Integrated sampling method used for coal sample detection and integrated sampling system

A technology for coal samples and coefficients, which is applied in the field of integrated mining and production methods and integrated mining and production systems suitable for coal sample detection, can solve the problems of high labor intensity, poor accuracy, long cycle, etc., so as to save labor costs, improve efficiency, Stable running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

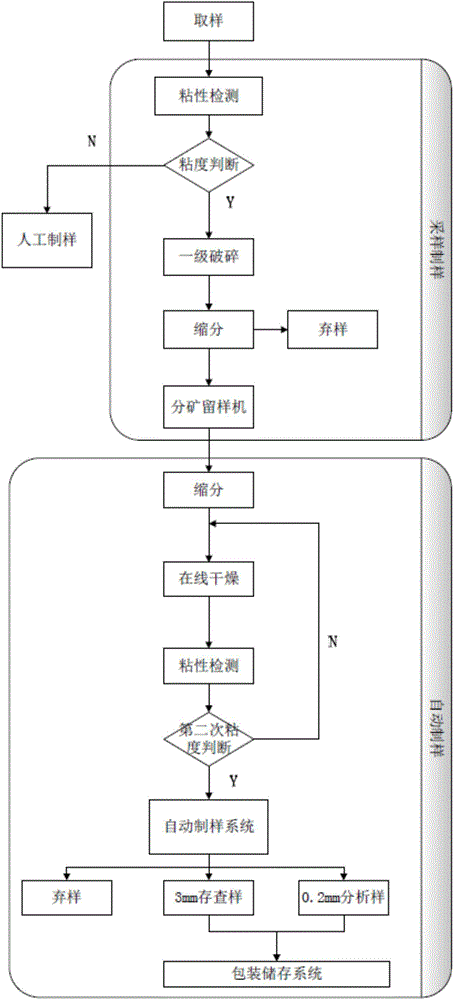

[0038] Such as figure 1 with figure 2 Shown, the coal sample detection of the present invention is used for the integrated mining method, and its steps are:

[0039] S1: Sampling;

[0040] Sampling is carried out in stockpiling or transportation equipment in conventional ways; according to actual needs, one or more methods of mechanical sampling, manual sampling, and semi-mechanical sampling can be selected for sampling.

[0041] S2: Viscosity judgment;

[0042] S3: sample preparation;

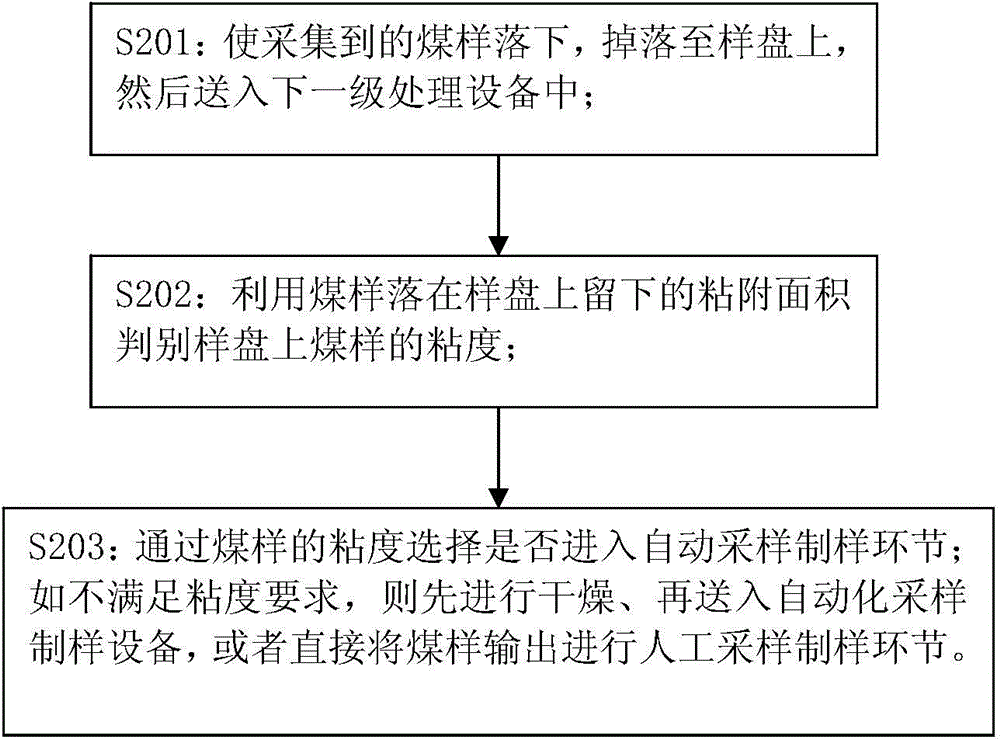

[0043] In a specific application example, the specific steps of the above step S2 are:

[0044] S201: Make the collected coal sample drop onto the sample tray, and then send it to the next-level processing equipment;

[0045] S202: judging the viscosity of the coal sample on the sample tray by using the adhesion area left by the coal sample falli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com