Reducing contact sphere diameter instrument

A contact-type, spherical-diameter technology, applied in the direction of mechanical counter/curvature measurement, etc., can solve the problems of poor synchronization performance, poor judgment of the ejector rod, and high cost, so as to eliminate random errors and the influence of human factors, overcome the Unable to measure multiple times, the effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

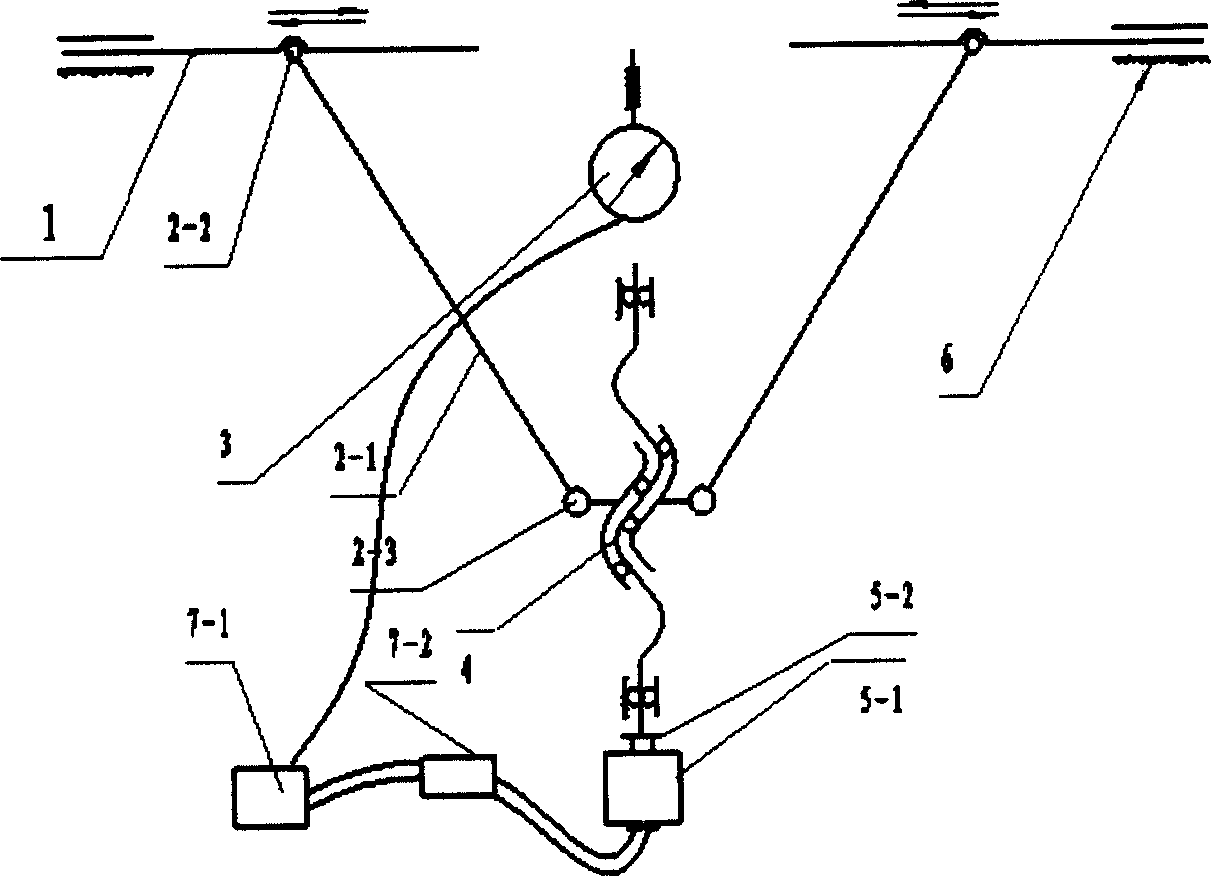

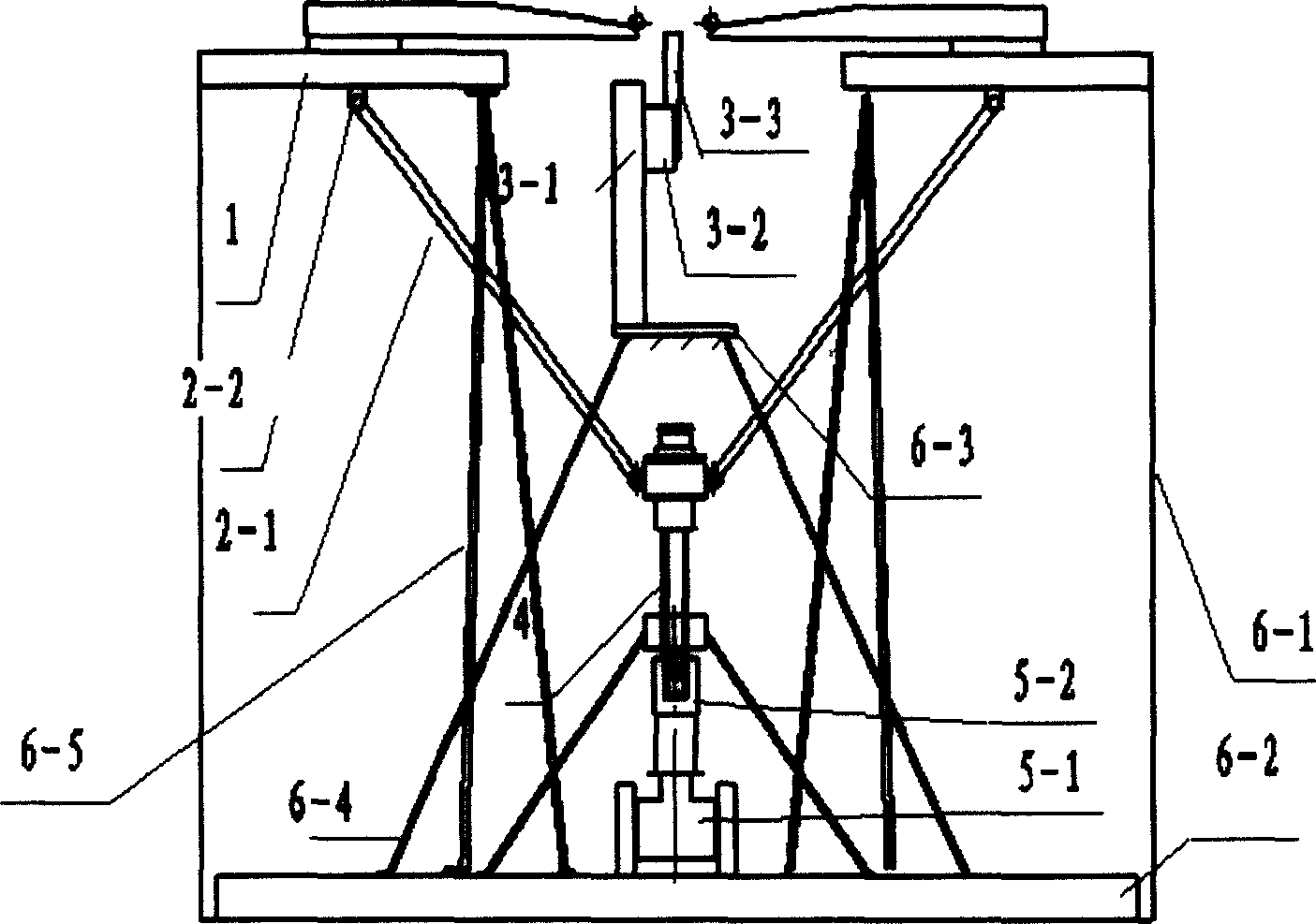

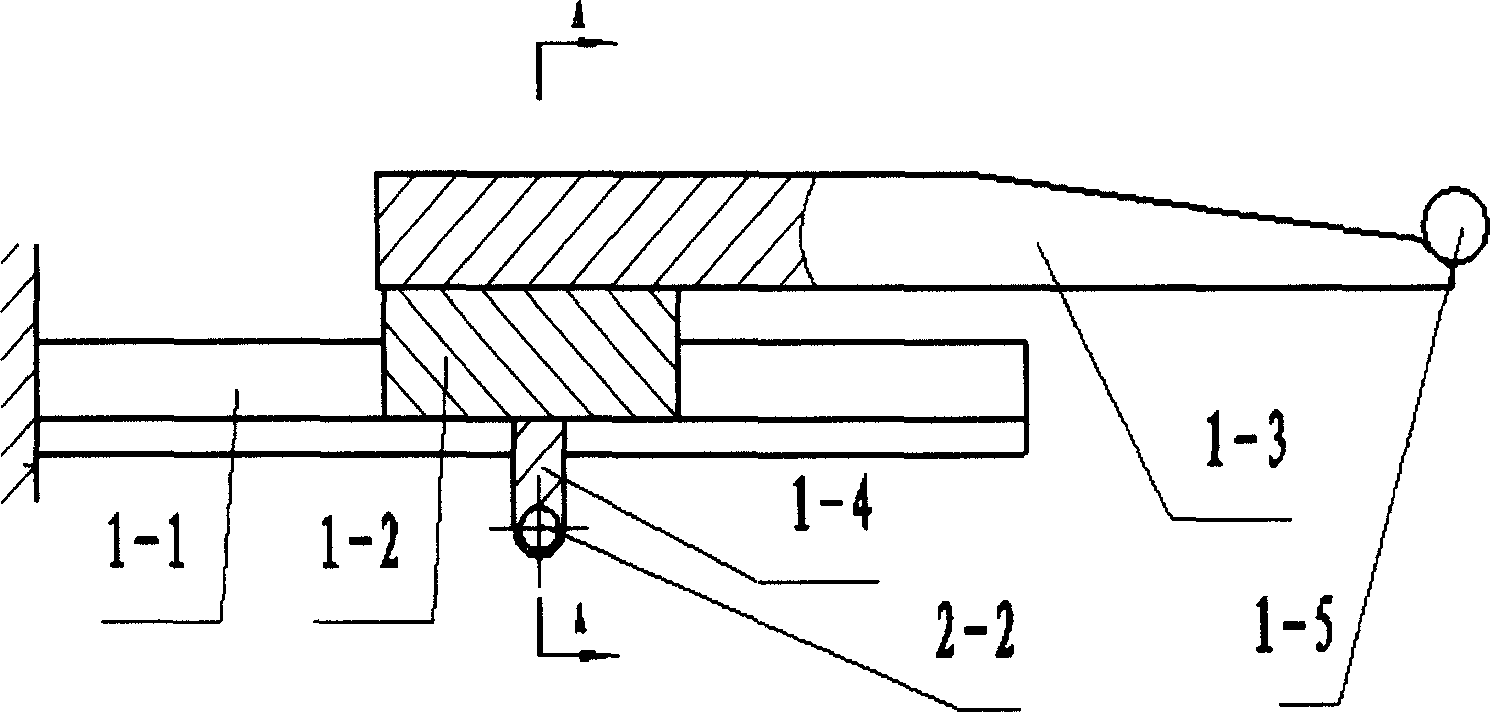

[0027] First see figure 1 , The variable-diameter contact ball diameter meter of the present invention is composed of an automatic control part and a mechanical main body: the automatic control part has a microcomputer 7-1, a driving power supply 7-2, and a stepping motor 5-1. By using the drive power supply 7-2 with the single-chip microcomputer 7-1 as the core, the stepping motor 5-1 is connected with the data line 7-3, the stepping motor 5-1 has the function of controlling the number of steps, direction and speed. The main part of the machine has a guide rail bracket 1, a connecting rod 2, a grating ruler 3, a roller screw mechanism 4 and a body 6.

[0028] The specific connection and installation are as follows:

[0029] The computer 7-1 has 2 lines connected, one is connected to the driving power supply 7-2 of the stepping motor 5-1 to give the signal pulse of the driving power supply 7-2, and the other is connected to the grating ruler 3 to receive the signal output by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com