Sector segment structure capable of compositely pressing continuous casting solidification tail end of extra-thick plate

A technology of solidification end and sector, applied in the field of metallurgy, can solve the problems of improving the qualified rate of plate flaw detection, low pulling speed, and reducing the center segregation and porosity of the cast billet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

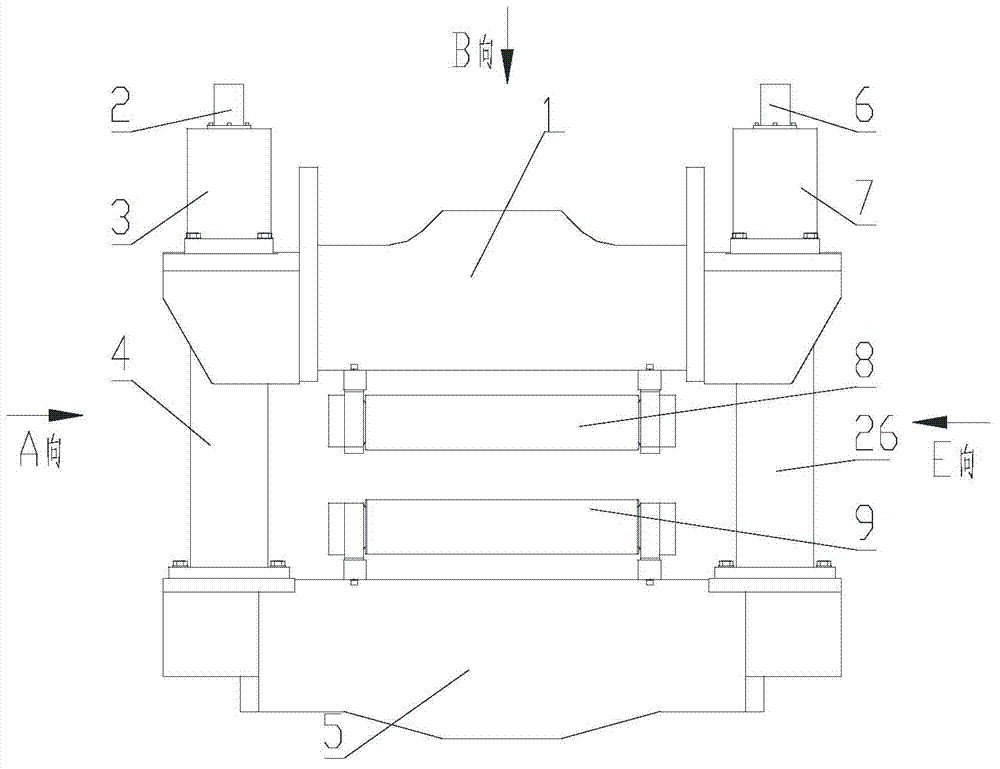

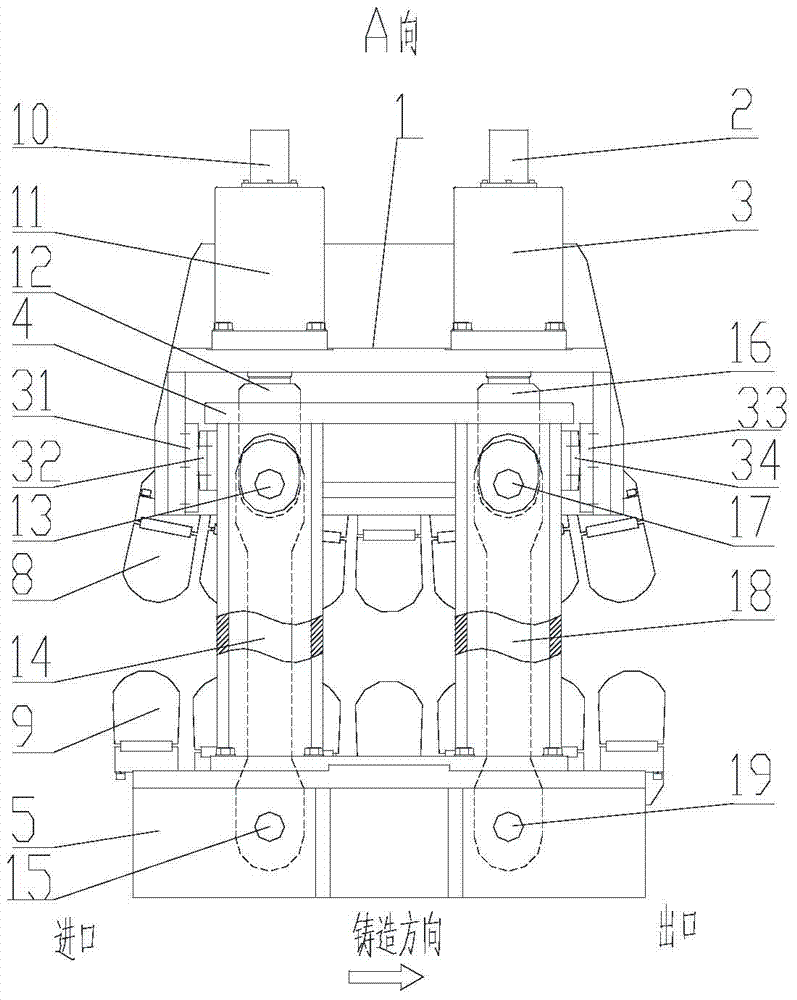

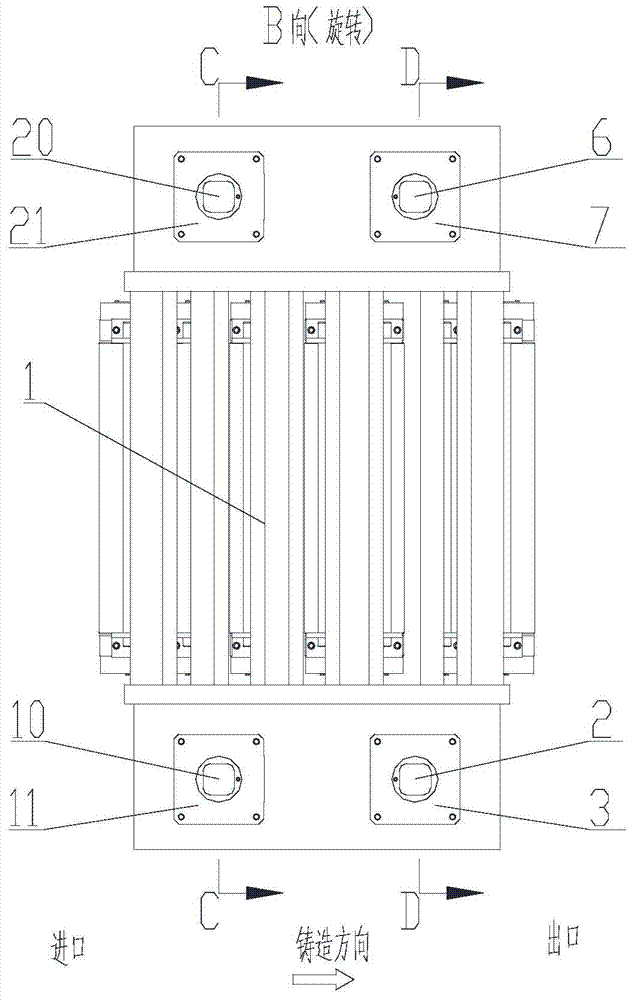

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0019] see attached Figure 1-Figure 6 , a sector structure capable of realizing composite pressing at the end of continuous casting and solidification of extra-thick plates, including inner arc rollers 8, the inner arc rollers 8 are connected to the upper frame 1 through bolts, and the outer arc rollers 9 are connected to the lower frame 5 through bolts; The upper frame 1 is connected with the first guide plate 31, the third guide plate 33, the fifth guide plate 35, and the seventh guide plate 37 through bolts; the second guide plate 32 and the fourth guide plate 34 are connected with the first side frame 4 through bolts. connection; the sixth guide plate 36 and the eighth guide plate 38 are connected to the second side frame 26 by bolts; the first side frame 4 and the second side frame 26 are respectively connected to the lower frame 5 by bolts; the first o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com