Method and device for improving continuous casting flaw detection qualification rate

A pass rate, continuous casting technology, applied in the field of metallurgy, can solve the problems of unqualified flaw detection, inability to quickly identify the pass rate of continuous casting billet flaw detection, aggravate the central segregation and banded structure of continuous casting billet, etc., to ensure internal quality, improve The pass rate of flaw detection and the effect of reducing inclusion content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

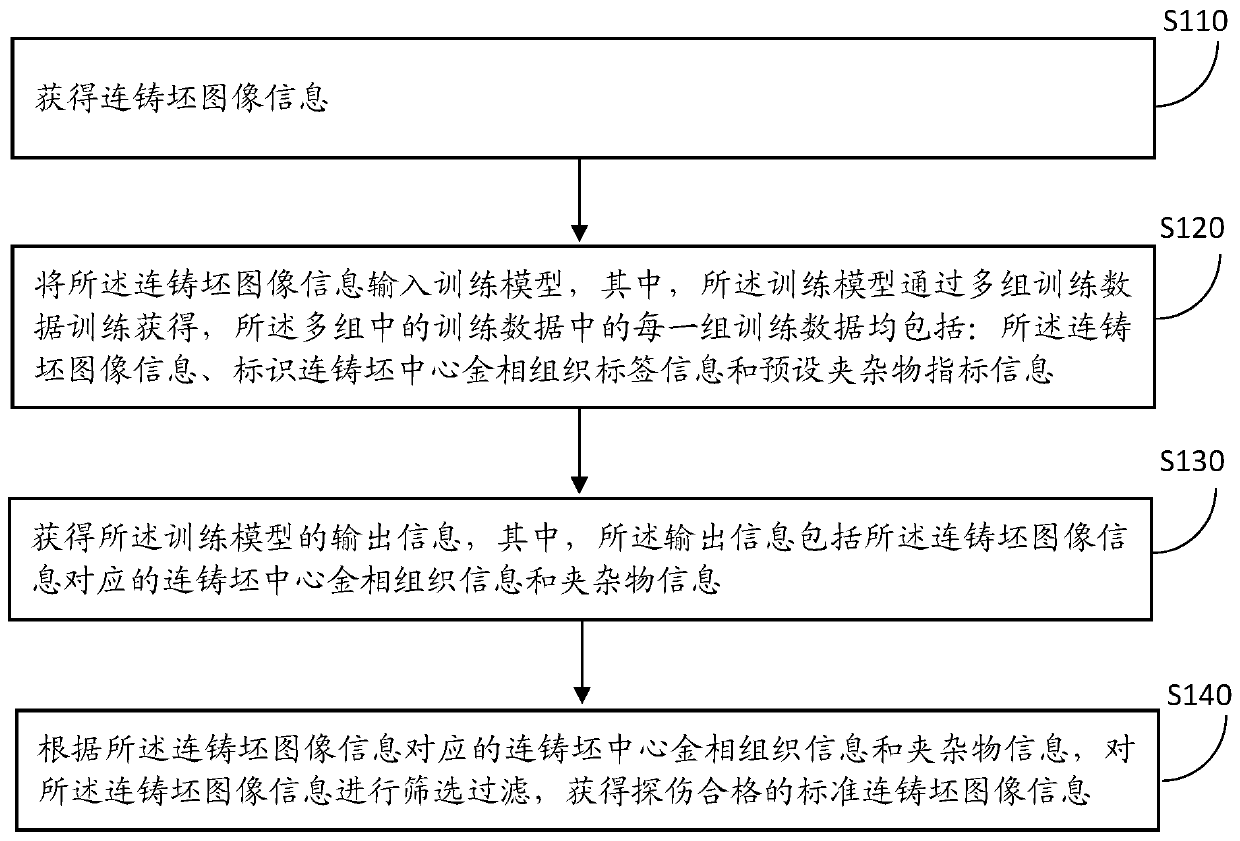

[0051] figure 1 It is a schematic flowchart of a method for improving the qualified rate of continuous casting flaw detection in the embodiment of the present invention. Such as figure 1 shown. The method is applied to a device for improving the qualified rate of continuous casting flaw detection. The processing device for improving the qualified rate of continuous casting flaw detection includes an input device and a display device. The input device has a picture input module, a picture processing module, and a memory inside. , a signal input module, the input device can be connected to the equipment that generates output signals such as energy spectrum scanners, scanning electron microscopes, etc., the display device is connected to the input device, and the energy spectrum scanner, scanning electron microscope, etc. The image processed by the input device is displayed on a device such as a display screen. The method includes steps S101-S104.

[0052] S101: Obtain image ...

Embodiment 2

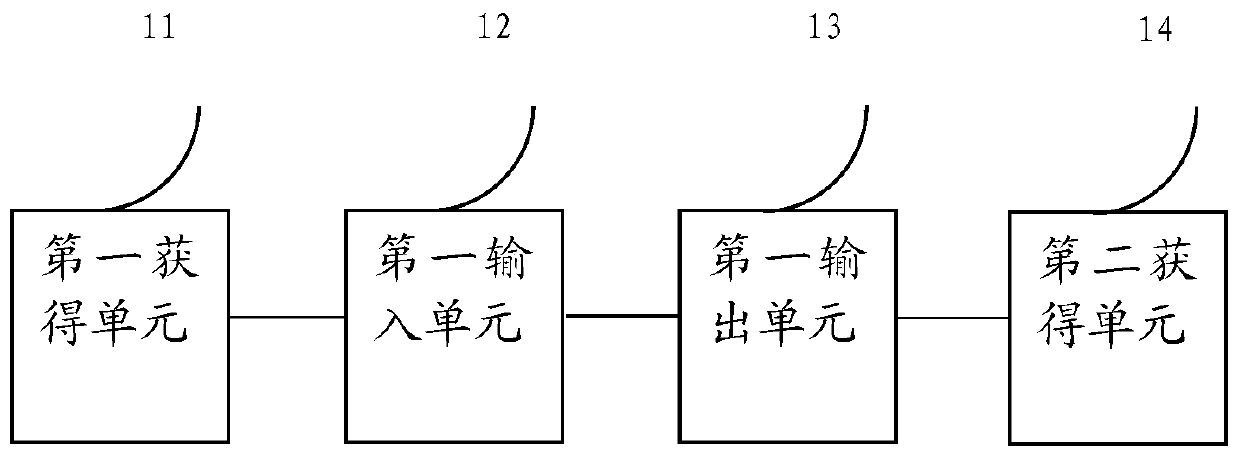

[0066] Based on the same inventive concept as a method for improving the pass rate of continuous casting flaw detection in the foregoing embodiments, the present invention also provides a device for improving the pass rate of continuous casting flaw detection, such as figure 2 shown, including:

[0067] The first obtaining unit 11 is used to obtain continuous casting slab image information;

[0068] The first input unit 12 is used to input the image information of the continuous casting slab into the training model, wherein the training model is obtained by training multiple sets of training data, and each set of training data in the multiple sets of training data is Including: the continuous casting slab image information, label information identifying the metallographic structure of the continuous casting slab center and preset inclusion index information;

[0069] The first output unit 13 is configured to obtain output information of the training model, wherein the output...

Embodiment 3

[0093] Based on the same inventive concept as the method for improving the qualified rate of continuous casting flaw detection in the first embodiment, the present invention also provides a computer-readable storage medium on which a computer program is stored, and when the program is executed by a processor, the foregoing A step in any method of the method for improving the qualified rate of continuous casting flaw detection.

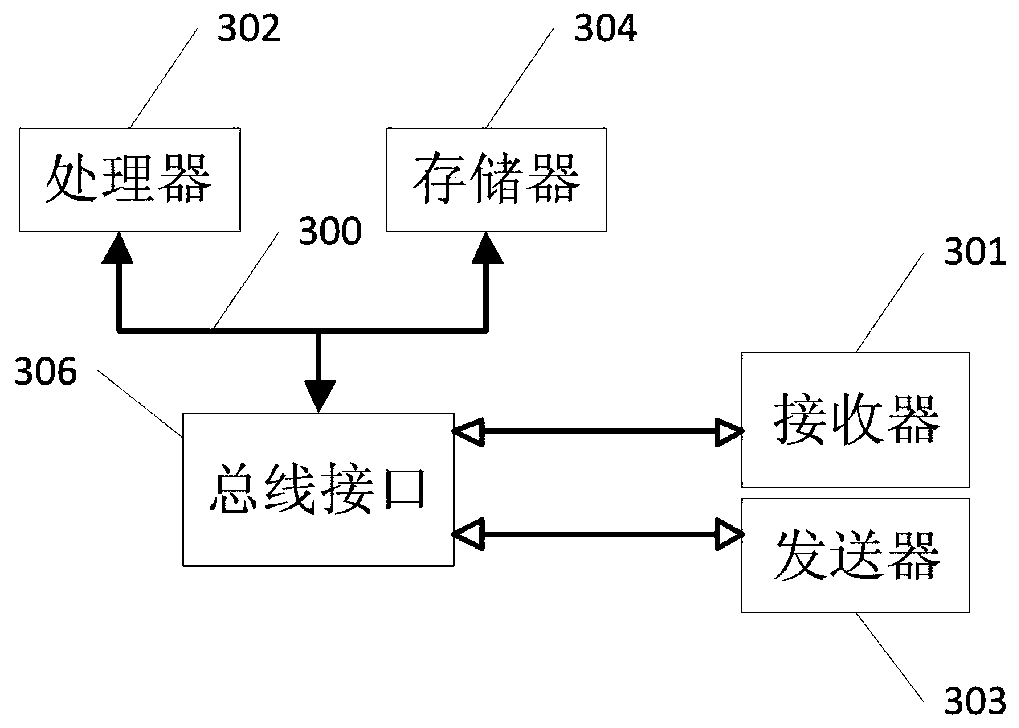

[0094] Among them, in image 3 In, bus architecture (represented by bus 300), bus 300 may include any number of interconnected buses and bridges, bus 300 will include one or more processors represented by processor 302 and various types of memory represented by memory 304 circuits linked together. The bus 300 may also link together various other circuits, such as peripherals, voltage regulators, and power management circuits, etc., which are well known in the art and thus will not be further described herein. The bus interface 306 provides an interfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com