Ultrasonic atomizer

An ultrasonic and nebulizer technology, applied in the field of electronic equipment, can solve problems such as large power differences, low production efficiency, and poor controllability, and achieve the effects of ensuring consistency, improving production efficiency, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

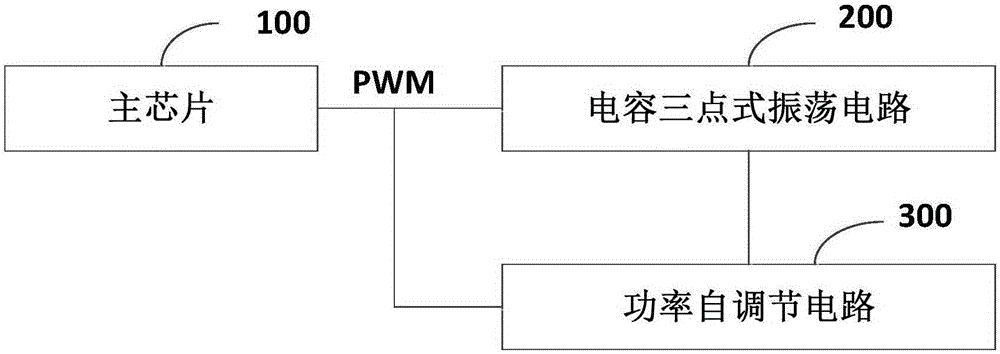

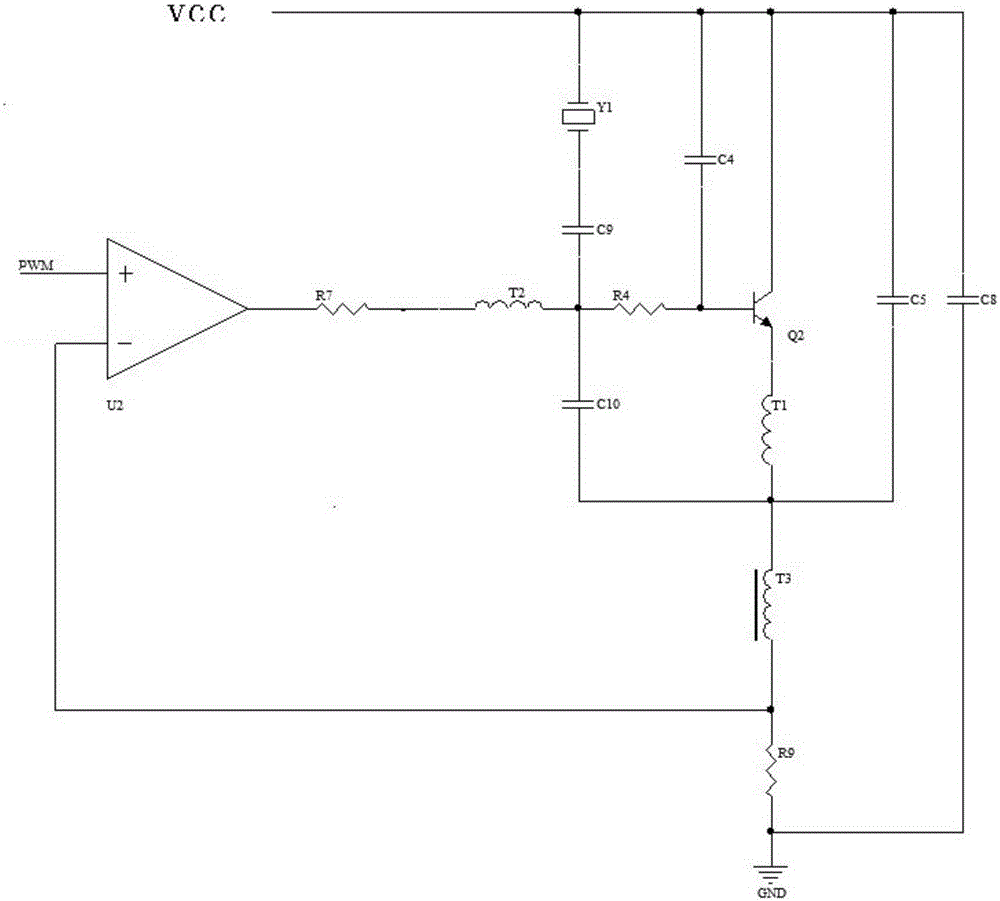

[0026] The invention provides an ultrasonic nebulizer, such as figure 1 As shown, the ultrasonic nebulizer includes a main chip 100, a capacitive three-point oscillation circuit 200 and a power self-regulating circuit 300. The main chip 100 is used to provide the fog volume control input signal PWM to the capacitive three-point oscillation circuit 200, so The capacitive three-point oscillation circuit 200 generates ultrasonic waves based on the mist volume control input signal, so as to make the atomizing sheet resonate, thereby atomizing the liquid. The power self-regulating circuit 300 is used to detect the DC signal of the emitter of the transistor in the capacitor three-point oscillator circuit 200, and use the DC signal and the fog volume control input signal transmitted from the main chip 100 to the capacitor three-point oscillator circuit 200 For comparison, the base current of the transistor is adjusted to ensure the stability and consistency of the output power.

[0...

Embodiment 2

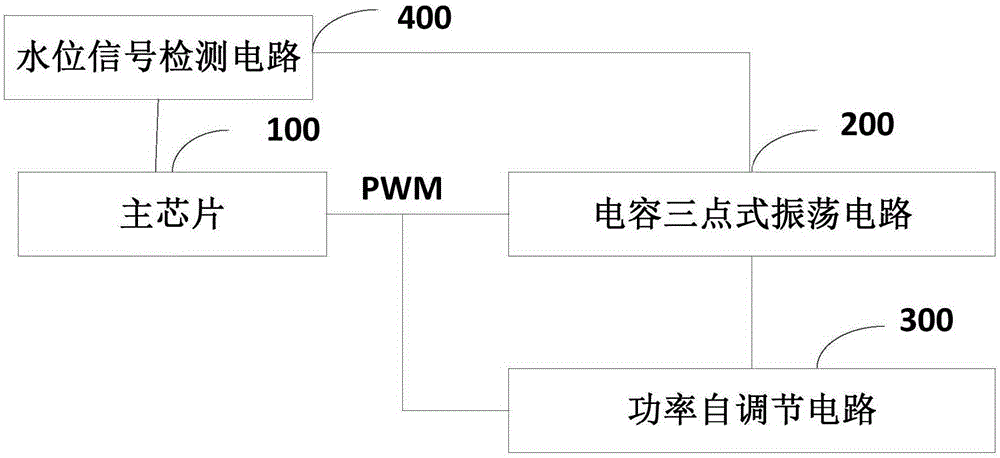

[0035] By introducing a power self-adjusting circuit, the invention solves the technical problem of poor power consistency of the produced atomizers caused by the differences in the accuracy of components and the manufacturing process of the atomizers. The existing ultrasonic atomizer does not integrate water level detection, but detects the water level height through the cooperation of discrete magnetic switches and magnets, which takes up a lot of space and brings certain troubles to the structural design. Under the consideration of this deficiency, the present invention has also carried out further improvement, as image 3 As shown, on the basis of the technical solution described in the above-mentioned embodiment 1, a new water level signal detection circuit 400 is introduced, thereby reducing the space occupied by the relevant water level detection components, and leaving enough space for the structural designer to make a beautiful appearance. design and structural design...

Embodiment 3

[0040] Existing ultrasonic nebulizers have no dry-burning protection, or are protected by resettable temperature limiters, disposable thermal protectors, or are protected by dry-burning signal detection programs, but the algorithm is complex and the action protection time is long, which directly affects the mist. The service life of the atomizer and the attenuation of the accelerated atomization amount. Considering this deficiency existing in the prior art, the present invention has carried out further improvement, proposes a kind of double protection idea, promptly adds a kind of new dry-burning signal detection circuit 500 on the basis of embodiment 2 (being anti-dry burning detection circuit), through this new dry burning signal detection circuit 500, the DC signal of the base of the transistor can be detected, and the DC signal can be provided to the main chip 100 for controlling the opening or cutting off of the fog volume control input signal, So as to prevent dry burnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com