Permanent-magnet motor stator by taking iron core as slotless partitioned type structure and production method thereof

A technology of permanent magnet motor and manufacturing method, applied in the direction of magnetic circuit shape/style/structure, manufacturing stator/rotor body, magnetic circuit static parts, etc., can solve the problem of mechanized automatic production that cannot adapt to large quantities and cannot establish large quantities Problems such as automatic production lines and restricting the promotion and development of motors can achieve the effect of eliminating the influence of human factors, improving product consistency and production efficiency, and facilitating assembly line production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

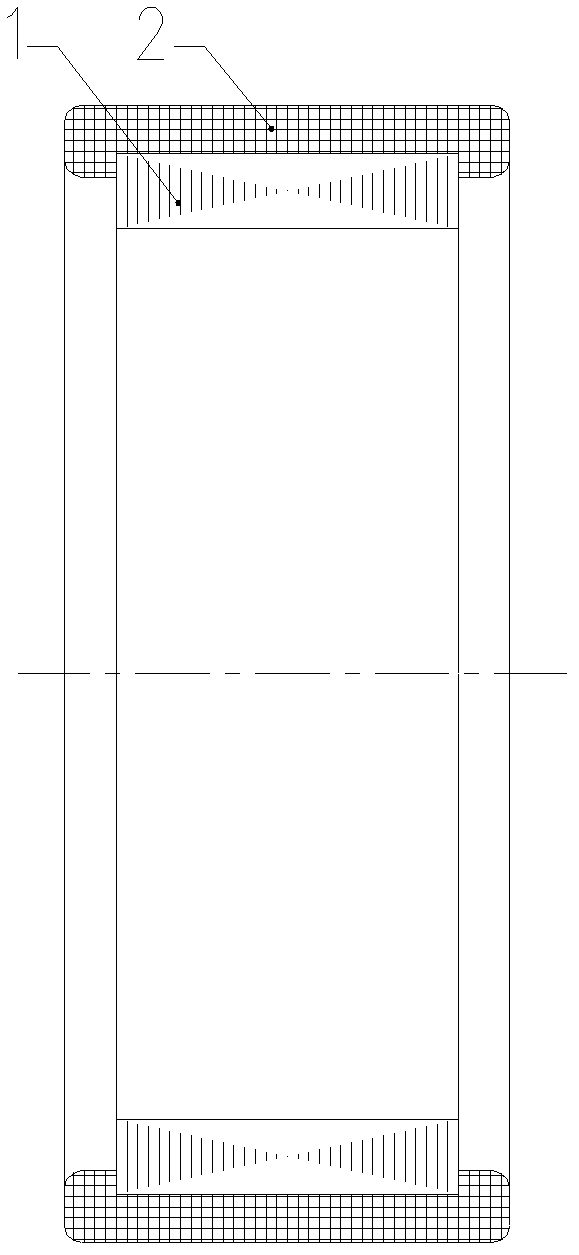

[0041] A permanent magnet motor stator whose core is a slotless split structure, including a split stator core 1 and a stator armature 2, the stator core is formed by stacking stator punches, and the whole is an annular cylinder. The alveolar structure of the cylindrical surface is a smooth plane. The stator armature is composed of a stator winding coil 5 and a plastic skeleton, the stator winding coil is directly wound on the bar-shaped comb-shaped plastic skeleton, and the stator armature is fixed on the cylindrical surface of the stator core.

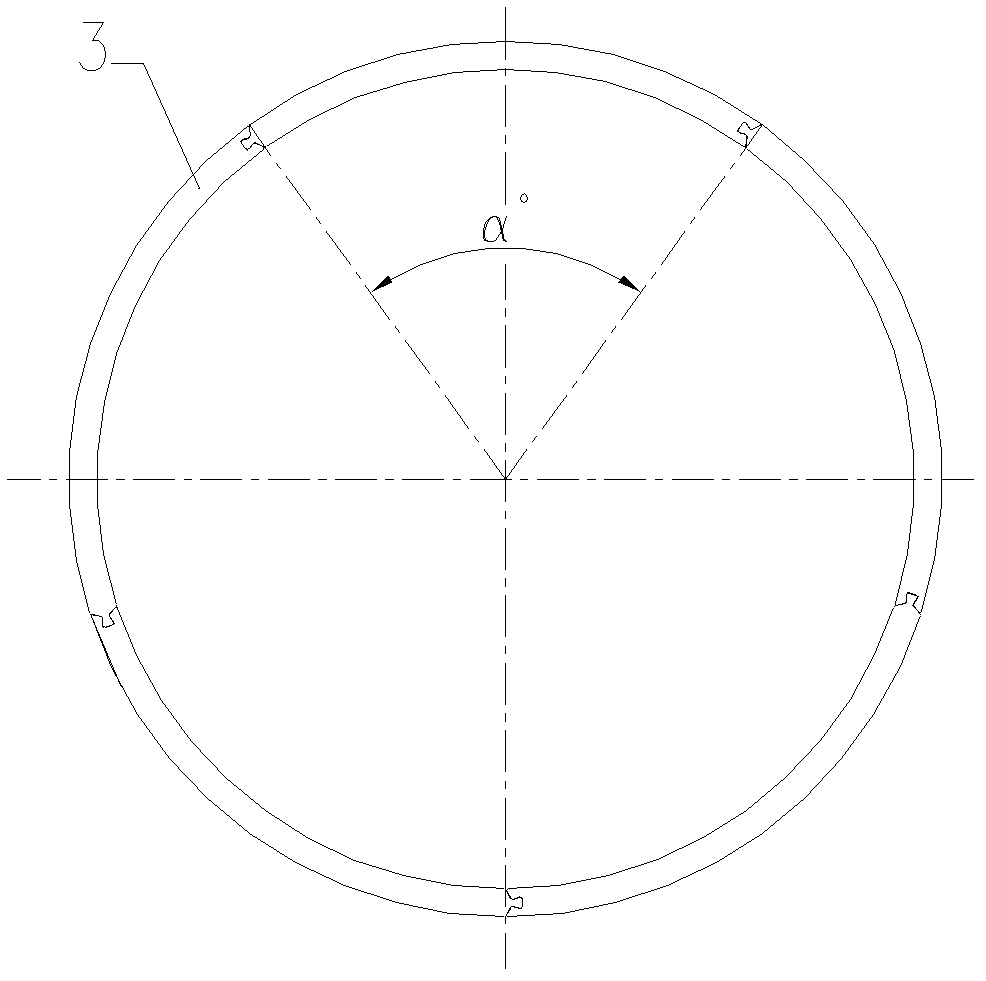

[0042] The innovation of the present invention is that the annular cylindrical stator core is designed and divided into multiple groups of the same arc-shaped structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com