Integrated air spring press-fitting device

A technology of press-fitting device and empty spring, which is applied in the field of rail transit, can solve the problems of low work efficiency and high labor intensity of assembly, and achieve the effect of simple structure, high labor intensity and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

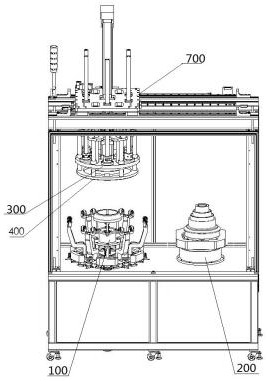

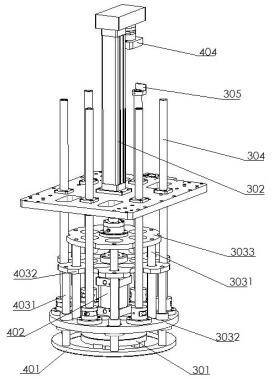

[0033] Provide an integrated air spring pressing device, such as figure 2 As shown, it is erected on the airbag and buckle assembly station 100 and the airbag and auxiliary spring assembly station 200; it includes a moving device 700, an auxiliary spring pressing device 300 and a buckle flattening device 400;

[0034] Such as Figure 4 As shown, the mobile device 700 includes a mounting plate 701 and a driving device 4, the auxiliary spring pressing device 300 and the clasp flattening device are all installed on the mounting plate 701, and the driving device 4 drives the mounting plate 701 in the airbag, buckle assembly station 100 Move between the airbag and auxiliary spring assembly station 200; such as Figure 4 As shown, the mounting plate 701 is square, with 4 square holes opening on it, and the square holes are for weight reduction. The mounting plate 701 is installed on two parallel beams 702, such as Figure 4 As shown, guide strips 703 are installed on the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com