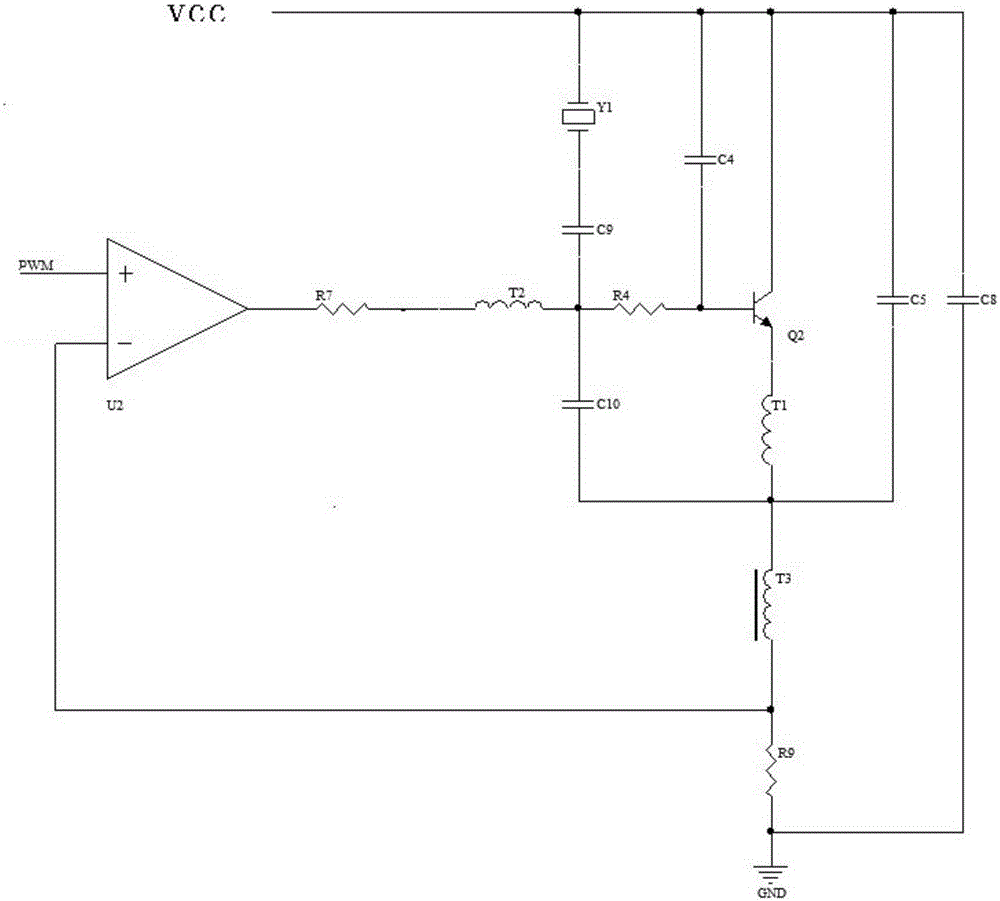

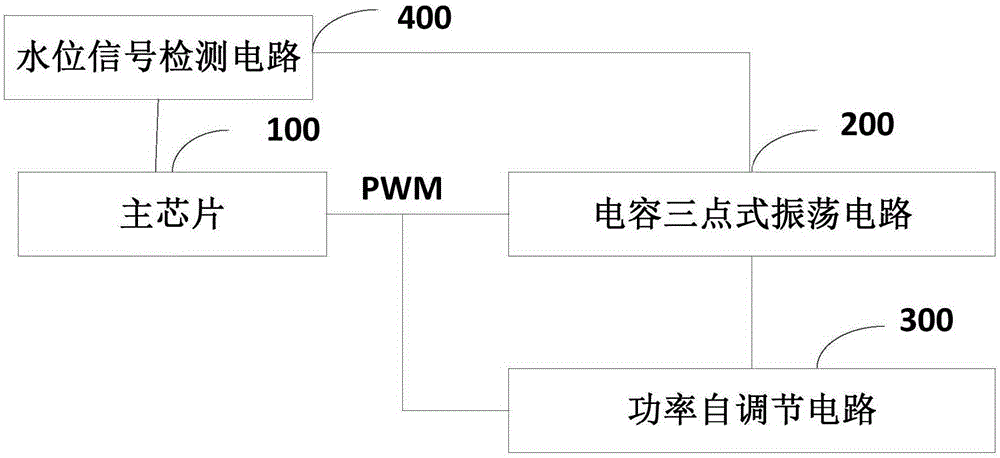

Ultrasonic atomizer

ActiveCN105195373AEnsure consistencyEliminate the influence of human factorsLiquid spraying apparatusCapacitanceProduction line

The invention discloses an ultrasonic atomizer which comprises a main chip, a three-point capacitance oscillating circuit and a power self-regulation circuit, wherein the main chip is used for providing a spray volume control input signal for the three-point capacitance oscillating circuit; the three-point capacitance oscillating circuit generates ultrasonic waves according to the spray volume control input signal, so as to drive an atomization pieces to atomize water; the power self-regulation circuit is used for detecting a direct current signal of an transistor emitter in the three-point capacitance oscillating circuit, and adopting the direct current signal to regulate the spray volume control input signal. The power self-regulation circuit is adopted for ensure power consistency for the ultrasonic atomizer, and the production procedure that a production line operator regulates power by changing the adjustable resistance value is removed, so that the influence of human factors is eliminated, the production efficiency is improved, and the controllability is high.

Owner:GREE ELECTRIC APPLIANCES INC

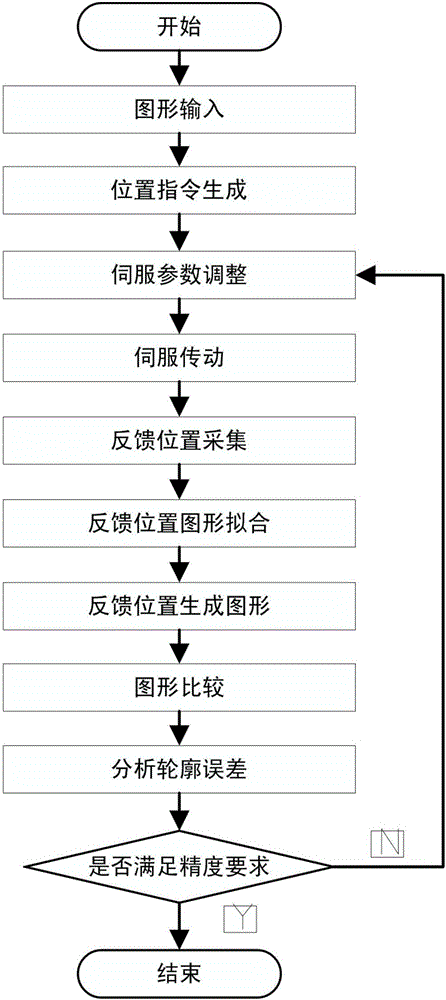

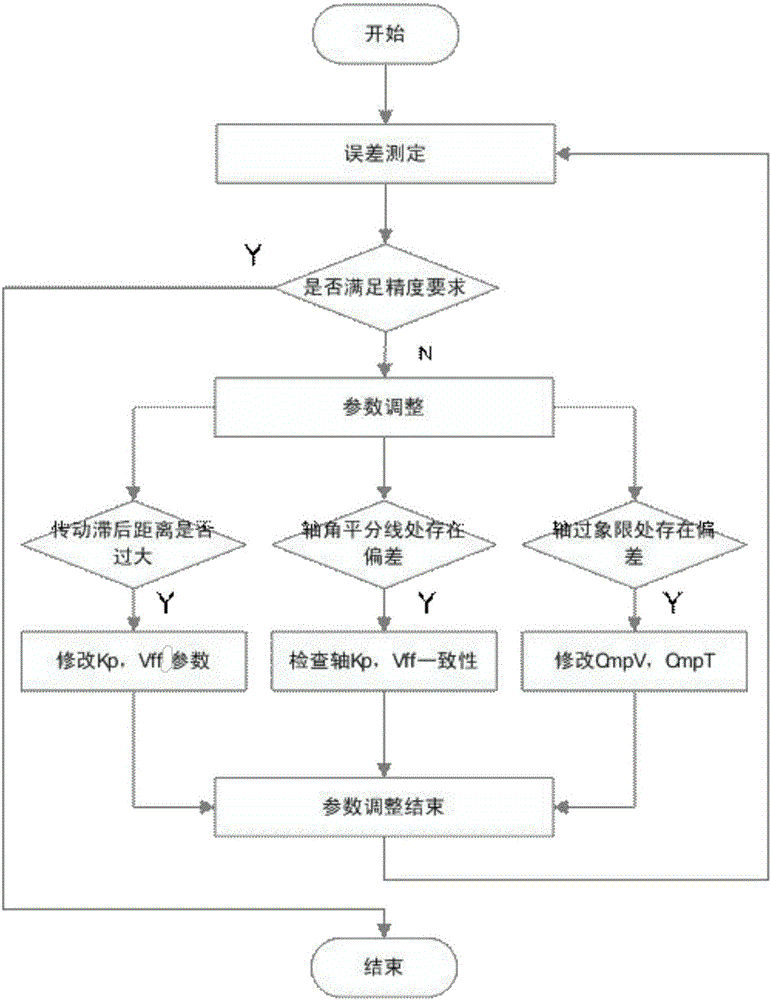

Servo parameter self-tuning method based on error measurement for numerical control system

ActiveCN106094733AImprove accuracyImprove reliabilityProgramme controlComputer controlSelf-tuningLaser cutting

The invention relates to the field of laser cutting numerical control and specially relates to a servo parameter self-tuning method based on error measurement for a numerical control system. The method comprises the following steps: 1) graph input; 2) position instruction sequence generation; 3) servo parameter adjustment; 4) servo driving; 5) feedback position acquisition; 6) feedback position graph fitting; 7) feedback position graph generation; 8) graph comparison; and 9) error analysis: the numerical control system analyzes contour error between a graph formed by fitted curves and an input graph, determines the position of the contour error and the value of the contour error, and if the value of the contour error accords with preset error parameters, terminates the operation, or otherwise, returns to the step 3) to reset the servo parameters until the contour error accords with the preset error parameters. Compared with the prior art, the method allows servo driving error to be seen clearly; and self-tuning can also eliminate influence of human factors, thereby improving accuracy and reliability of servo parameter setting.

Owner:上海柏楚电子科技股份有限公司

Automobile spare tire cover plate binding device

ActiveCN104385766AGuaranteed positioning accuracyEliminate the influence of human factorsLamination ancillary operationsLaminationPunchingSpare tire

The invention provides an automobile spare tire cover plate binding device. The automobile spare tire cover plate binding device comprises an upper die mounting frame, a lower die rotary table and three lower forming dies, wherein the lower side rotary table is horizontally mounted on an equipment foundation, the three lower forming dies are fixed on the edge of the lower die rotary table and uniformly distributed around an axis of the lower die rotary table, the upper die mounting frame is fixed on the equipment foundation and arranged above the lower die rotary table, three work stations uniformly distributed around the axis of the lower die rotary table are arranged on the upper die mounting frame, the work stations are a fabric punching work station, a glue spraying work station and a binding work station, the three work stations are respectively provided with a fabric cropping upper die, a glue spray device and a binding upper die which are corresponding to the lower forming dies. A fabric is transmitted among the three work stations by using the lower die rotary table, the fabric is automatically located in the process of punching, glue-spraying and composite binding, the influence caused by human factors is totally eliminated. The device not only can guarantee the locating precision of a workpiece and the consistency of a product, and the production efficiency is greatly improved.

Owner:GREAT WALL MOTOR CO LTD

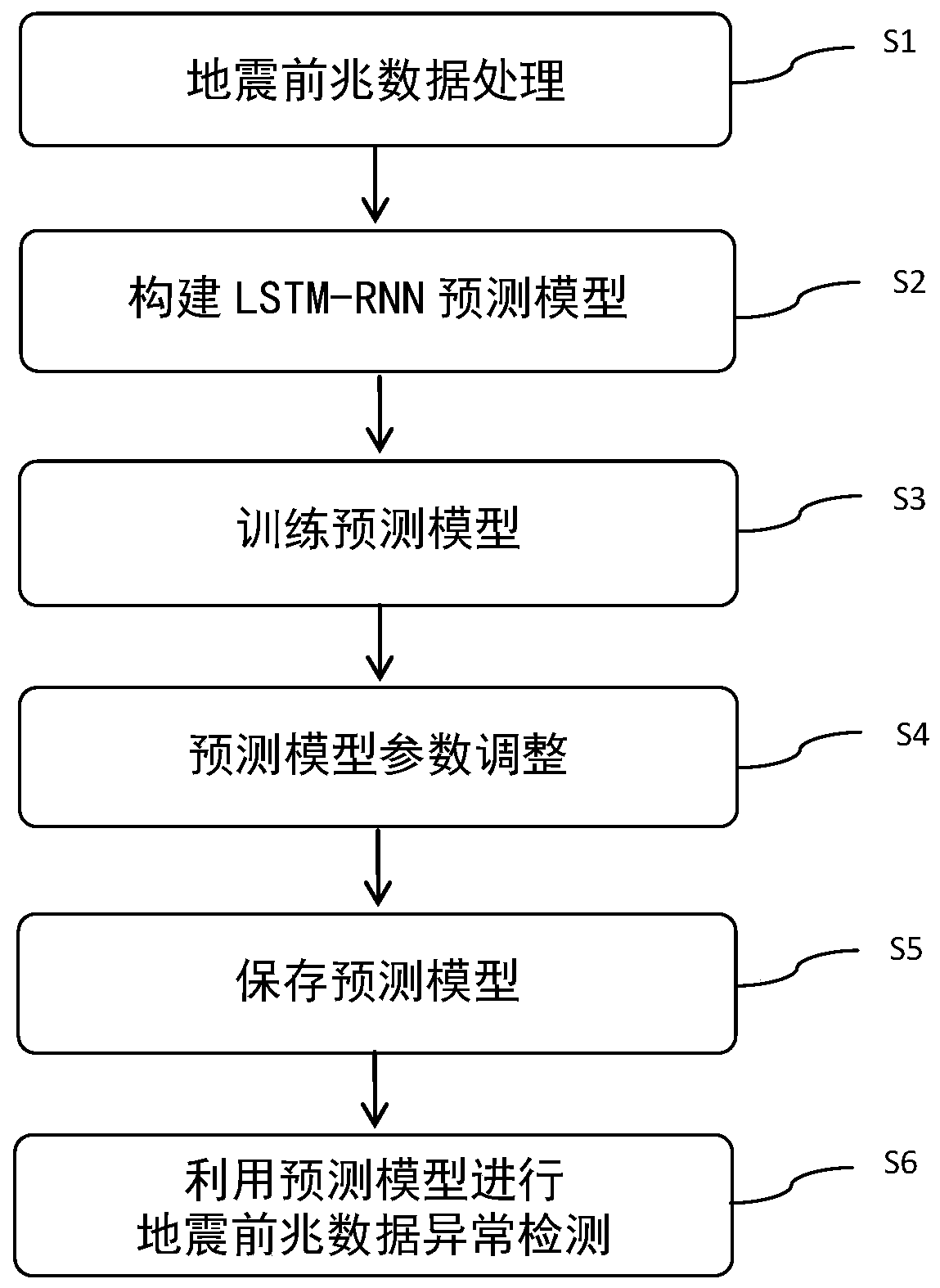

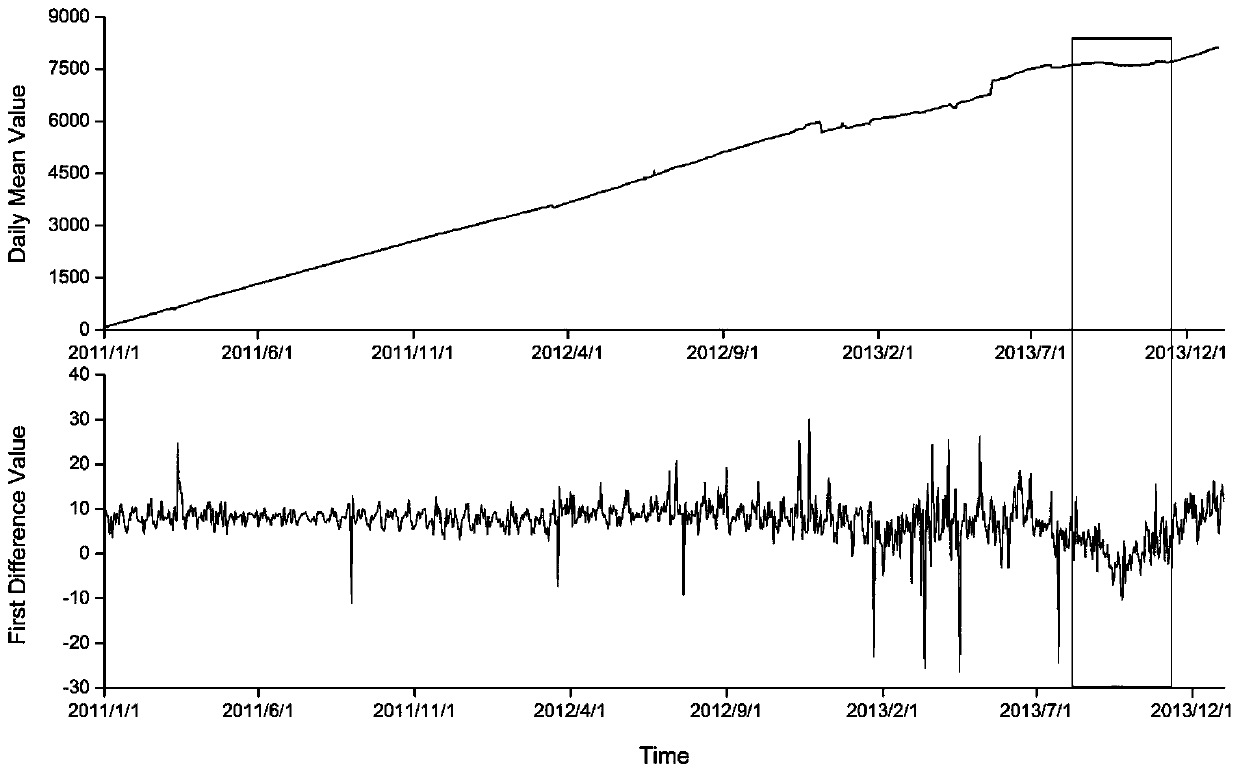

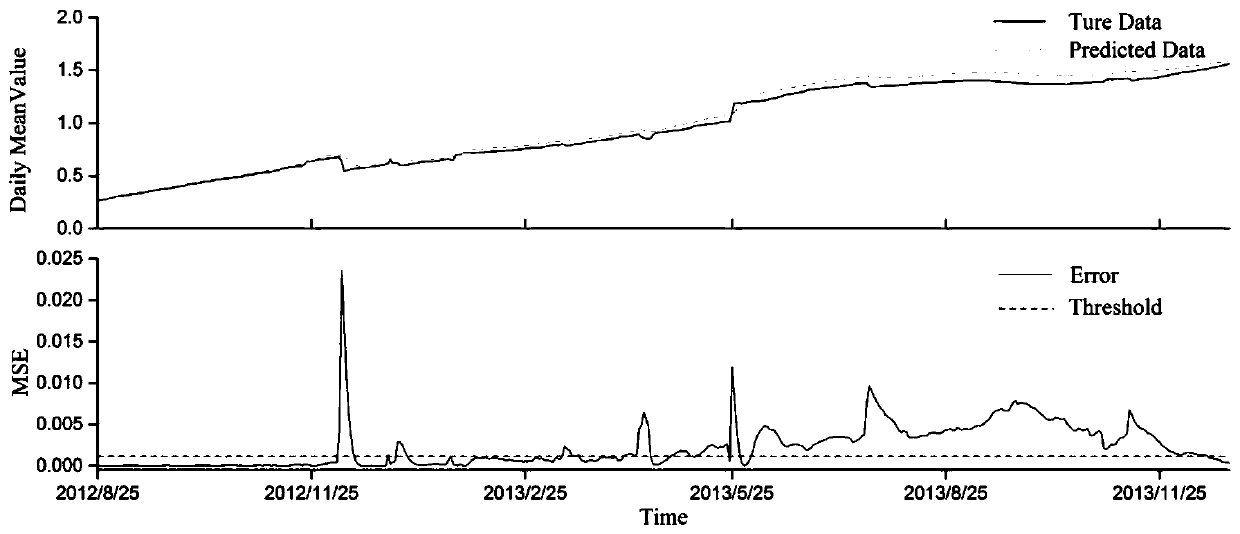

Earthquake precursor data abnormity detection method

ActiveCN109738939AMitigate Vanishing GradientsEliminate the influence of human factorsSeismic signal processingData setAnomaly detection

The invention provides an earthquake precursor data abnormity detection method. The method comprises the following steps: obtaining a historical earthquake precursor data set, carrying out data pre-processing and dividing the processed data set into a training set, a verification set and a test set; constructing an LSTM-RNN prediction model; serving the data in the training set as input, and training the prediction model; checking error changes during training with the data in the verification set; setting an abnormal trigger threshold according to a loss function; testing the prediction modelwith the data in the test set, and adjusting the value of hyperparameters according to recognition rate of abnormal data in the test set; and carrying out earthquake precursor data abnormity detection by utilizing the prediction model. The method can identify all kinds of abnormities in the earthquake precursor data and make clear description and accurate distinguishing, and can identify the abnormal information that is not easily perceived by human.

Owner:蔡寅

Permanent-magnet motor stator by taking iron core as slotless partitioned type structure and production method thereof

InactiveCN102332759AIncrease productivityImprove product qualityMagnetic circuit stationary partsManufacturing stator/rotor bodiesProduction linePunching

The invention relates to a permanent-magnet motor stator by taking an iron core as a slotless partitioned type structure and a production method thereof. An annular cylindrical stator iron core of the stator is composed of a plurality of arc-shaped laminated members which are mutually spliced and all the arc-shaped laminated members are piled by arc-shaped punching sheets. The invention provides the permanent-magnet motor stator by taking the iron core as the slotless partitioned type structure which has the advantages of simple structure, scientific design, safety and reliability and strong practical applicability and the production method thereof; and with the adoption of the motor stator and the production method of the motor stator, the material cost can be greatly saved, the production efficiency and the product consistency are improved, a large batch of mechanically automatic production lines are established, and the popularization and the development of the stator permanent-magnet motor with the stator which takes the iron core as the slotless type structure are convenient.

Owner:TIANJIN NAVIGATION INSTR RES INST

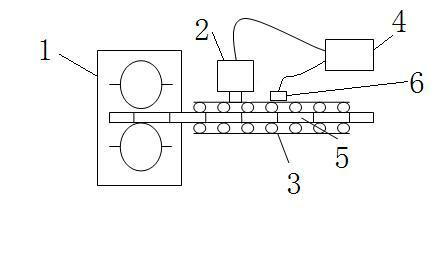

Bud injury preventing system for sugarcane cutting

InactiveCN102630429AReduce manufacturing costReduce the rate of damaged budsHarvestersCharacter and pattern recognitionEngineeringBud

The invention discloses a bud injury preventing system for sugarcane cutting, comprising a cutter and a clamping conveying mechanism driven by a motor controller, wherein the distance between the clamping conveying mechanism and the cutter is fixed; a camera is arranged above the clamping conveying mechanism; the distance from the center position of the camera to the cutting position of sugarcane is just the length of the sugarcane after being cut off; an output end of the camera is connected with a computer equipped with a MATLAB (MATrix LABoratory) software; and an output end of the computer is connected with the motor controller of the clamping conveying mechanism. According to the invention, accurate shutter triggering time interval is matched according to the rotating speed of the cutter and the conveying speed of the sugarcane to ensure that image collecting positions are consistent with actual cutting positions; and filtering, noise reduction and binarization processing are carried out on the collected images to judge whether sugarcane joints are cut by the cutter or not. The bud injury preventing system disclosed by the invention has the advantages that the rapid and accurate judgment on the sugarcane positions cut by the cutter is realized; the bud injury rate of the sugarcane seed stem joints and the production cost of the sugarcane are reduced; the sugarcane seed is saved; and the labour productivity is improved.

Owner:GUANGXI UNIV

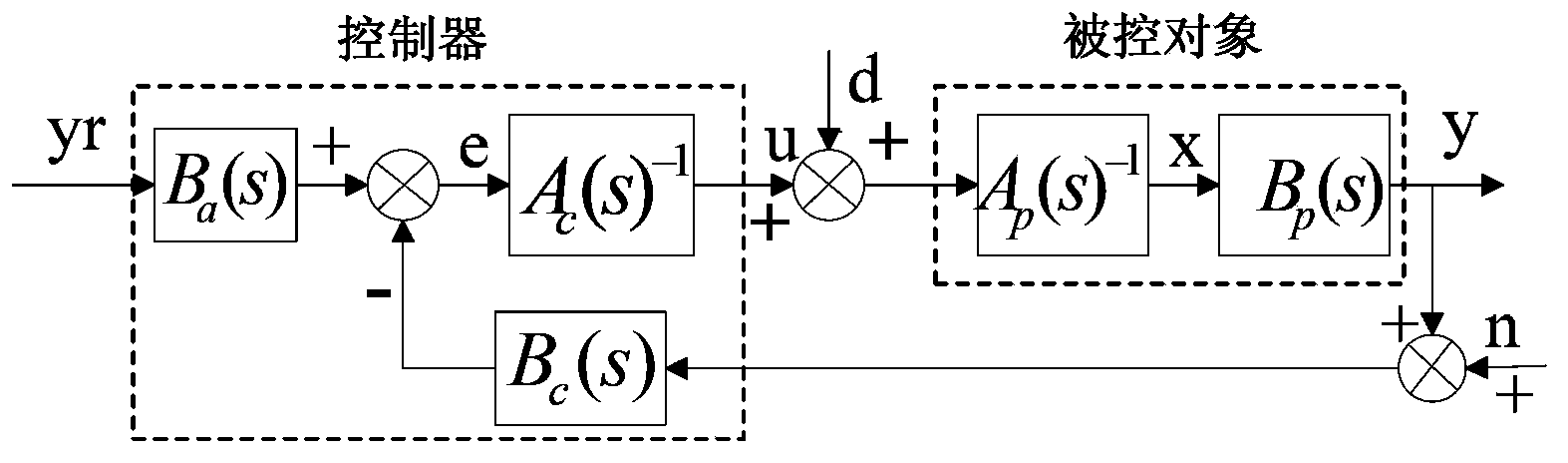

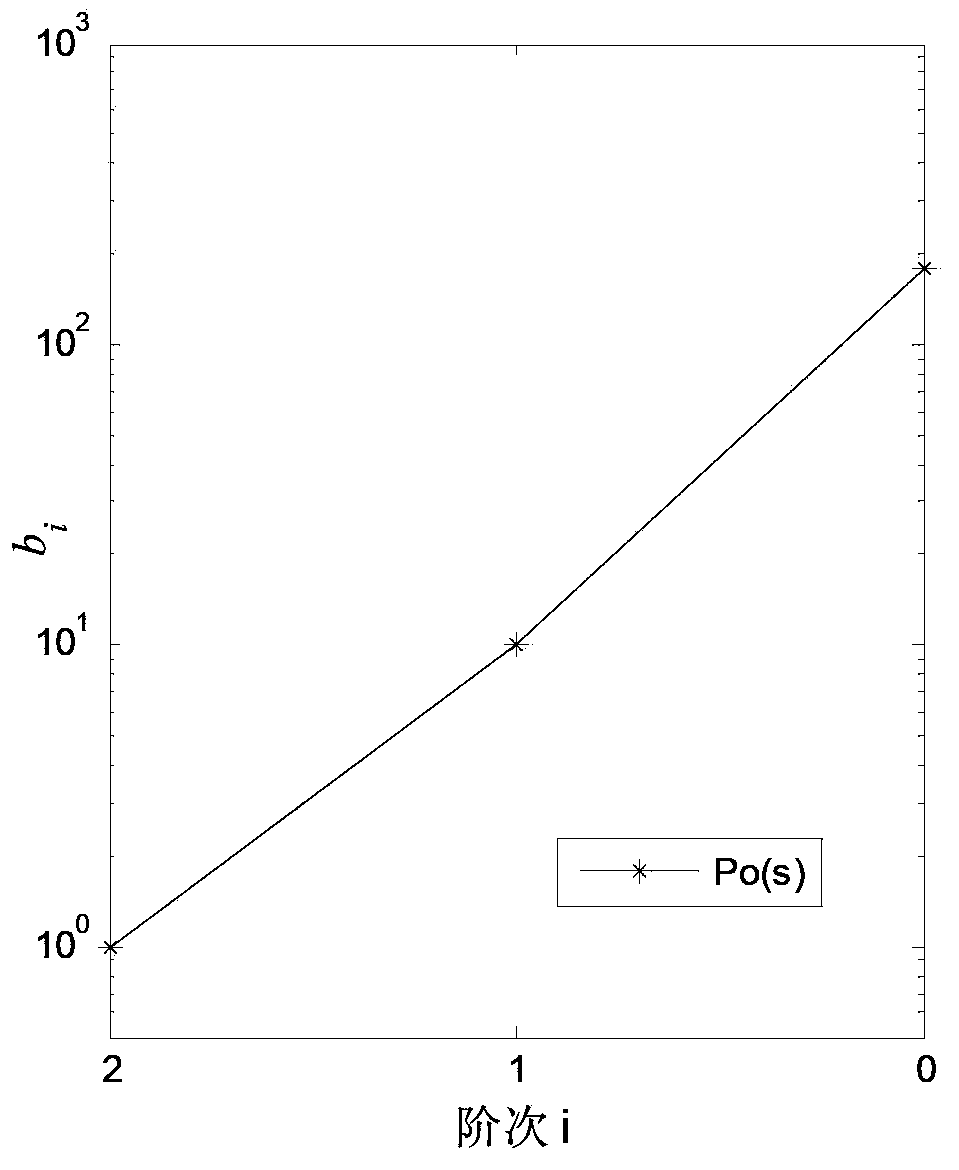

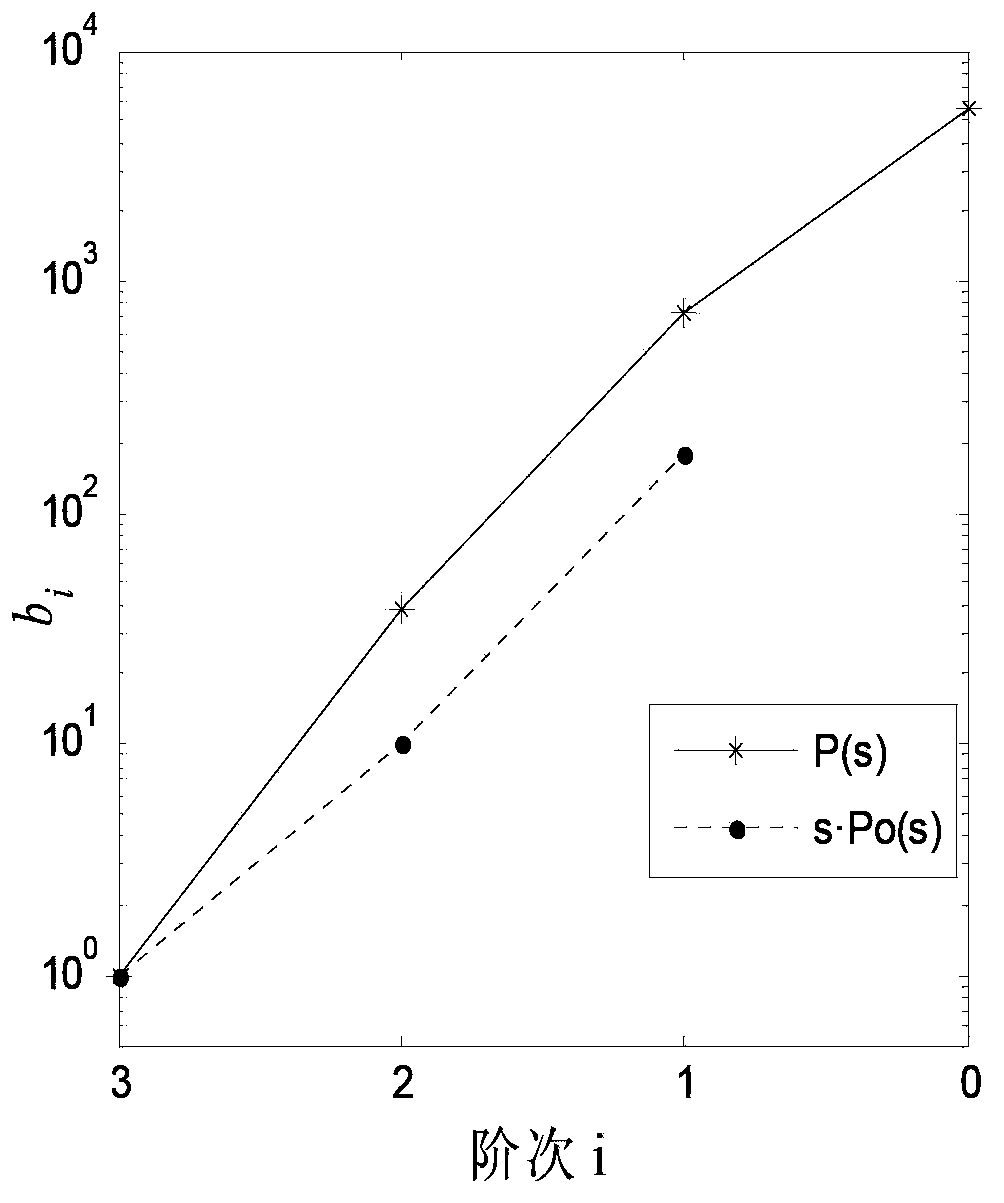

CDM (Coefficient Diagram Method)-based missile autopilot design method

InactiveCN103353759ATake full account of uncertaintyEliminate the influence of human factorsSimulator controlTarget-seeking controlStability indexCoefficient diagram method

The present invention provides a CDM (Coefficient Diagram Method)-based missile autopilot design method. The design method comprises: figuring out an open-loop characteristic polynomial P0(s), and drawing a coefficient map of the open-loop characteristic polynomial P0(s) based a coefficient map drawing method in the CDM; determining the structure of an autopilot according to the convexity of curves in the coefficient map of the open-loop characteristic polynomial P0(s), and obtaining a closed-loop characteristic polynomial P(s) having autopilot control parameters; selecting a stability index [gamma]i and an equivalent time constant tau, and figuring out a closed-loop characteristic polynomial P(s) of the system; and equating coefficients of corresponding orders of the two closed-loop characteristic polynomial P(s), and working out the autopilot control parameters. The method provided by the invention is applicable in the design of the missile autopilot, and can realize online setting of the parameters of the autopilot, providing simple operation and convenience in implementation, and achieving satisfactory effects in overload instruction tracking and anti-interference performance.

Owner:XI AN JIAOTONG UNIV

Brain focus target puncture positioning method and puncture positioning device thereof

PendingCN109998648AImprove puncture accuracyRelieve painDiagnosticsSurgical needlesComputed tomographyMiddle line

The invention provides a brain focus target puncture positioning method and a puncture positioning device. The puncture positioning device comprises a vertical positioning ruler, a first sliding baseand a horizontal positioning ruler, wherein the vertical positioning ruler is provided with first scales in the vertical direction; the first sliding base is vertically and slidably arranged on the vertical positioning ruler; the horizontal positioning ruler is arranged on the first sliding base. The puncture positioning method comprises the steps that a middle-line sagittal view surface of the brain of a patient is determined; brain CT scanning is carried out; CT scanning data is analyzed, and a target transverse-cutting layer image of a brain focus of the patient is determined; a middle-linesagittal image and the target transverse-cutting layer image are modeled in proportion, and simulated puncture is carried out; then solid puncture is carried out on the brain of the patient. The focus target puncture positioning method and the puncture positioning device thereof are used so that multi-point puncture positioning can be realized, the influence of human factors is eliminated, the puncture accuracy of a focus target and the success rate of an operation are improved, the operation difficulty is reduced, the operation time and the pain of the patient are reduced, and the method andthe device have high application and popularization significance.

Owner:杨俊

Method used for drilling tool thread repair by using numerically controlled lathe

The invention provides a method used for drilling tool thread repair by using a numerically controlled lathe, and belongs to the field of thread machining. The method comprises the steps that firstly,tool selection is conducted; secondly, a thread turning starting point is determined; thirdly, tool setting is completed, wherein the fact that a tool nose does not collide with a workpiece to be repaired is used as a basis in the X direction, in the Z direction, the tool nose is located in the middle of threads and then moved into a spiral groove of the threads, the radial X and axial Z positionof the tool nose is slightly adjusted until the tool nose coincides with the spiral groove, single step run is selected, reading is conducted through public variables, and tool setting operation is completed; fourthly, the tool nose is moved to the position of N thread pitches of the tool setting spiral groove to serve as an initial point of continuous machining; and fifthly, continuous machiningis carried out to complete thread repair. According to the method, the inaccuracy caused by human factors is eliminated, the drilling tool repair quality is improved, dimensional stability is realized after thread repair, the numerically controlled lathe runs automatically, the labor intensity is reduced, and the efficiency is high.

Owner:CNPC BOHAI DRILLING ENG

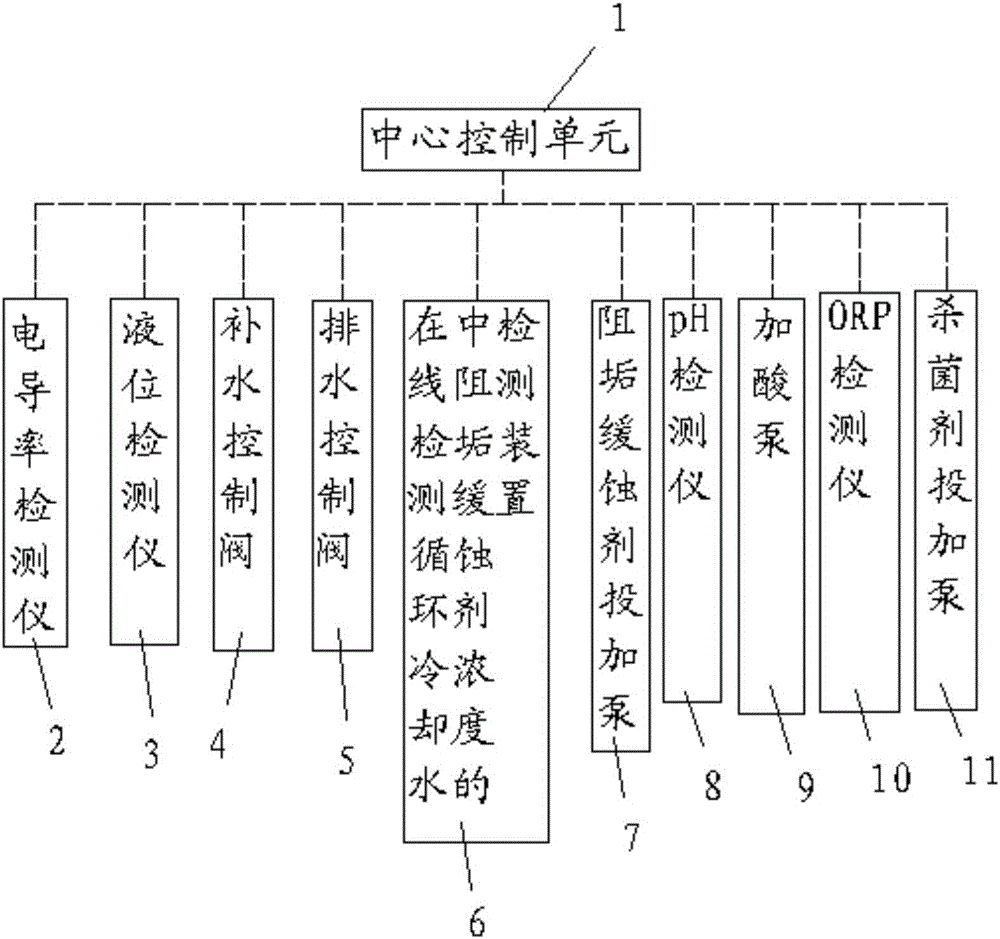

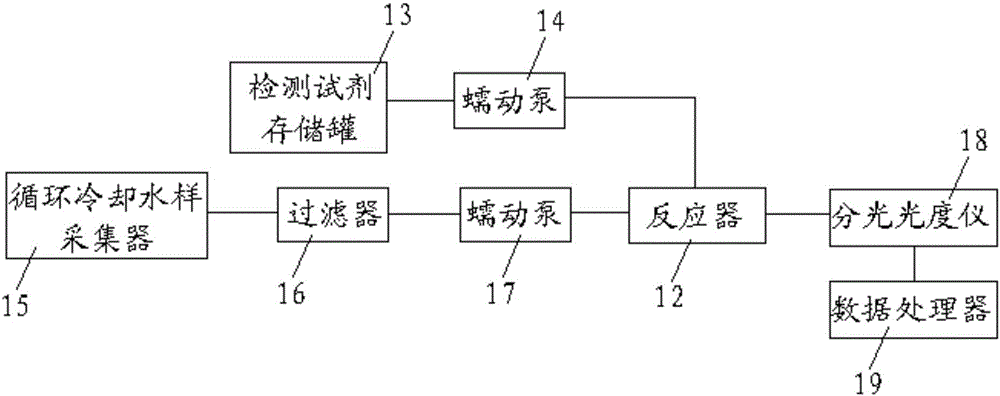

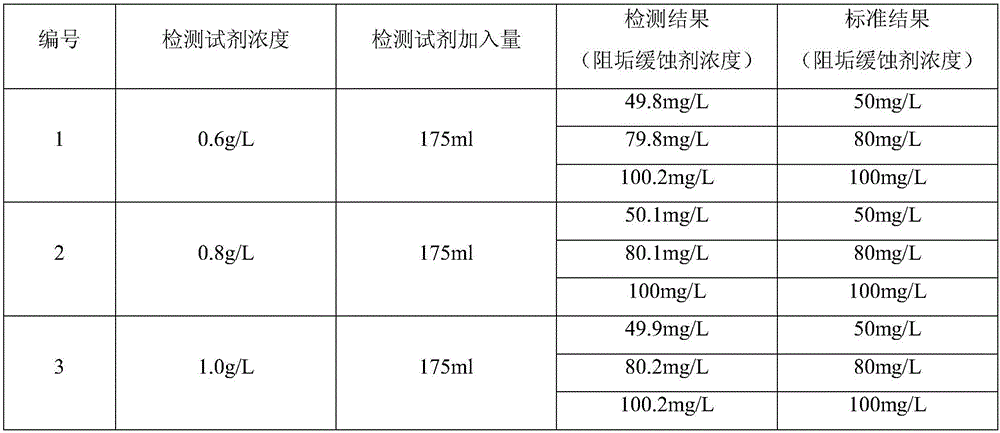

Detection method and detection device for online detection of scale and corrosion inhibitor concentration in circulating cooling water and circulating cooling water treatment control system

ActiveCN105717054ARealize real-time detectionRealize full automation managementWater treatment parameter controlNature of treatment waterCationic polyelectrolytesControl system

The invention provides a detection method for online detection of the scale and corrosion inhibitor concentration in circulating cooling water. A cationic polyelectrolyte serves as a detection reagent, the detection reagent is added to a circulating cooling water sample, full mixing is performed, reaction is performed for 15-20 minutes, then an absorbance value of the reacted circulating cooling water sample is detected under the wavelength condition of 400-600 nm, and the scale and corrosion inhibitor concentration in the circulating cooling water is determined according to the absorbance value. The detection method is wide in application range, short in detection period, high in detection accuracy and good in stability and is not limited by the condition whether a scale and corrosion inhibitor is a phosphorus-containing or phosphorus-free agent. The detection device adopting the detection method can achieve online automatic detection, replace manual operation and eliminate various human factors and the influence of response time lag of all links and is simple in operation and low in operation cost. In addition, the circulating cooling water treatment control system composed of the online detection device can achieve whole-process management and automatic dosing control of circulating cooling water and is suitable for industrial application.

Owner:SHIJIAZHUANG JIYUAN ENVIRONMENTAL TECH CO LTD

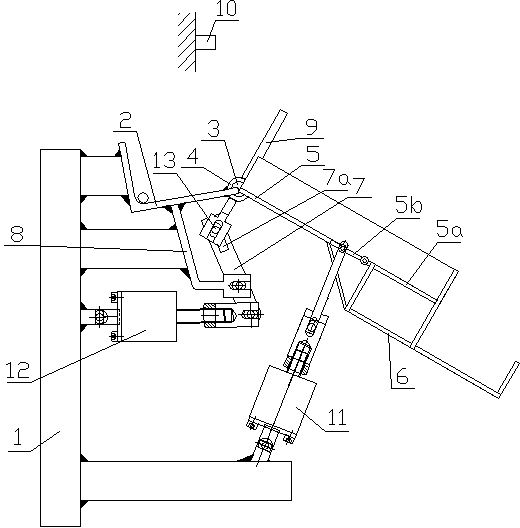

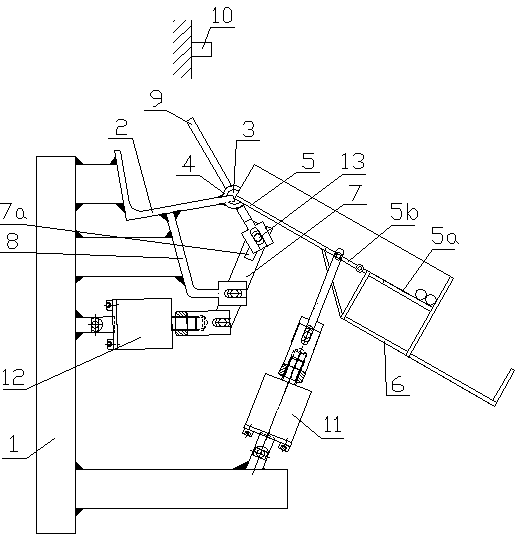

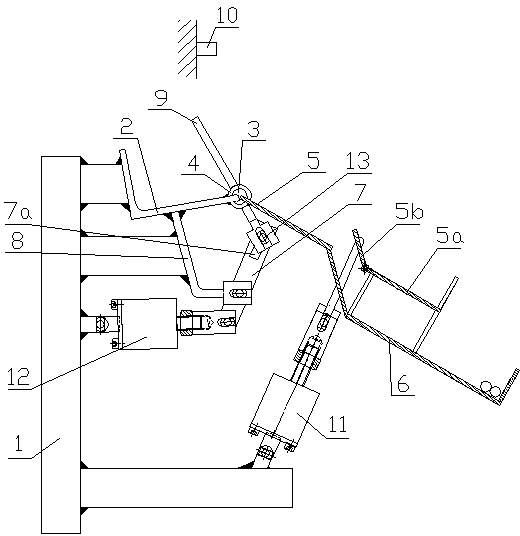

Bar stock heating automatic sorting device

ActiveCN103381409AEliminate the influence of human factorsIncrease productivitySortingProgrammable logic controllerEngineering

The invention discloses a bar stock heating automatic sorting device which comprises a support. The bar stock heating automatic sorting device is characterized by further comprising a discharging plate, a rotating shaft, a rotating shaft sleeve, an upper material supporting plate, a connecting rod, a connecting rod support body and a material distributing plate. One end of the discharging plate is fixedly connected with the support, the other end of the discharging plate and the upper material supporting plate are respectively located on two sides of the rotating shaft sleeve and are fixedly connected with the rotating shaft sleeve, the fixedly arranged connecting rod support body is hinged to the middle of the connecting rod, the lower portion of the connecting rod is connected with a piston rod of a cylinder, the rear end of the cylinder is connected to the support, the upper portion of the connecting rod is hinged to the lower portion of the material distributing plate, and a hinged shaft is placed in a sliding groove of the material distributing plate or the connecting rod. The middle of the material distributing plate is fixedly connected with the rotating shaft, the rotating shaft is placed in the rotating shaft sleeve, a temperature sensor is arranged above the material distributing plate, the cylinder is connected with an air source through a self-control valve, and the temperature sensor and the self-control valve are connected with a programmable logic controller (PLC). The bar stock heating automatic sorting device has the advantages of being high in production efficiency, good in sorting accuracy and high in safety, and overall quality of products is guaranteed.

Owner:CHINA RAILWAY LONGCHANG MATERIALS

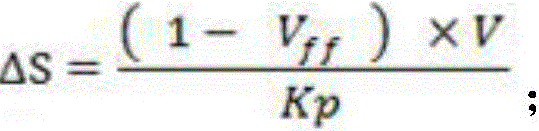

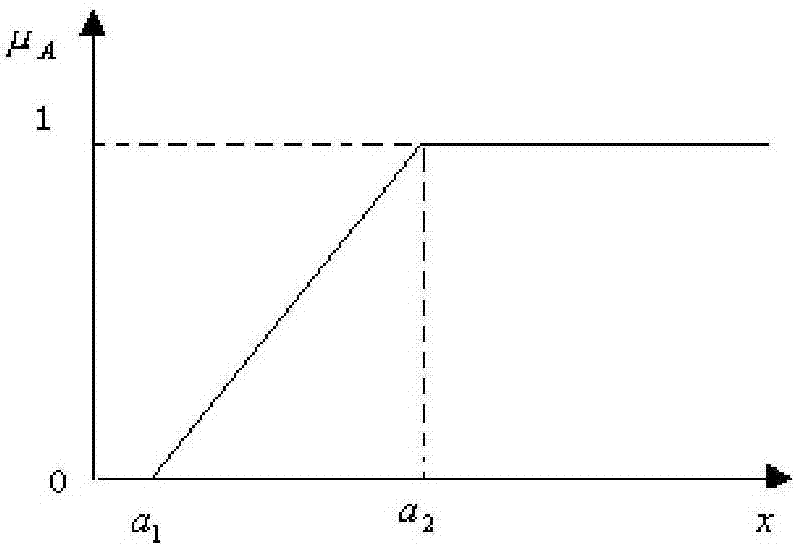

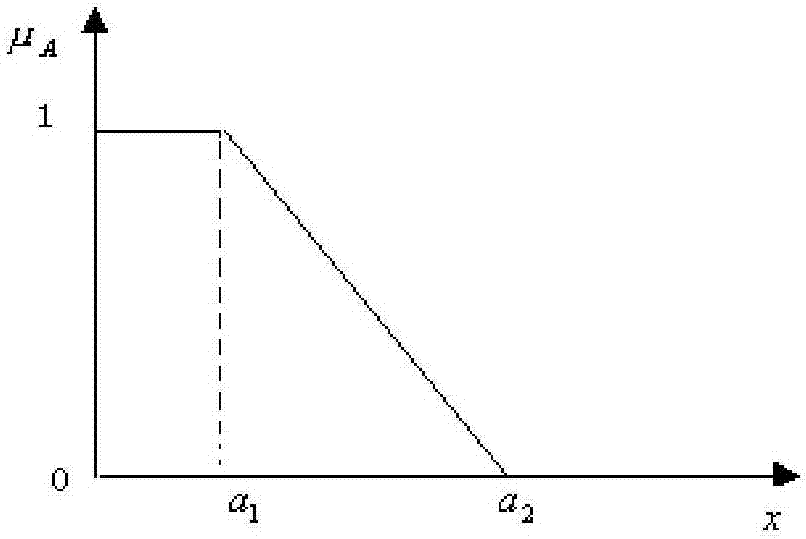

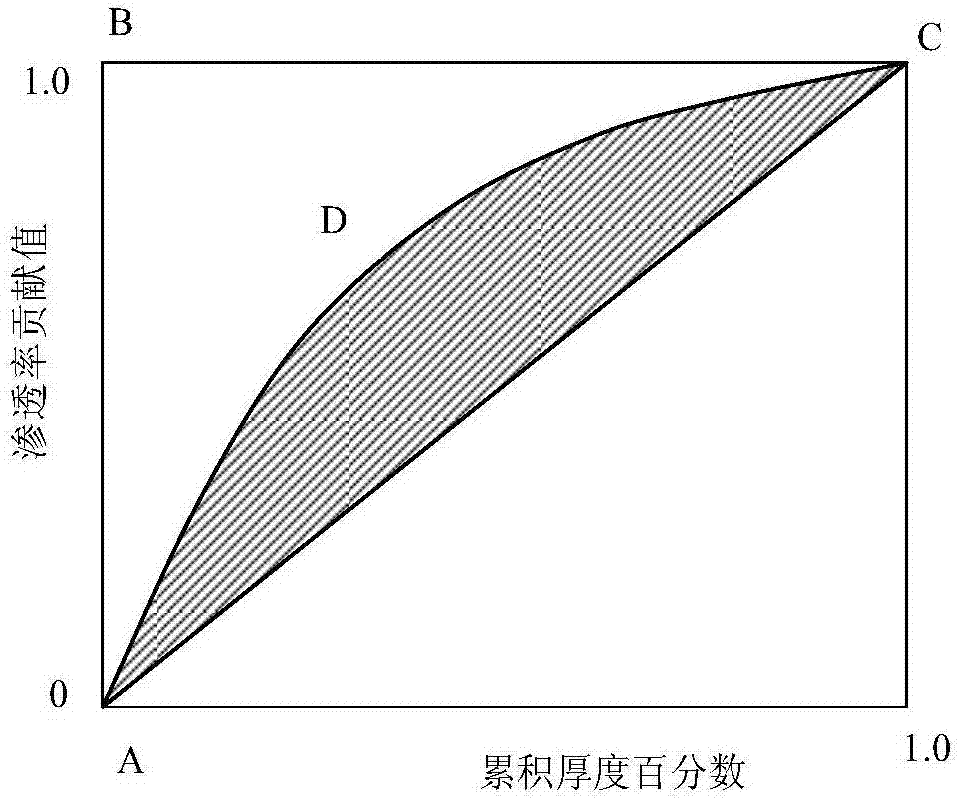

Profile control well selection decision-making method suitable for offshore heavy oil reservoir

ActiveCN106894800AThe decision-making method of profile control and well selection is accurateEliminate the influence of human factorsFluid removalResourcesEngineeringViscosity

The invention relates to a profile control well selection decision-making method suitable for an offshore heavy oil reservoir. The profile control well selection decision-making method comprises the following steps that (1), single factor indexes in profile control well selection decision-making are divided according to index properties; (2), the numerical value of a comprehensive evaluation index of a water injection well to be evaluated is calculated; (3), the average value of comprehensive evaluation indexes of water injection wells of a block is calculated; and (4), the numerical value, obtained in the step (2), of the comprehensive evaluation index of the water injection well to be evaluated is compared with the average value, obtained in the step (3), of the comprehensive evaluation indexes of the water injection wells of the block so as to decide whether the water injection well to be evaluated needs to be subjected to a profile control measure or not. The method has the following advantages that (1), the influence of the viscosity of crude oil is fully considered in offshore heavy oil reservoir profile control well selection decision-making, so that the profile control well selection decision-making method is more accurate; and (2), all weight values are calculated through an analytic hierarchy process method, and the influence of human factors is removed, so that the profile control well selection decision-making method is more scientific and reasonable.

Owner:CHINA NAT OFFSHORE OIL CORP +1

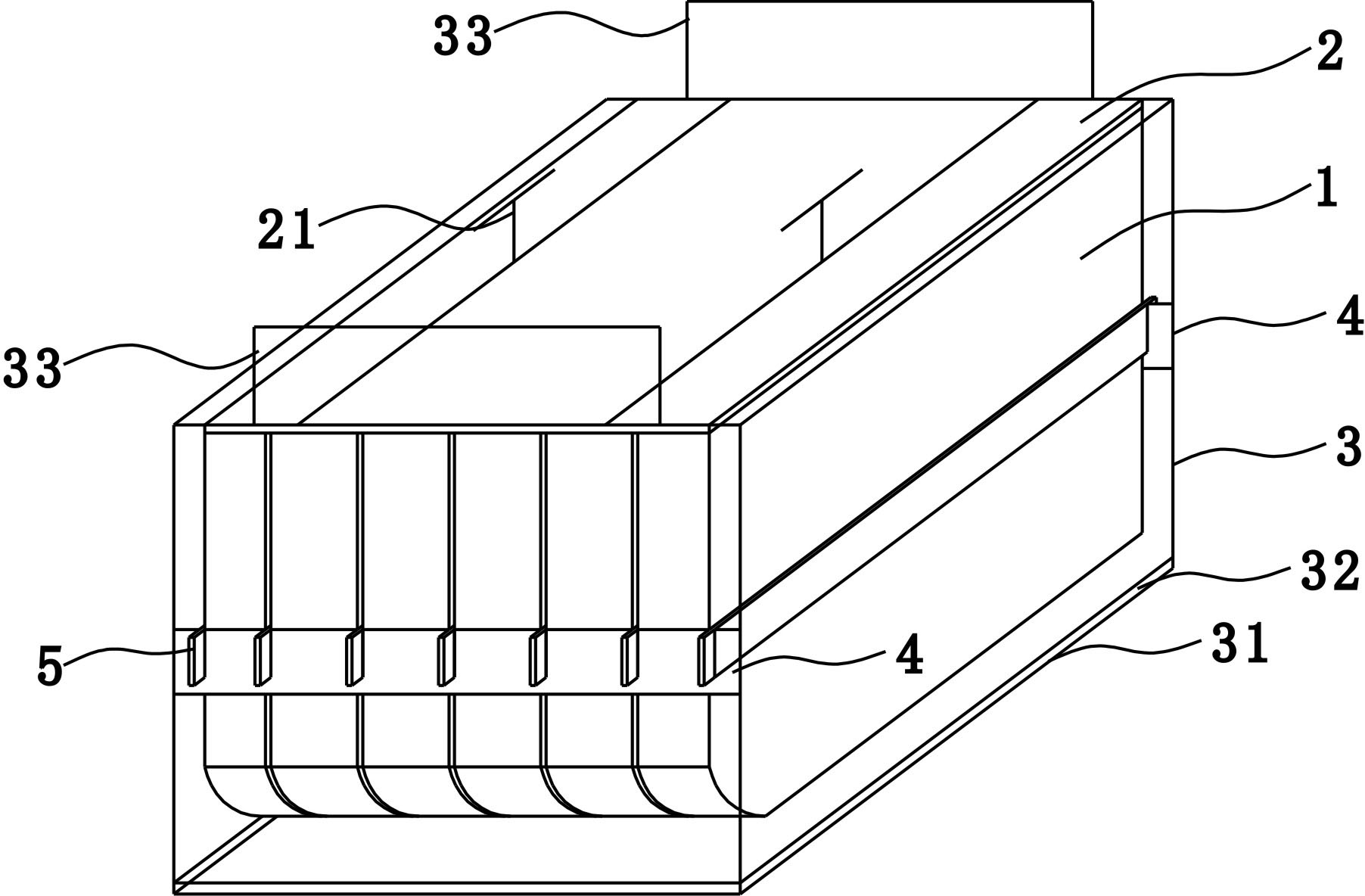

Automatic degumming method and device for multi-wire cutting of monocrystal/ polycrystalline silicon wafer

InactiveCN102275234AReduce water consumptionEliminate the influence of human factorsSemiconductor/solid-state device manufacturingWorking accessoriesWire cuttingPolycrystalline silicon

The invention discloses an automatic degumming method and an automatic degumming device for the multi-wire cutting of a monocrystal / polycrystalline silicon wafer. The automatic degumming device comprises a workpiece (silicon wafer) which is to be degummed and is adhered to a connection plate, a bearing frame capable of accommodating and suspending the workpiece (the silicon wafer), wherein the bearing frame comprises a bottom plate and baffle plates which are arranged on the front lateral surface and the rear lateral surface and are matched with the positioning workpiece (the silicon wafer); positioning inserting strips which are inserted into the workpiece (the silicon wafer) at intervals are arranged on the two baffle plates on the front lateral surface and the rear lateral surface; the connection plate is suspended on the bearing frame; the bottom of the workpiece (the silicon wafer) which is to be degummed and is adhered to the connection plate is suspended relative to the bottom plate; and a buffer layer which drops after the workpiece (the silicon wafer) is degummed is laid on the bottom plate. By the automatic degumming method and the automatic degumming device, the influence of personal factors can be eliminated; the method is feasible and safe in operation; and the device is easy to manufacture, convenient to apply and obvious in an effect.

Owner:沈利军

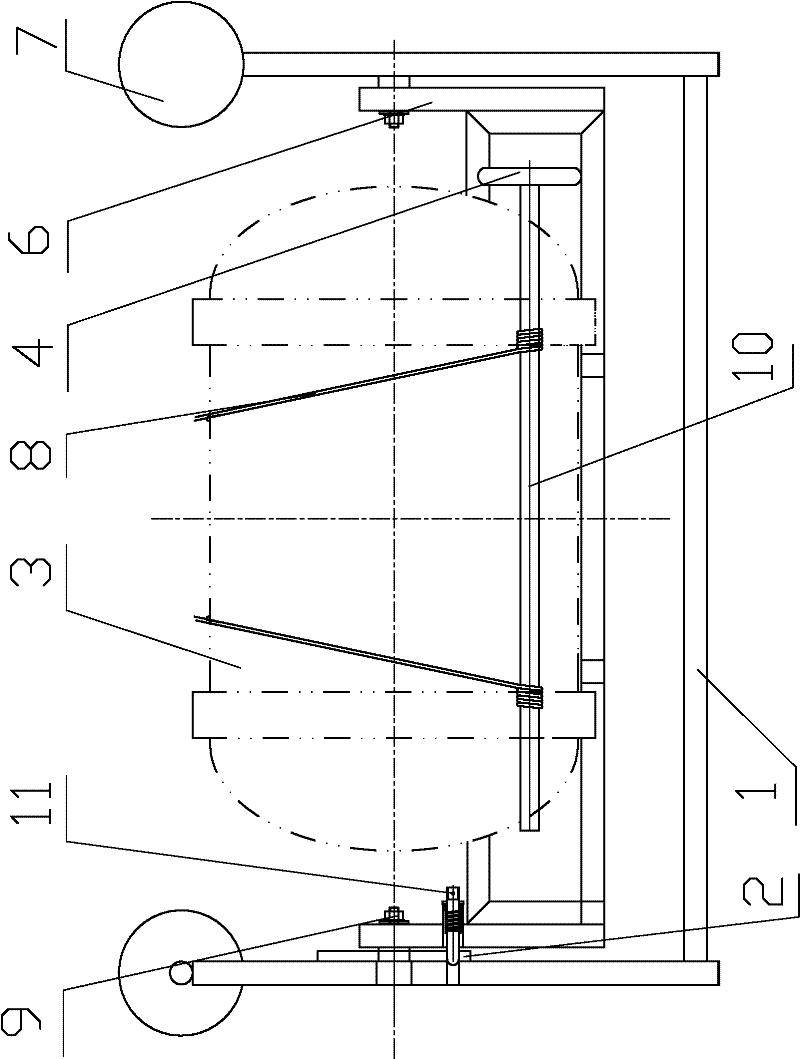

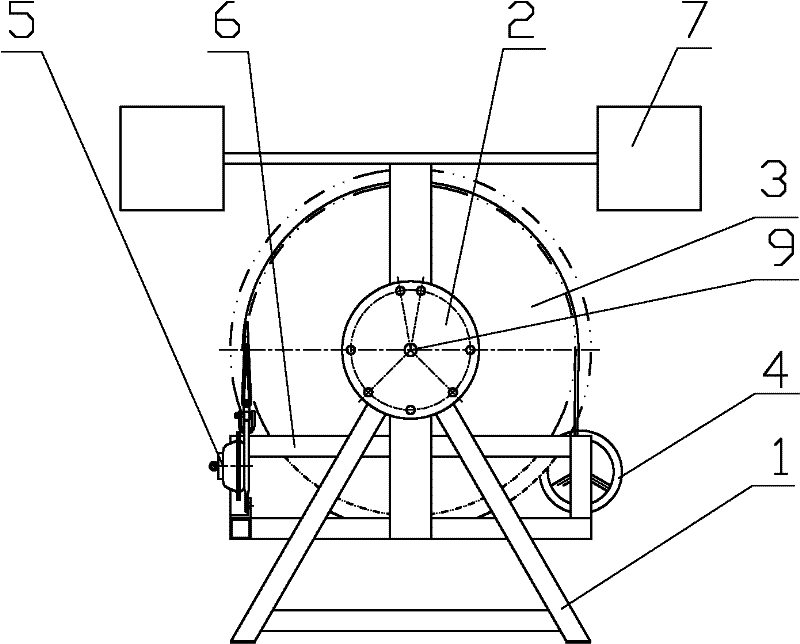

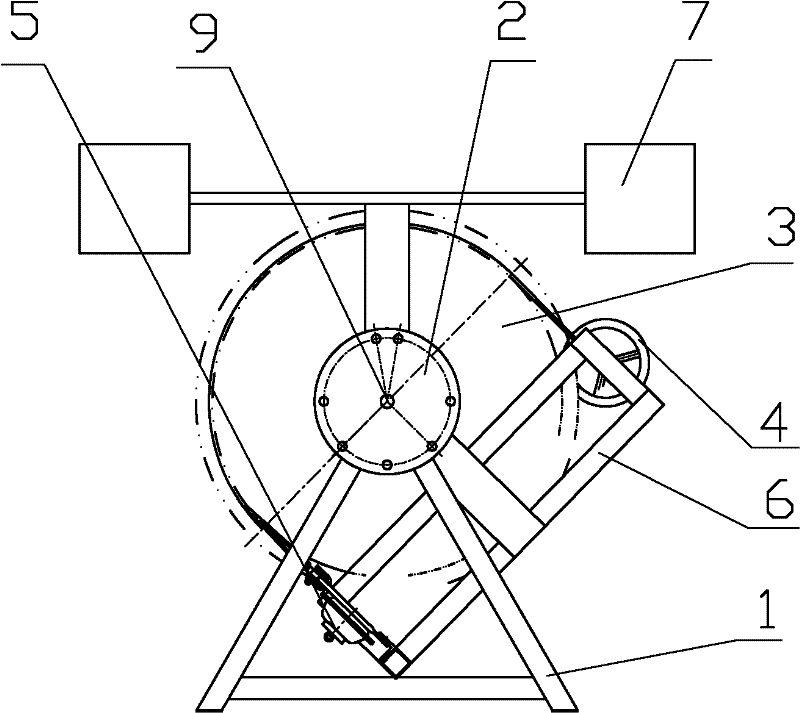

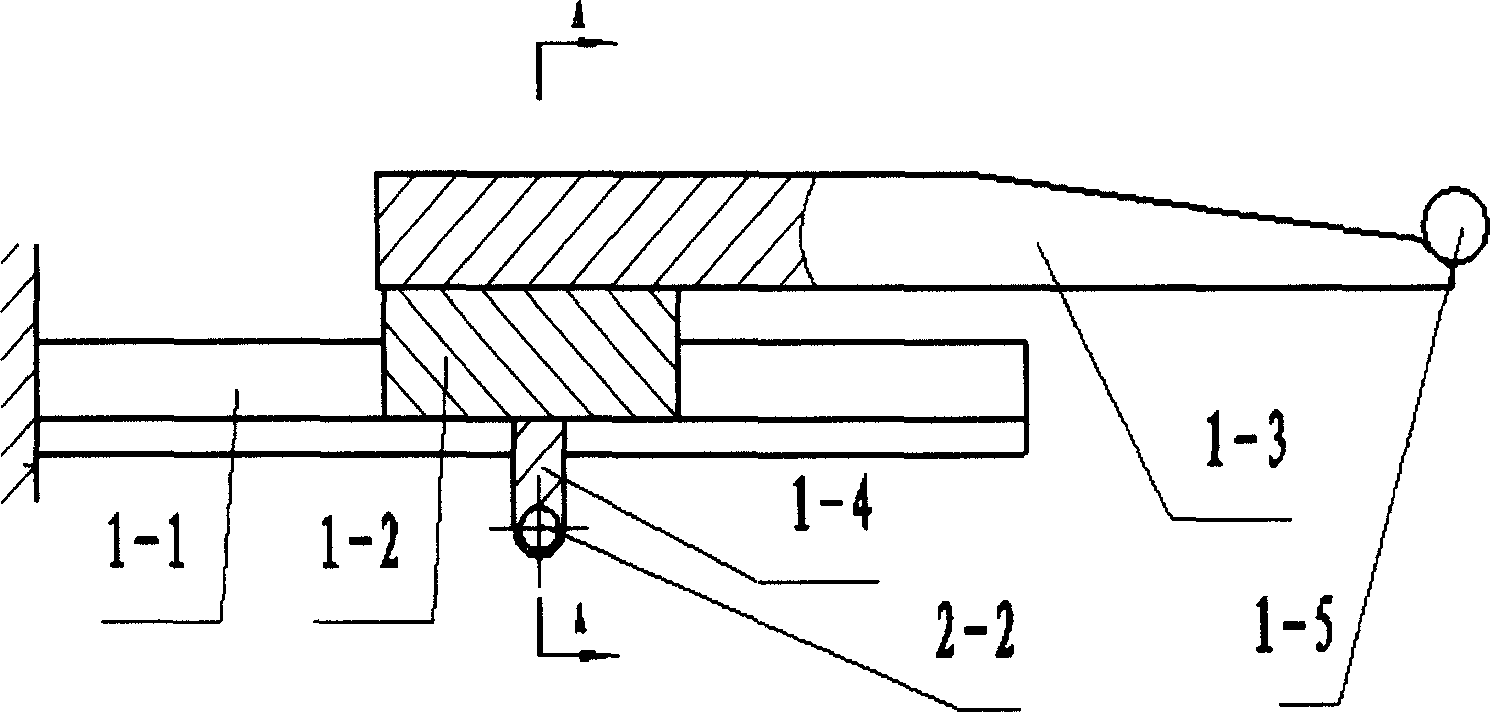

An inflatable life raft pressure release device test device

The invention relates to a device for testing life rafts and discloses a device for testing an inflatable life raft pressure release unit. A horizontal lifting frame (1) has a U shape, a balance bar is fixedly connected to the upper parts of two side frames respectively, and floaters (7) are fixed at two ends of balance bars; a bearing is respectively arranged at central positions of the two sideframes and is rotationally connected with a life raft mounting turntable (6); one side of the life raft mounting turntable (6) is connected with one end of a life raft pressure release unit (5) to betested; the other end of the life raft pressure release unit (5) to be tested is penetrated by a rope (8); the two ends of the rope press against an expansion life raft (3) and are wound on a rope winding stick (10); the rope (8) can be tightened by a rotating hand wheel (4); and one or two graduated disks (2) are fixed on the side frames of the horizontal lifting frame (1). The invention provides a device for testing and judging whether a life raft pressure release unit releases pressure qualifiedly or not at a standard specified water depth when the life raft pressure release unit to be tested and the bound expansion life raft are put into water together, the device is convenient to use and operate, the influence of personal factors is eliminated, and all standard specified parameter items can be finished on one device.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

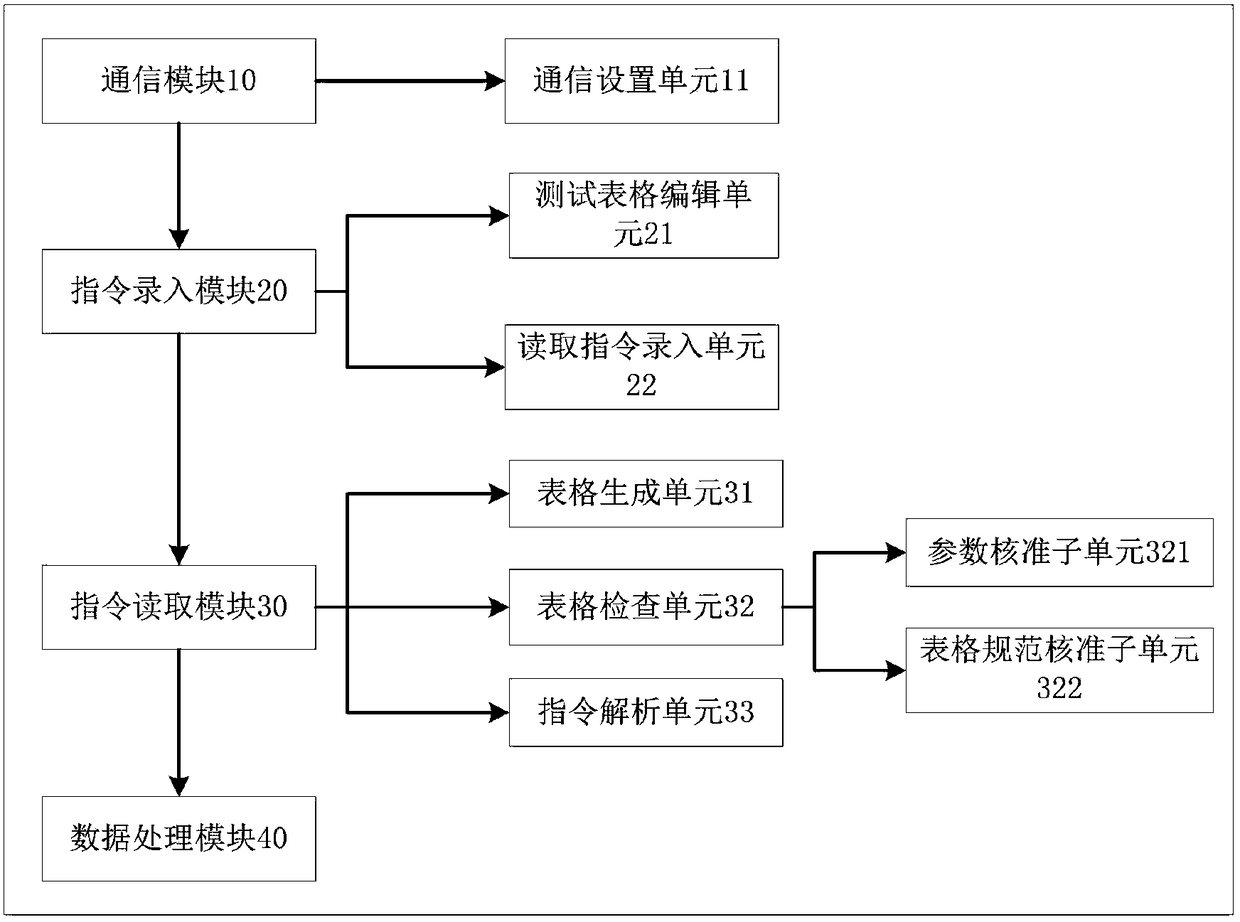

Electric car controller automatic test platform and method

InactiveCN108170118AImprove efficiencyImprove reliabilityElectric testing/monitoringElectric carsInformation transmission

The present invention discloses an electric car controller automatic test platform and method. An information transmission path between a test platform and an electric car controller is established through a communication module; workers input operation control instructions into a control processor of the test platform through an instruction input module; the input instructions are analyzed and read through an instruction reading module, and the electric car controller is correspondingly controlled according to the read instruction information; and finally, each data generated by the electriccar controller is collected through a data processing module, the collected data and expected data are compared and analyzed to obtain a test result. Therefore, all the tests required by ex-factory test of electric car controllers are integrated such as a regulatory compliance test, a pretest, a zero load test, a loading test and a signal test to achieve one-key test and achieve unmanned duty in the whole process.

Owner:WISDRI WUHAN AUTOMATION

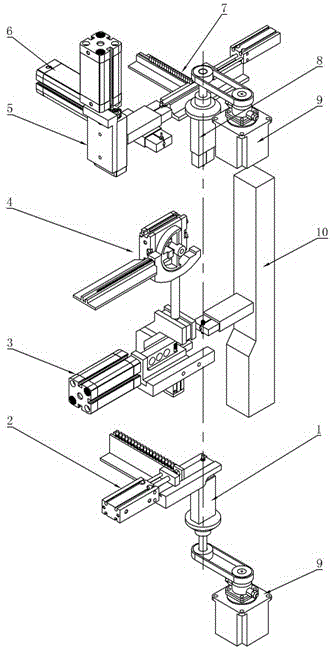

Automatic assembling device for flexible shaft

ActiveCN105414956AAvoid causingHigh degree of automationAssembly machinesMetal working apparatusElectric machineryControl theory

The invention discloses an automatic assembling device for a flexible shaft. The flexible shaft is formed by assembling connectors at the two ends of a spring. The automatic assembling device for the flexible shaft comprises an automatic spring supply mechanism, a spring positioning, clamping and feeding mechanism, two automatic connector supply mechanisms, two connector positioning and clamping rotating shaft mechanisms and two rotating torque control mechanisms. According to the automatic assembling device for the flexible shaft, positioning and screwing of the spring and the connectors of the flexible shaft are achieved through the automatic mechanical devices such as the automatic spring supply mechanism, and the automatic degree is high; torque clutches are adopted in the rotating torque control mechanisms; when torque is increased to a certain extent, driving force is lost between the torque clutches and rotating shafts of servo motors of the control mechanisms; scrapped products caused when the torque is excessively large and the spring and the connectors are screwed excessively are avoided, and the production cost is lowered; and the clutch torque can be adjusted by adjusting adjustment screw rods and nuts, and the requirement for assembling different flexible shafts is met.

Owner:宁波韵声机芯制造有限公司 +1

Force application device for test of door-closing speed of vehicle

InactiveCN105115736AReduce labor intensityImprove work efficiencyVehicle testingClassical mechanicsPulley

Provided is a force application device for the test of the door-closing speed of a vehicle. The force application device comprises a rack with universal wheels. The device is characterized in that a slide rail is arranged above the rack, a force application rod capable of sliding along the slide rail is arranged in the slide rail, a fixed pulley is fixedly arranged at the upper front part of the slide rail, a steel wire rope latch fixedly connected with the force application rod is arranged at the lower rear part of the slide rail, one end of a steel wire rope arranged on the pulley in a sleeved manner is fixed on the steel wire rope latch, the other end of the steel wire rope is provided with a hook capable of lifting a gravity weight, a force application rod block is arranged at the upper rear part of the force application rod, the upper rear part of the slide rail, corresponding to the force application rod block, is provided with a pin, the pin is movably connected with a handle with a stop pin, and the upper front part of the slide rail is provided with a slide rail block for limiting the force application rod. During practical detection of the door-closing speed, a speedometer is not needed, only the force application device is needed, the vehicle is qualified if the door is closed, and the vehicle is unqualified if the door cannot be closed; and the force application device can be used for the detection of the door-closing speed of left-right doors.

Owner:BRILLIANCE AUTO

Rapid determination method for content of total sugar in dry red wine

InactiveCN105954278ASimple stepsEliminate the influence of human factorsMaterial analysis by observing effect on chemical indicatorSize determinationAcid hydrolysis

The invention relates to a rapid determination method for the total sugar content in dry red wine, comprising the following steps: 1) sample preparation; 2) instrument calibration: selecting an automatic reducing sugar measuring instrument based on the Fehling titration reaction principle, and automatically measuring reducing sugar After the instrument is started, it automatically completes three blank tests, that is, calibration T1. After the titration time of the three times of automatic memory tends to be stable, perform calibration T2, and manually add 0.5 mL of a glucose standard solution with a mass fraction of 1% for verification; 3) the sample Measurement: Add the dry red wine after acid hydrolysis treatment in step 1) dropwise into the reaction pool of the automatic reducing sugar tester, press the test button, automatically enter the measurement program, and automatically print after the measurement is completed. The rapid determination method of the total sugar content in dry red wine of the present invention has simple steps, and the automatic reducing sugar measuring instrument based on the Fehling titration reaction principle can stabilize various conditions affecting biochemical reactions, and can simply, quickly and accurately determine the total sugar in wine content.

Owner:INSPECTION & QUARANTINE COMPREHENSIVE TECH CENT JIANGXI ENTRY EXIT INSPECTION & QUARANTINE BUREAU

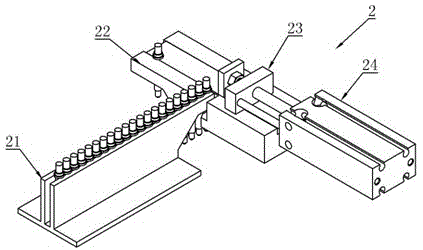

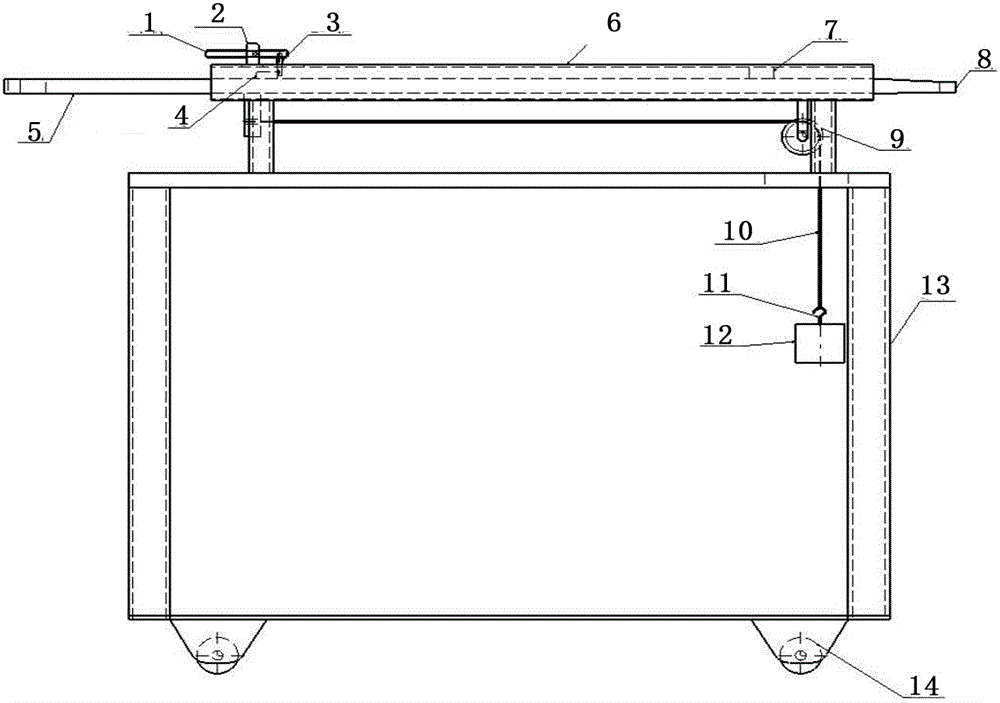

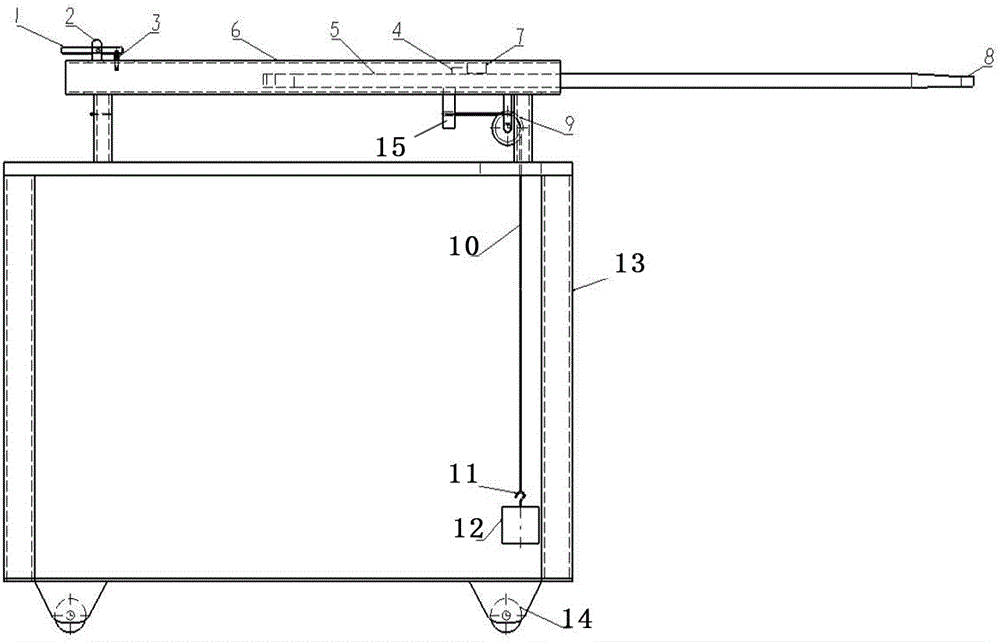

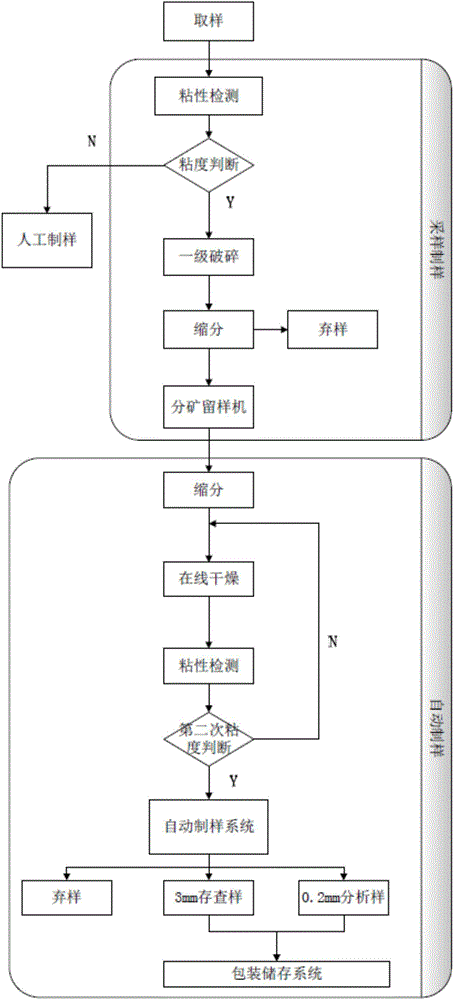

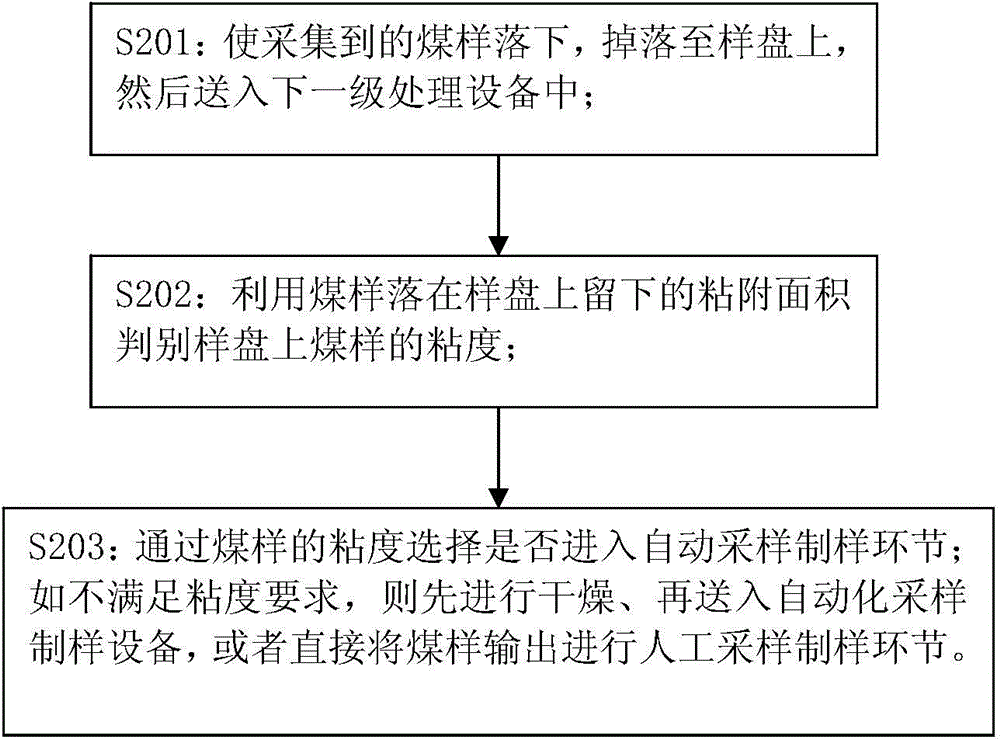

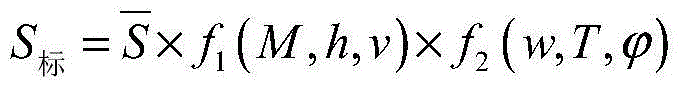

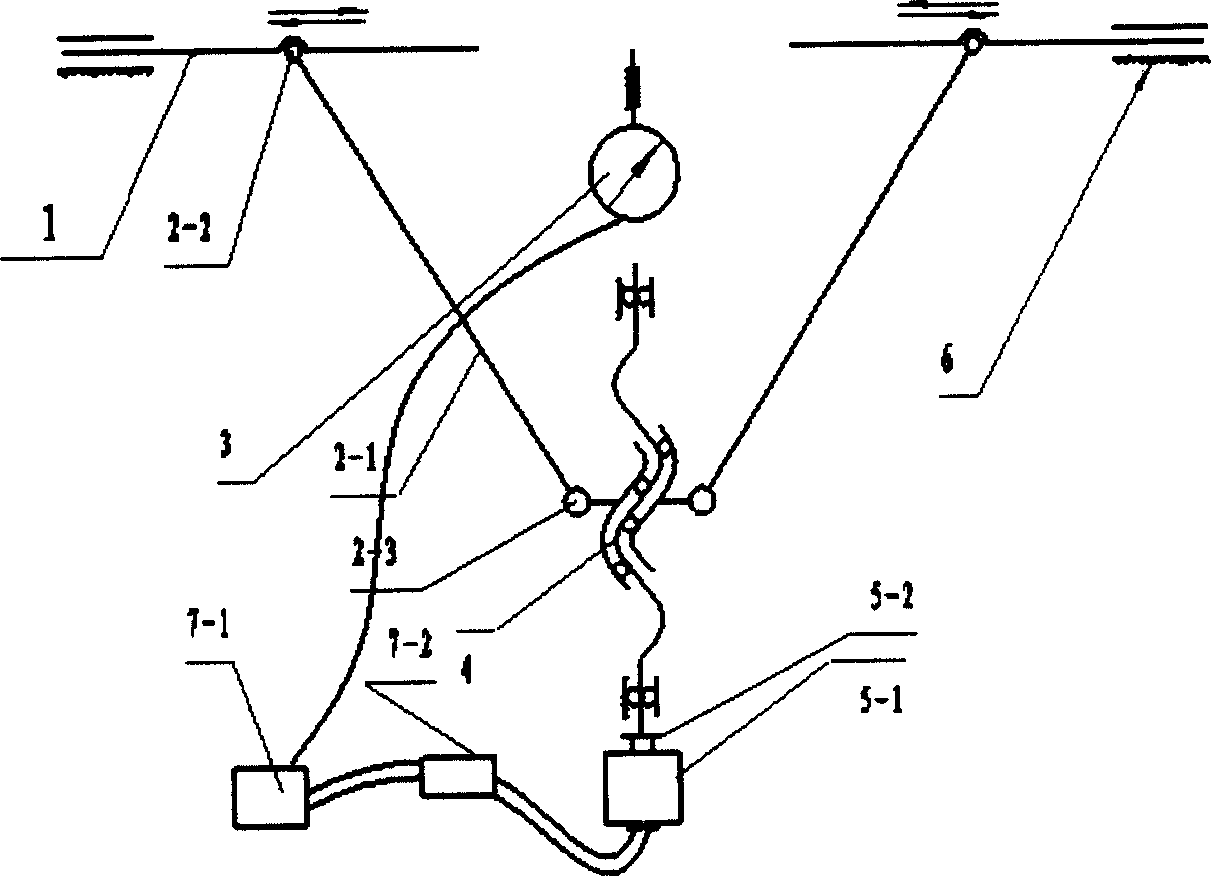

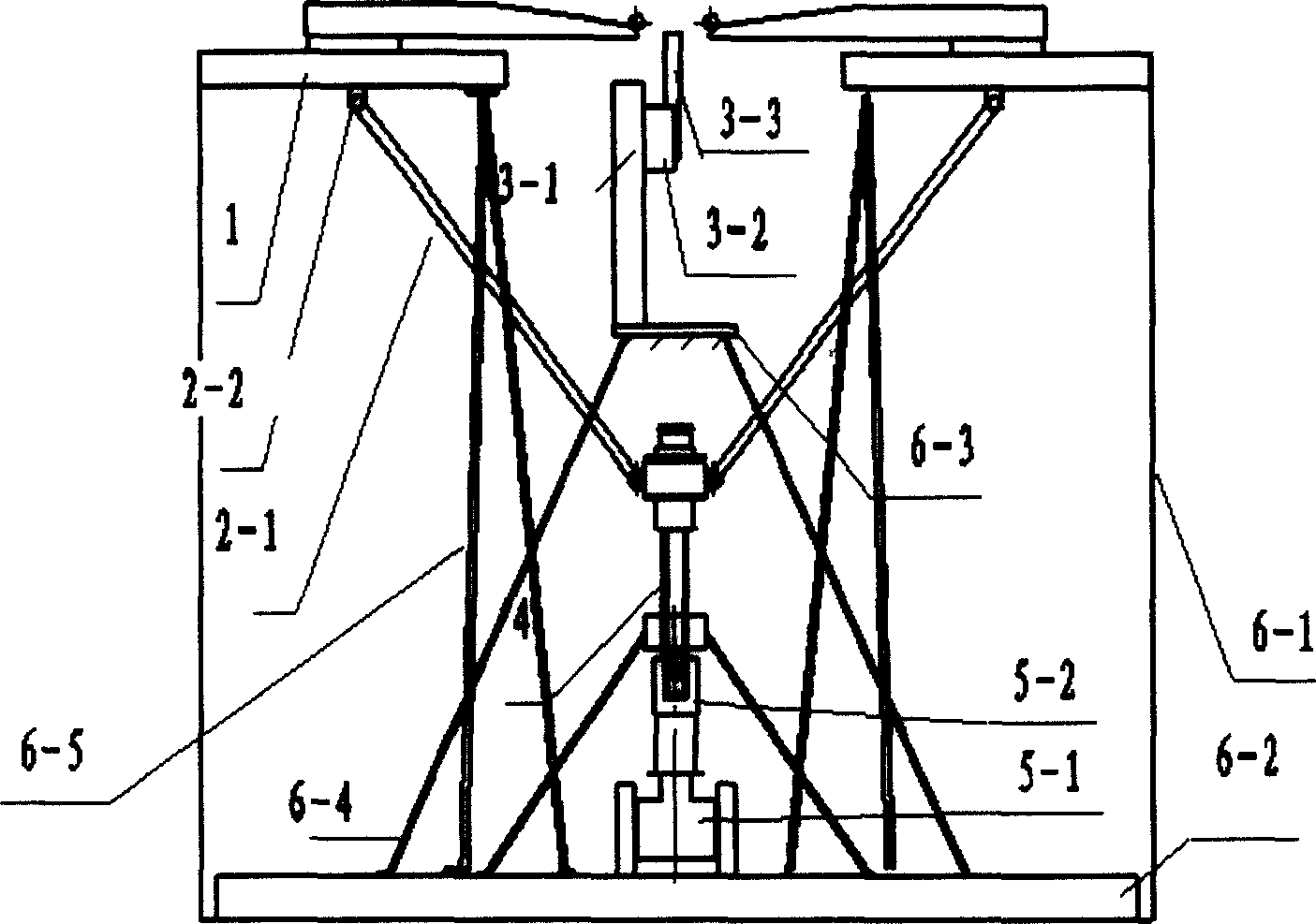

Integrated sampling method used for coal sample detection and integrated sampling system

ActiveCN105987834AImprove reliabilityRealize automatic controlFlow propertiesPreparing sample for investigationEngineeringViscosity

The invention relates to an integrated sampling method used for coal sample detection and an integrated sampling system. The method comprises the following steps: S1) sampling; sampling is carried out in stacking or transport equipment; S2) viscosity determination; by determining the viscosity of the coal sample, whether an automatic sampling and sample production link is introduced or not is selected; if the viscosity requirement cannot be satisfied, drying is carried out, and then the coal sample is sent to automation sampling and sample production equipment, or is directly output for artificial sampling and sample production; and S3) sampling and sample production; through viscosity determination of the coal sample in the step 2), if the requirement is satisfied, the sampling and sample production are automatically carried out. The system is used for carrying out the above method. The system has the advantages of principle and simple operation, and the reliability of the automation work and flow process smooth degree can be greatly increased.

Owner:HUNAN SUNDY SCI & TECH DEV

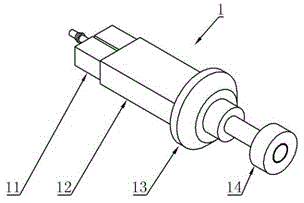

Reducing contact sphere diameter instrument

InactiveCN1580688AEasy to useHigh precisionMechanical counters/curvatures measurementsGratingBall bearing

This is a contact sphero-meter, which comprises computer, the step-by-step electric motor, the straight-line slide way, the grating ruler, the ball bearing, and screw rod. At first, to measure the curvature of the spherical mirror by the grating ruler, then the computer calculates the radius of the spherical, mirror according the formula. This device can measure any spherical mirrors and lenses. This instrument has more measure precision.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com